Apparatus for producing biodiesel for vehicle and its preparing method

A biodiesel and production device technology, applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, biofuels, etc., can solve the problems of unsuitability for large-scale industrial production, difficult quality control, long reaction time, etc., and improve recovery efficiency , low cost, low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

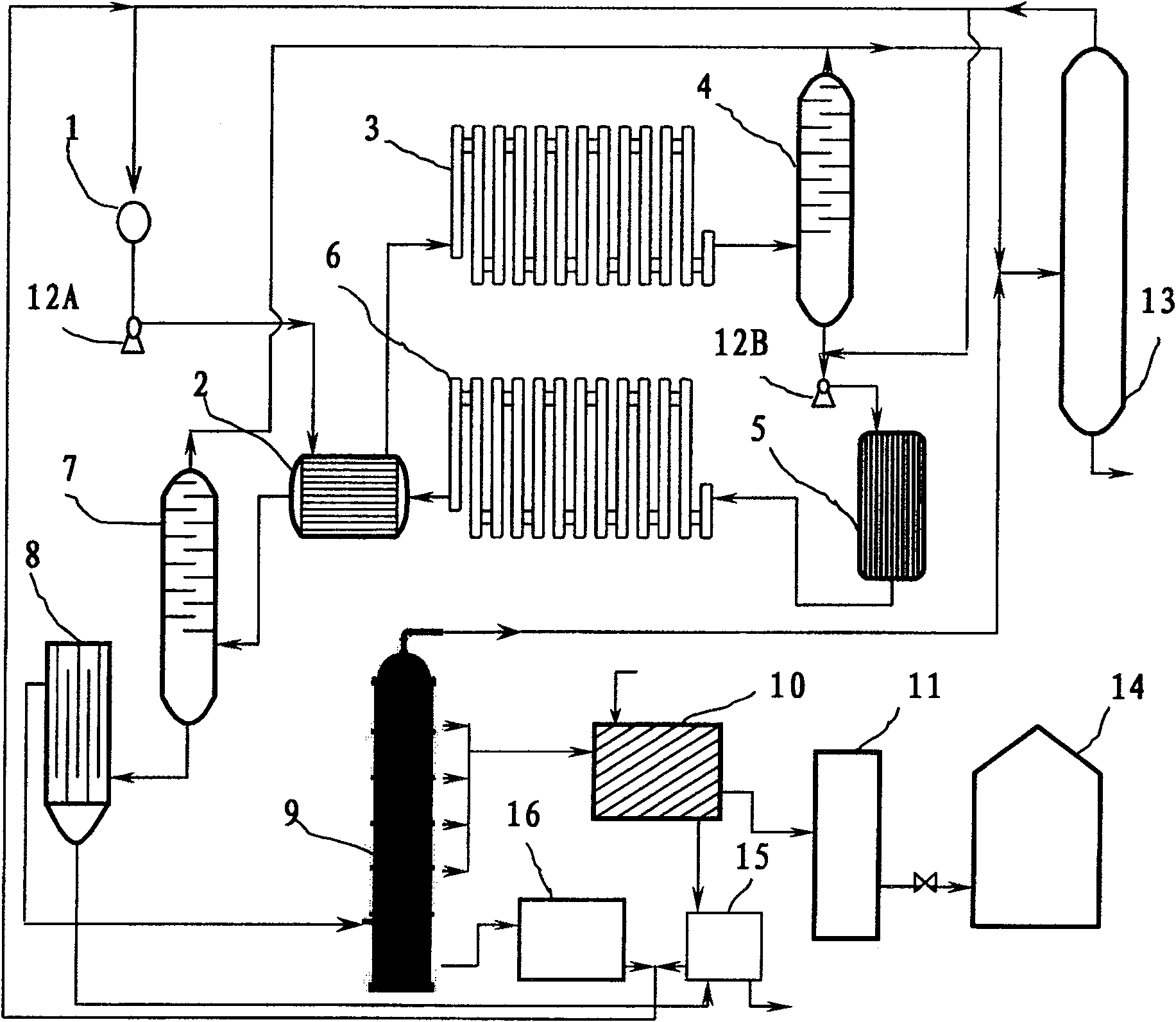

Method used

Image

Examples

Embodiment

[0061] 1. Esterification and transesterification:

