Lightweight high-strength elastic ceramic and preparation method thereof

A ceramic and elastic technology, applied in the field of lightweight and high-strength elastic ceramics and its preparation, can solve the problems of low strength and high brittleness, and achieve the effects of high porosity, low density and excellent high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment has prepared the density is 100mg / cm 3 The lightweight and high-strength elastic ceramics, the specific steps are as follows:

[0035] 1) Using 2g of SiC nanowire airgel disclosed in Chinese patent 201811626203.6 as a raw material, fill it into a graphite mold with an inner diameter of 40mm, and keep the filled height fixed at 15.9mm;

[0036] 2) Place it in a nitrogen atmosphere at 1100°C for 2 hours, and cool with the furnace to obtain a density of about 0.10g / cm 3 Lightweight and high-strength elastic ceramics.

Embodiment 2

[0038] This embodiment has prepared the density is 300mg / cm 3 The lightweight and high-strength elastic ceramics, the specific steps are as follows:

[0039] 1) Si disclosed in 4g Chinese invention patent 201811626361.1 3 N 4 Nanoribbon airgel is used as raw material, which is filled in a graphite mold with an inner diameter of 40mm, and the filled height is kept fixed at 10.6mm;

[0040] 2) Put it in a nitrogen atmosphere at 1200°C for 2 hours, and cool it with the furnace to obtain a density of about 0.30g / cm 3Lightweight and high-strength elastic ceramics.

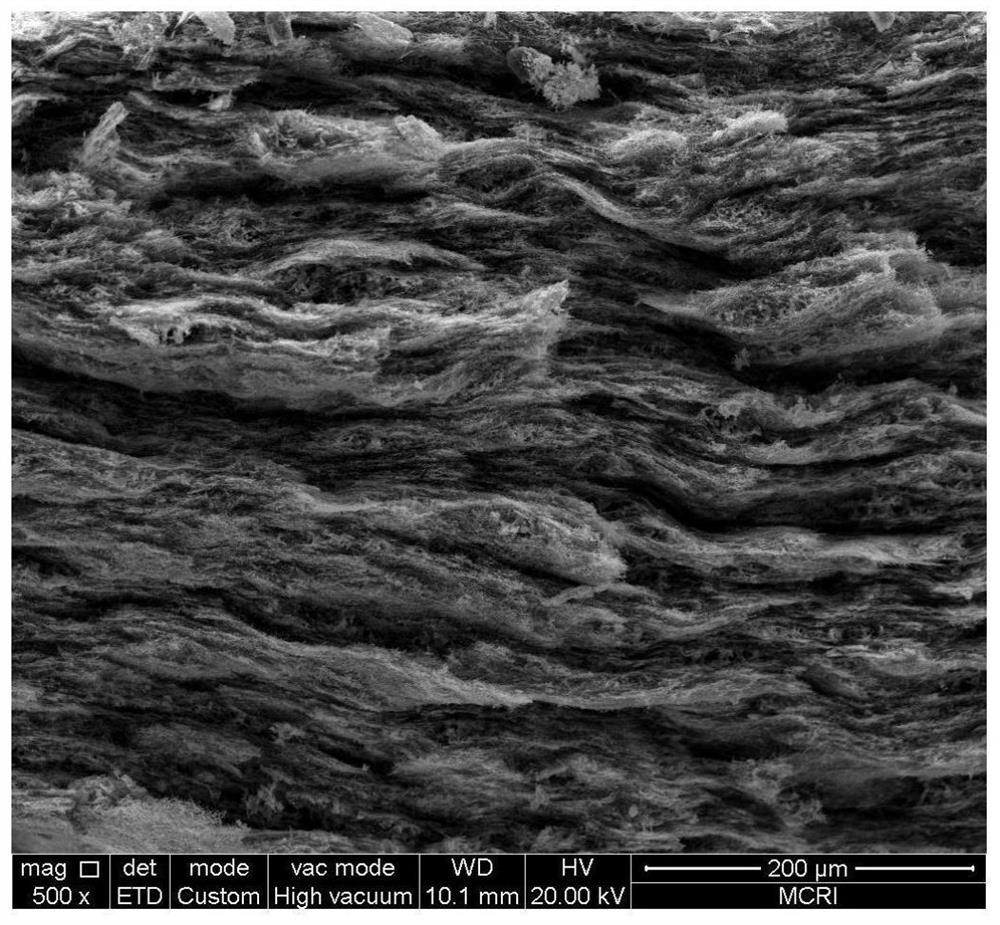

[0041] Depend on figure 1 It can be seen that the lightweight and high-strength elastic ceramics prepared in this example have an obvious layered structure.

