Patents

Literature

72results about How to "Offset torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hybrid vehicle

ActiveCN104627183ASmall rotational inertiaReduce input torqueHybrid vehiclesSpeed controllerElectricityElectric machine

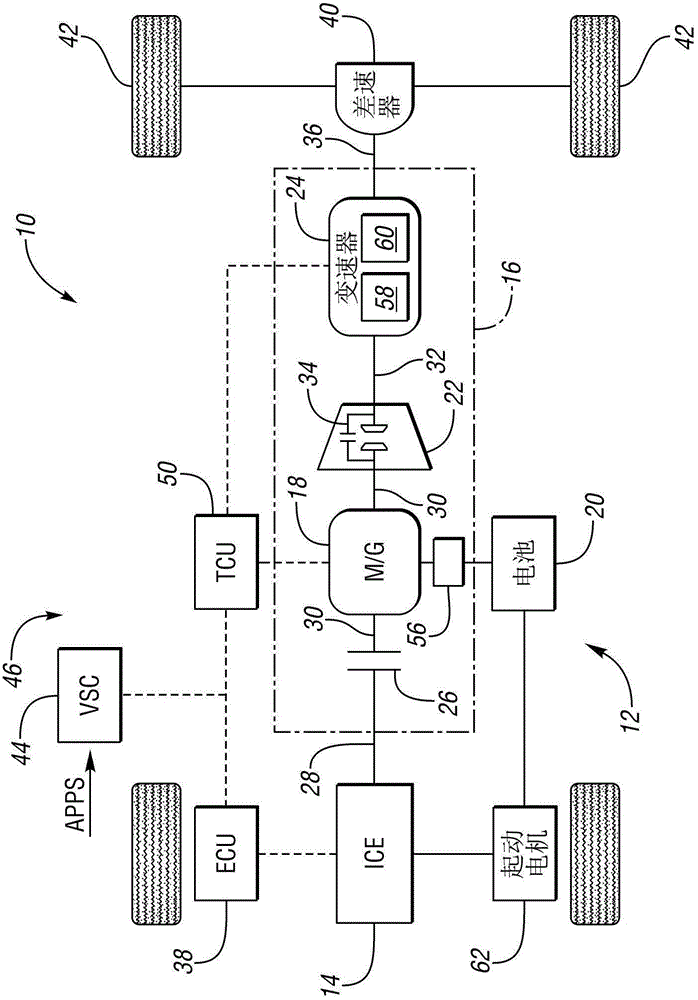

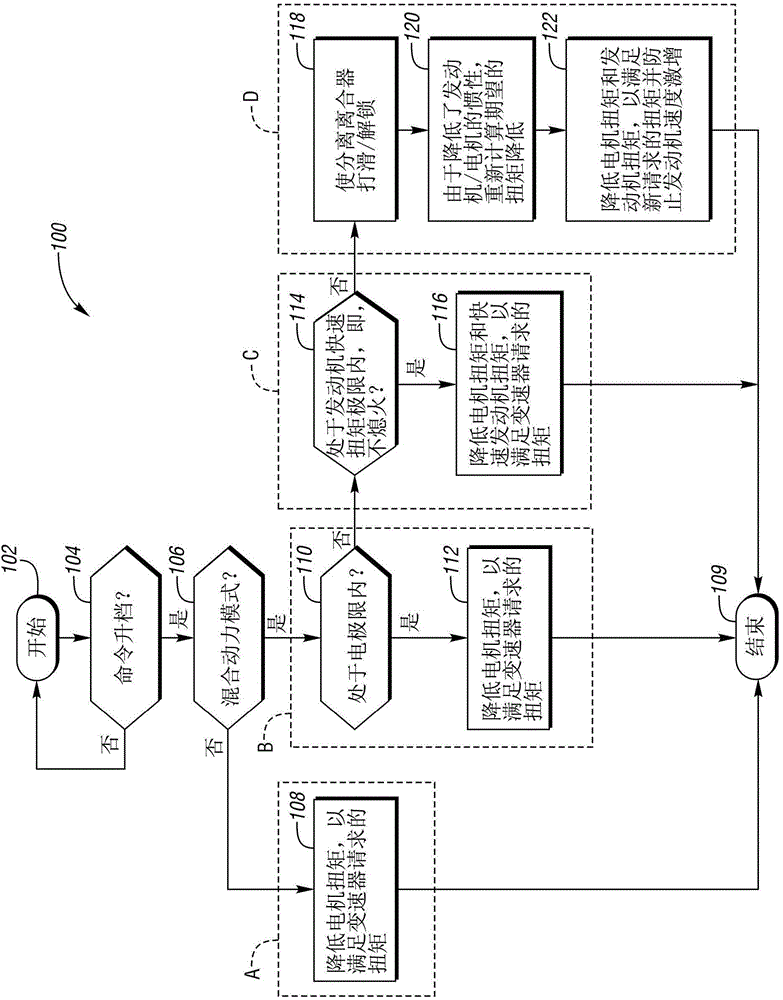

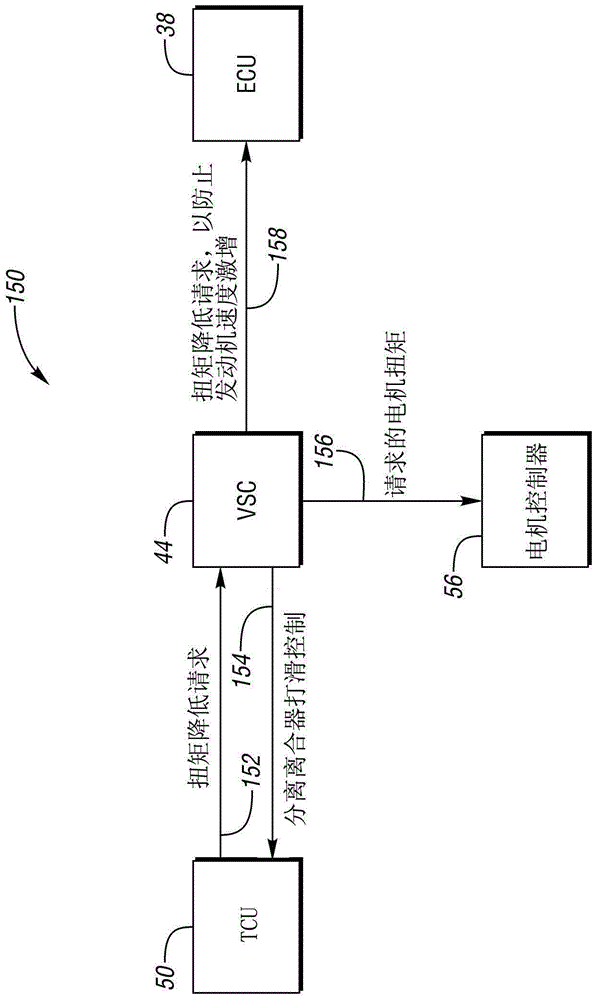

A hybrid vehicle has an engine, an electric machine connected to the engine by an upstream clutch, a transmission gearbox connected to the electric machine by a downstream clutch, and a controller. The controller is configured to, in response to a commanded upshift of the gearbox, modulate a pressure of the upstream clutch. A method for controlling a vehicle includes, in response to a commanded upshift of a gearbox, controlling an upstream clutch to a first nonzero speed differential corresponding to a first inertia connected to and upstream of the gearbox to reduce inertia torque during the upshift. A method for controlling a vehicle includes, in response to a commanded upshift of a gearbox when the vehicle is beyond an electrical limit and a fast path torque reduction limit, slipping an upstream clutch and reducing torque outputs of an engine and an electric machine.

Owner:FORD GLOBAL TECH LLC

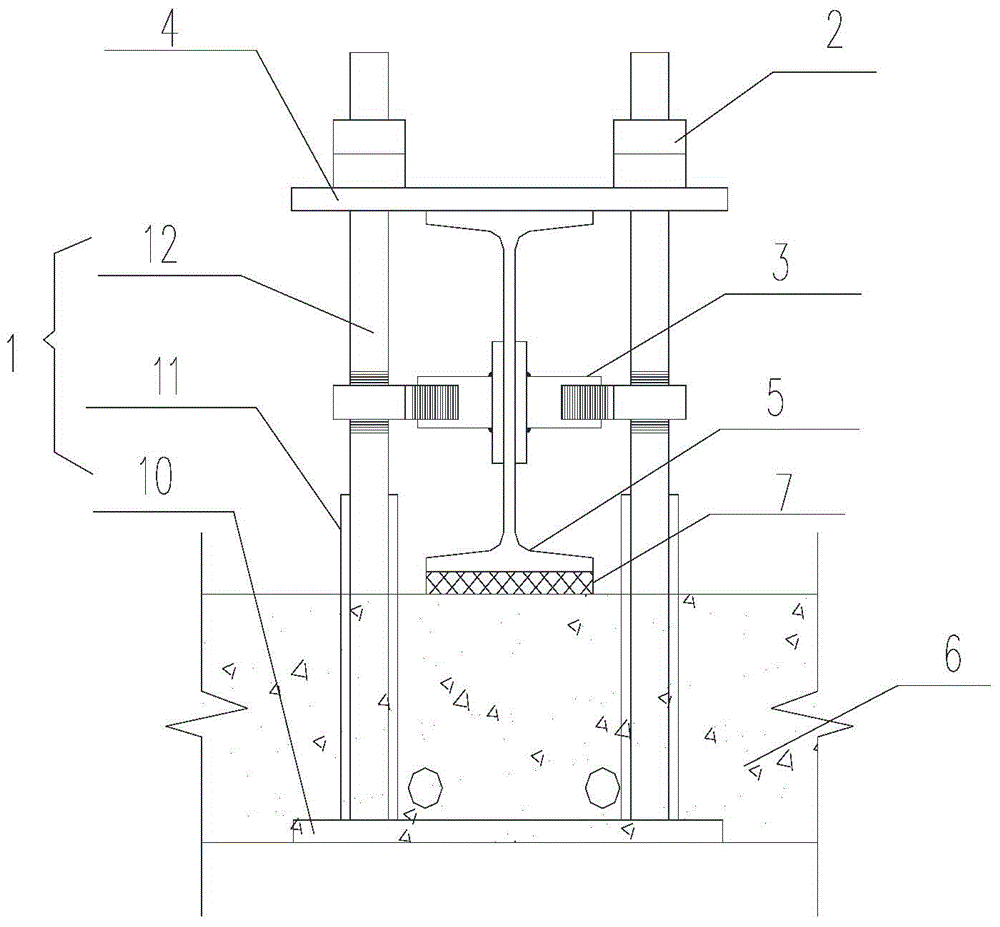

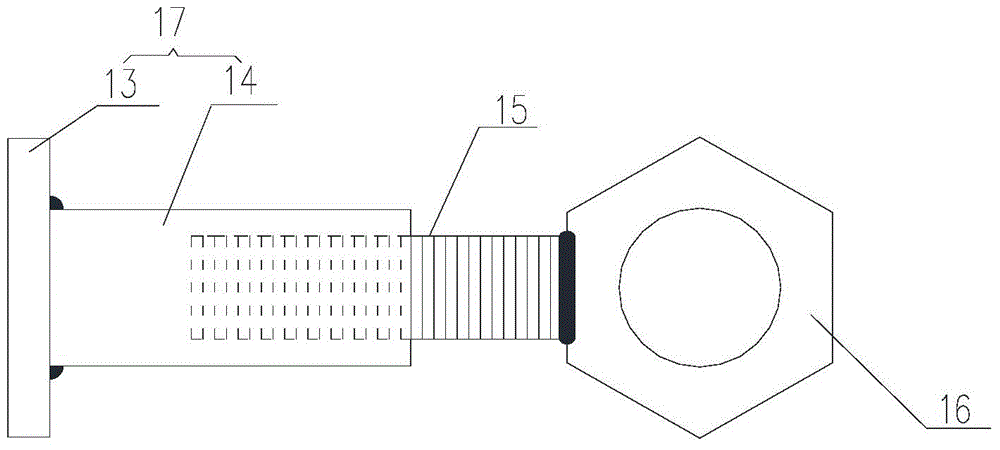

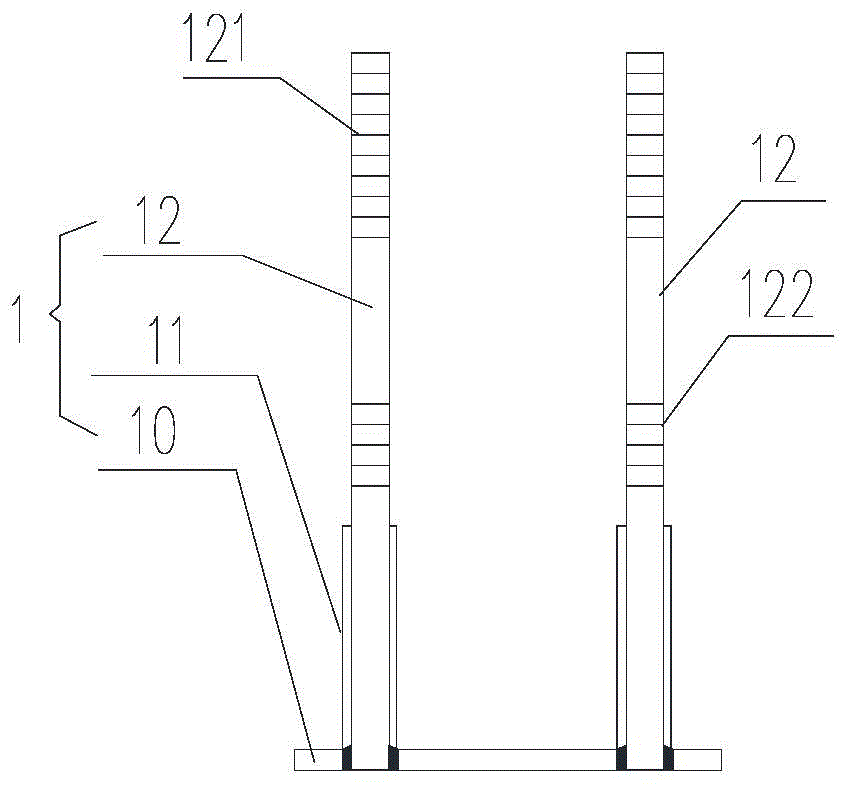

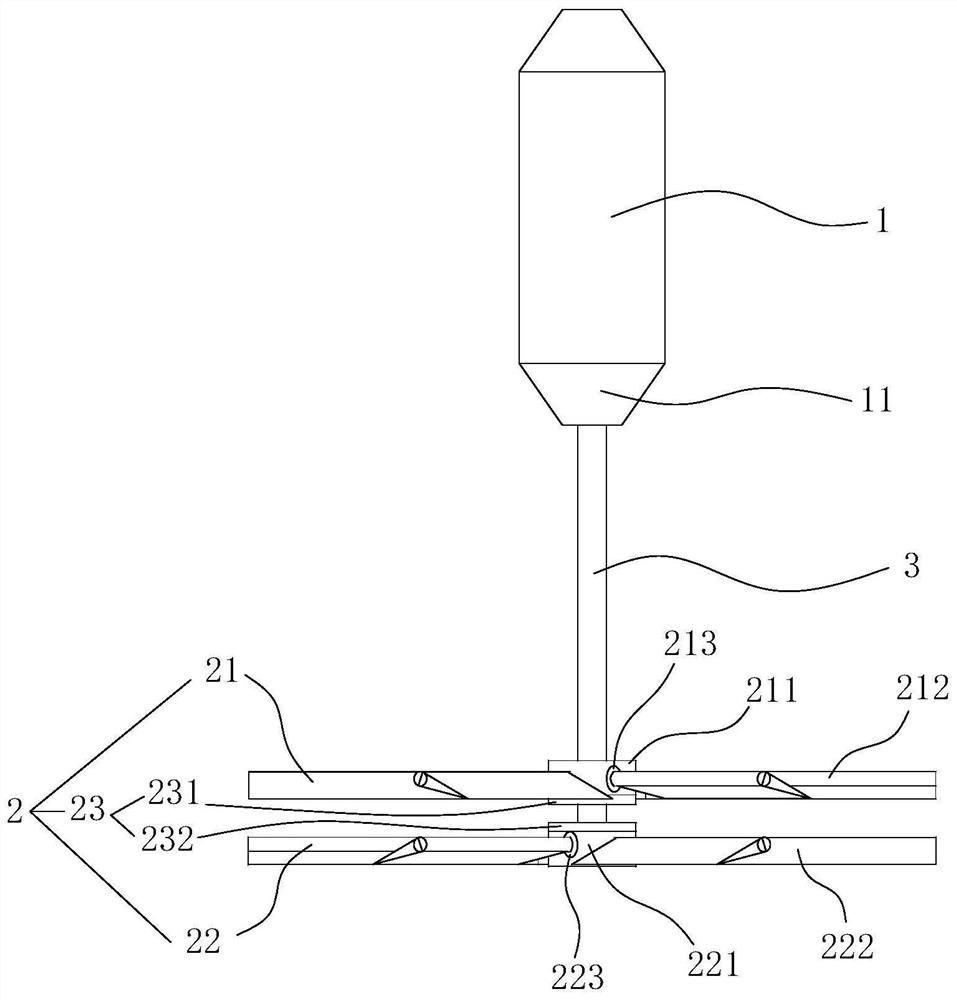

Detachable overhung steel beam pre-buried fixing device with horizontal fixing assembly

InactiveCN104153555AOffset torqueGuaranteed stabilityScaffold accessoriesBuilding support scaffoldsScrew thread

The invention discloses a detachable overhung steel beam pre-buried fixing device with a horizontal fixing assembly. The detachable overhung steel beam pre-buried fixing device comprises an overhung steel beam, a concrete structural member, the horizontal fixing assembly, a pressing plate, a bottom plate, at least two screws and first nuts matched with the screws respectively in a threaded mode. The screws are arranged on the two sides of the overhung steel beam and are vertically arranged at intervals, one end of the horizontal fixing assembly is detachably connected with the screws, the other end of the horizontal fixing assembly abuts against and is matched with the side face of the overhung steel beam in the horizontal direction, the lower portions of the screws and the bottom plate are pre-buried in the concrete structural member, the bottom ends of the screws are fixed to the bottom plate, the top ends of the screws are locked and connected with the first nuts in a threaded mode after penetrating through the pressing plate, the pressing plate abuts against and is matched with the top end of the overhung steel beam in the vertical direction, and the concrete structural member abuts against and is matched with the bottom end of the overhung steel beam in the vertical direction. The overhung steel beam is fixed in the horizontal direction and is convenient to assemble and disassemble and can be repeatedly used conveniently.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

