Ternary layered MAX phase material with A site as magnetic element as well as preparation method and application thereof

A ternary layered, elemental technology, applied in the field of materials, can solve the problems that magnetic MAX phase materials have not yet been reported, the MAX phase structure is unstable, and the magnetic properties have not been discussed, achieving high damage tolerance, simple preparation methods, high The effect of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

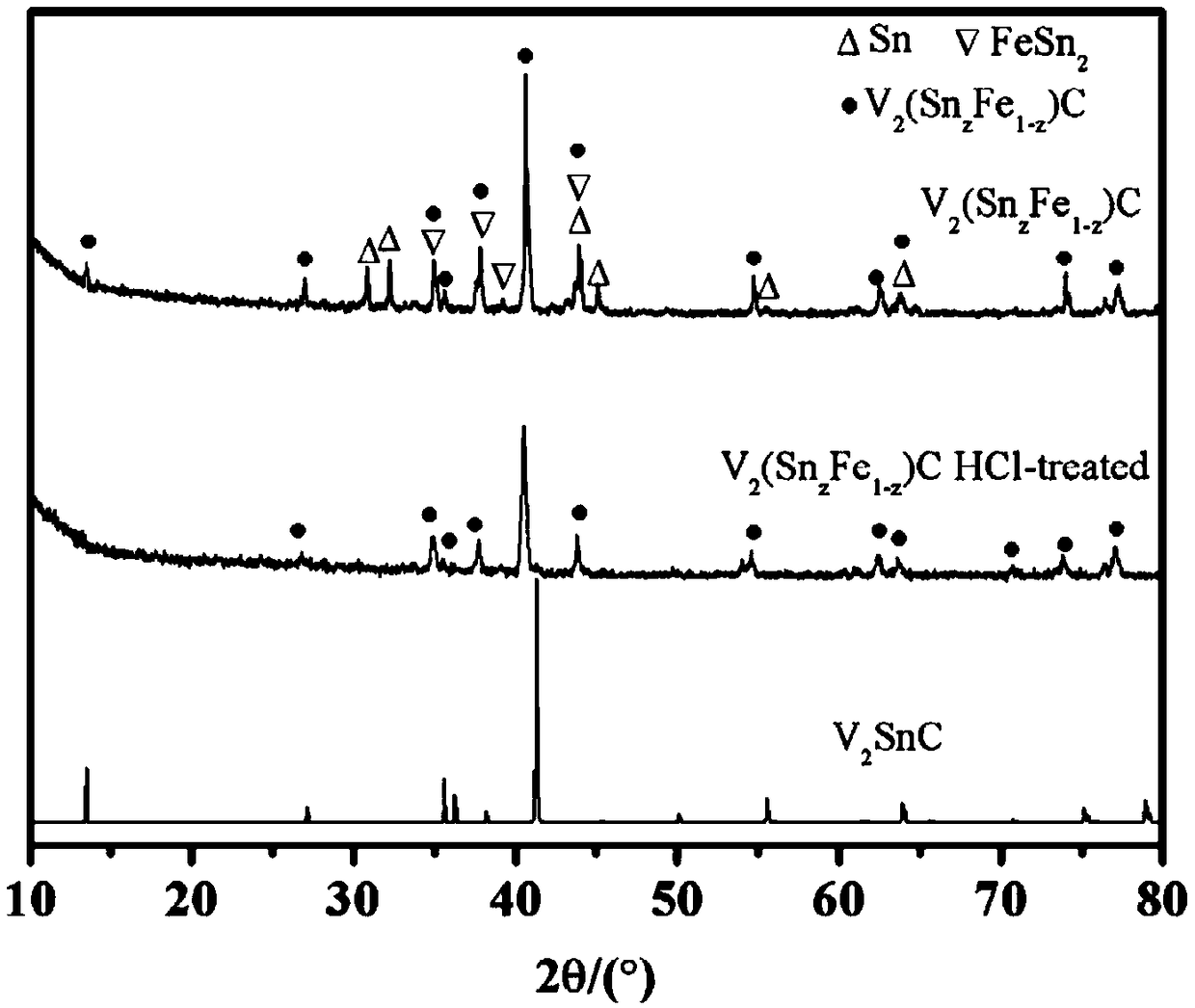

[0041] Embodiment 1: In this embodiment, the ternary layered MAX phase material whose A position is a magnetic element is V 2 (Sn z Fe 1-z ) C powder material.

[0042] The V 2 (Sn z Fe 1-z ) The preparation method of C powder is as follows:

[0043] (1) Weigh 1.2g of sodium chloride, 1.5g of potassium chloride, 1.53g of vanadium powder with a particle size of 10 μm, 0.24g of 300 mesh carbon powder, 1.3g of 300 mesh Sn powder, and 0.56g of 300 mesh iron powder, and grind the above materials Mix to get a mixture.

