Backing roll fiber-braided composite layer

A technology of fiber weaving and composite layers, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve the problems affecting product quality and production volume, large rotational inertia, large mechanical waves, etc., and improve product quality. and production capacity, increase the thickness of the outer layer, and the effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

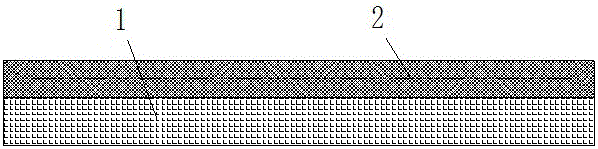

[0011] Example 1: The composite layer includes: a fiber braided structure reinforced layer 1 and a cast layer 2; the cast layer 2 is wrapped outside the fiber braided structure reinforced layer 1; the fiber braided structure reinforced layer 1 is woven by a composite material in a braiding machine The sleeve net-like braided fabric is single-layer or multi-layer; the casting layer 1 is coated on the outer cylinder of the fiber braided structure reinforcement layer 1 by various materials through the casting process; the material of the casting layer is resin, rubber or polyurethane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com