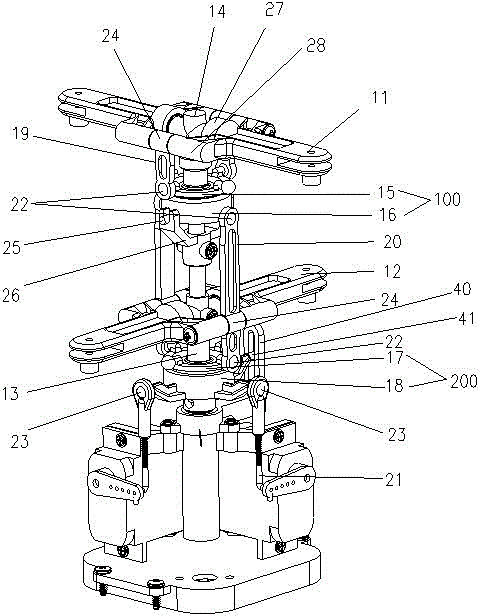

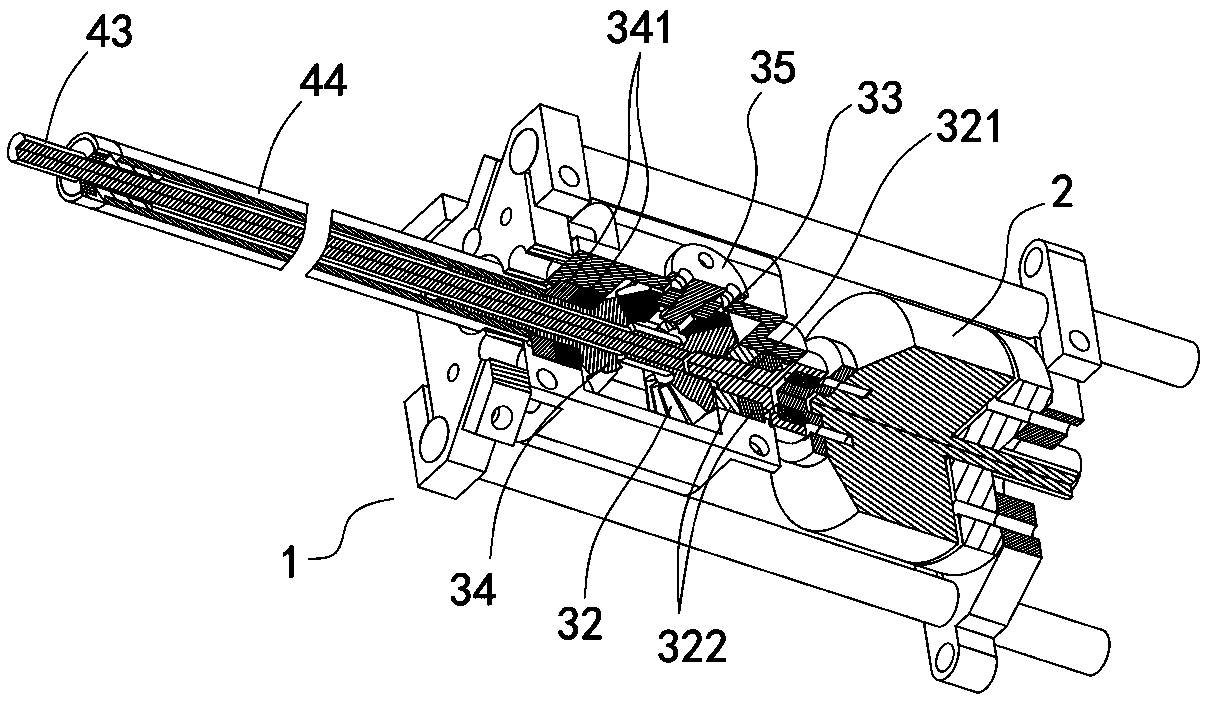

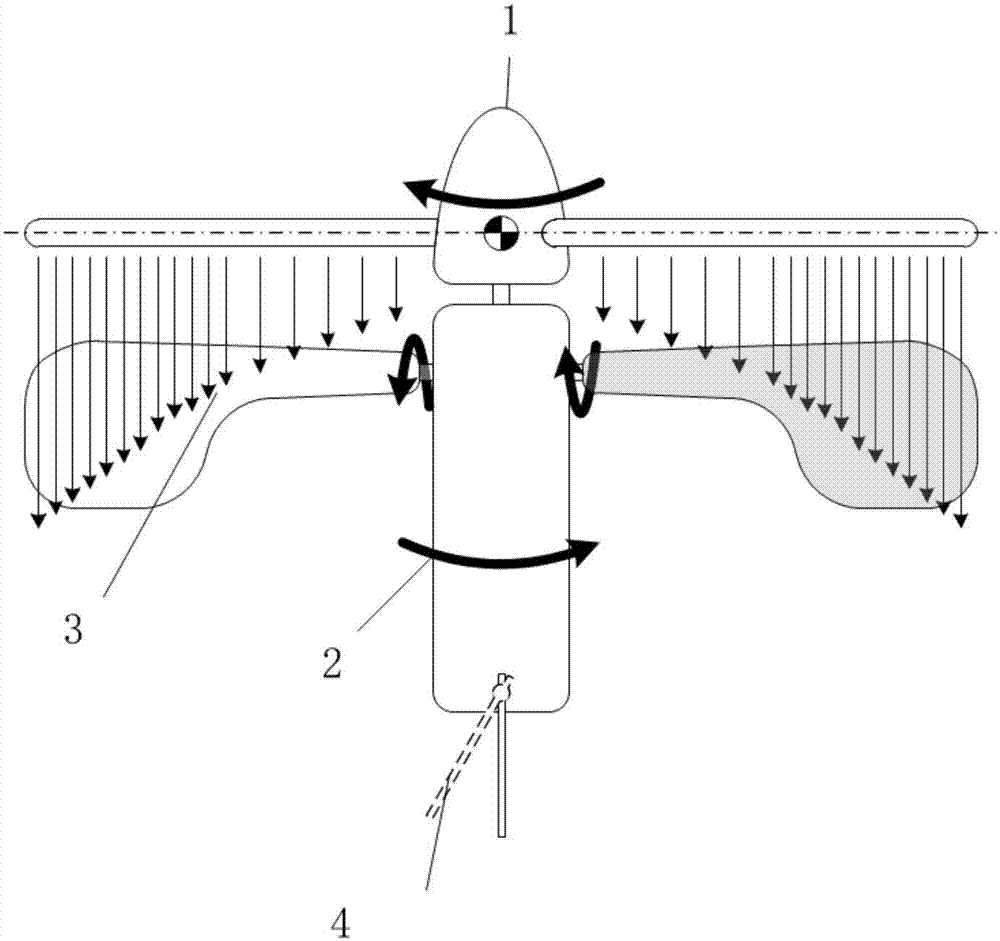

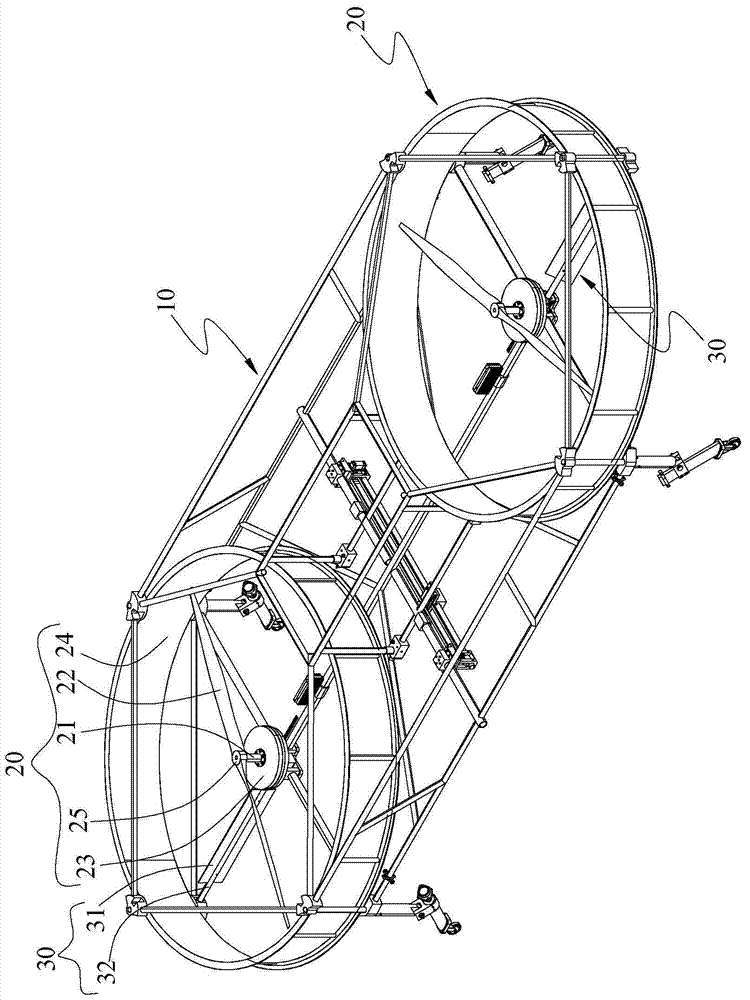

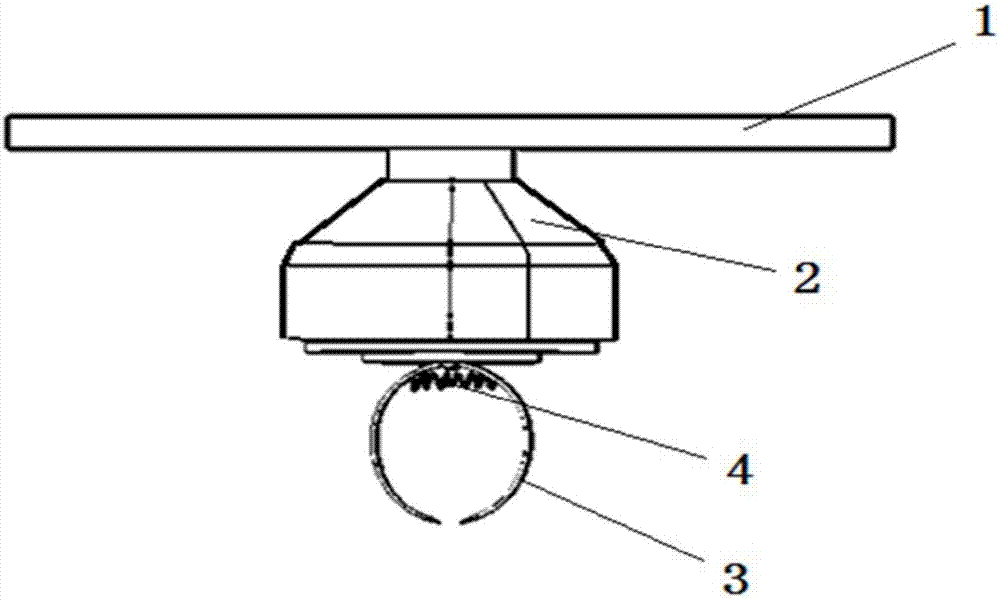

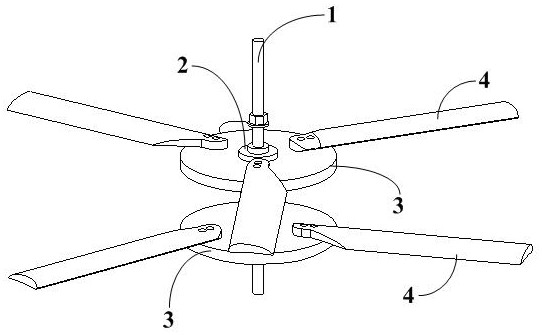

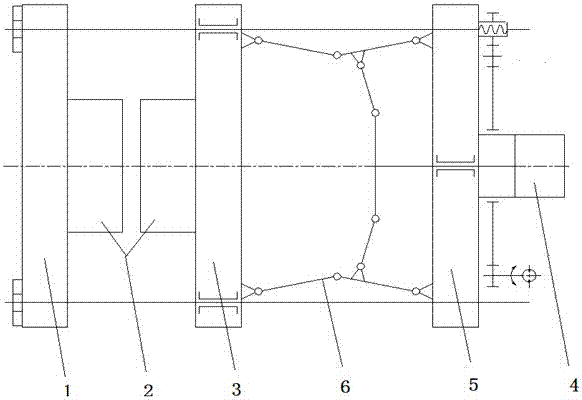

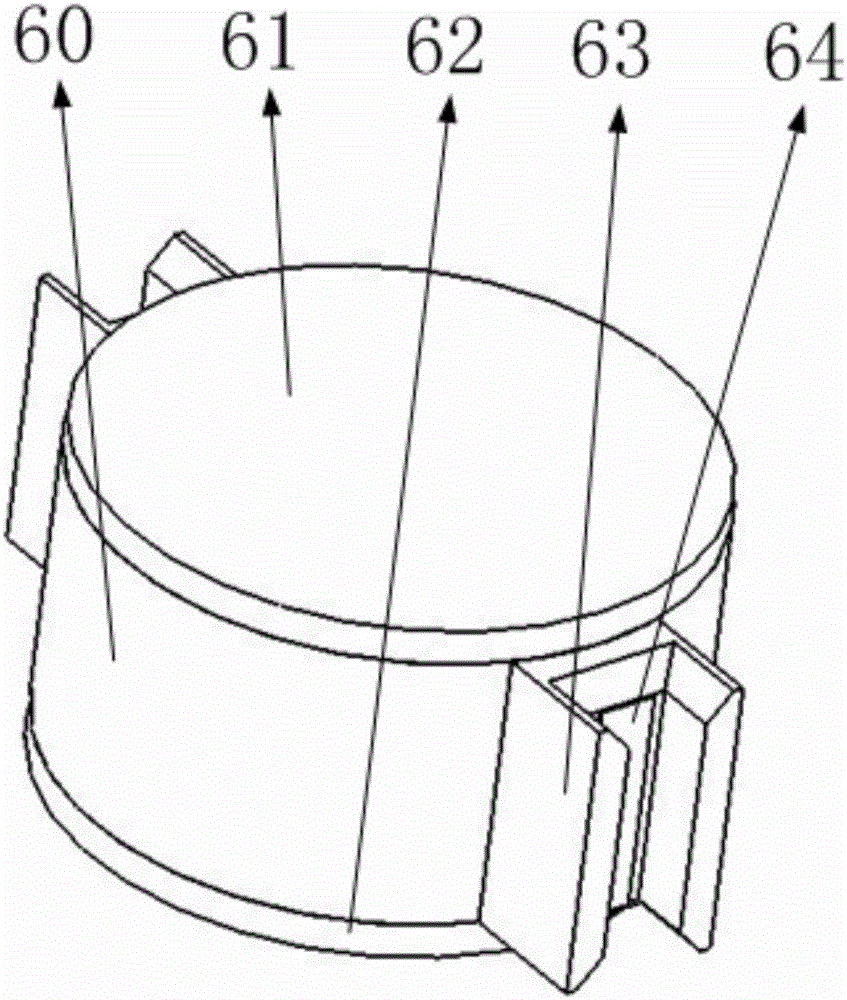

Coaxial double-rotor helicopter core and helicopter

The invention discloses a coaxial double-rotor helicopter core and a helicopter. The coaxial double-rotor helicopter core comprises an upper rotor and a lower rotor which are coaxially connected through a rotary shaft, a server for controlling the upper rotor and the lower rotor to swing and motors for controlling the upper rotor and the lower rotor to rotate oppositely. The rotary shaft comprises an inner shaft body and an outer shaft body, the inner shaft body is connected with the upper rotor, the outer shaft body is connected with the lower rotor, and the upper rotor and the lower rotor are connected through a swash plate assembly. The swash plate assembly comprises an upper swash plate and a lower swash plate. Each of the upper swash plate and the lower swash plate comprises an inner control panel and an outer control panel which are connected through a knuckle bearing. The inner control panel of the upper swash plate is connected with the upper rotor through first connecting rods and rotates reversely along with the upper rotor. The outer control panel of the lower swash plate is connected with the server and controlled by the server to be linked vertically. The inner control panel of the lower swash plate and the outer control panel of the upper swash plate are in linkage through second connecting rods and rotate forwards along with the outer shaft body. By the adoption of the coaxial double-rotor helicopter core, the linkage synchronous adjustment of the upper rotor and the lower rotor is achieved, the torque generated in the rotation process of the two rotors can be effectively counteracted, and the helicopter is more stable.

Owner:深圳市富微科创电子有限公司

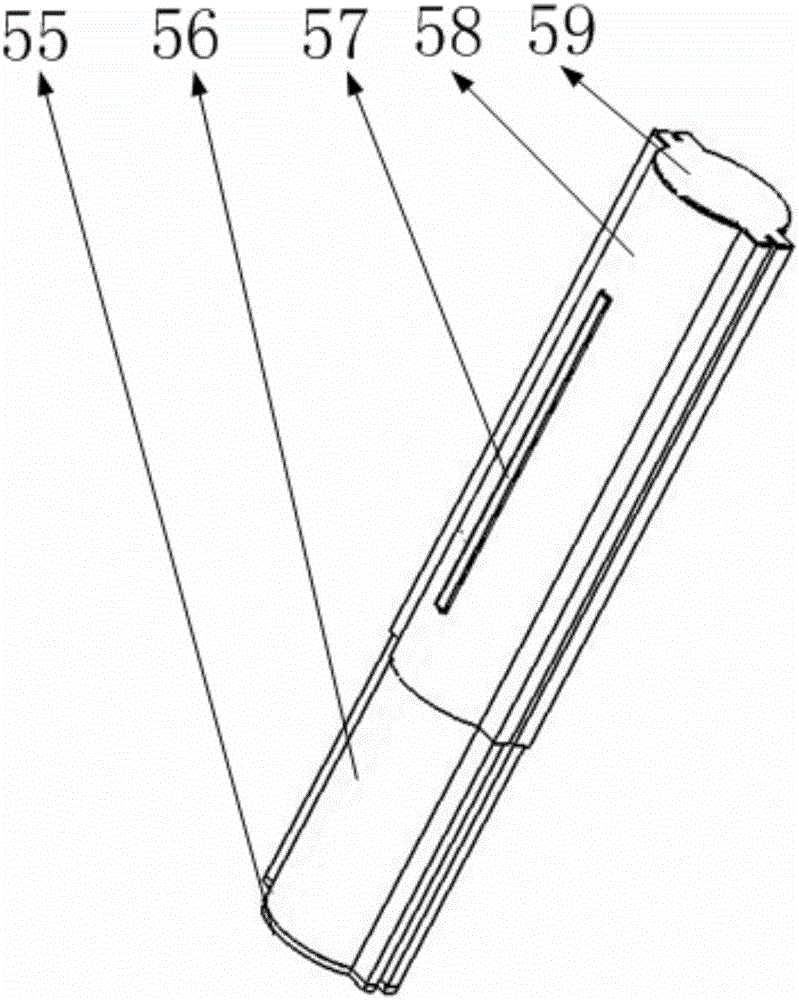

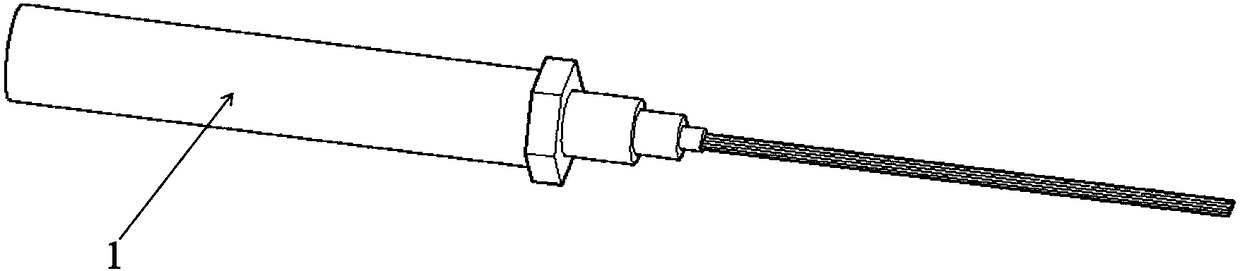

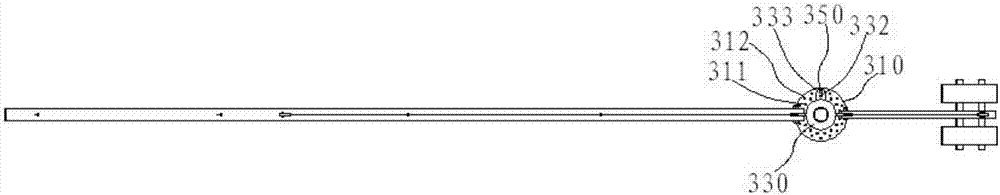

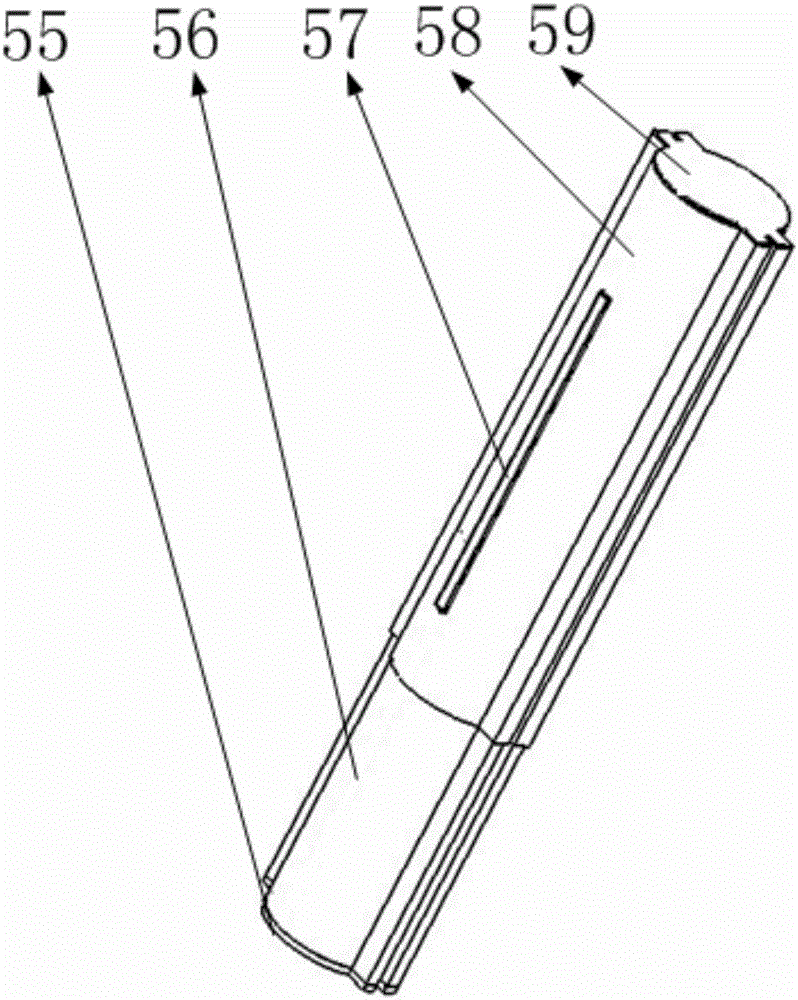

Directional drilling executing mechanism based on three-speed drill bit

InactiveCN105863511ADrilling GuaranteeImprove universal applicabilityDrilling rodsConstructionsUniversal jointDirectional drilling

The invention belongs to the technical field of drilling, and particularly relates to a directional drilling executing mechanism based on a three-speed drill bit. The directional drilling executing mechanism comprises a drill bit drill string, a drill bit, a pressure exerting support plate, pressure exertion electromagnetic telescopic rods, a connecting structure, a positioning mechanism, a motor, an electromagnetic telescopic rod support plate, rotating pairs and a universal joint, wherein the drill bit is connected with the motor through the drill bit drill string, the connecting structure, the universal joint and a motor rotating shaft; through the design of the universal joint, the drill bit drill string can still be driven to rotate by the motor after forming a certain angle relative to the motor rotating shaft; the drill bit drill string is arranged on the pressure exerting support plate; and the three rotating pairs are added to the installation of the two pressure exertion electromagnetic telescopic rods on the pressure exerting support plate and the pressure exerting telescopic rod support plate. By adopting such a design, when the drill bit is enabled to do forward drilling, the drill bit is allowed to form a certain angle relative to the motor. The angle of the drill bit drill string and the motor rotating shaft can be controlled for directional drilling, and high practicability is realized.