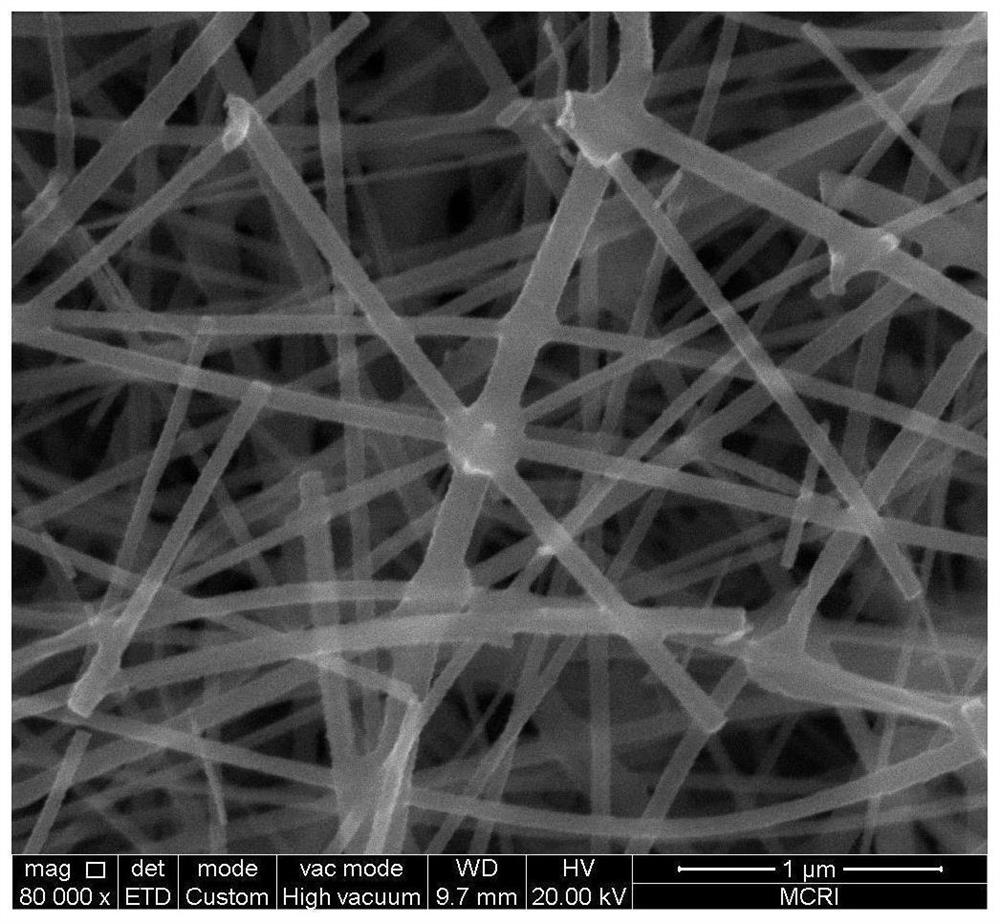

[0042] Depend on figure 2 It can be seen that in the lightweight and high-strength elastic ceramics prepared in this example, the inner layer is a porous network structure formed by cross-linked SiC nanowires.

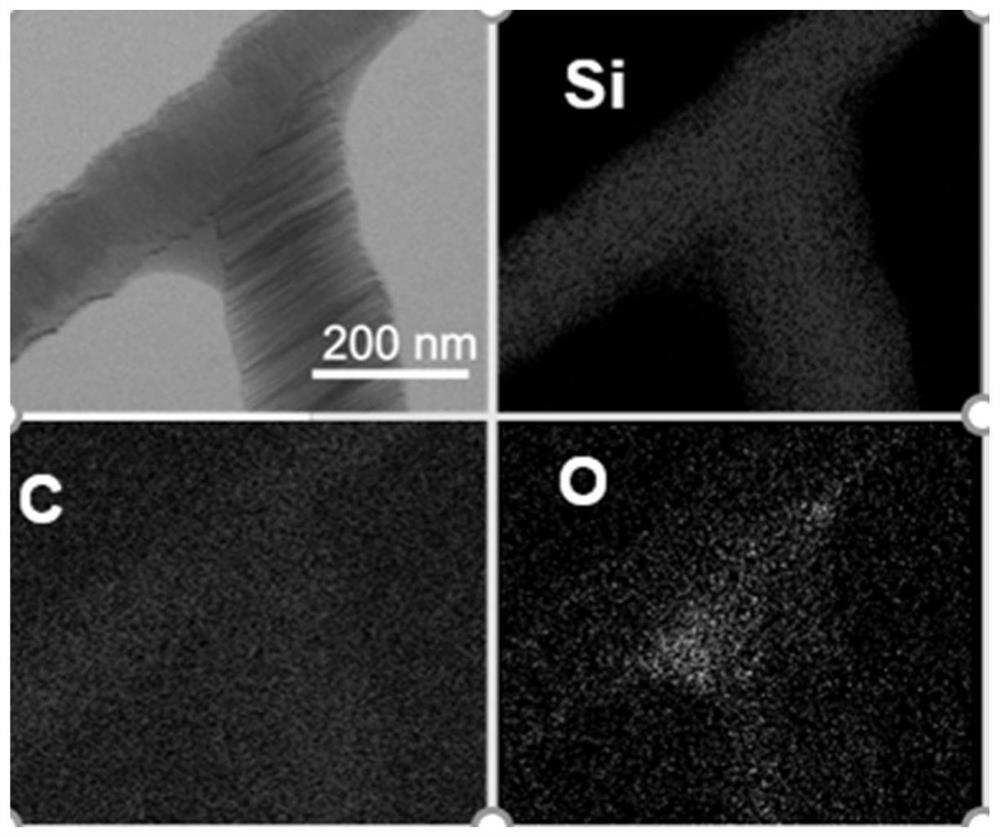

[0043] Depend on image 3 It can be seen th...

Embodiment 3

[0045] This embodiment has prepared the density is 500mg / cm 3 The lightweight and high-strength elastic ceramics, the specific steps are as follows:

[0046] 1) Using 6g of SiC nanowire airgel disclosed in Chinese patent 201811626203.6 as a raw material, fill it in a graphite mold with an inner diameter of 40mm, and keep the filled height fixed at 9.5mm;

[0047] 2) Place it in a nitrogen atmosphere at 1100°C for 2 hours, and cool with the furnace to obtain a density of about 0.50 / cm 3 Lightweight and high-strength elastic ceramics.

[0048] Depend on Figure 4 It can be seen that the compressive stress-strain diagram of the lightweight and high-strength elastic ceramics prepared in this embodiment is in the direction perpendicular to the layer. The brittle behavior of traditional ceramics, when the compressive strain is less than 20%, the resulting lightweight and high-strength elastic ceramics can achieve complete recovery, when the compressive strain is 20%, the density ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com