Method for preparing high-strength solid buoyancy material

A solid buoyancy, high-strength technology, applied in the field of preparation of solid buoyancy materials, can solve the problems of low compressive strength and high density of composite foam, and achieve the effects of improving production efficiency, reducing labor intensity, and enriching varieties and application scopes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

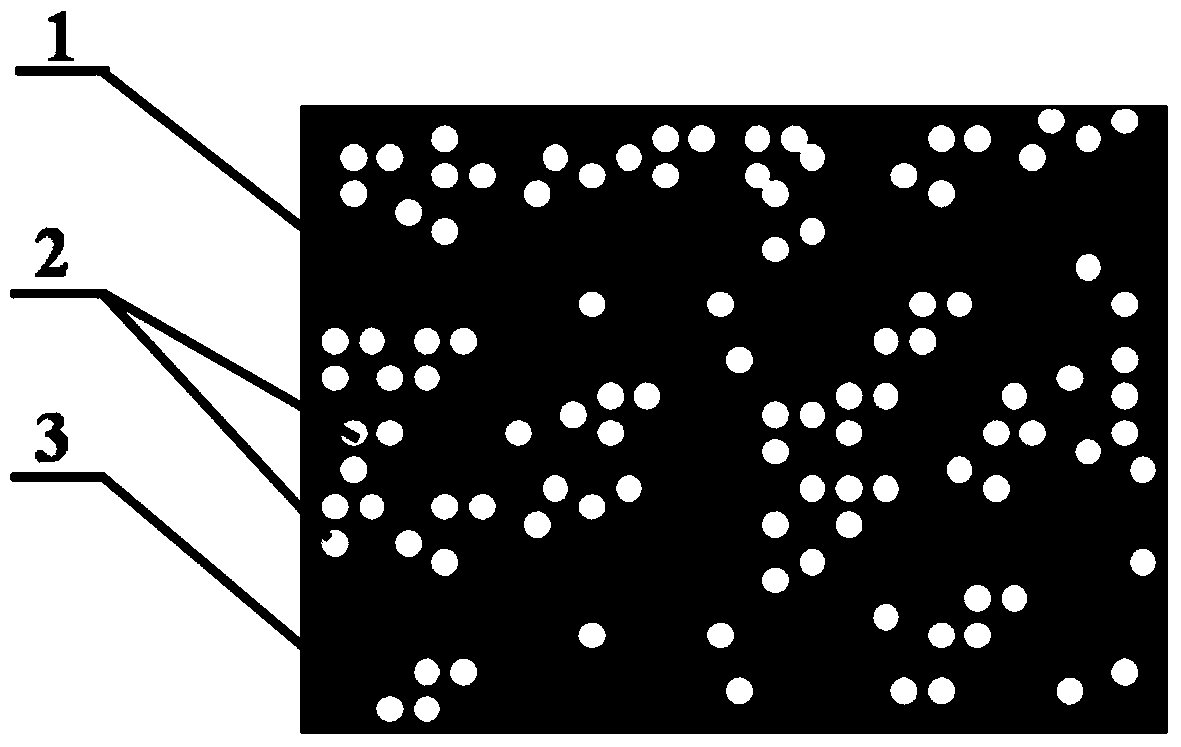

Image

Examples

Embodiment 1

[0036] In this embodiment, millimeter-scale or even centimeter-scale fiber balls and micron-scale hollow microspheres are used to coordinately reinforce the resin matrix to prepare a low-density, high-strength solid buoyancy material. The specific steps are:

[0037] (1) The hollow glass microspheres are pretreated with a silane coupling agent (gamma-aminopropyltriethoxysilane coupling agent), and the optimal amount of the coupling agent is 0.2wt% of the mass of the glass microspheres;

[0038] (2) According to the mass fraction ratio, 100 parts of epoxy resin (diglycidyl ether epoxy resin, polyglycidyl ether epoxy resin or glycidyl amine epoxy resin can be used, and diglycidyl alcohol is used in this embodiment) Ether epoxy resin), 50 parts of triethylenetetramine, 10 parts of nitrile rubber toughening agent, 5 parts of dispersant, 10 parts of thinner (n-butyl glycidyl ether) are mixed, and mechanically Stirring, the stirring time is 20min; the stirring speed is 100r / min;

...

Embodiment 2

[0044] The difference between this embodiment and Example 1 is that the hollow microspheres used in the prepared high-strength solid buoyancy material are hollow ceramic microspheres with an apparent density of 0.35 g / cm 3 , the compressive strength is 80MPa, and other steps and parameters are the same as in Example 1. The measured density of the obtained material is 0.67g / cm 3 , the hydrostatic pressure resistance of all-round test is 120MPa, and the water permeability rate is 0.39% per day, which fully meets the performance indicators of buoyancy materials in my country under the condition of 12000 water depth.

Embodiment 3

[0046] The difference between this example and Example 1 is that the amount of fiber pellets used in the prepared high-strength solid buoyancy material is 15 parts, and other steps and parameters are the same as in Example 1. The measured density of the obtained material is 0.53g / cm 3 The hydrostatic pressure resistance of all-round test is 83MPa, and the water seepage rate is 0.40% per day, which fully meets the performance indicators of buoyancy materials in my country at a water depth of 7000 meters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com