Owner:柳超

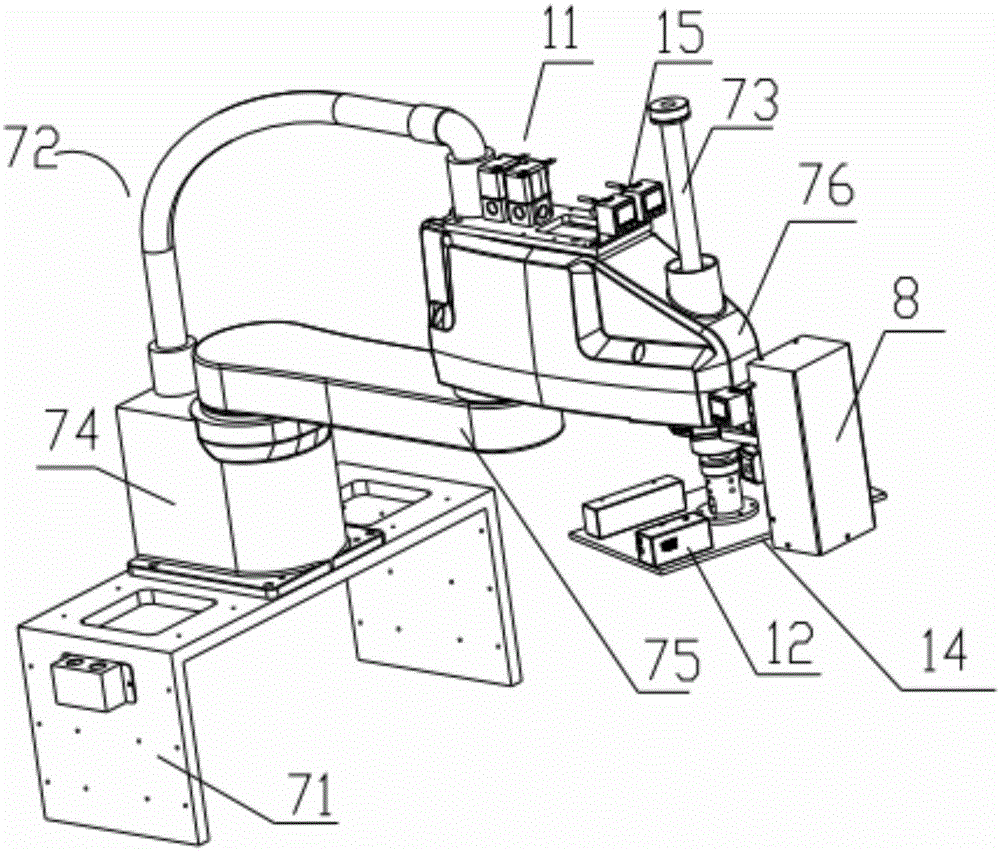

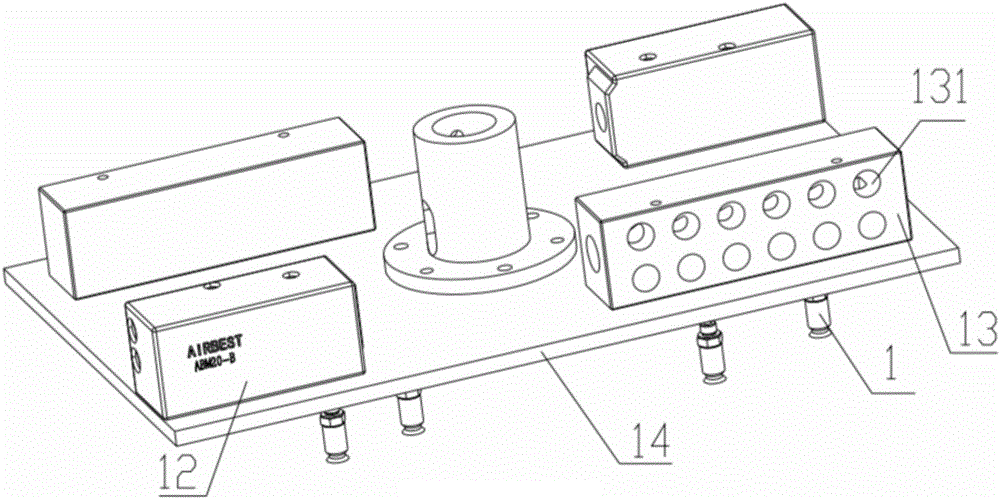

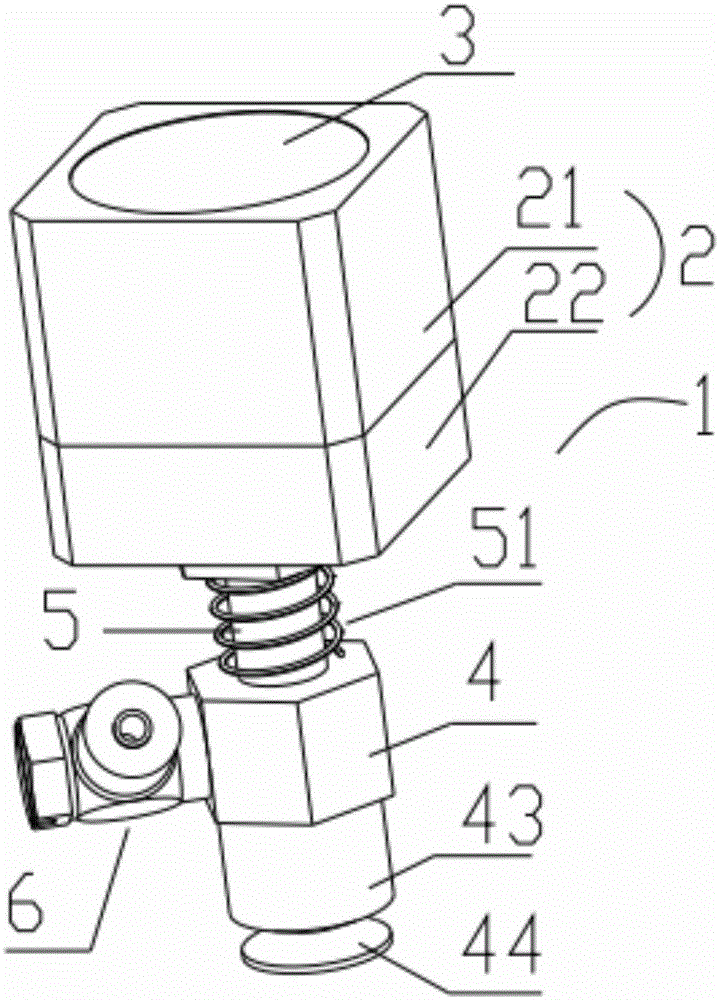

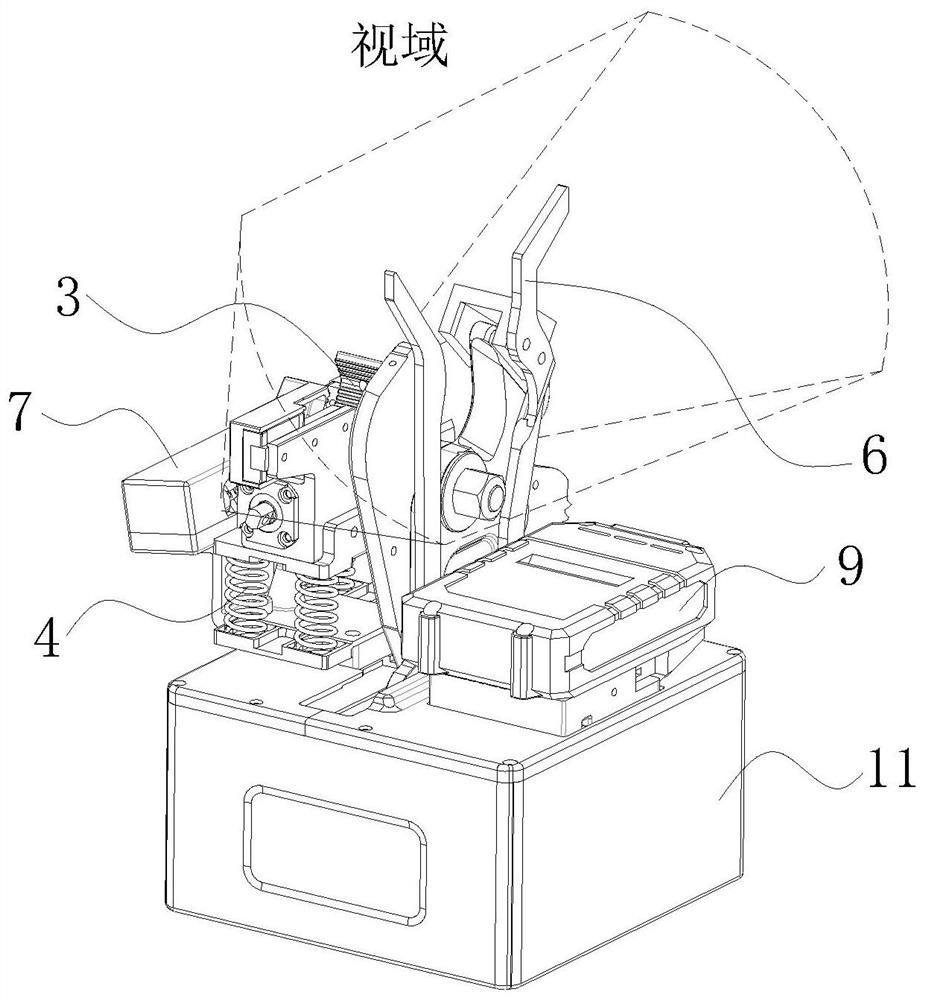

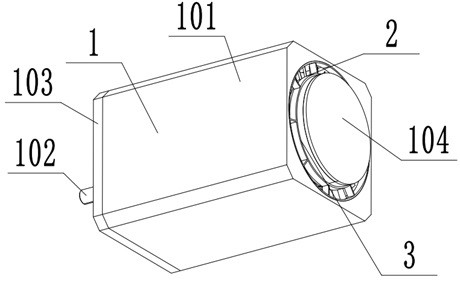

Adjustable FPC (Flexible Printed Circuit) laminating machine material taking mechanism with target identification function

The invention discloses an adjustable FPC (Flexible Printed Circuit) laminating machine material taking mechanism with a target identification function. The adjustable FPC laminating machine material taking mechanism comprises a base, a manipulator which is arranged on the base, a lifting rod, a material sucking disc and a position capture device; the lifting rod is arranged at the movable tail end of the manipulator; the position capture device is a camera which is arranged at the tail end of the manipulator; the material sucking disc comprises a magnetic conductive sucking disc and a vacuum assembly; the vacuum assembly comprises a compressed air source, a vacuum solenoid valve, vacuum generators, vacuum branching blocks and a plurality of vacuum sucking nuzzles; the upper surface of the sucking disc is fixed to the tail end of the lifting rod. The adjustable FPC (Flexible Printed Circuit) laminating machine material taking mechanism with the target identification function has the advantages that the structure is simple and compact; vacuum adsorption of a workpiece can be realized; the adsorption position can be adjusted freely according to adsorption workpieces in different specifications; the automation degree is high; the operation range is wide; the workpiece can be captured in a large range; meanwhile, target identification can be realized for determining an accurate coordinate position of a target by cooperating with built-in software.

Owner:DONGGUAN MUTE AUTOMATION EQUIP CO LTD

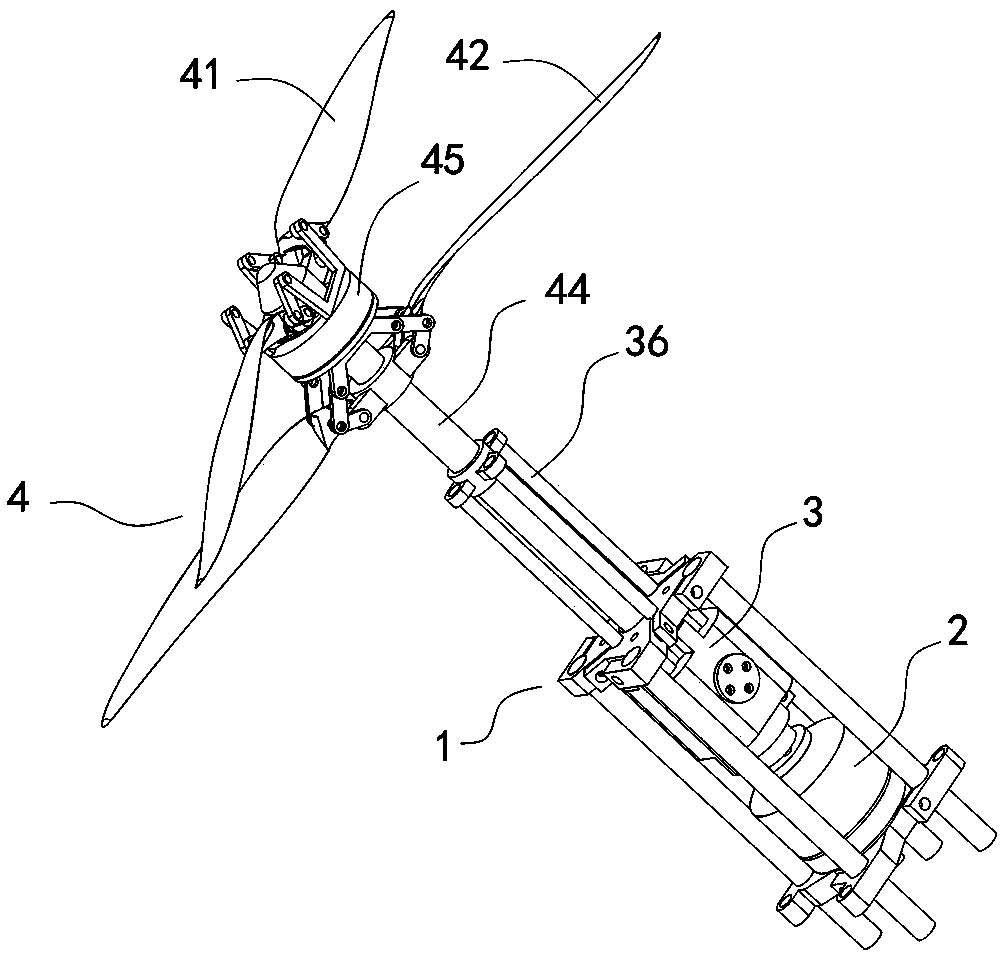

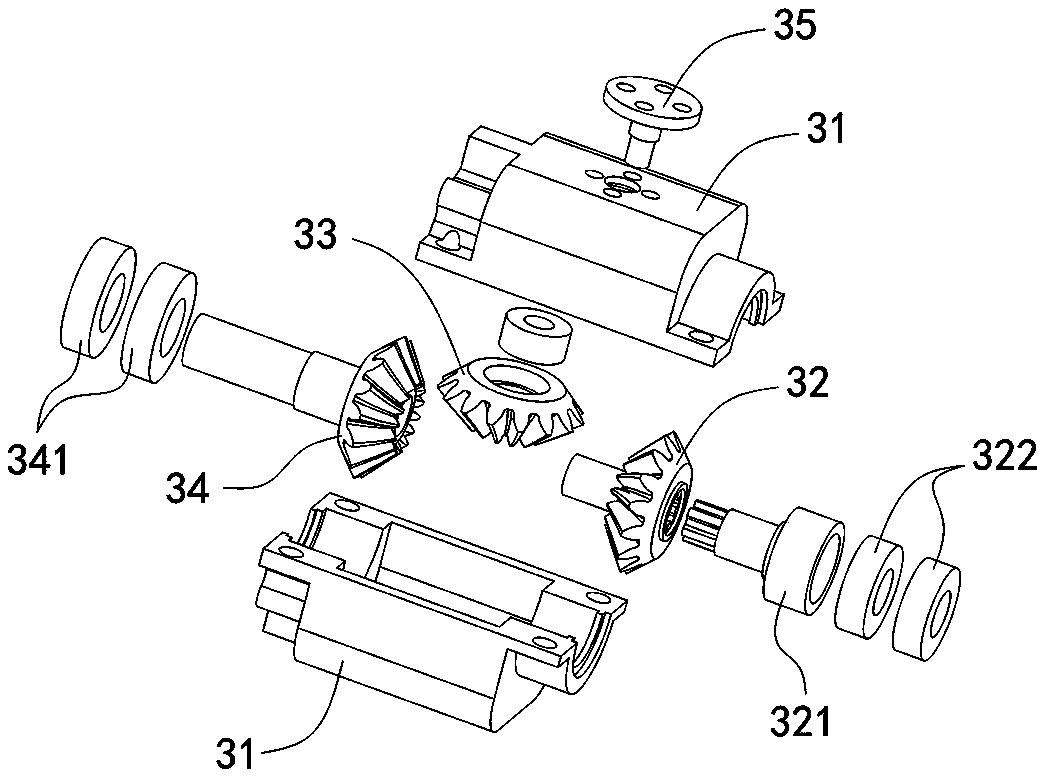

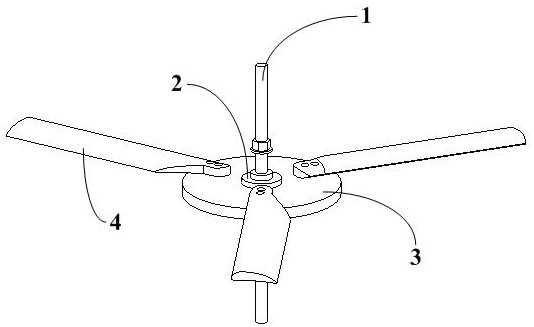

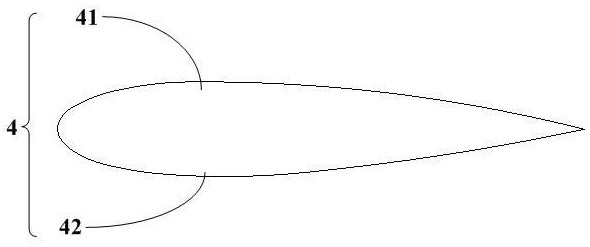

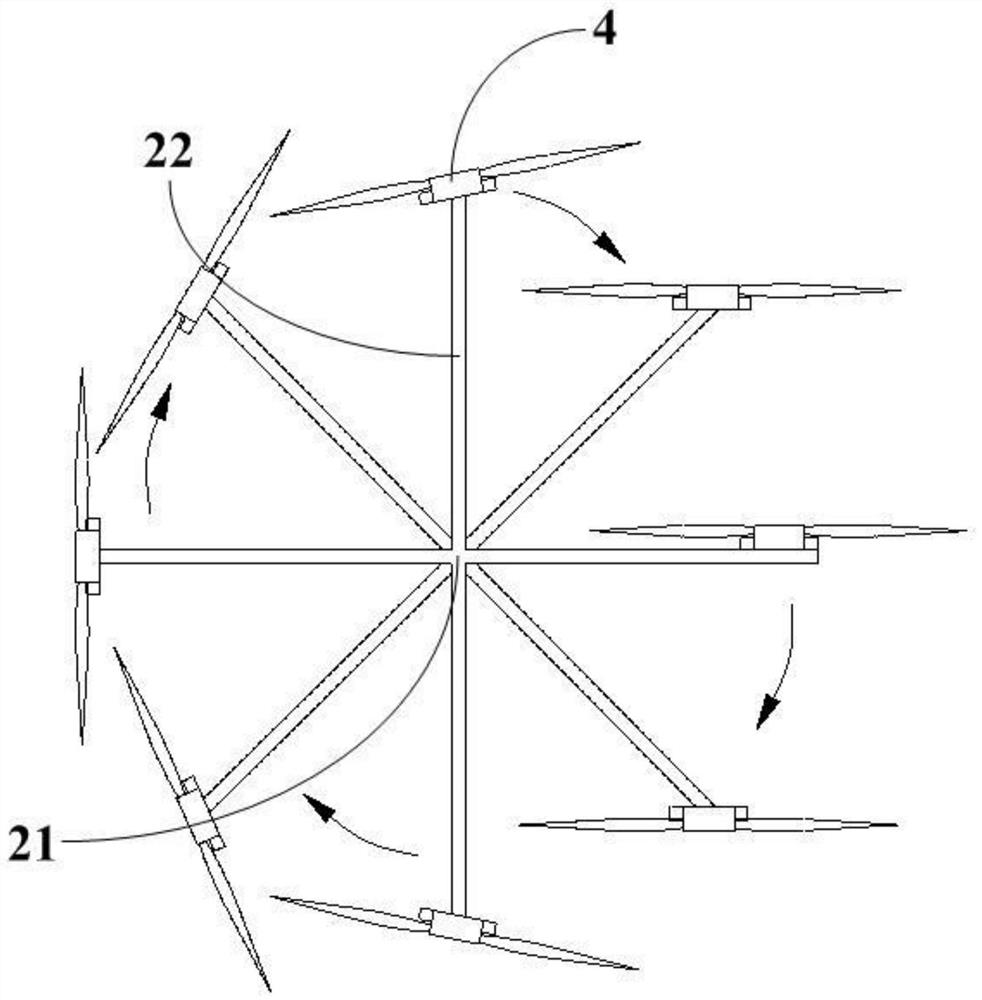

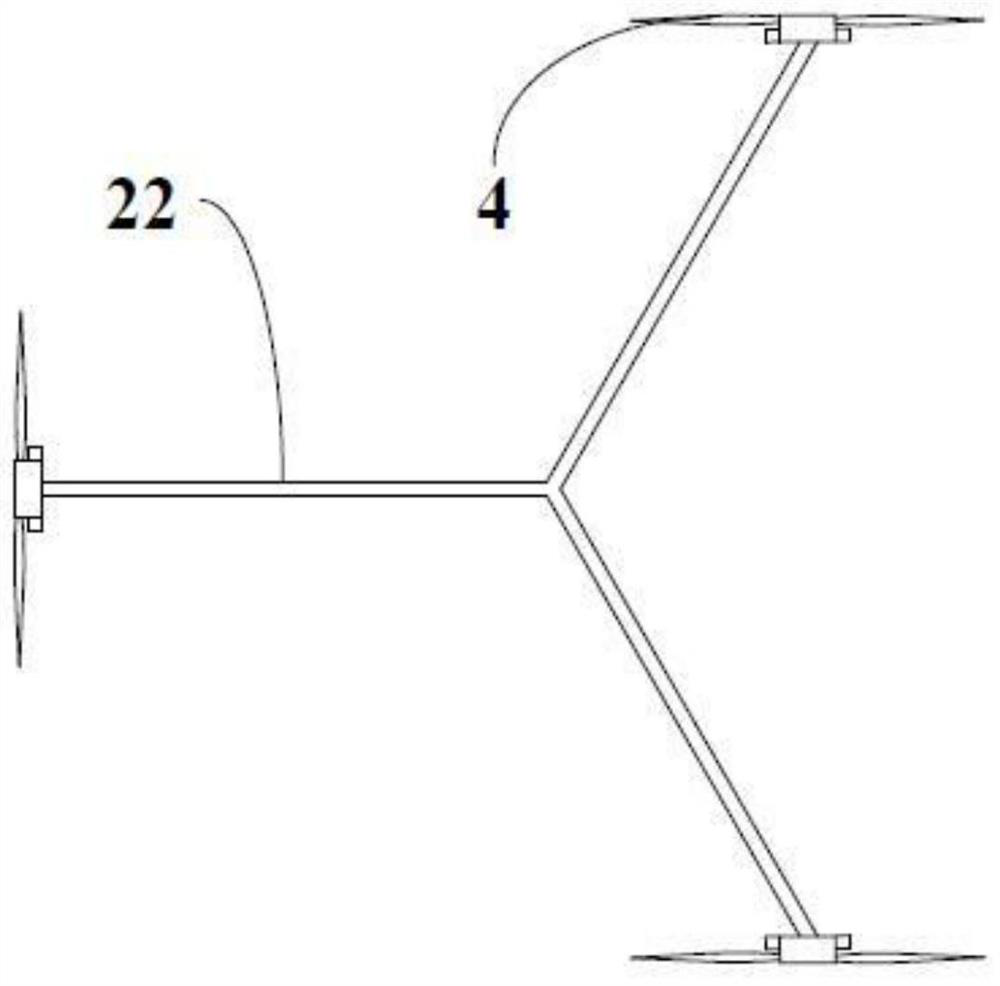

Coaxial dual-propeller mechanism capable of achieving synchronous folding of paddles

The invention discloses a coaxial dual-propeller mechanism capable of achieving synchronous folding of paddles. A mounting bracket is provided with a motor, a rotary reversing gear assembly and a coaxial dual-propeller part, and the coaxial dual-propeller part comprises a forward foldable propeller, a reverse foldable propeller, an inner shaft and an outer shaft tube; a linkage rotation mechanismis arranged between the end of the outer shaft tube and the inner shaft, the inner shaft and the outer shaft tube are coaxially embedded, one of the inner shaft and the outer shaft tube drives the forward foldable propeller, the other of the inner shaft and the outer shaft tube drives the reverse foldable propeller, and the output end of the motor is directly connected with the inner shaft, and connected with the outer shaft tube through the rotary reversing gear assembly. By means of the coaxial dual-propeller mechanism, the moment when an aircraft enters water, the propellers can be folded,the impact force can thus be reduced, and the use of the coaxial dual propellers offsets the torque generated when the propellers rotate; meanwhile, through synchronization of folding angles of the propellers, the probability of collision generated when the dual-propeller mechanism rotates relatively is also avoided, and the propelling requirement of an underwater-aerial amphibious aircraft is metto a certain degree.

Owner:NAT UNIV OF DEFENSE TECH

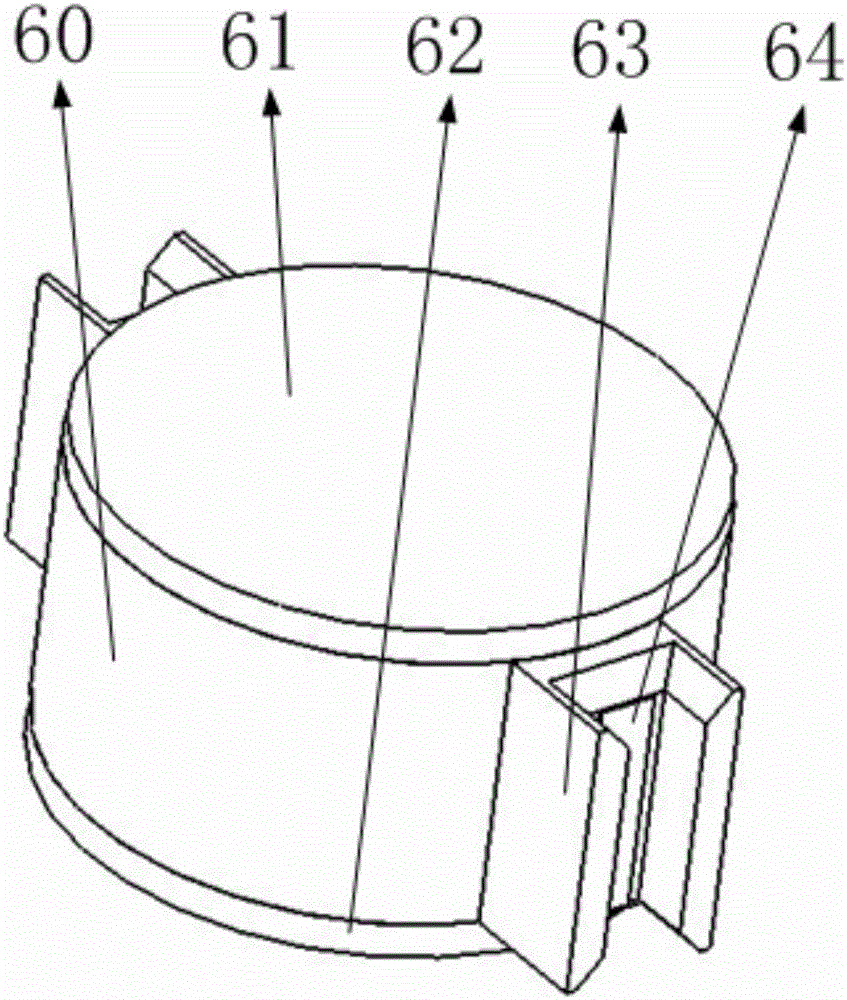

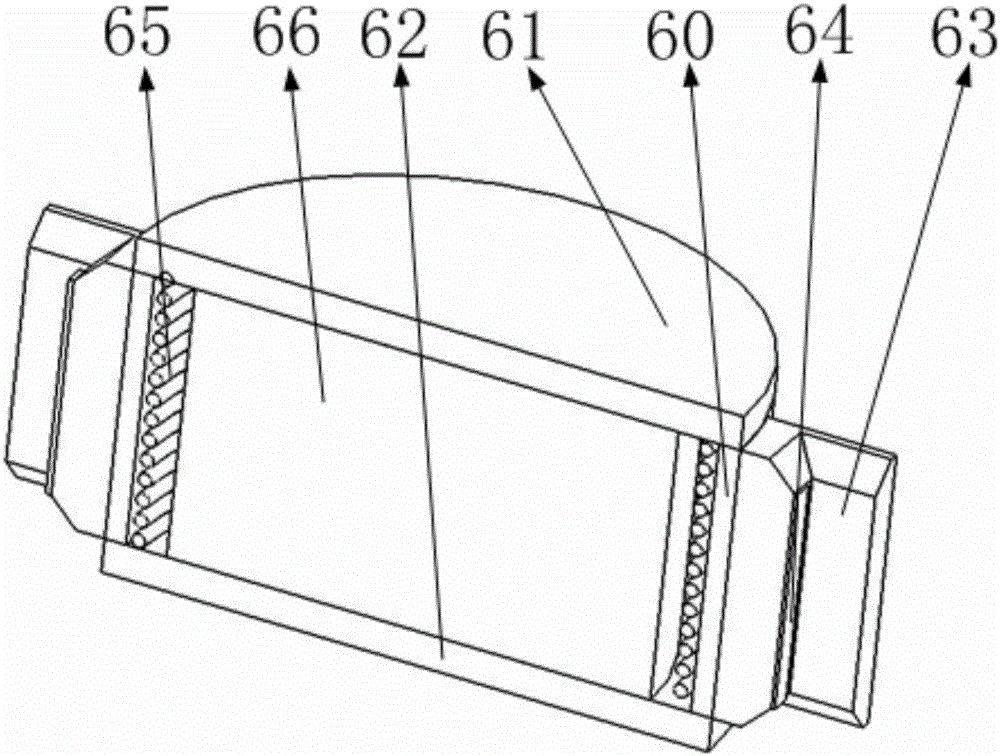

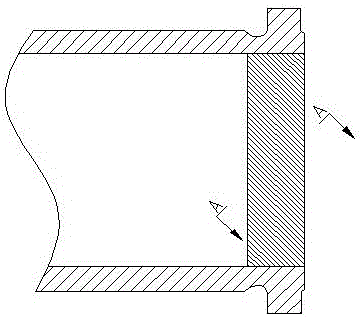

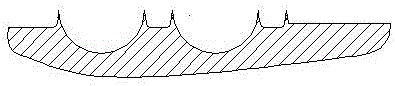

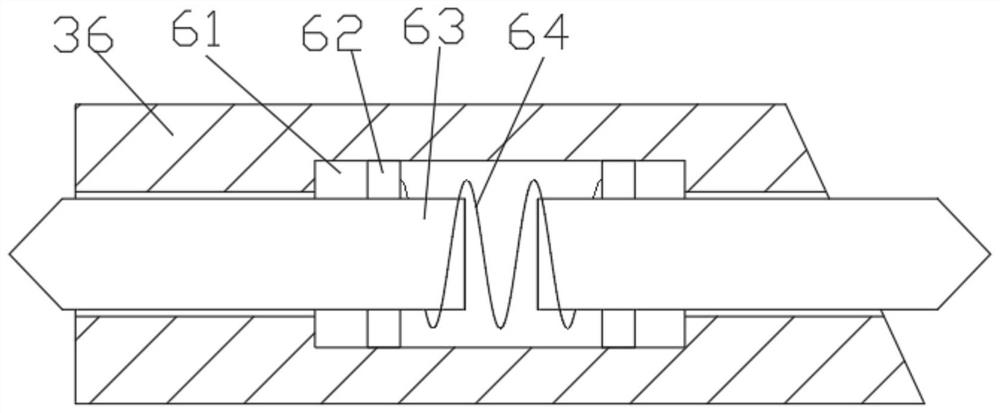

Tool and method for machining comb lines on inner wall of cylinder liner

The invention discloses a tool and method for machining comb lines on an inner wall of a cylinder liner, and belongs to the field of machining. The tool for machining the comb lines on the inner wall of the cylinder liner comprises a knife holder and a comb line knife. The comb line knife comprises a hilt, a crossbeam, auxiliary hilts and rollers, a U-shaped groove is formed in each auxiliary hilt, and directions of openings of the U-shaped grooves in the two auxiliary hilts are opposite to each other. Each U-shaped groove is connected with the corresponding roller through a corresponding hinge pin, and outer circle surfaces of the two rollers are higher than the tops of the corresponding U-shaped grooves. A threaded rod is mounted in the middle of each of the two auxiliary hilts, and each auxiliary hilt is connected with the corresponding threaded rod through a corresponding fixing device. In addition, the method for machining the comb lines on the inner wall of the cylinder liner comprises the following steps: step A, mounting a clamp and a knife; step B, adjusting the clamp and the knife; step C, rolling the comb lines; step D, removing burrs; and step E, cleaning and polishing the comb lines. The special tool is used for machining the comb lines, damage to a machine tool is small, and machining steps are simple; and the machined cylinder liner can adsorb carbon deposits and is high in strength.

