Composite-forming ultra-light floor roller

A composite molding, floor roller technology, applied in textiles and papermaking, can solve problems affecting product quality and production, complex manufacturing process, short service life, etc., to improve product quality and production, high accuracy of outer cylinder, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

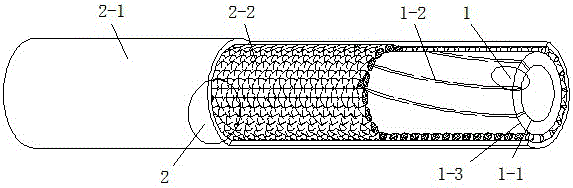

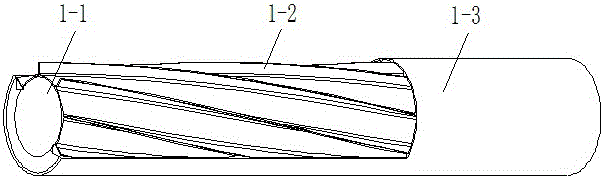

[0021] Embodiment 1: The ground roller includes: a shaft core 1 and a fiber braided composite layer 2 ; the fiber braided composite layer 2 is wrapped on the outer cylinder of the shaft core 1 .

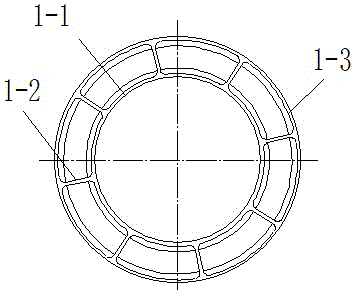

[0022] The shaft core includes: an outer cylinder 1-3, an inner cylinder 1-1 and a support 1-2; the inner cylinder 1-1 is concentric with the outer cylinder 1-3, and there are several The support 1-2 is uniformly distributed in a spiral shape between the inner cylinder 1-1 and the outer cylinder 1-3.

[0023] Both the inner cylinder 1-1 and the outer cylinder 1-3 are cylindrical.

[0024] The support 1-2 is a plurality of plate-shaped spiral rotating ribs, which extend spirally between the inner cylinder 1-1 and the outer cylinder 1-3, and both ends are connected to the inner cylinder 1-1 and the outer cylinder 1-3 at the same time. connected to form a whole.

[0025] The composite layer includes: a fiber braided structure reinforced layer 2-1 and a pouring layer 2-2; the poured la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com