Electric machine - fluid machine stanchev aggregation set

A fluid machinery, axisymmetric technology, applied in the direction of mechanical equipment, machine/engine, rotary piston machinery, etc., can solve the problems of high manufacturing, maintenance and repair costs, and achieve low inertia force and easy forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

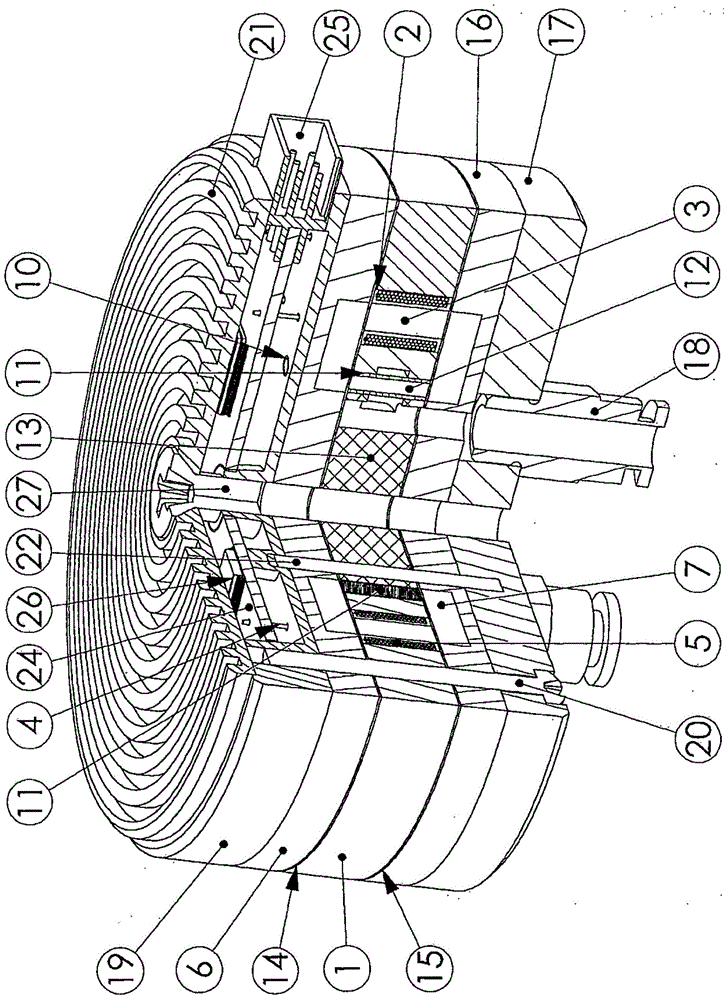

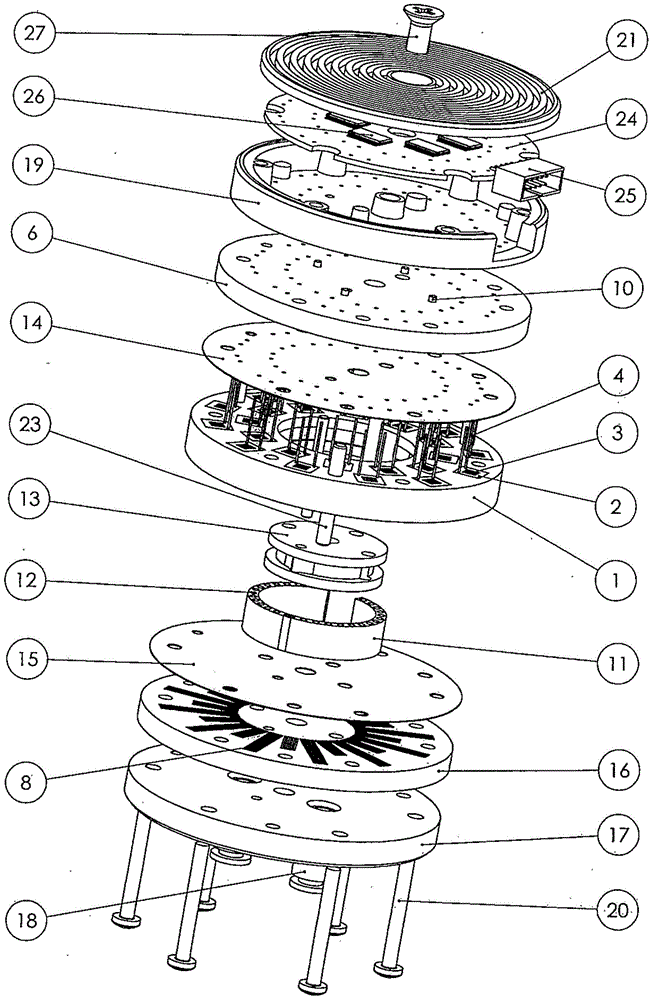

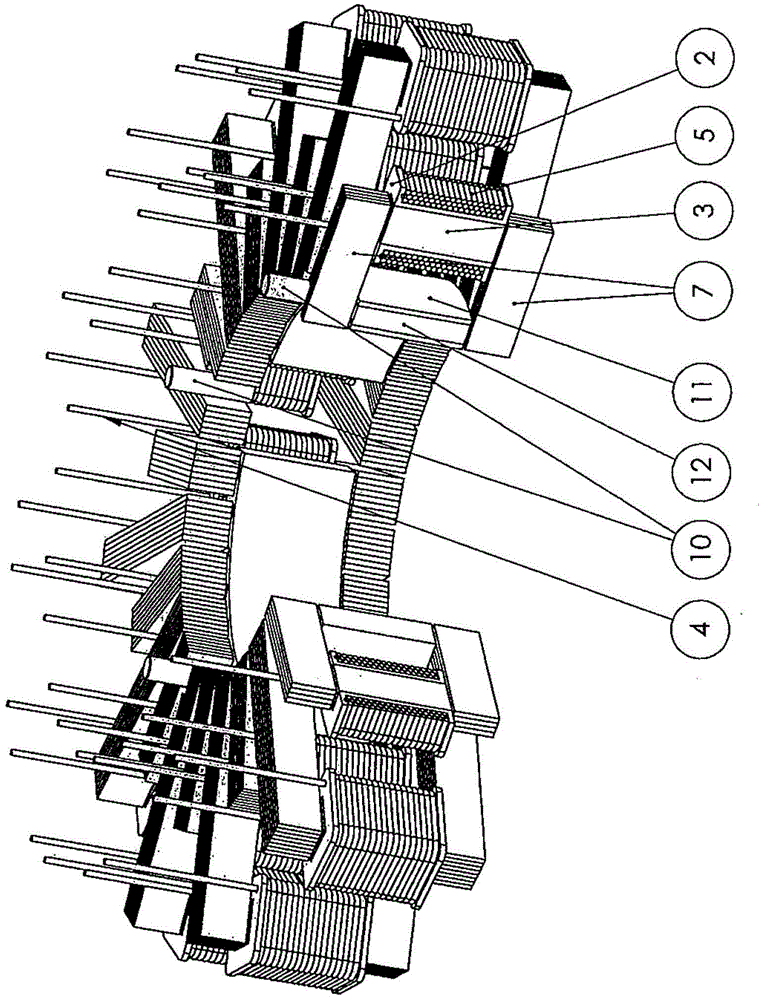

[0031] EFSAS that works like an electric pump ( figure 1 ) wraps the stator, the two rotor / piston units and the power control unit. Its stator includes: main body 1, core 13 and electromagnet-coil 2, coil pin 5 and 4 ( image 3 ) and U-shaped magnetic rails - set 3 in body 1, set 7 in plates 6 and 16 ( figure 1 )and( figure 2 ) among. The rotor / piston unit 11 comprises a segmented body in which there are permanent magnets 12 fixedly equidistant axially.

[0032] The rotor / piston unit 11 has a gap in the rotating volume with a sliding joint radially limited by the body 1 and the core 13 and axially by the spacers 14 and 16 ( figure 1 )and( figure 2 ) to limit. The winding 5 , bobbin 2 is connected to the pin 4 to provide an electrical connection to the power module 24 . Input and output ports 18, plate 17, openings in plate 16, openings in isolators 15 and 13, and openings in core 13 provide hydraulic (actuated) Connected to the external space to form a volume of rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com