Owner:HEBEI HUABEI DIESEL ENGINE

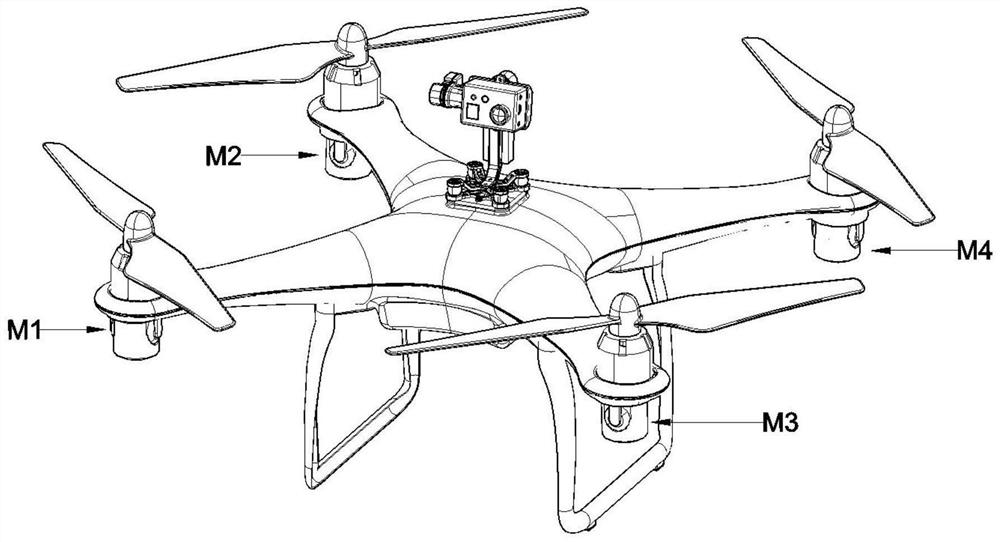

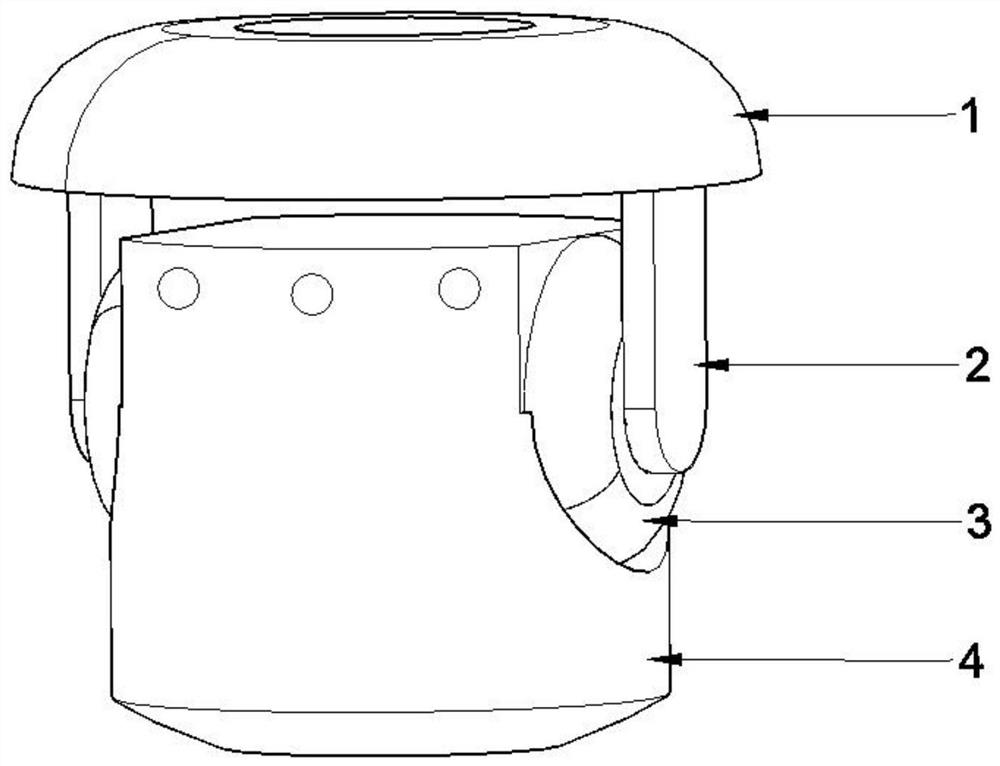

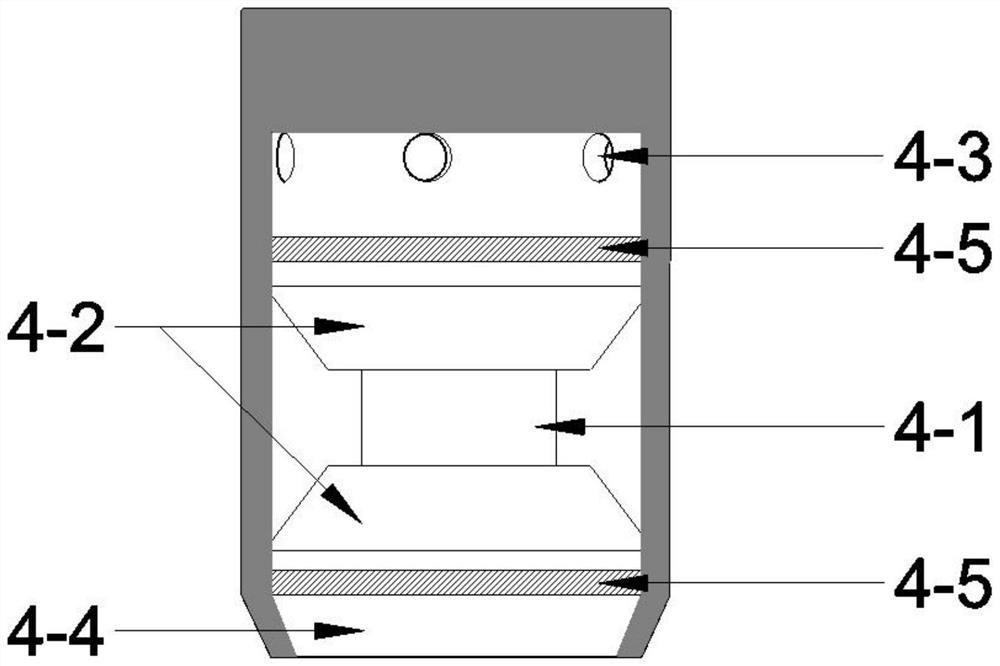

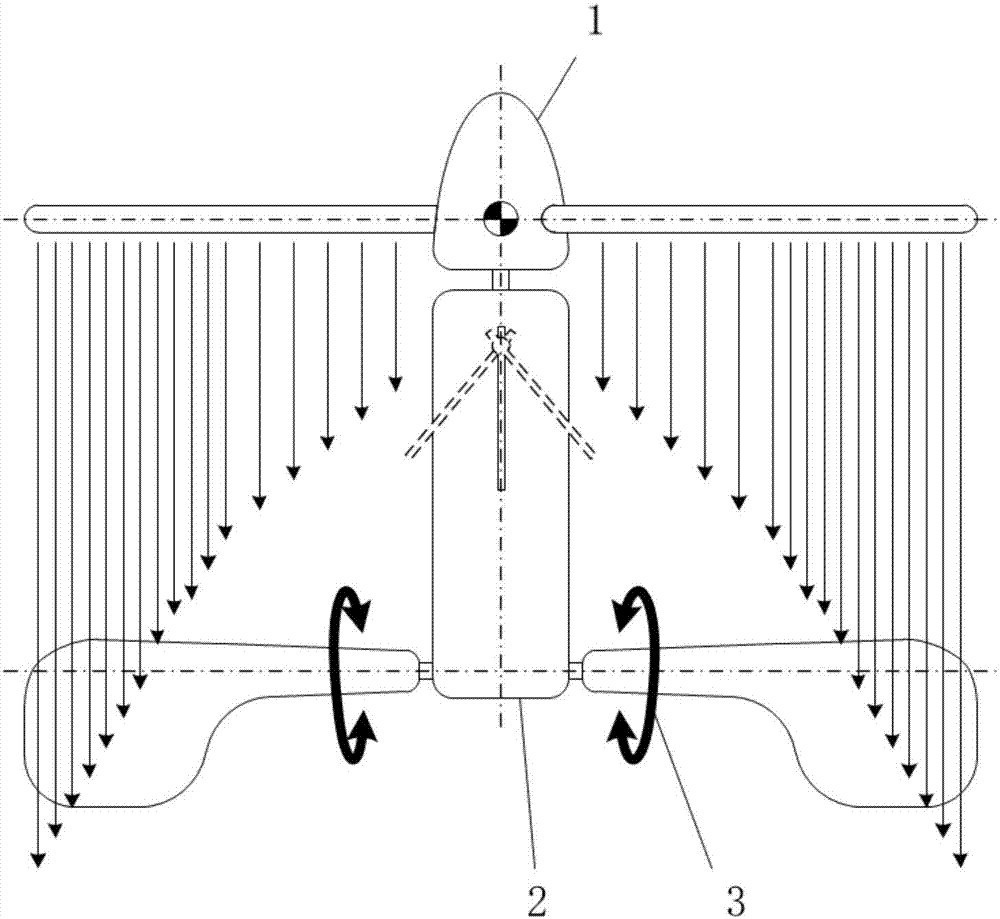

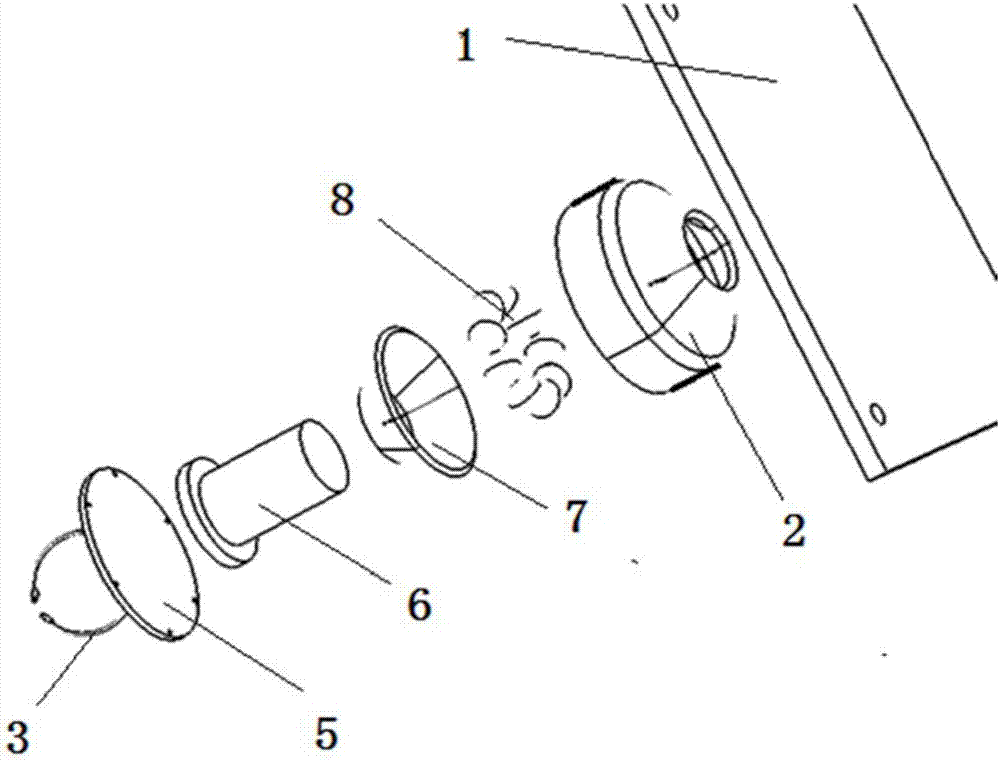

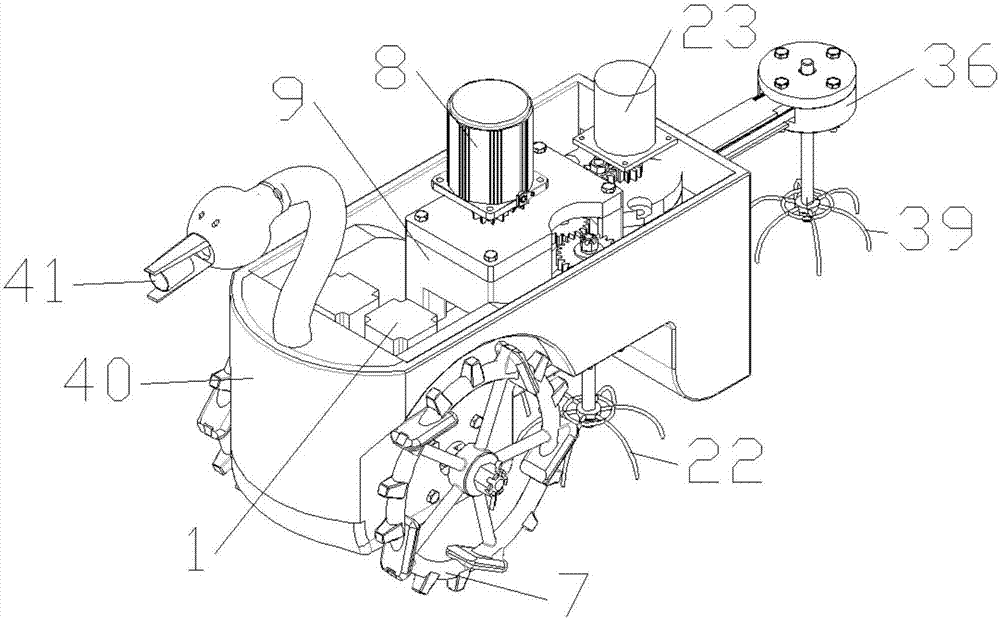

Air injection auxiliary device of rotor unmanned aerial vehicle

PendingCN113135285AImprove wind resistanceSolve the problem of excessive tilt angleAircraft navigation controlAttitude controlUncrewed vehicleElectric machinery

The invention discloses an air injection auxiliary device of a rotor unmanned aerial vehicle. The air injection auxiliary device comprises an unmanned aerial vehicle body, a visual module and an air injection auxiliary device body. The visual module comprises a three-axis holder and a camera. The air injection auxiliary device body comprises a base, a rotating shaft, a connecting rod and an air injection device. The air injection device comprises a motor, a fan, an air inlet, an air injection port and a filter screen. The wind resistance of the unmanned aerial vehicle is improved by spraying air towards the same direction of the wind direction through the air spraying auxiliary device. The three-axis holder and the camera are carried, and the air injection mode of the air injection auxiliary device is adopted, so that the active obstacle avoidance capability and the response speed of the unmanned aerial vehicle are improved. The unmanned aerial vehicle can take off and land more simply and stably through different air injection forces of the air injection auxiliary device, and the reliability of the unmanned aerial vehicle is improved. When the unmanned aerial vehicle air injection auxiliary device is in an auxiliary take-off state, all the air injection auxiliary devices inject air vertically and downwards at the same time, and the maximum load of the unmanned aerial vehicle is further improved.

