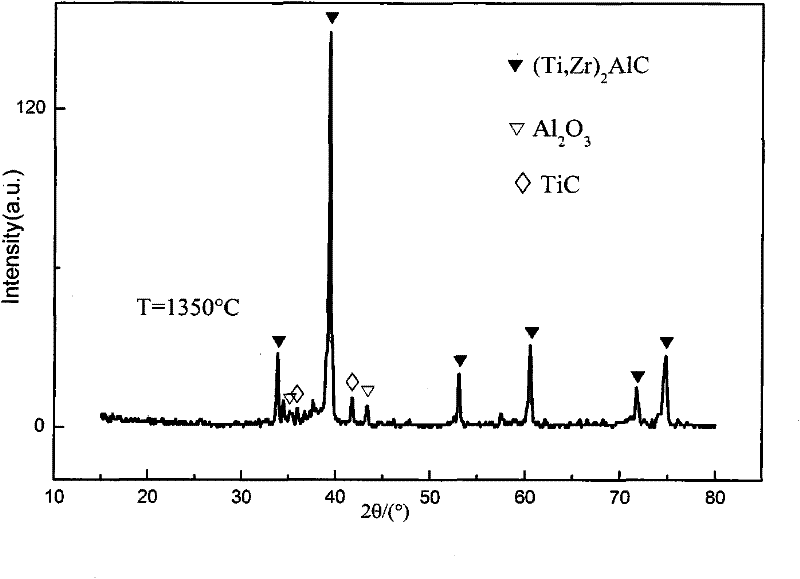

(Ti, Zr)2AlC/Al2O3 solid solution composite material and preparation method thereof

A composite material and solid solution technology, applied in the field of composite material manufacturing, can solve the problems of high synthesis temperature, high reaction temperature, and high raw material cost, and achieve uniform and compact structure, broaden the application range, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A (Ti, Zr) 2 AlC / Al 2 o 3 Solid solution composite material, its raw material weight composition is: 270 purpose Ti powder accounts for 63.86% of total weight, 200 purpose Al powder accounts for 20.38% of total weight, 1200 purpose C powder accounts for 8.15% of total weight and ZrO 2 Powder accounts for 7.61% of the total weight.

[0020] The preparation process steps of the present embodiment are as follows:

[0021] Step 1. First, the purity is greater than or equal to 99%, and the fineness is less than or equal to 200 mesh metal Ti powder, Al powder, C powder and metal oxide ZrO 2 Weighing according to the following proportions, 270 mesh Ti powder accounts for 63.86% of the total weight, 200 mesh Al powder accounts for 20.38% of the total weight, 1200 mesh C powder accounts for 8.15% of the total weight, ZrO 2 Powder accounts for 7.61% of the total weight;

[0022] Step 2, put the ingredients in step 1 into an alumina ball mill tank and carry out mixed ball milli...

Embodiment 2

[0029] A (Ti, Zr) 2 AlC / Al 2 o 3 Solid solution composite material, its raw material weight composition is: 270 purpose Ti powder accounts for 66.08% of total weight, 200 purpose Al powder accounts for 21.64% of total weight, 1200 purpose C powder accounts for 8.46% of total weight and ZrO 2 Powder accounts for 3.82% of the total weight.

[0030] The preparation process steps of the present embodiment are as follows:

[0031] Step 1. First, the purity is greater than or equal to 99%, and the fineness is less than or equal to 200 mesh metal Ti powder, Al powder, C powder and metal oxide ZrO 2 Weighing according to the following proportions, 270 mesh Ti powder accounts for 66.08% of the total weight, 200 mesh Al powder accounts for 21.64% of the total weight, 1200 mesh C powder accounts for 8.46% of the total weight, ZrO 2 Powder accounts for 3.82% of the total weight;

[0032] Step 2, put the ingredients in step 1 into an alumina ball mill tank and carry out mixed ball mil...

Embodiment 3

[0038] A (Ti, Zr) 2 AlC / Al 2 o 3 Solid solution composite material, its raw material weight composition is: 270 purpose Ti powder accounts for 54.56% of total weight, 200 purpose Al powder accounts for 21.04% of total weight, 1200 purpose C powder accounts for 7.53% of total weight and ZrO 2 Powder accounts for 16.87% of the total weight.

[0039] The preparation process steps of the present embodiment are as follows:

[0040] Step 1. First, the purity is greater than or equal to 99%, and the fineness is less than or equal to 200 mesh metal Ti powder, Al powder, C powder and metal oxide ZrO 2 Weighing according to the following proportions, 270 mesh Ti powder accounted for 54.56% of the total weight, 200 mesh Al powder accounted for 21.04%, 1200 mesh C powder accounted for 7.53%, ZrO 2 Powder accounted for 16.87;

[0041] Step 2, put the ingredients in step 1 into an alumina ball mill tank and carry out mixed ball milling on a planetary ball mill, with absolute ethanol as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com