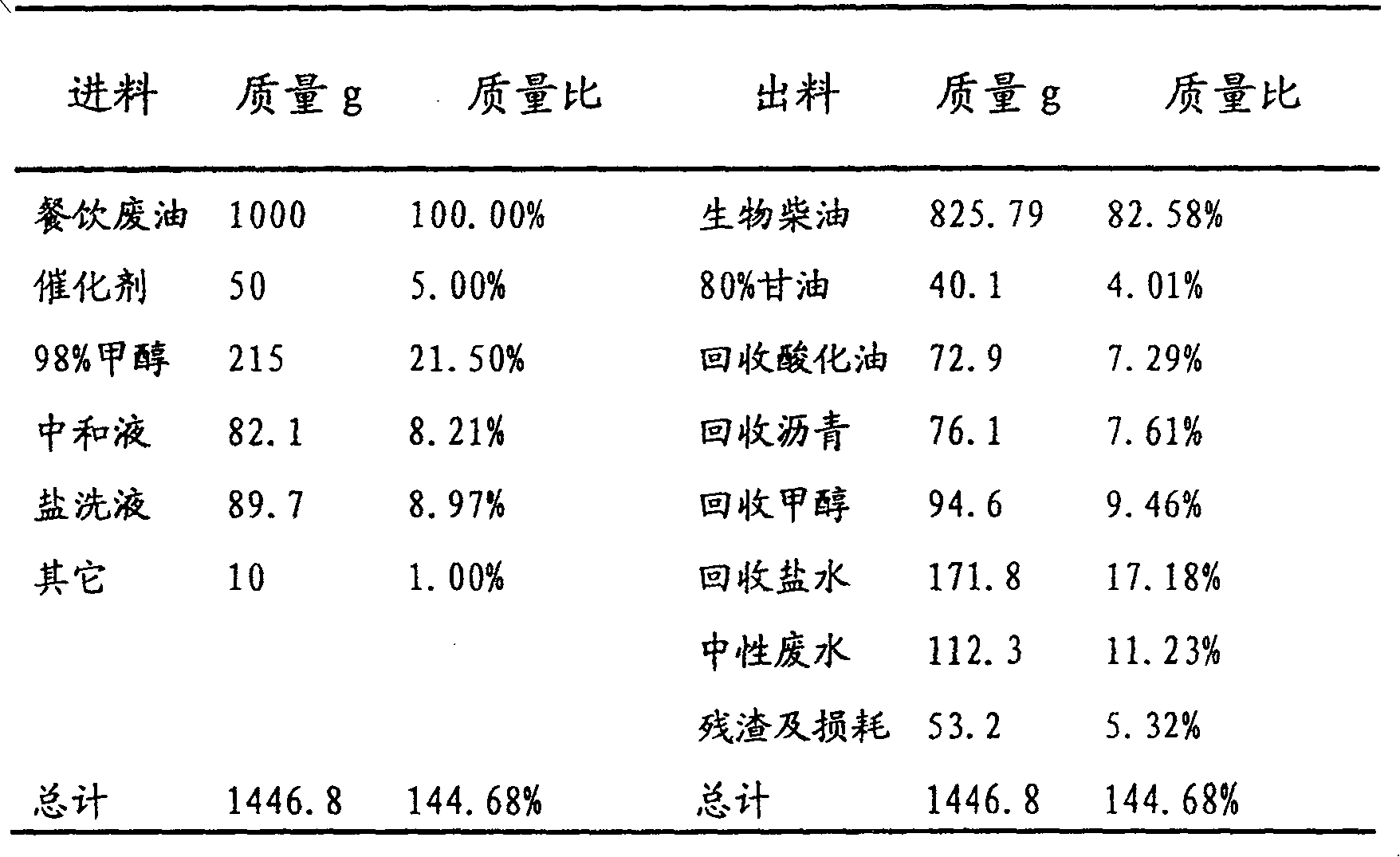

[0062] First, 1000 g of dehydrated and miscellaneous catering waste oil (liquid, free fatty acid content is 40%) is mixed with 50 g of acid catalyst sulfuric acid (98%) and 215 g of methanol (98%). The pressure is increased to 0.8MPa by the booster pump 12A, and the temperature is raised to 70-75°C by the heat exchanger 2, which is continuously sent to the first-stage tubular reactor 3, and the reacted material is continuously transferred to the first flash evaporation Tower 4 (operating temperature is 80 ~ 85 ℃), dilute methanol is introduced from the top of the first flash tower 4 into the alcohol fractionation tower 13 to be concentrated into 98% methanol (about 160.5g), and then with the bottom of the first flash tower 4 The materials coming out are mixed, the pressure is increased to 2.0MPa by the booster pump 12B, the temperature is raised to 110°C by the heater 5, and sent to the second-stage tubular reactor 6 for furt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com