Owner:TAIZHOU UNIV

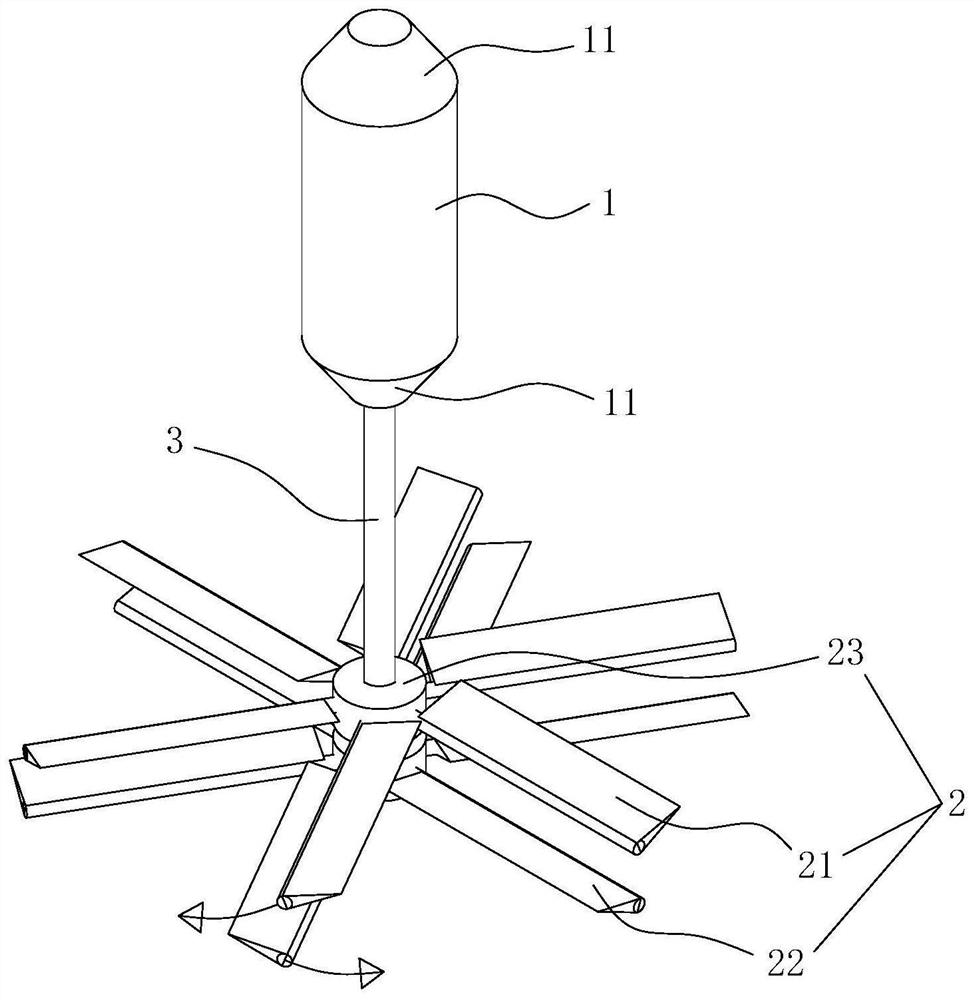

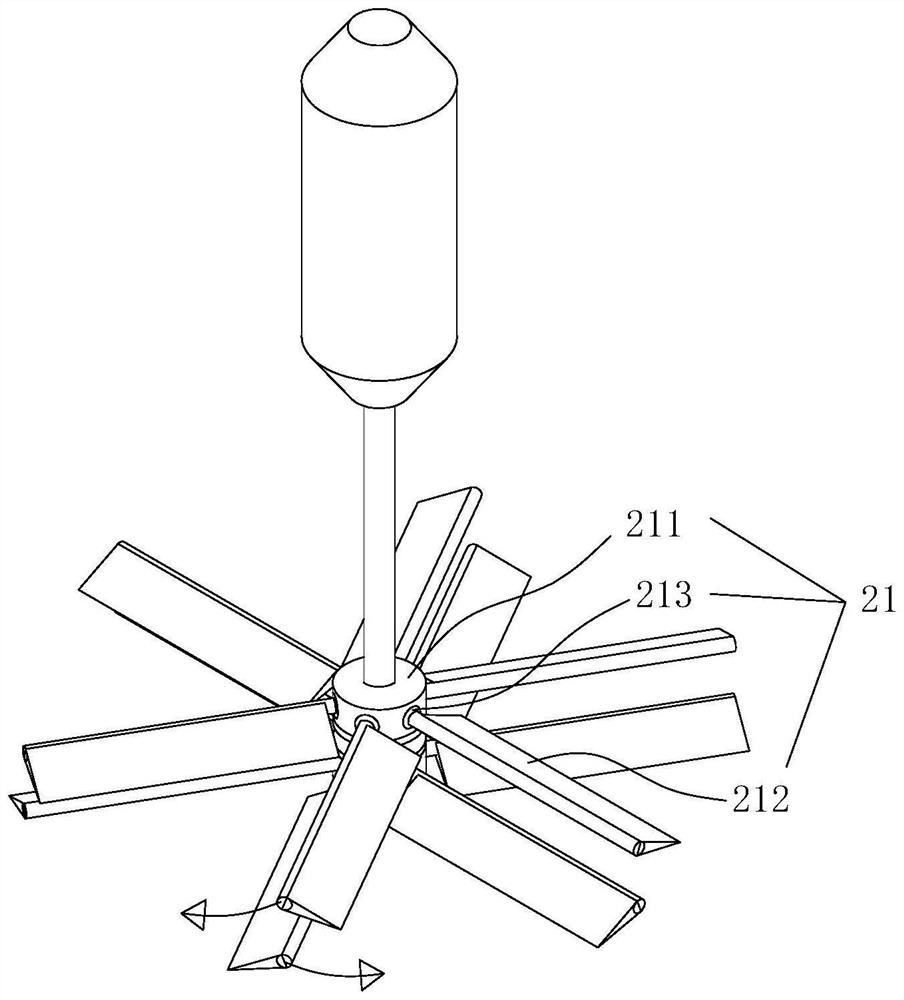

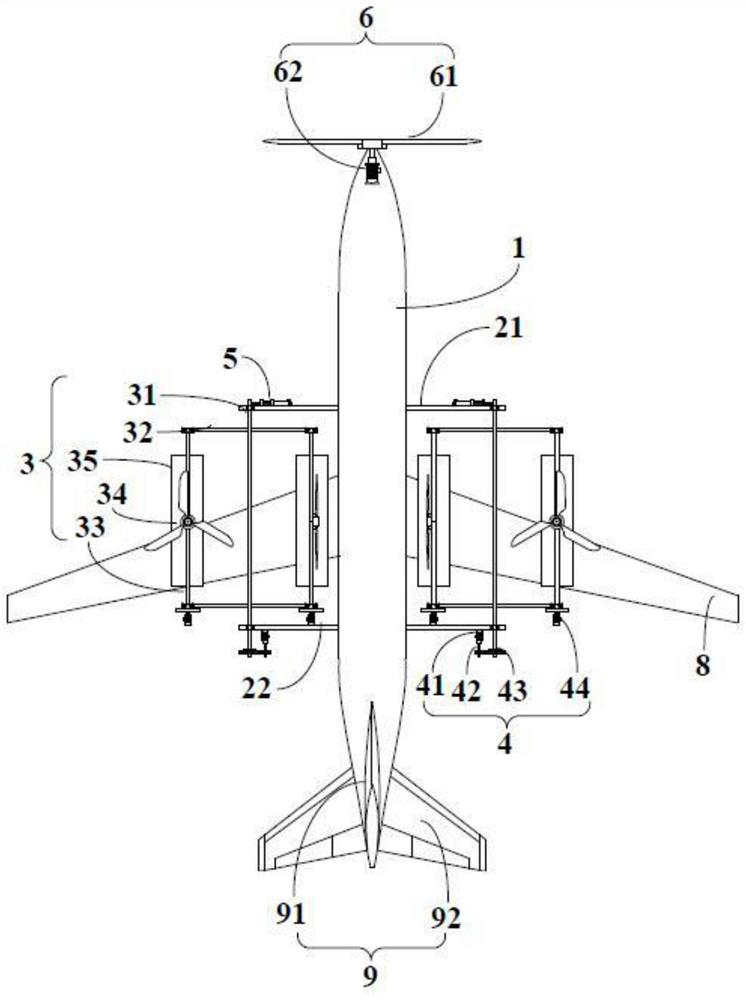

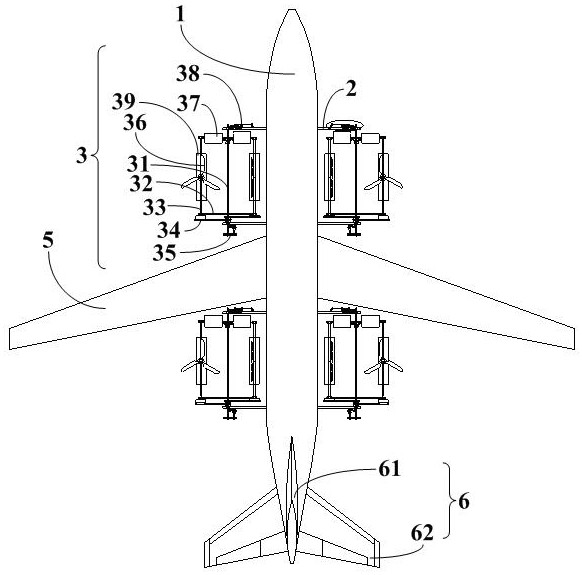

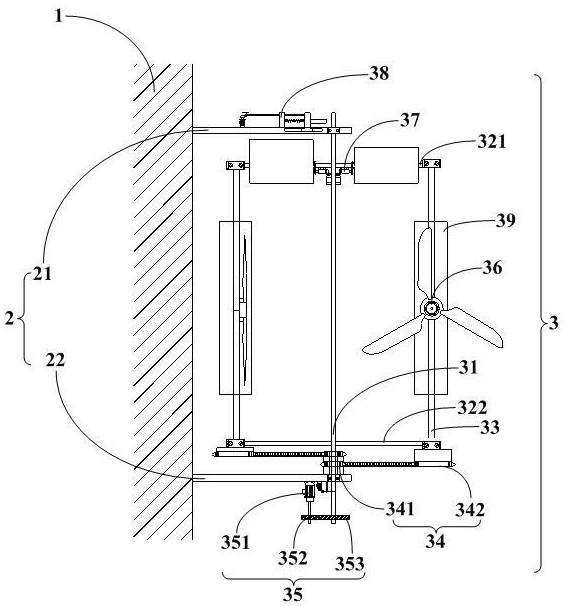

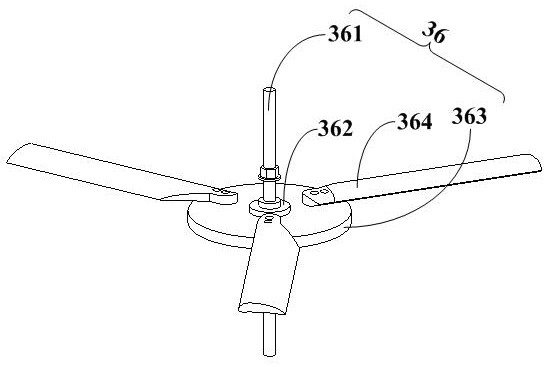

Straight-lifting aircraft

PendingCN106965923AReasonable structureSimple structureAircraft controlRotocraftFlight vehiclePropeller

The invention discloses a straight-lifting aircraft comprising an aircraft body, a propeller, a drive device, a controller and at least two wing blades. The propeller is arranged on the upper portion of the aircraft body; and the wing blades are arranged on the aircraft body, driven by the drive device independently and uniformly distributed in the circumferential direction of the aircraft body. According to the straight-lifting aircraft provided by the invention, the structure of the straight-lifting aircraft is reasonable, the wing blade structures can counteract the torsion of the propeller, a tilt plate is omitted, and adjustment of the flight direction of the aircraft body is realized by controlling the wing blades, so that the structure is simplified, and the manufacturing cost of the straight-lifting aircraft is saved.

Owner:苏州科伊嘉航空科技有限公司

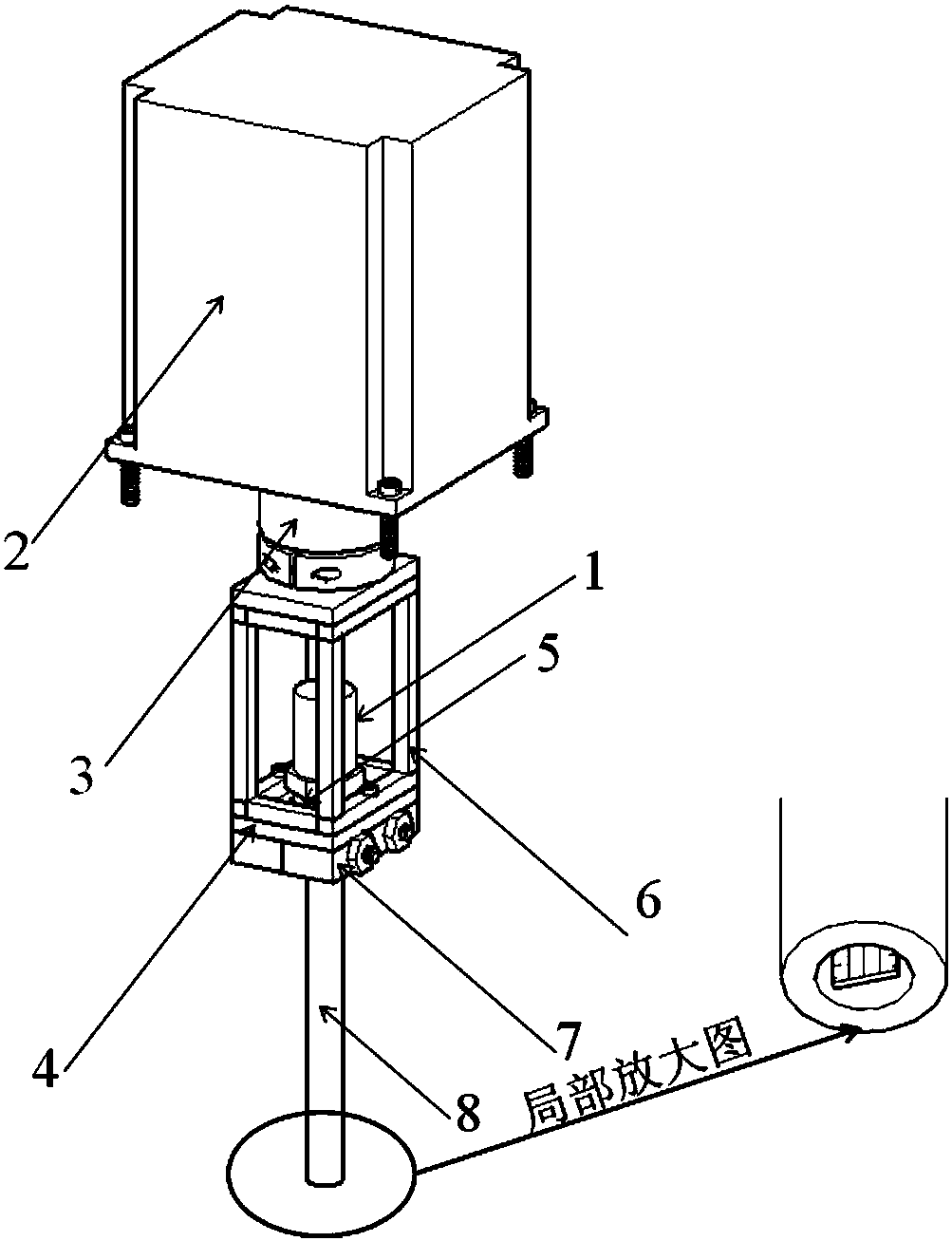

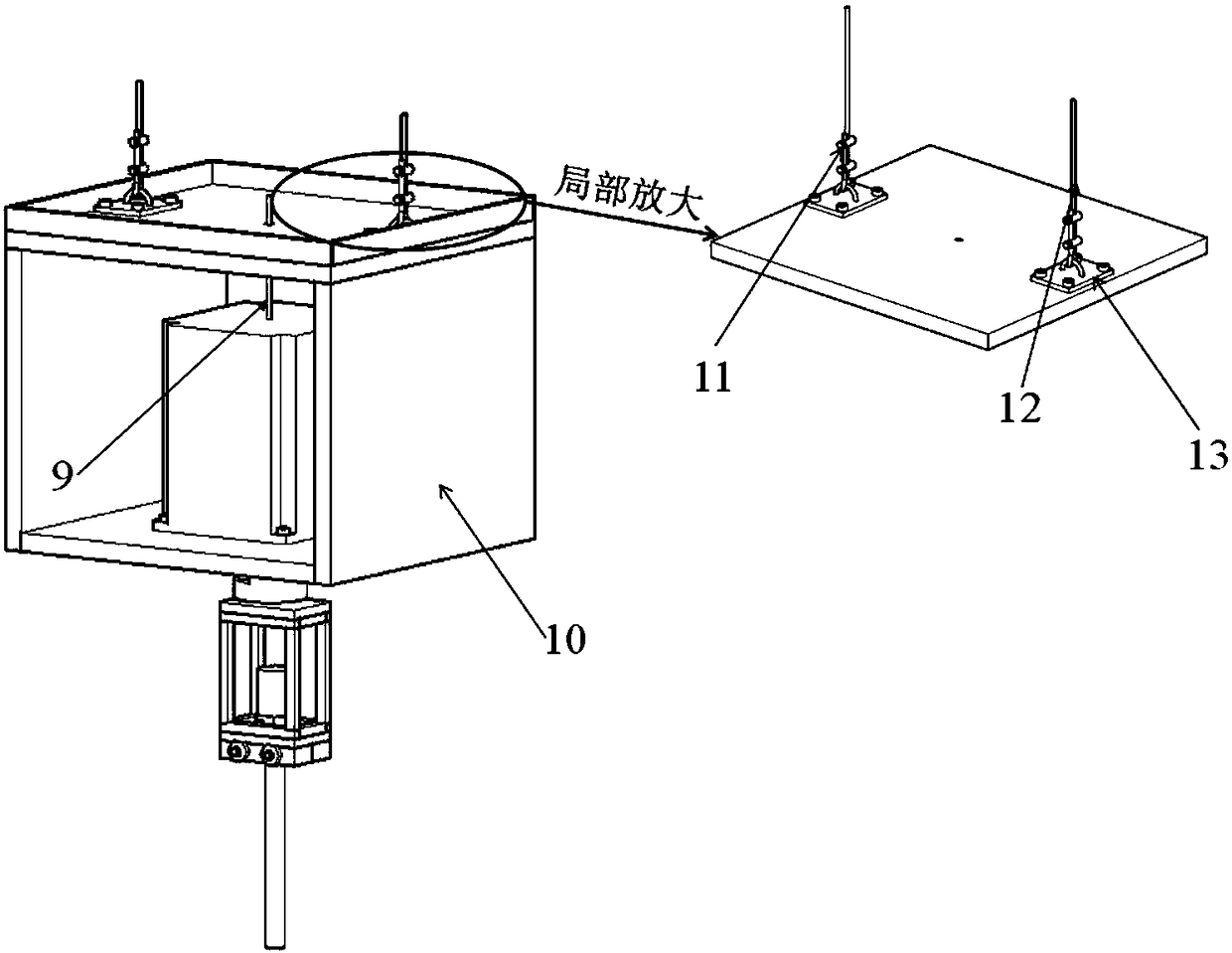

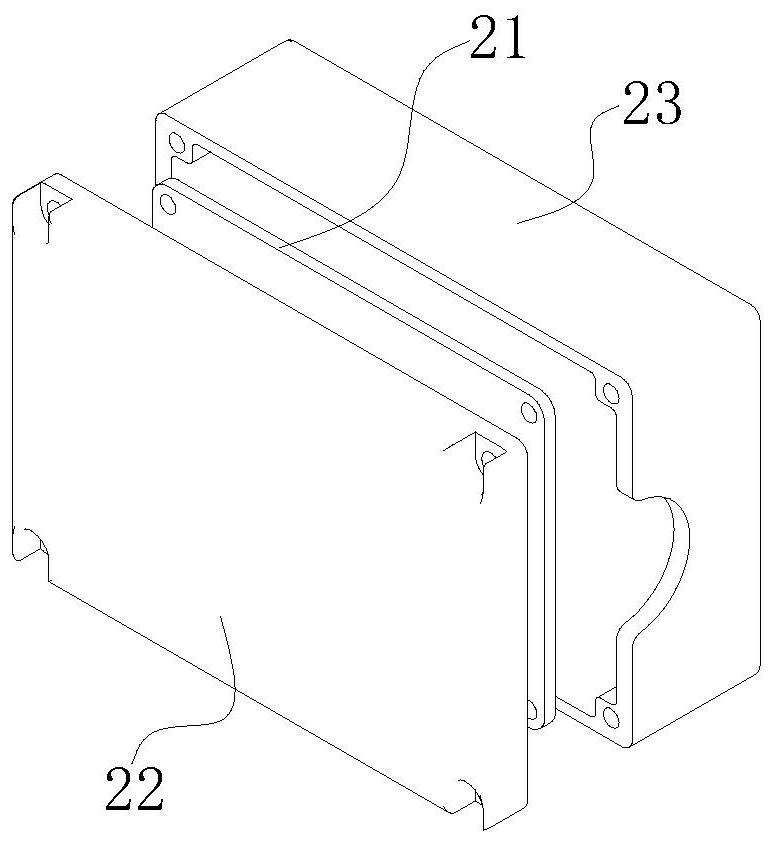

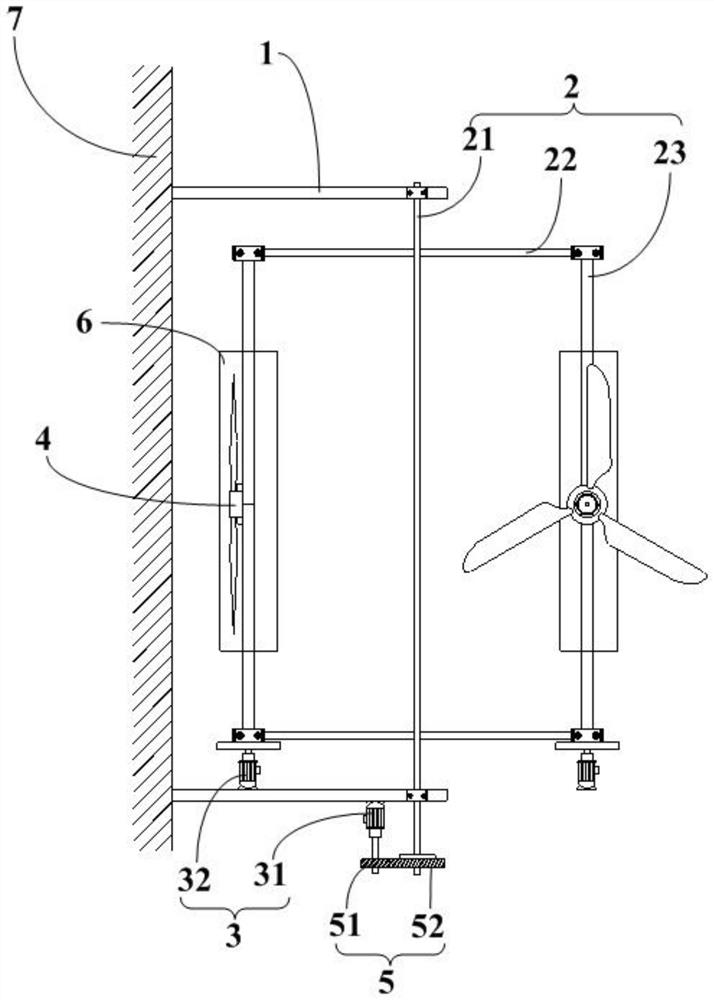

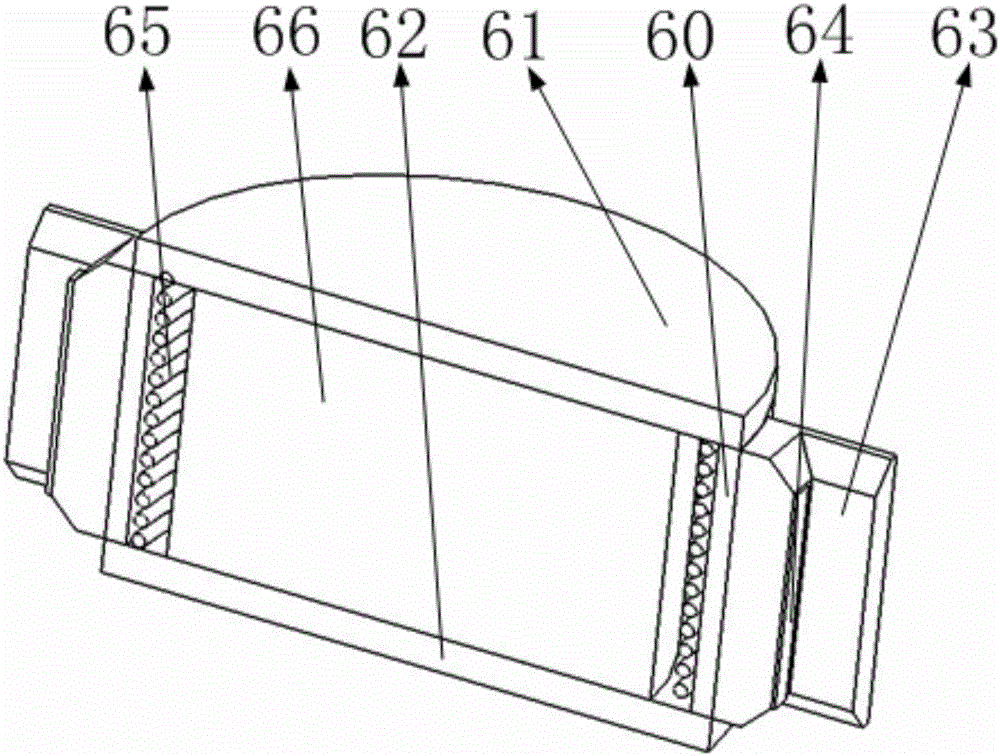

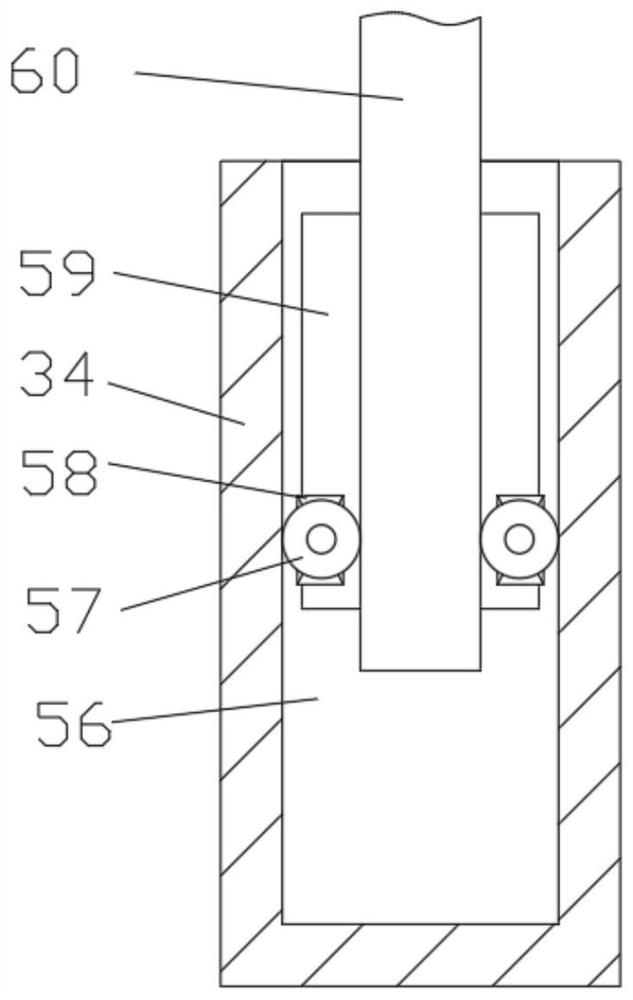

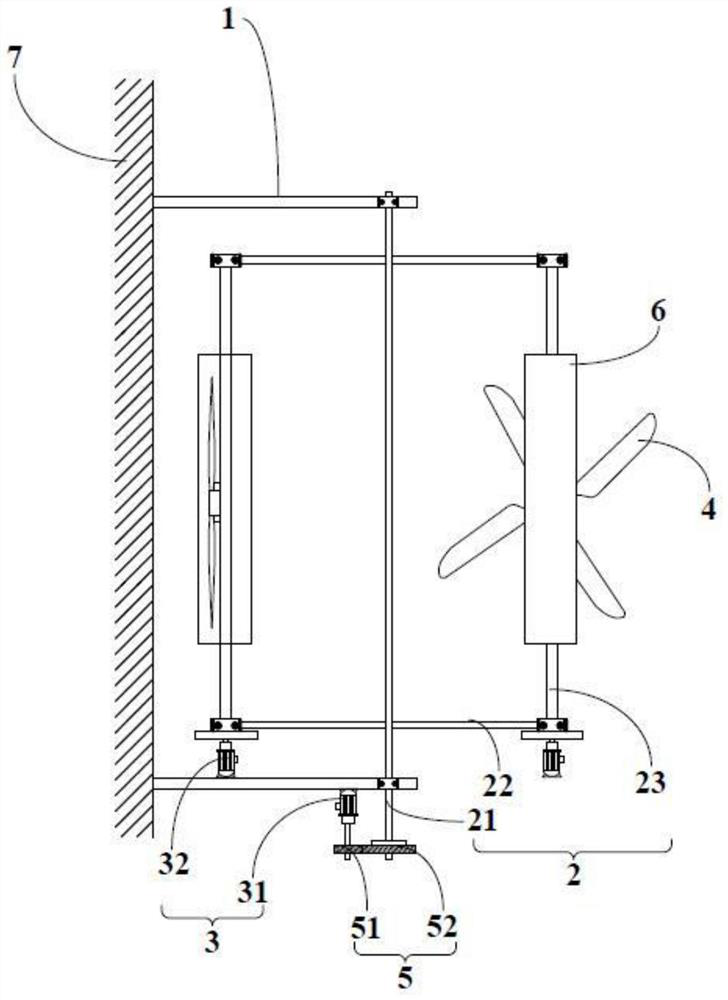

Real-time measuring device and measuring system for ice layer thickness of ice pool

ActiveCN108444375AImprove balanceImprove stabilityLifting devicesElectrical/magnetic thickness measurementsElectrical resistance and conductanceMeasurement device

The invention provides a real-time measuring device and a measuring system for ice layer thickness of an ice pool. A fixing box of a lifting device fixes the lifting device and a measuring and separating device on a wall above an ice pool. The fixing box of the lifting device is also internally provided with a stepping motor, a shaft coupling, a steel pipe U-type pulley, and a vertical bearing pedestal, and other components. The bottom of the fixing box is connected with five extension tubes. A steel wire rope is wound on the steel pipe U-type pulley of the lifting device. The steel wire ropeis connected with the fixing box of the measuring and separating device through the extension tube. The fixing box of the measuring and separating device is also internally provided with a stepping motor, a resistance-type ice thickness measuring instrument, a direction connection base, a shaft coupling, a resistance outer sleeve, a bearing, a bearing supporting plate, and a shockproof pipe clamp,and other components. The device and the system are suitable for real-time measurement of ice layer thickness of a water surface of an ice pool in an ice making process, and are advantaged by convenient measurement, high precision, and real-time measurement of ice layer thicknesses on different positions, and effectively improve efficiency of ice layer thickness measurement of the ice pool in anice making process.

