Cement-based compound material used for mobile phone shell and ceramic-based compound material mobile phone shell

A composite material and mobile phone case technology, which is applied in the field of ceramic matrix composite mobile phone case and its preparation, can solve the problems of brittleness and no plasticity of the back cover, and achieve the effects of simple and easy operation, low cost, good appearance and texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Correspondingly, the embodiment of the present invention also provides a method for preparing a ceramic matrix composite mobile phone case, comprising the following steps:

[0035] S01. Provide each formula component according to the above-mentioned ceramic matrix composite material for mobile phone shell;

[0036] S02. Perform banburying treatment on each component to obtain a mixed material;

[0037] S03. Breaking the mixed material into pellets;

[0038] S04. Put the granules into the injection molding machine to melt and plasticize, inject them into the mold, keep the pressure and cool down, and demould to obtain the mobile phone case.

[0039] Specifically, in the above step S01, the components of the ceramic matrix composite material formulation for the mobile phone case and its preferred situation have been stated above, and will not be repeated here to save space.

[0040]In the above step S02, the various material components obtained in the above step S01 are...

Embodiment 1

[0047] A ceramic matrix composite mobile phone case, made of the ceramic matrix composite material, the ceramic matrix composite material is composed of the following components in the following parts by weight:

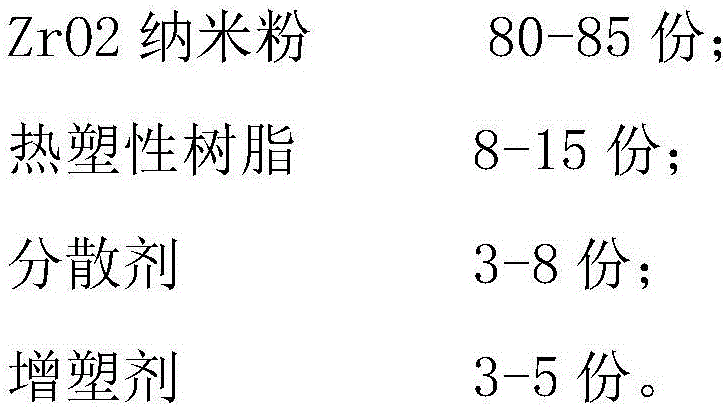

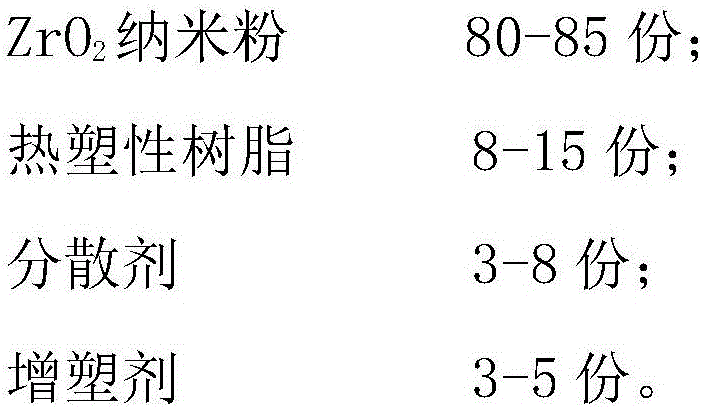

[0048]

[0049]

[0050] Wherein, the thermoplastic resin is at least one of polycarbonate and acrylonitrile-butadiene-styrene copolymer; the powder is liquid paraffin; and the plasticizer is dioctyl adipate.

[0051] The preparation method of the ceramic matrix composite material mobile phone shell comprises the following steps:

[0052] S11. Provide each formula component according to the above-mentioned ceramic matrix composite material for mobile phone case;

[0053] S12. Banburying each component at 260-280°C for 0.5-1h to obtain a mixed material;

[0054] S13. Breaking the mixed material into granules;

[0055] S14. Put the granules into the injection molding machine to melt and plasticize, inject them into the mold, and release the mobile phone case af...

Embodiment 2

[0057] A ceramic matrix composite mobile phone case, made of the ceramic matrix composite material, the ceramic matrix composite material is composed of the following components in the following parts by weight:

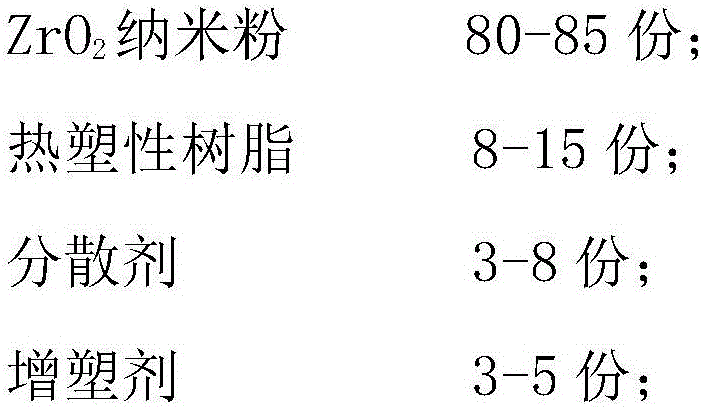

[0058]

[0059] Wherein, the thermoplastic resin is at least one of polycarbonate and acrylonitrile-butadiene-styrene copolymer; the powder is liquid paraffin; and the plasticizer is dioctyl adipate.

[0060] The preparation method of the ceramic-matrix composite mobile phone case is the same as that of the specific example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com