Biodegradable vinasse protein film as well as preparation method and application thereof

A distiller's grain protein and biodegradation technology, which is applied in the field of distiller's grain protein film and its preparation, can solve the problems of difficulty in meeting the functional requirements of different products, low mechanical properties and moisture resistance of distiller's grain protein film, and solve pollution problems and improve Water resistance, mechanical strength, and the effect of expanding the range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of a biodegradable distiller's grain protein film, comprising the following steps,

[0027] (1) Extraction of distiller's grain protein: Add quantitative sodium hydroxide and alcohol mixed solution to extract the ground and pulverized fresh distiller's grains. Leaching, after combining the extracts, adding hydrochloric acid solution, adjusting the pH, then washing with deionized water, centrifuging, repeating three times, and spray drying to obtain distiller's grain protein;

[0028] (2) Distiller's grain protein modification: the ratio of protein modification, in parts by mass, includes 60-85 parts of distiller's grain protein, 5-15 parts of plasticizer, 0.3-2 parts of crosslinking agent, and 0.3-2 parts of chain extender 10-30 parts of glycol oligomers and 0.3-1 parts of water-repellent agent, put the distiller's grain protein into the internal mixer first, and then put in the chain extender, glycol oligomers, cross-linking agent, The plasticizer...

Embodiment 1

[0035] This embodiment provides a method for preparing a biodegradable distiller's grain protein film, which mainly includes the following steps:

[0036] (1) Distiller's grain protein modification: protein modification raw material ratio, in parts by mass, 60 parts of distiller's grain protein, 15 parts of plasticizer, 0.3 part of crosslinking agent, 2 parts of chain extender, 10 parts of diol oligomer 1 part, 1 part of anti-water agent, put the distiller's grain protein into the internal mixer first, and then put in the chain extender, glycol oligomer, cross-linking agent, plasticizer and anti-water agent in turn, at a temperature of 90°C and a speed of Under the condition of 35rpm, react for 50min to obtain the modified protein, which is ready for use;

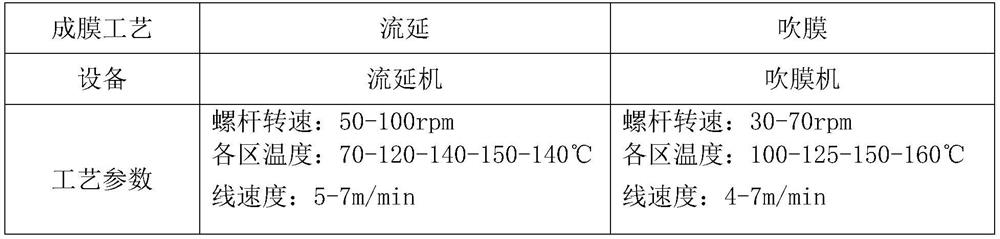

[0037] (2) Process the modified protein obtained in step (1) by casting and forming a film to obtain a thin film of distiller's grain protein.

Embodiment 2

[0039] This embodiment provides a method for preparing a biodegradable distiller's grain protein film, which mainly includes the following steps:

[0040](1) Distiller's grain protein modification: The ratio of protein modification raw materials, in terms of parts by mass, is 85 parts of distiller's grain protein, 5 parts of plasticizer, 2 parts of crosslinking agent, 0.3 part of chain extender, and 30 parts of diol oligomer. part, 0.3 part of water-resistant agent, put the distiller's grain protein into the internal mixer first, and then put in chain extender, glycol oligomer, cross-linking agent, plasticizer and water-resistant agent in turn, at a temperature of 90°C and a speed Under the condition of 35rpm, react for 50min to obtain the modified protein, which is ready for use;

[0041] (2) Process the modified protein obtained in the step (1) by casting into a film to obtain a distiller's grain protein film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com