Owner:HARBIN ENG UNIV

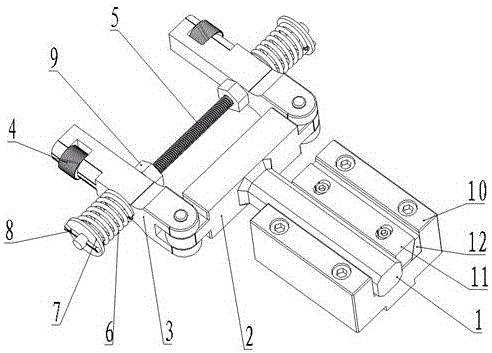

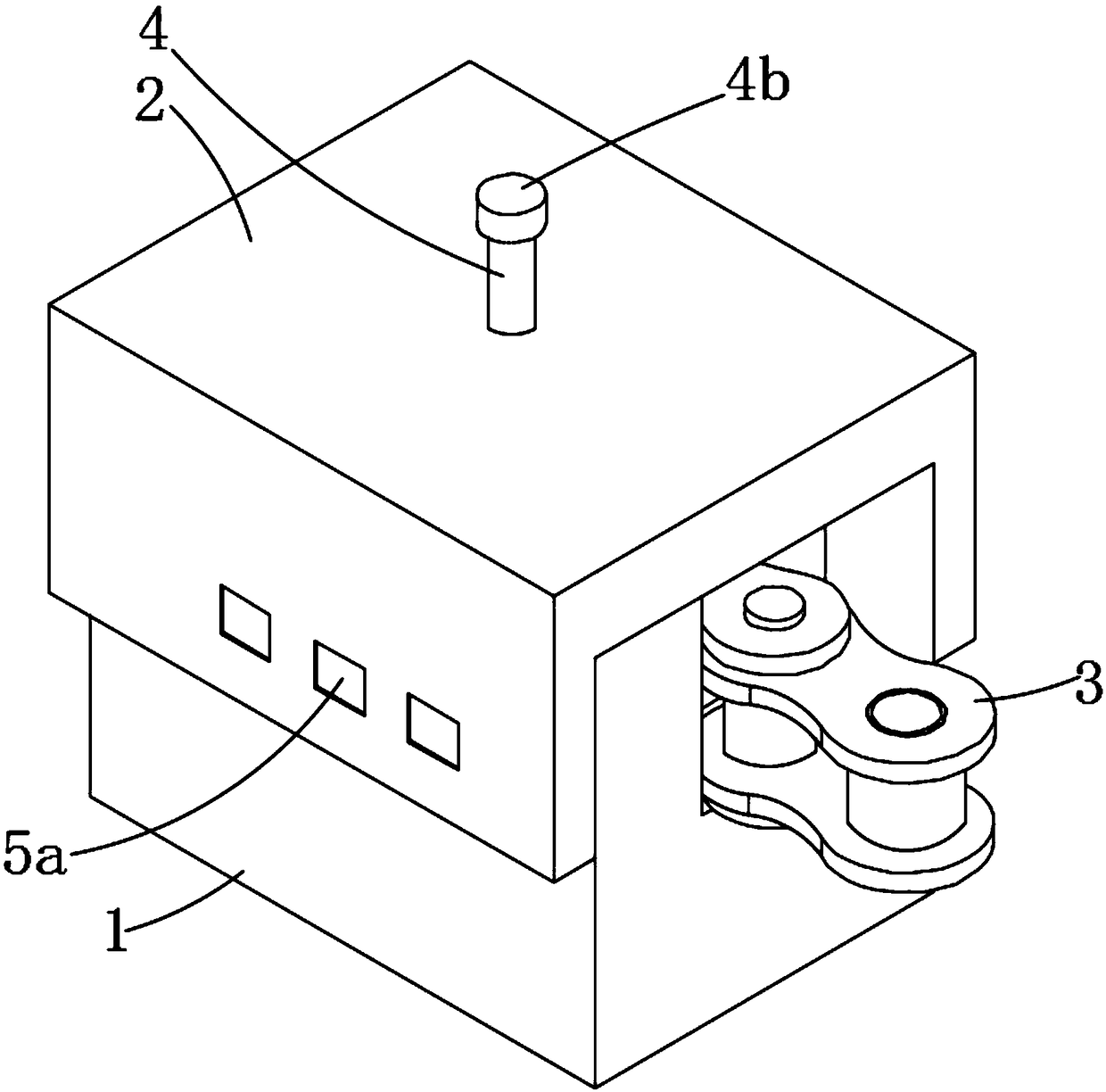

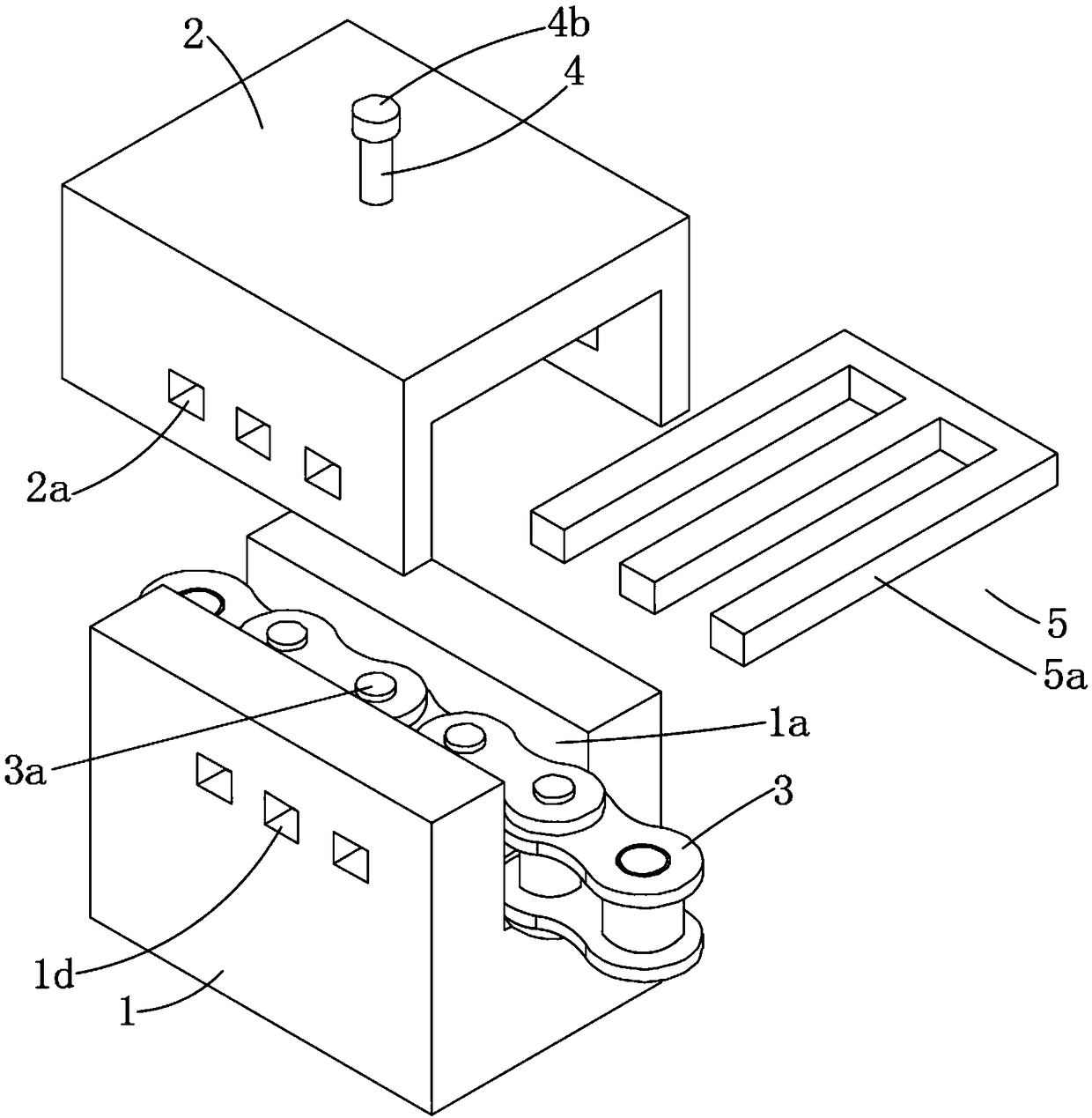

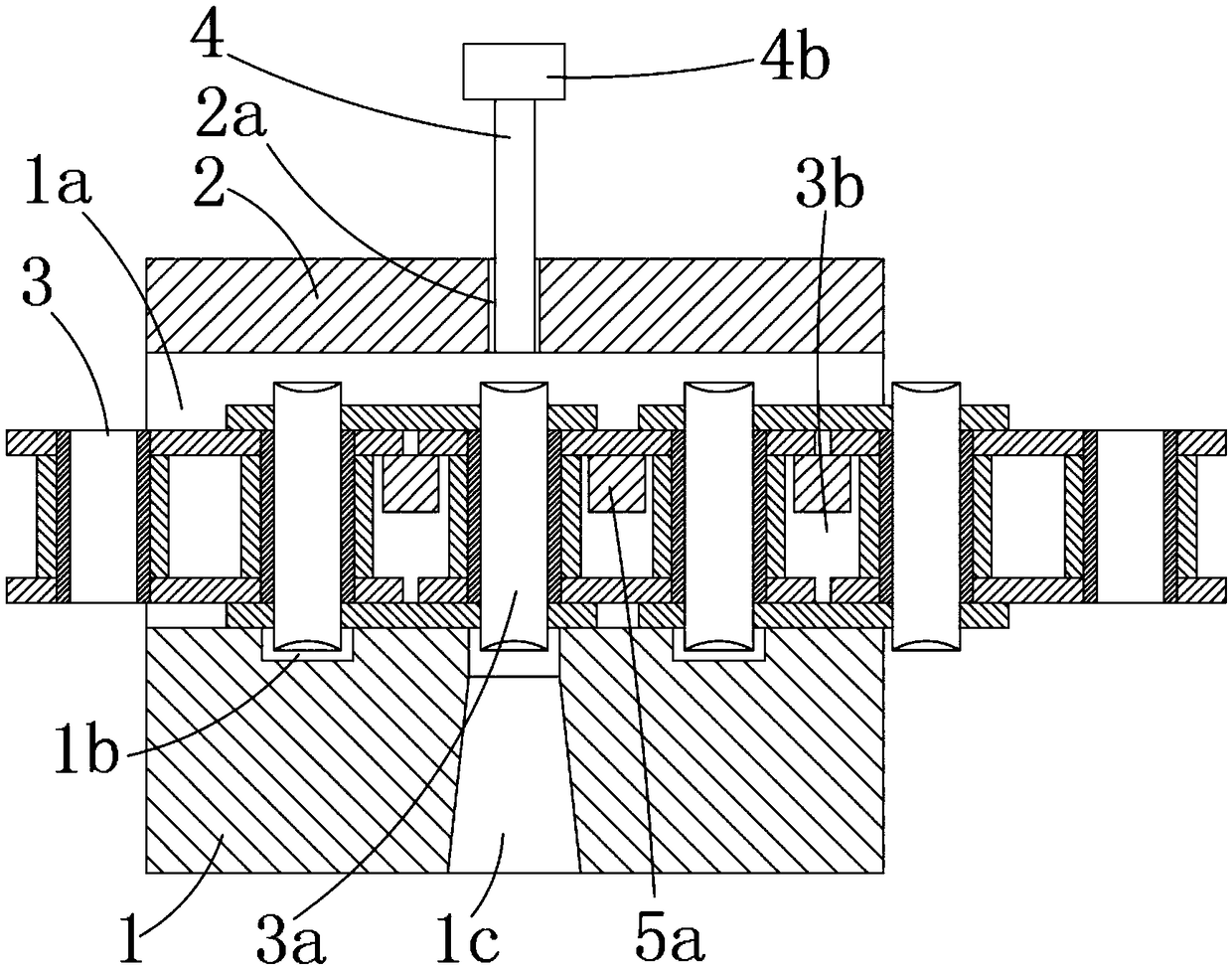

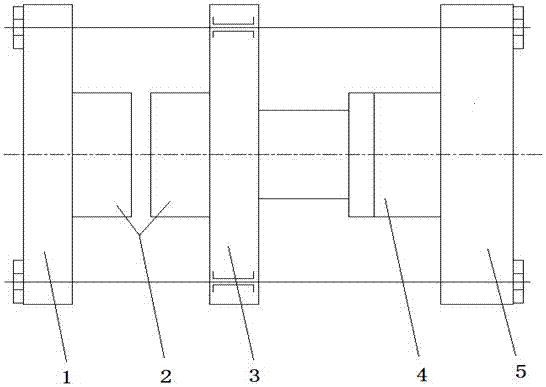

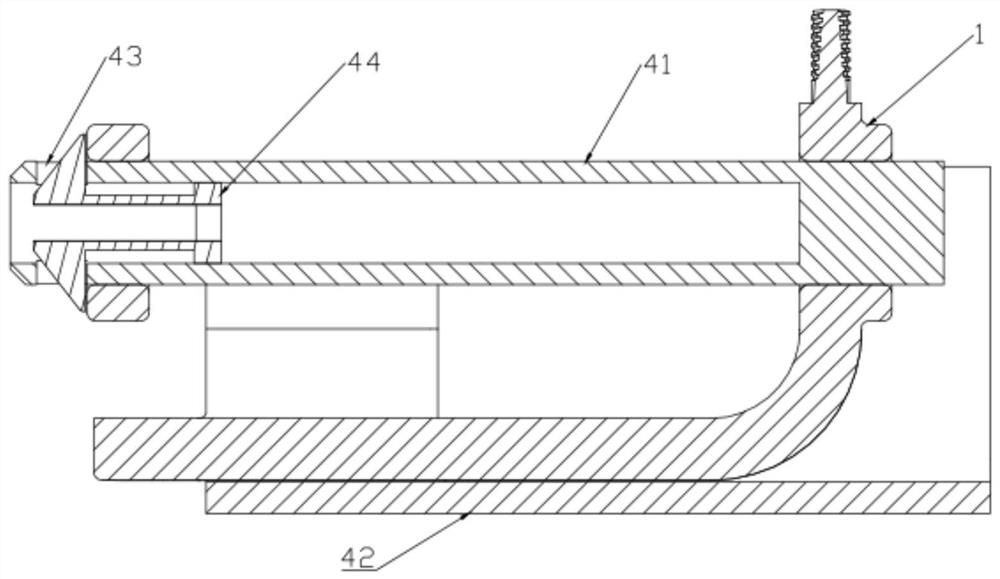

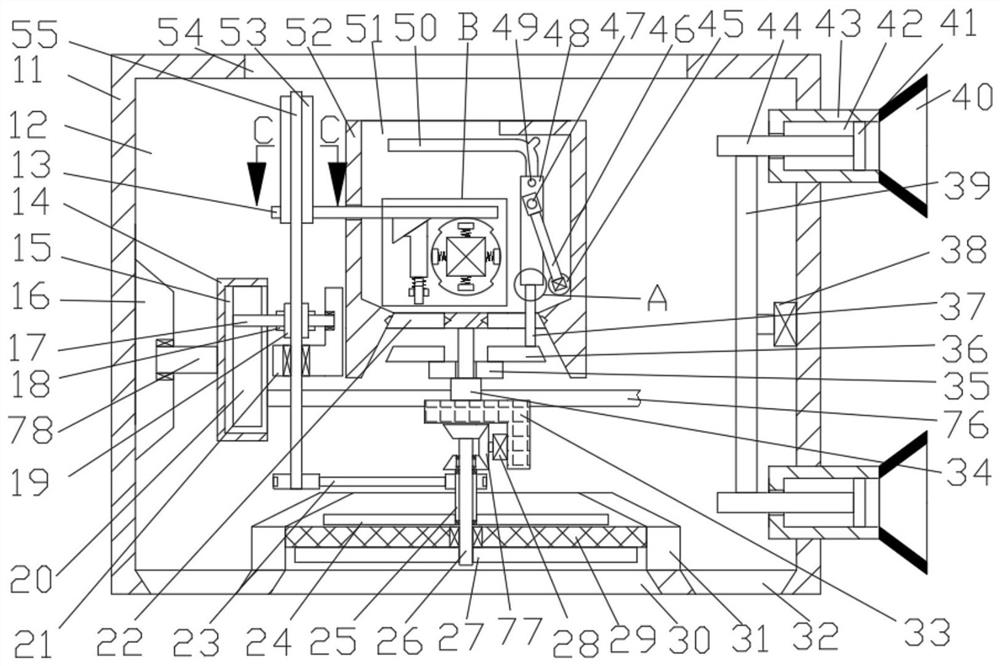

Device and method for chain demounting

PendingCN109396324AOffset torqueAvoid damageMetal chainsMetal chainmaking toolsEngineeringMechanical engineering

The device discloses a device for chain demounting. The device comprises a bearing base and a buckle cover. The bearing base is provided with a placing groove where a chain is placed, avoiding groovesmatched with pin shafts of the chain are arranged at the bottom of the placing groove, a discharge hole communicates with the bottom of the avoiding groove located in the middle, an ejection shaft used for ejecting out the pin shaft located over the discharge hole is arranged on the buckle cover in an up-down moving mode, and the bearing base and the buckle cover are connected through a supporting device. In the operation process, chain sections on the two sides of the pin shaft to be demounted are directly positioned, chain torque is effectively neutralized, no extra staff is needed for auxiliary operation, the demounting process can be completed through one person, the working efficiency is improved, and the chain is prevented from being damaged in the demounting process.