[0044] (2) Put the mixture in a corundum crucible and put it into a high-temperature tube furnace for reaction. The reaction conditions are: reaction temperature 1300° C., holding time 60 minutes, and inert atmosphere protection. After the temperature of the tube furnace dropped to room temperature, the reaction product in the crucible was taken out.

[0045] (3) Wash the reaction product with deionized water and alcohol: put the reaction product into a beak...

Embodiment 2

[0048] Embodiment 2: In this embodiment, the ternary layered MAX phase material whose A position is a magnetic element is V 2 (Sn z Fe 1-z ) C powder material.

[0049] The V 2 (Sn z Fe 1-z ) The preparation method of C powder is as follows:

[0050] (1) Weigh 2.4 g of sodium chloride, 3.1 g of potassium chloride, 1.26 g of vanadium carbide powder with a particle size of 10 μm, 1.3 g of 300 mesh Sn powder, and 0.34 g of 300 mesh iron powder, and grind and mix the above materials to obtain a mixture.

[0051] (2) Put the mixture in a corundum crucible and put it into a high-temperature tube furnace for reaction. The reaction conditions are: reaction temperature 900° C., holding time 420 minutes, and inert atmosphere protection. After the temperature of the tube furnace dropped to room temperature, the reaction product in the crucible was taken out.

[0052] (3) Wash the reaction product with deionized water and alcohol: put the reaction product into a beaker, add deioni...

Embodiment 3

[0056] Embodiment 3: In this embodiment, the ternary layered MAX phase material whose A position is a magnetic element is V 2 (Sn z Fe 1-z ) C bulk material.

[0057] The V 2 (Sn z Fe 1-z ) The preparation method of C block material is as follows:

[0058] (1) Weigh 1.26 g of vanadium carbide powder with a particle size of 10 μm, 1.3 g of 300-mesh Sn powder, and 1 g of 300-mesh iron powder, and grind and mix the above materials to obtain a powder mixture.

[0059] (2) Put the above powder mixture into a graphite mold, and then sinter by SPS. The sintering conditions are: 1100°C for 120min, heating rate of 100°C / min, argon protection, and pressure of 37MPa. After the reaction was over, the product was taken out.

[0060] (3) Remove the graphite paper on the surface of the obtained block, then polish it to a mirror surface with sandpaper of different meshes, put it in an oven at 100° C., and take it out for 12 hours to obtain a block material.

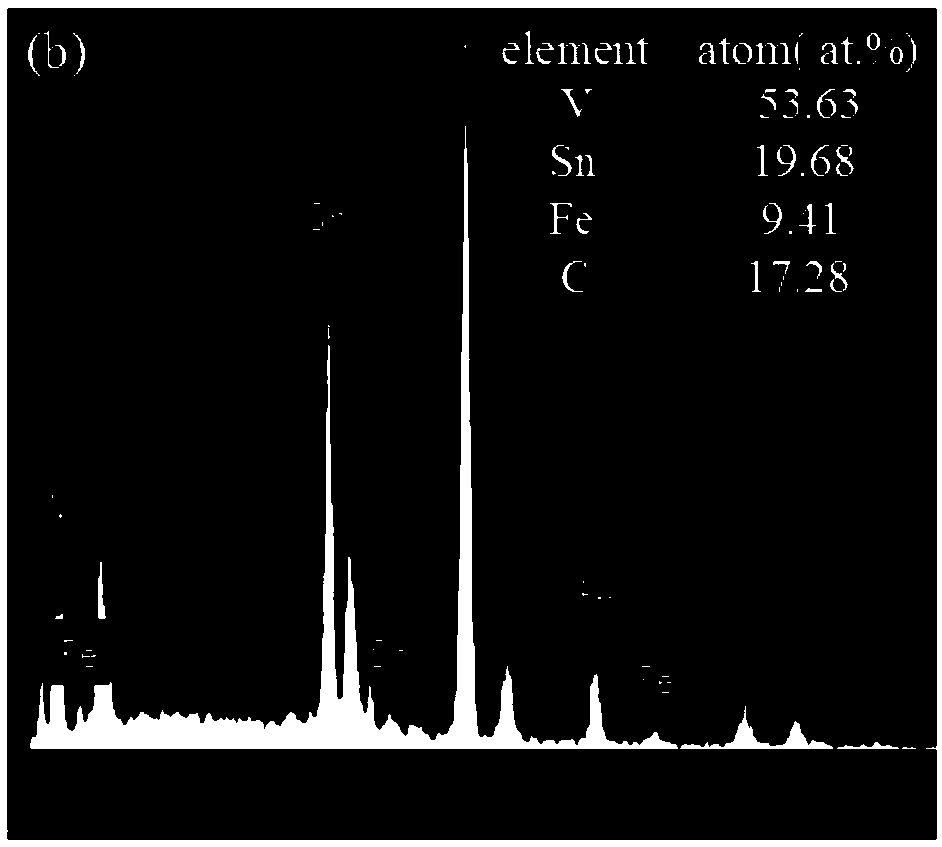

[0061] Image 6 It is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com