Apparatus for manufacturing aspherical microlens array

A technology of microlens arrays and manufacturing devices, which is applied in the fields of lenses, optics, instruments, etc., can solve the problems that microlenses cannot control the lens surface shape, and cannot detect the lens surface shape and optical performance in real time, so as to achieve good focusing and imaging performance, The effect of high repeatability and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

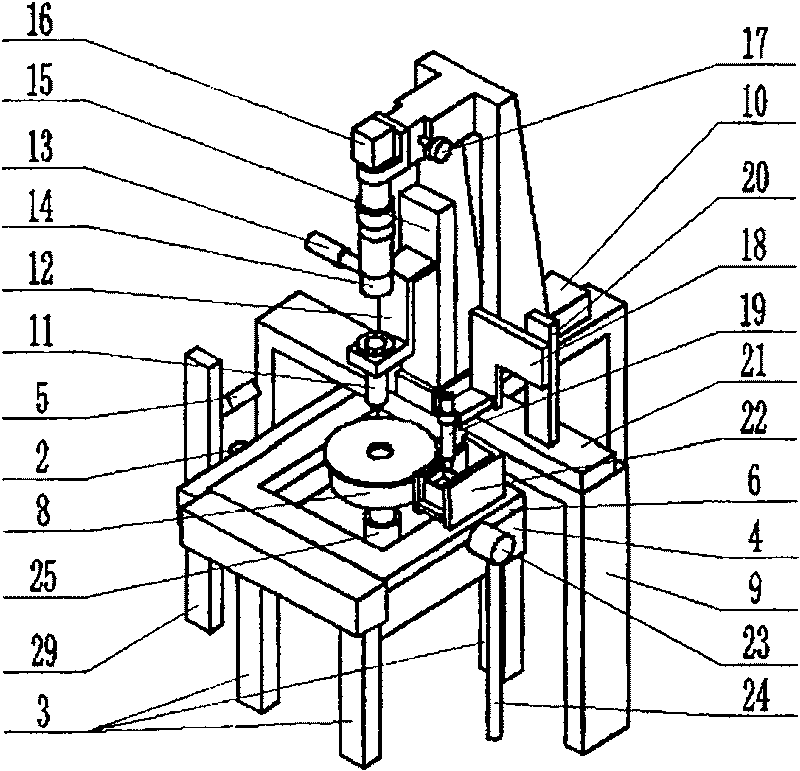

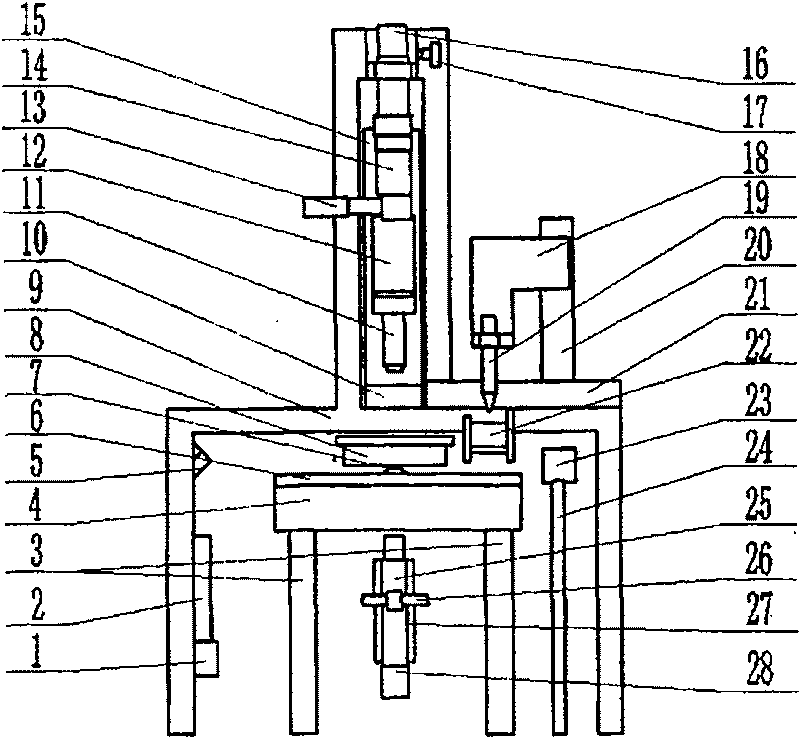

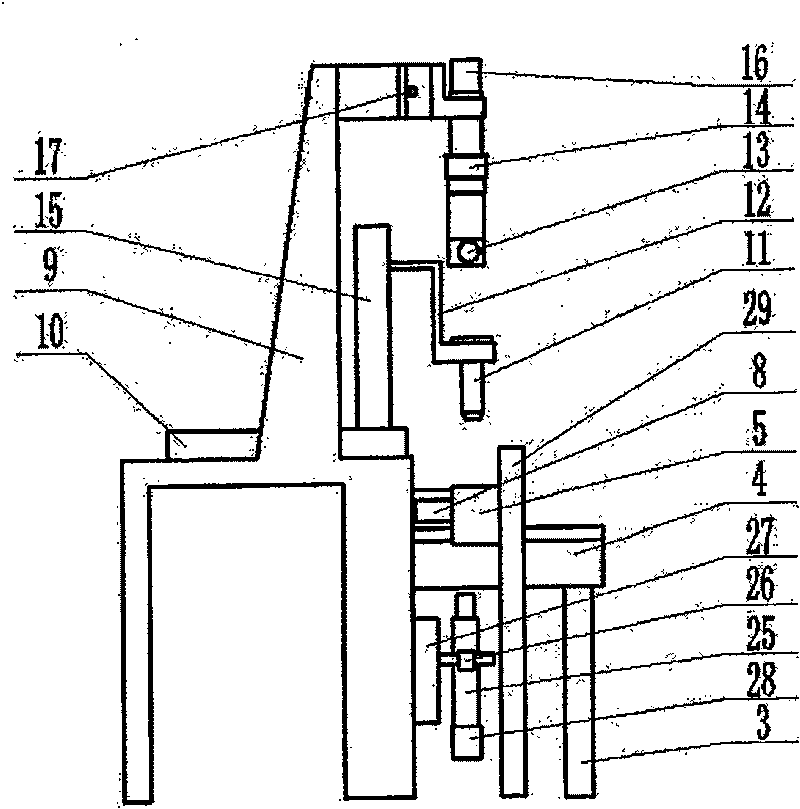

[0035] see figure 1 , figure 2 and image 3 , an aspheric microlens array manufacturing device includes a main frame 9, a syringe 19, an upper electrode 11, a transverse detection optical path, a longitudinal detection optical path, an annular ultraviolet light source 8 and an integral two-dimensional translation stage 4.

[0036] The lower part of the main body support 9 is a workbench shape, and the middle part of the workbench is a door-shaped vertical vertical arm upwards, and the upper end of the vertical vertical arm is a cantilever;

[0037] The syringe 19 is fixed on the syringe longitudinal translation platform 20 through the syringe bracket 18, the syringe longitudinal translation platform 20 is fixed on the syringe transverse translation platform 21, and the syringe 19 is driven by the syringe transverse translation platform 21 and the syringe longitudinal translation platform 20 to move horizontally and vertically in two dimensions , the syringe lateral translat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com