Owner:北京天瑞星光热技术有限公司

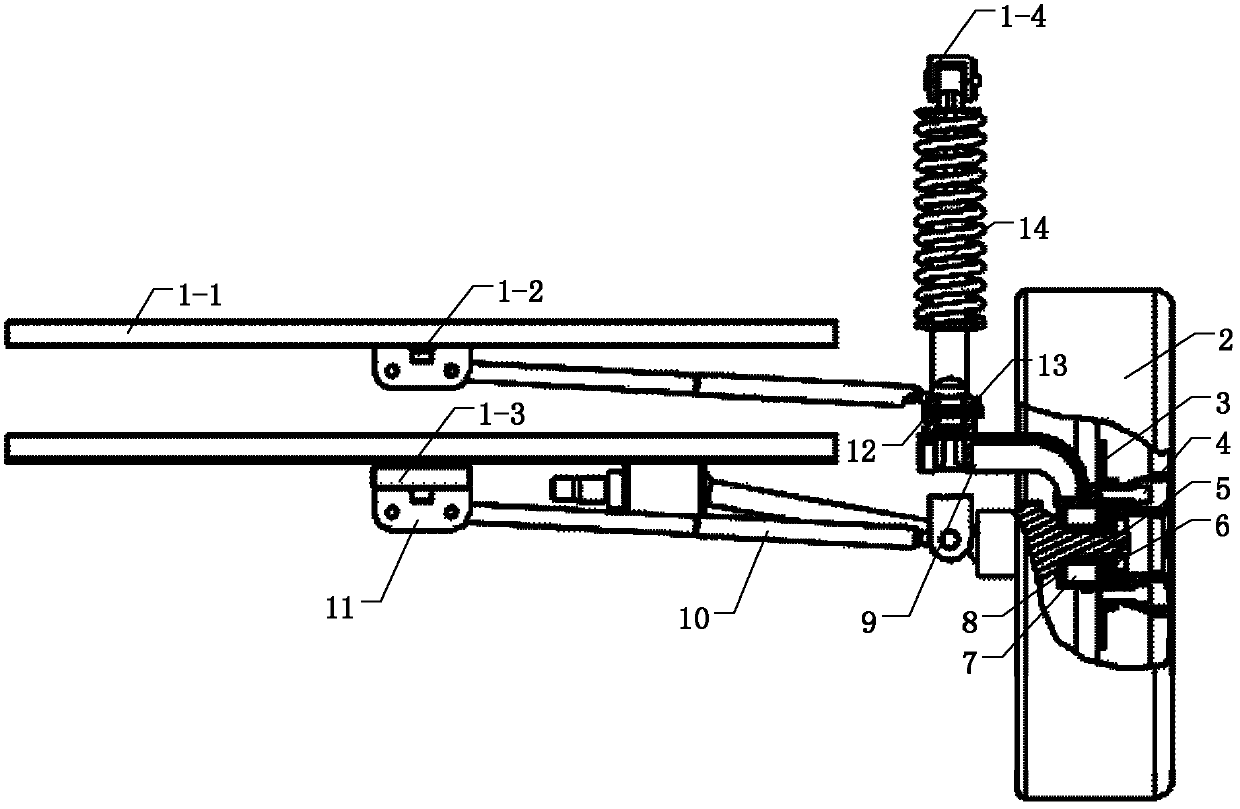

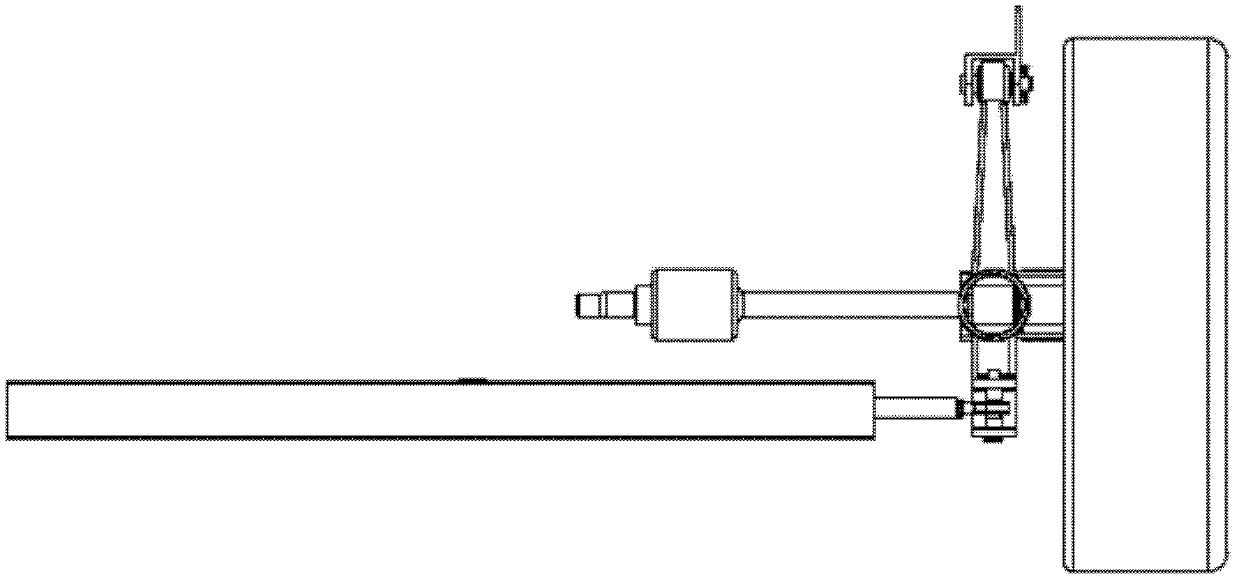

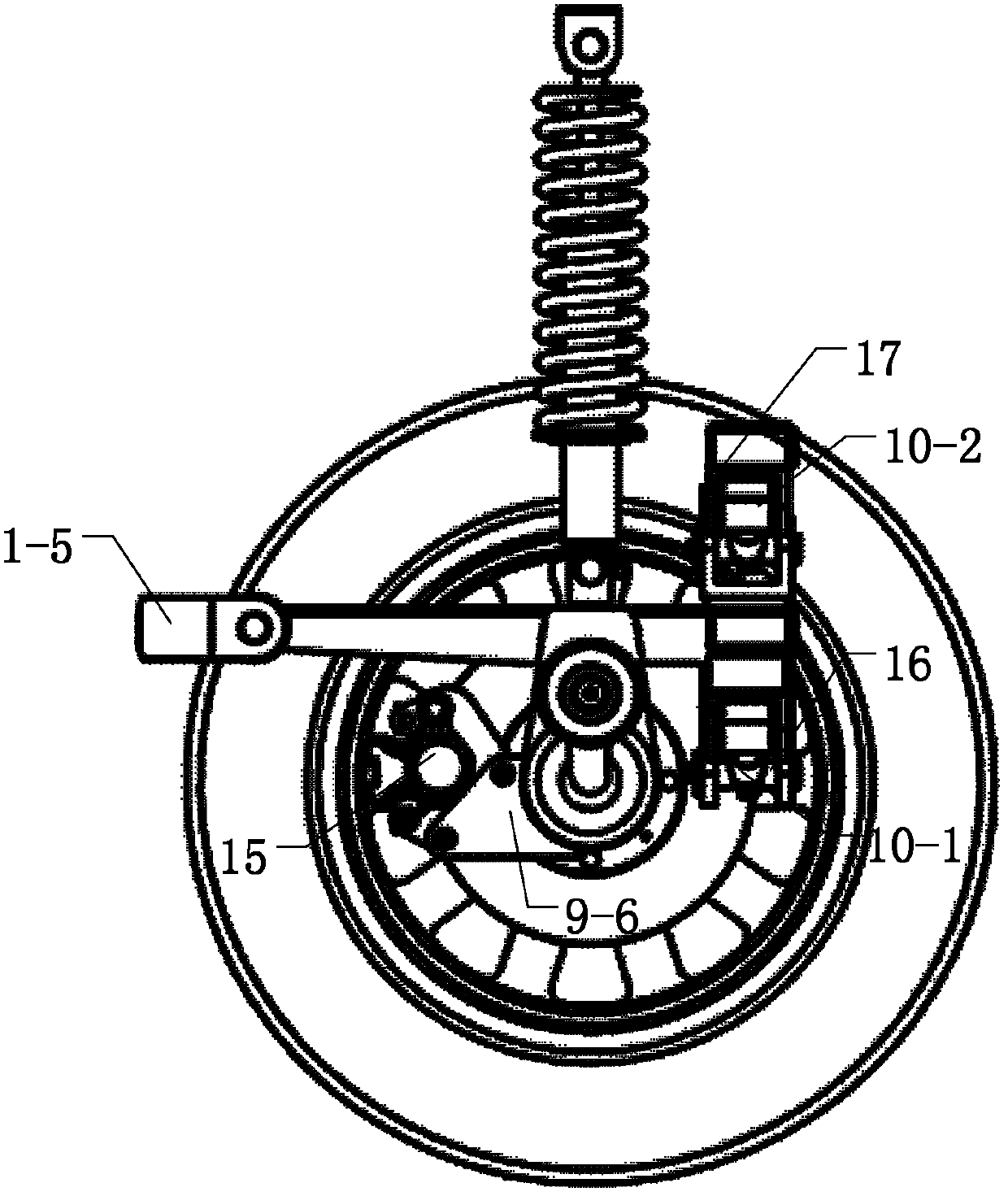

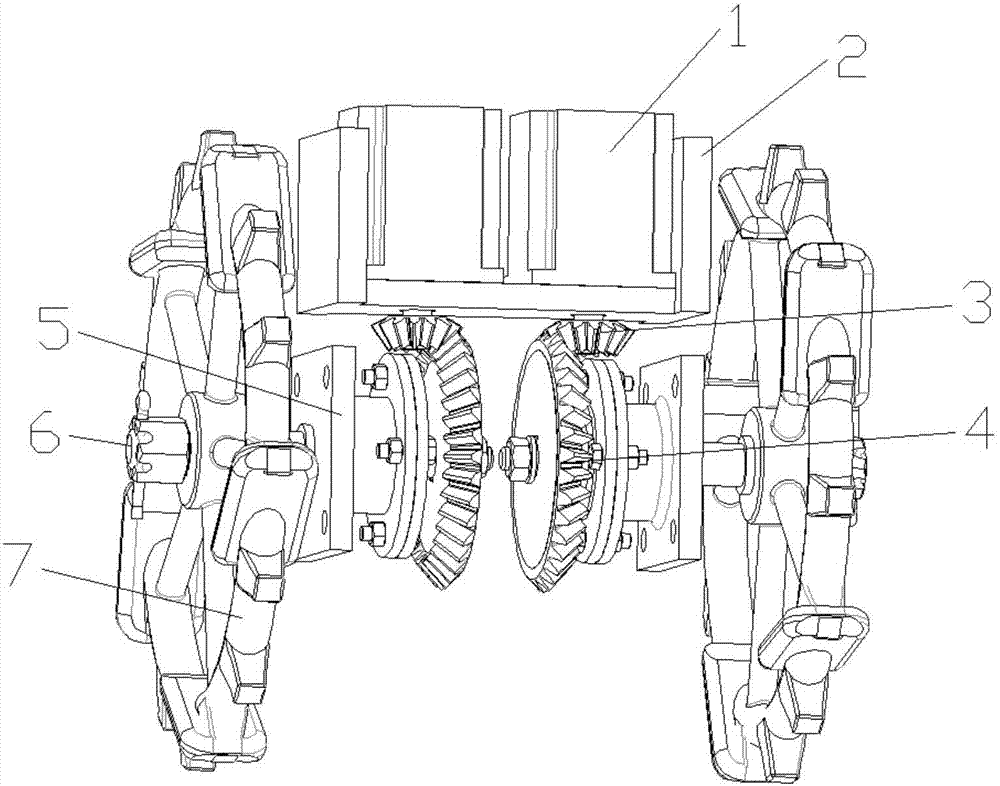

Suspension system for unmanned vehicle

ActiveCN102416834BEnhanced priming responseAvoid excessive lateral twistBraking element arrangementsResilient suspensionsBrake padShock absorber

The invention discloses a suspension system for an unmanned vehicle. The suspension system comprises a suspension axle, a driving axle and a braking axle; the suspension axle comprises a swing arm, two cross pull rods and a spring shock absorber assembly; the driving axle comprises a cage universal constant speed transmission shaft, a bearing, a handlebar head and wheels; and the braking axle comprises a brake caliber, a brake pad and a brake disc. The system well bears impact and torque under the combined action of the swing arm for bearing a longitudinal force, the cross pull rods for bearing lateral forces of the wheels and the spring shock absorber assembly for bearing the longitudinal force; and the driving axle and the braking axle are directly connected with the wheels through the swing arm, so that the structure is simplified and the transmission link is reduced. The suspension system has the advantages of simple, reasonable and compact structure, good shock absorption performance and the like, and can be applied to the unmanned vehicle or other independently driven vehicles.

Owner:HAIAN JIAORUI ROBOT TECH

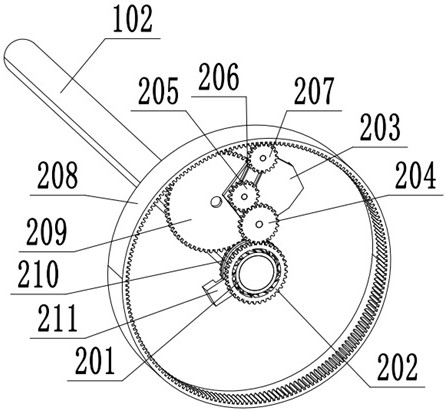

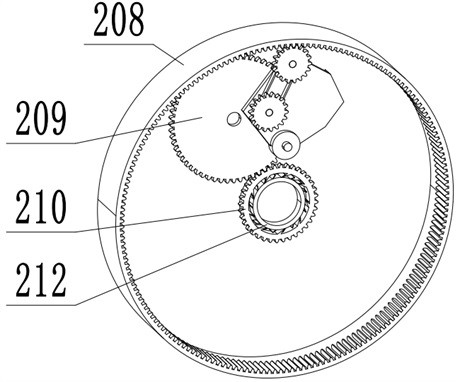

Wave power generation device

InactiveCN111779616ALow costReduce volumeHydro energy generationSatellite radio beaconingWave power generationEngineering

The invention relates to the technical field of power generation, and particularly discloses a wave power generation device. The wave power generation device comprises a float bowl arranged on the water surface and a power generation unit arranged under the water surface; a connecting rod is arranged between the float bowl and the power generation unit; the power generation unit comprises a firstpaddle structure and a second paddle structure which are coaxially arranged, and a generator is arranged between the first paddle structure and the second paddle structure; the generator comprises a stator structure and a rotor structure, the rotor structure can rotate relative to the stator structure, and the stator structure is fixed to the connecting rod; the first paddle structure is fixedly connected with the stator structure, and the second paddle structure is fixedly connected with the rotor structure; the rotating directions of the first paddle structure and the second paddle structureare always opposite; and when the first paddle structure and the second paddle structure rotate along with flowing of water, the generator generates electric energy. The wave power generation deviceis simple in structure, small in size and low in cost, can effectively resist impact, can generate power when waves rise or fall, and also improves the energy conversion efficiency.

Owner:GUANGDONG POWER GRID CO LTD +1

Aerocar

Owner:CHINA HANGFA SOUTH IND CO LTD

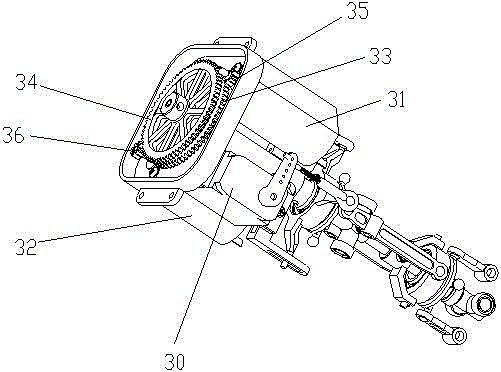

10kV distribution network robot line breaking tool and control method

PendingCN114800540AAvoid Meshing Drive FailuresSimple and compact structureGripping headsBristleDrive wheel

The invention discloses a 10kV distribution network robot line breaking tool and a control method, the 10kV distribution network robot line breaking tool comprises a rotary cutter, a fixed cutter and a cutter driving assembly, the rotary cutter is hinged to the fixed cutter, the cutter driving assembly comprises a cutter motor and a cutter driving wheel, the cutter motor drives the cutter driving wheel, the edge of the rotary cutter is provided with gear teeth, and the cutter driving wheel drives the rotary cutter to rotate. The cutter driving wheel is in meshing transmission with the rotary cutter and comprises bristles, the bristles make contact with the gear teeth, and the axial direction of the bristles is parallel to the tooth surfaces of the gear teeth. According to the invention, the brush hairs are utilized to thoroughly sweep away the insulating skin scraps, the aluminum scraps, the steel scraps and other scraps falling on the gear teeth of the rotary cutter, and the failure of meshing transmission between the rotary cutter and the cutter driving wheel is avoided.

Owner:山东乐普韦尔自动化技术有限公司

Flapping rotor device with ascending shaft wing vertically operating and descending shaft wing horizontally operating

InactiveCN112441229AReasonable designSimple structureDepending on power plant typePower plant typeFlight vehicleClassical mechanics

The invention discloses a flapping rotor device with an ascending shaft wing vertically operating and a descending shaft wing horizontally operating, which comprises a support assembly, a rotating assembly, a driving assembly, a rotor assembly and a transmission assembly, and is characterized in that the supporting assembly, the rotating assembly, the driving assembly, the rotor assembly and the transmission assembly are in linkage fit, an autorotation spindle in the flapping rotor device can revolve under the driving of a revolution spindle, and meanwhile, autorotation is kept under the driving of a second driving motor. According to the flapping rotor device, in the descending revolution process of the autorotation spindle, the rotation surface of the rotor assembly is always kept parallel to the horizontal plane under the driving of the second driving motor, so that vertically upward lifting force is continuously provided for an aircraft; and in the ascending revolution process of the autorotation spindle, the second driving motor drives the rotor assembly to keep the rotating surface of the rotor assembly perpendicular to the axis of the rotating arm all the time, so that resistance is not generated or small resistance is generated, counteracting of lift force in the revolution process of the rotor wing assembly is avoided, and continuous and stable lift force is provided for the aircraft.

Owner:GUANGDONG GUOSHIJIAN TECH DEV CO LTD

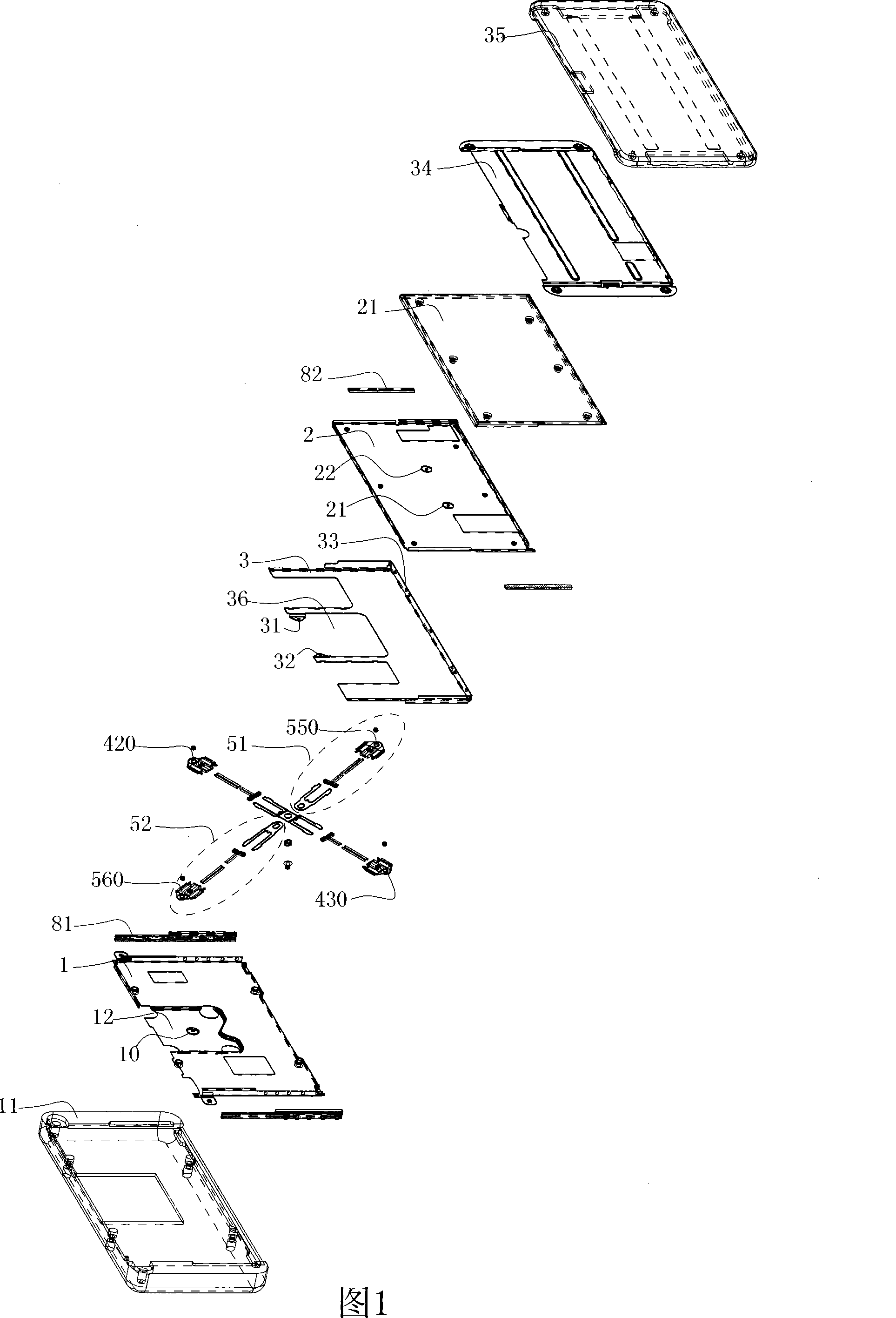

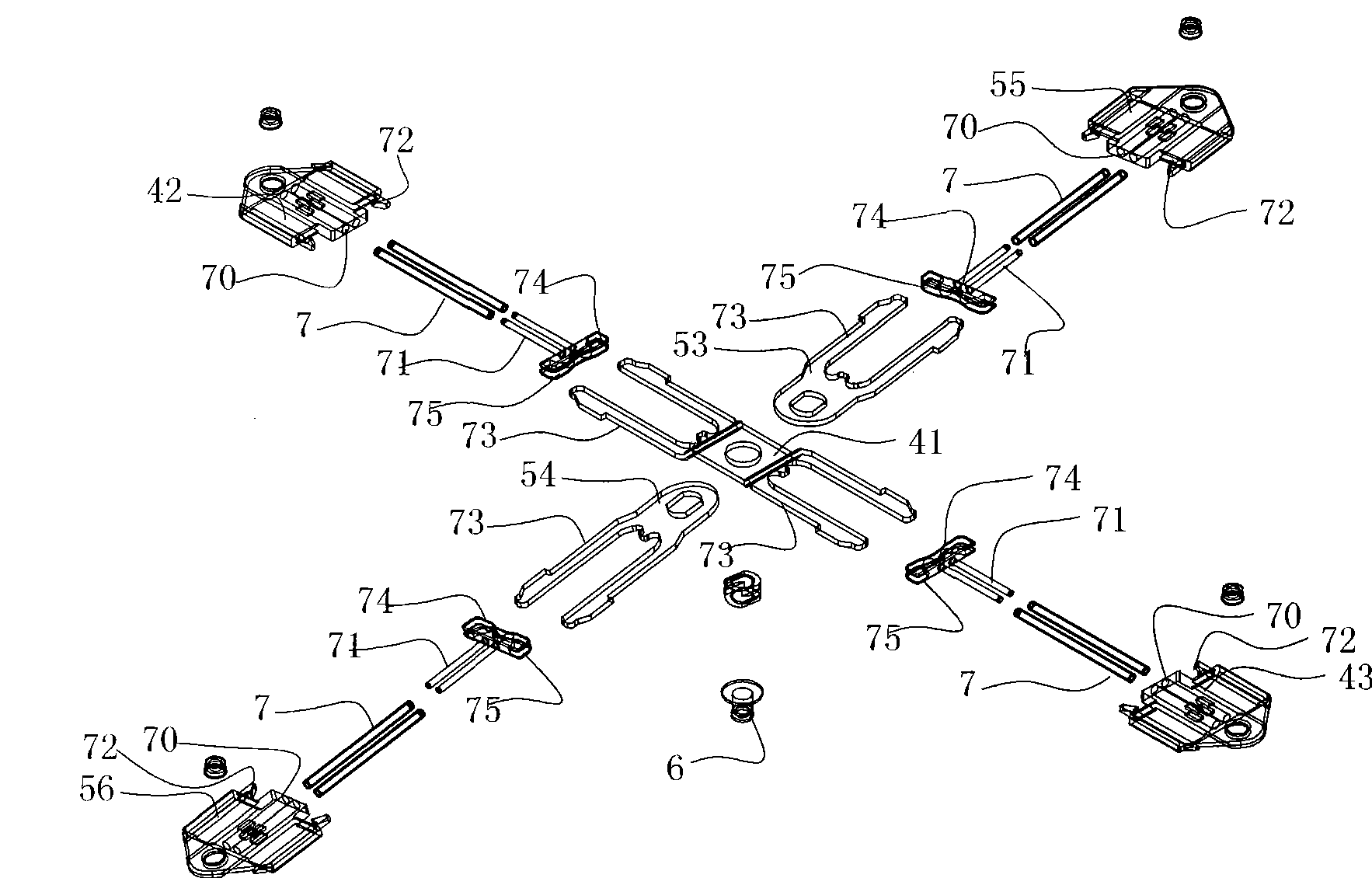

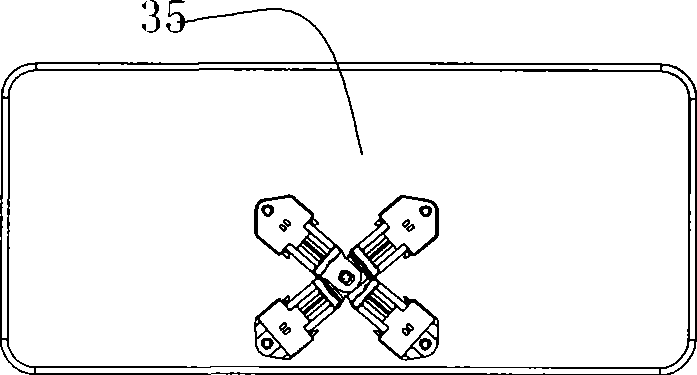

Sliding closure hinge of sliding closure type mobile electronic equipment

InactiveCN101370366BImprove travel satisfactionSmall sizeCasings/cabinets/drawers detailsTelephone set constructionsEngineeringMobile electronics

Owner:HANGZHOU AMPHENOL PHOENIX TELECOM PARTS

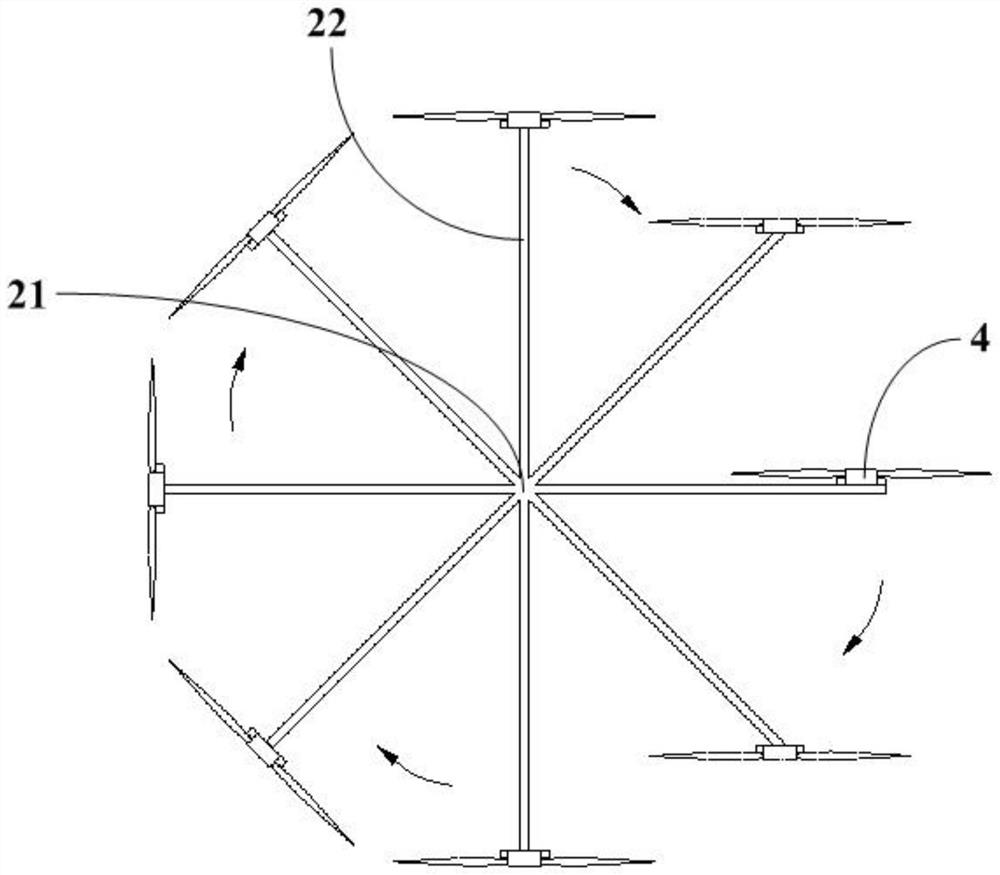

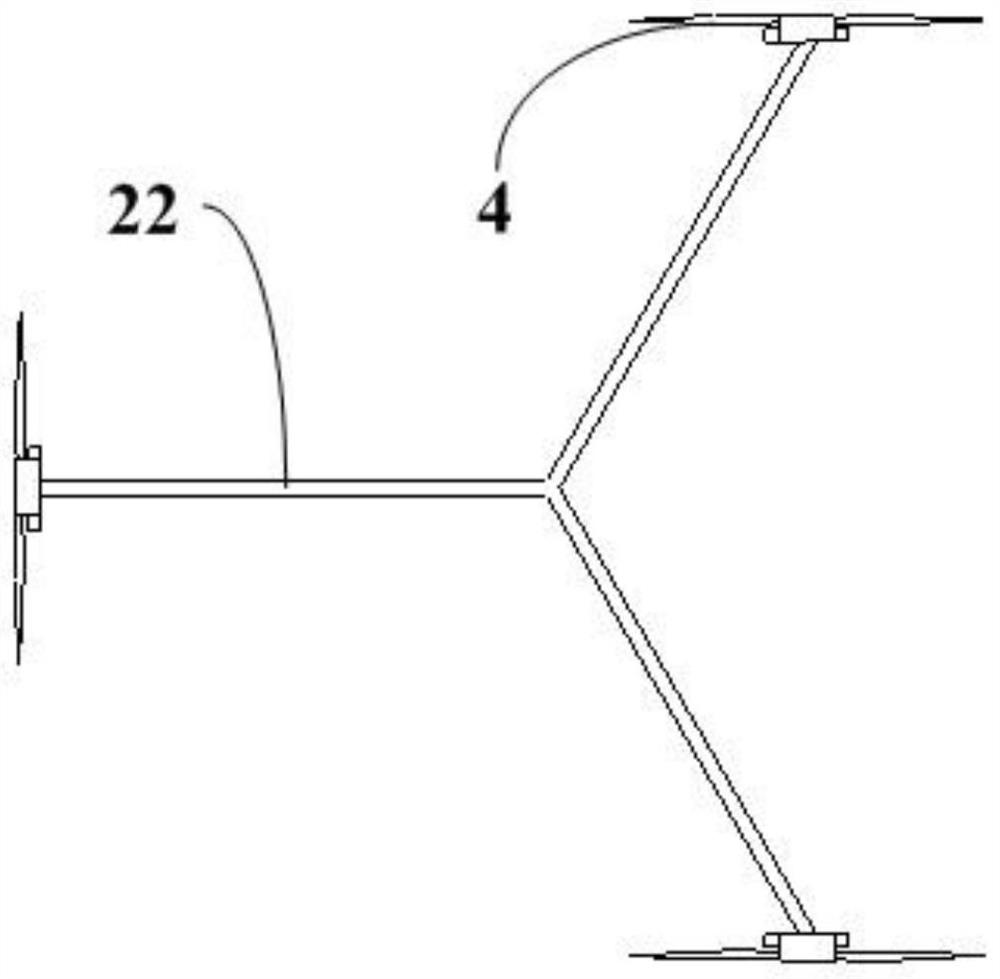

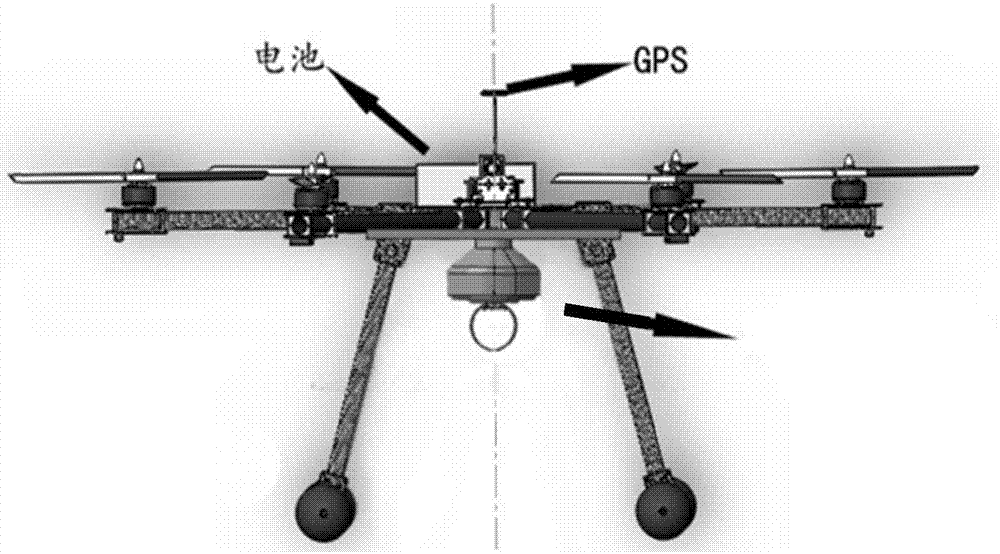

Unmanned plane for project traction

The invention discloses an unmanned plane for project traction. A traction device with a universal transmission characteristic is additionally installed under the unmanned plane for project traction.In the process of loading a hauling cable, through transmitting of the traction device, the torque acting on the unmanned plane by a long distance hauling cable can be effectively counteracted, and the hindering effect on the unmanned plane by a rear attached hauling cable is reduced as far as possible. In special application scenarios, especially in demand scenarios such as crossing canyon rivers, power cable bottom, steep walls, and high-rise buildings, the unmanned plane has the characteristics that the success rate is high; geography restriction is small; and the unmanned plane is economicin space, time and money, convenient to carry and simple in operation. Meanwhile, the unmanned plane has a safety set value. A wire rope falls off when the force value of a traction hook spring is exceeded, so that the unmanned plane can be protected to avoid crash.

Owner:DALIAN UNIV OF TECH

Device and method for converting reciprocating motion into continuous rotation and application

InactiveCN112478153AReasonable designSimple structureRotary propellersFrom muscle energyConvex structureReciprocating motion

The invention discloses a device and a method for converting reciprocating motion into continuous rotation and application, and the device comprises a central shaft and a rotating disc, the rotating disc is connected with the central shaft through a bearing, and the rotating disc and the bearing are concentrically arranged; fins are arranged on the circumference of the rotating disc, and the upperwing surfaces of the fins are of convex structures. According to the device for converting the reciprocating motion into the continuous rotation, by means of the wing-shaped structures of the fins inthe device and the limited installation angles of the fins, the rotation direction of the fins can be kept unchanged all the time in the reciprocating motion process of the device, and therefore thelift force in the continuous constant direction can be obtained. The device is reasonable in design, simple in structure, easy to operate, easy to control, high in efficiency, safe, reliable and capable of providing continuous lifting force for an aircraft or providing continuous thrust for ship navigation.

Owner:FOSHAN SHENFENG AVIATION SCI & TECH

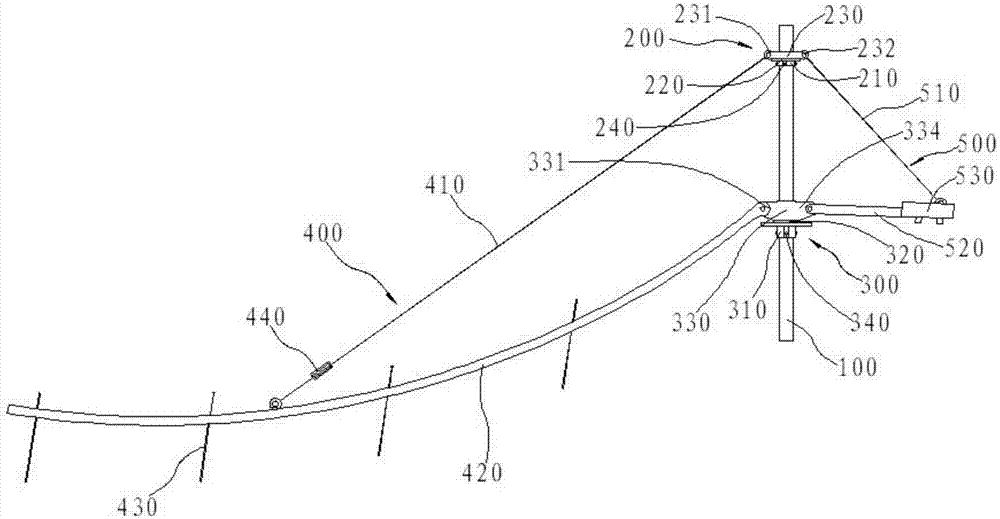

Pavilion roof droop ridge radian installation positioning device

ActiveCN107356184AImprove consistencyImprove efficiencyMechanical counters/curvatures measurementsControl theoryMechanical engineering

The invention discloses a pavilion roof droop ridge radian installation positioning device. The device comprises a positioning support shaft, a cable rotation assembly, a rotary positioning assembly and a detection assembly; the positioning support shaft is coaxially installed on the top of a short column; the cable rotation assembly rotatably sleeves the positioning support shaft; the rotary positioning assembly rotatably sleeve the positioning support shaft; the rotary positioning assembly and the cable rotation assembly are arranged at intervals; the detection assembly includes a detection cable, a detection arm and at least two detection probes; one end of the detection cable is connected with the cable rotation assembly, and the other end of the detection cable is connected with the detection arm; one end of the detection arm is rotatably connected with the rotary positioning assembly, and the other end of the detection arm extends outward freely; and the probe tips of the at least two detection probes are matched with each other so as to form a detection arc portion for detecting the radian of a droop ridge. With the pavilion roof droop ridge radian installation positioning device of the invention adopted, high-precision positioning, installation and correction can be performed on the radian of the droop ridges of the roof of a pavilion, so that the radian of all the droop ridges can be consistent, achieve masonry quality and meet requirements. The pavilion roof droop ridge radian installation positioning device of the invention has the advantages of simple operation, high efficiency and low labor intensity.

Owner:广州市第三建筑工程有限公司

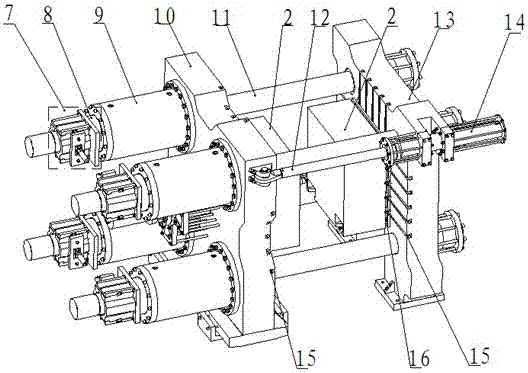

A twin-platen squeeze casting machine for light metal

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

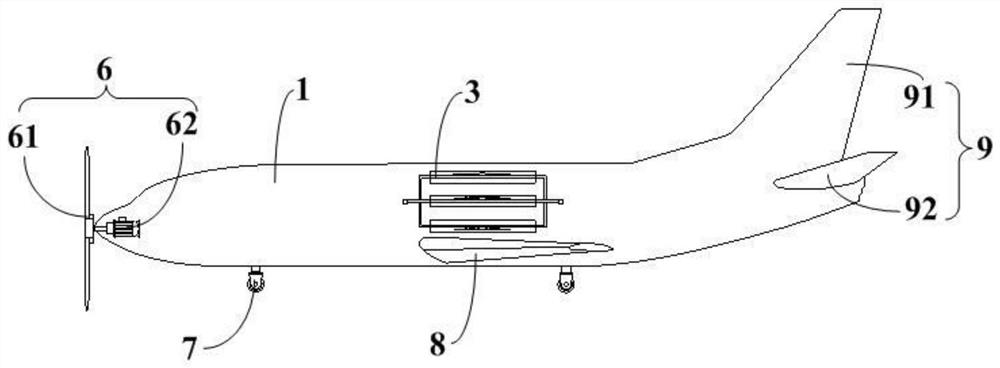

Flapping-wing-like device capable of simultaneously generating thrust and lift force

InactiveCN112498677AStable thrustSmooth liftEfficient propulsion technologiesPower plant typeStructural engineeringRotary wing

The invention discloses a flapping-wing-like device capable of simultaneously generating a thrust and a lift force. The device comprises a fuselage, a support assembly, two rotor wing assemblies, a driving assembly, a brake assembly, a pulling assembly, a control assembly and a take-off and landing assembly. The two rotor wing assemblies are symmetrically arranged on two sides of the fuselage; each rotary wing assembly comprises a revolution main shaft, a rotary arm, an autorotation main shaft and a rotary wing part, and through linkage cooperation of the revolution main shaft, the rotary arms, the autorotation main shaft, the rotary wing part and the driving assembly, the autorotation main shaft can also autorotate while the revolution main shaft in each rotary wing assembly drives the rotary arm and the autorotation main shaft to revolve; and continuously rotating wing pieces can generate an upward lift force, the pull assembly can provide a forward pull force or a push force for theflapping-wing-like device, the forward and upward push force and lift force are provided for take-off and landing of the flapping-wing-like device, and the technical effect of short-distance take-offand landing of the flapping-wing-like device can be achieved.

Owner:GUANGDONG GUOSHIJIAN TECH DEV CO LTD

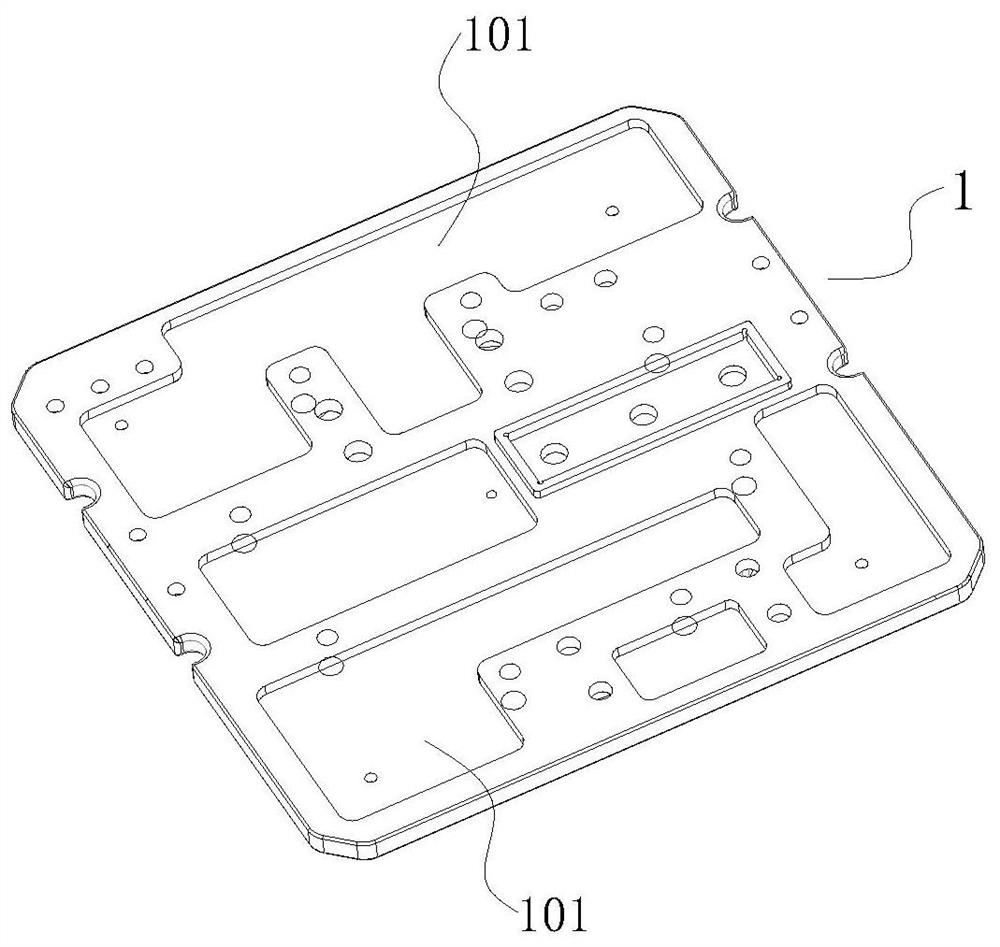

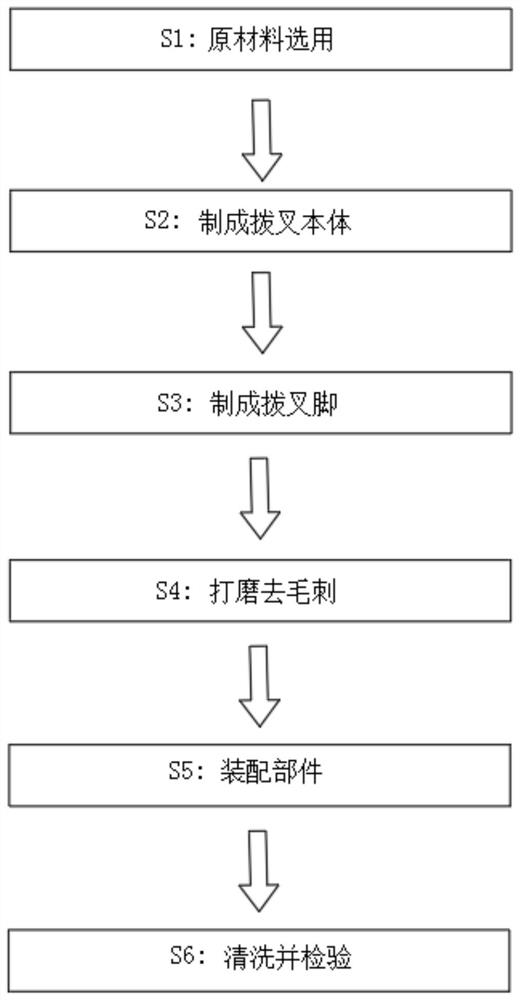

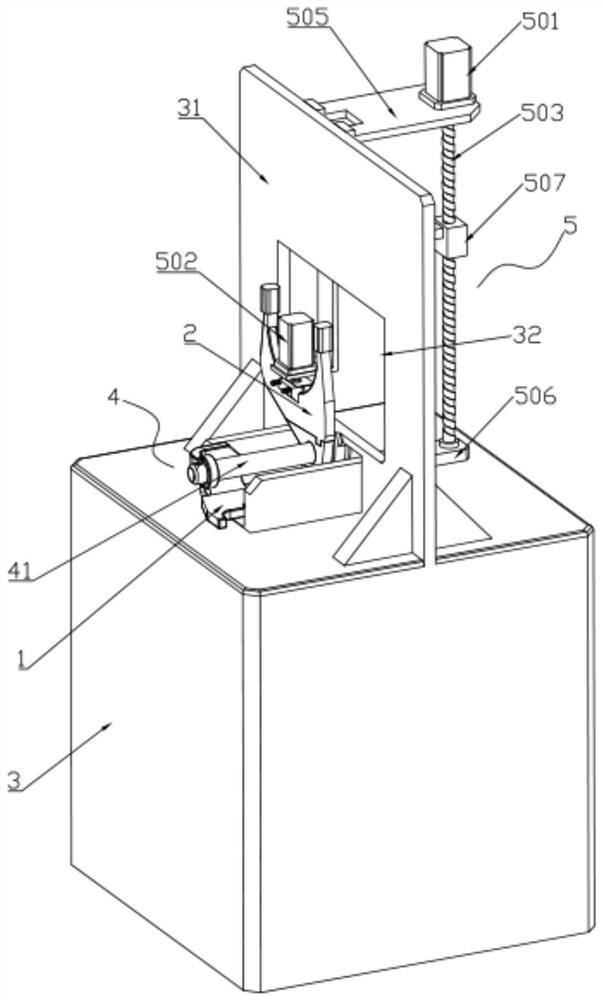

Preparation method of transmission shifting fork assembly

ActiveCN113084462AImprove structural strengthGuaranteed structural strengthMetal working apparatusMechanical componentsElectric machinery

The invention discloses a preparation method of a transmission shifting fork assembly, and relates to the technical field of mechanical part production methods. The method comprises the following steps of selecting raw materials, preparing a shifting fork body, preparing shifting fork legs, polishing to remove burrs, assembling parts, and conducting cleaning and inspection. By adoption of the method, the shifting fork body and the shifting fork legs which are made of different materials are adopted, a novel shifting fork product is manufactured in a split assembling mode, the shifting fork product can be completely held and clamped in the horizontal direction and the vertical direction under the rotating working condition, and meanwhile the shifting fork body and the shifting fork legs are matched with the assembling end face position between the shifting fork body and the shifting fork legs, and the torsional moment of a half-thread stud and a chuck in the rotating process of the shifting fork is greatly reduced, so that the overall structural strength of the shifting fork is guaranteed, and the purpose of reducing the weight of the shifting fork is achieved on the premise that the structural strength is guaranteed. A positioning mechanism and a rotary clamping mechanism are arranged on a rack, and automatic assembly of the shifting fork body and the shifting fork legs can be achieved under driving of a first driving motor and a second driving motor.

Owner:JILIN DAHUA MACHINERY MANUFACTURING CO LTD

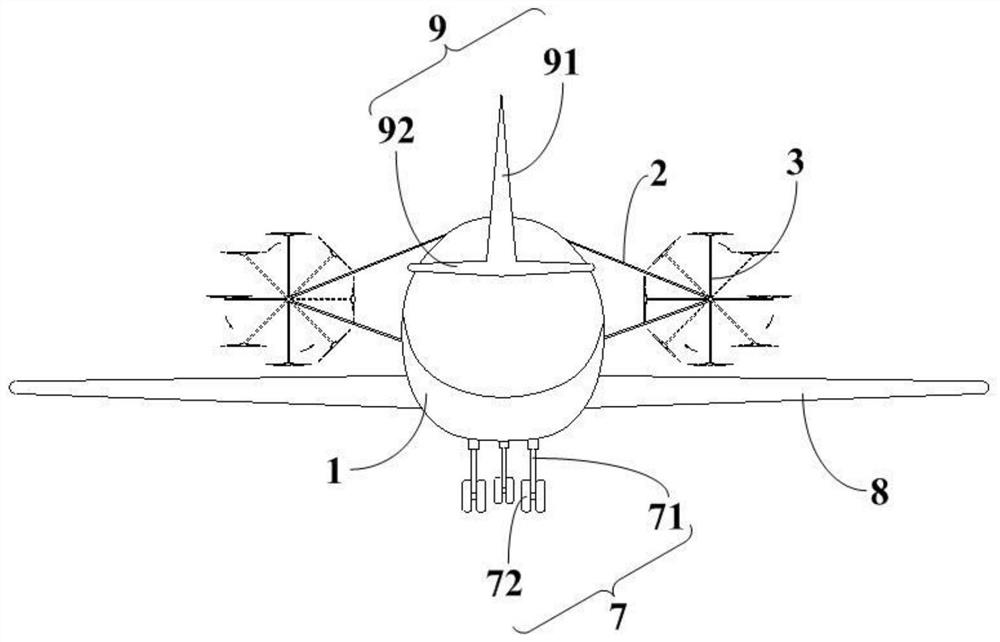

Multi-flapping-rotor aircraft

InactiveCN112429228ATake off smoothlySmooth air hoverAircraft stabilisationOrnithoptersClassical mechanicsAirframe

The invention discloses a multi-flapping-rotor aircraft which comprises an aircraft body, supporting assemblies and flapping rotor assemblies, each flapping rotor assembly comprises four sets of flapping rotor devices, and the four sets of flapping rotor devices are symmetrically arranged on the two sides of the aircraft body in pairs through the supporting assemblies correspondingly; each flapping rotor wing device comprises a revolution main shaft, a rotating arm, an autorotation main shaft, a rotating wheel, a driving part, a rotor wing part, a pulling part, a brake part and a rotor wing frame, and the revolution main shaft, the rotating arm, the autorotation main shaft, the rotating wheel, the driving part, the rotor wing part, the pulling part, the brake part and the rotor wing frameare in linkage fit. Through the arrangement of the rotating wheel, the autorotation main shaft can also rotate in the revolution process, so that the rotor wing part is driven to rotate, and in the autorotation process, an upward lifting force is generated by utilizing the continuously rotating wing pieces, and the relatively large lifting force is provided for take-off and hovering of the aircraft.

Owner:FOSHAN SHENFENG AVIATION SCI & TECH

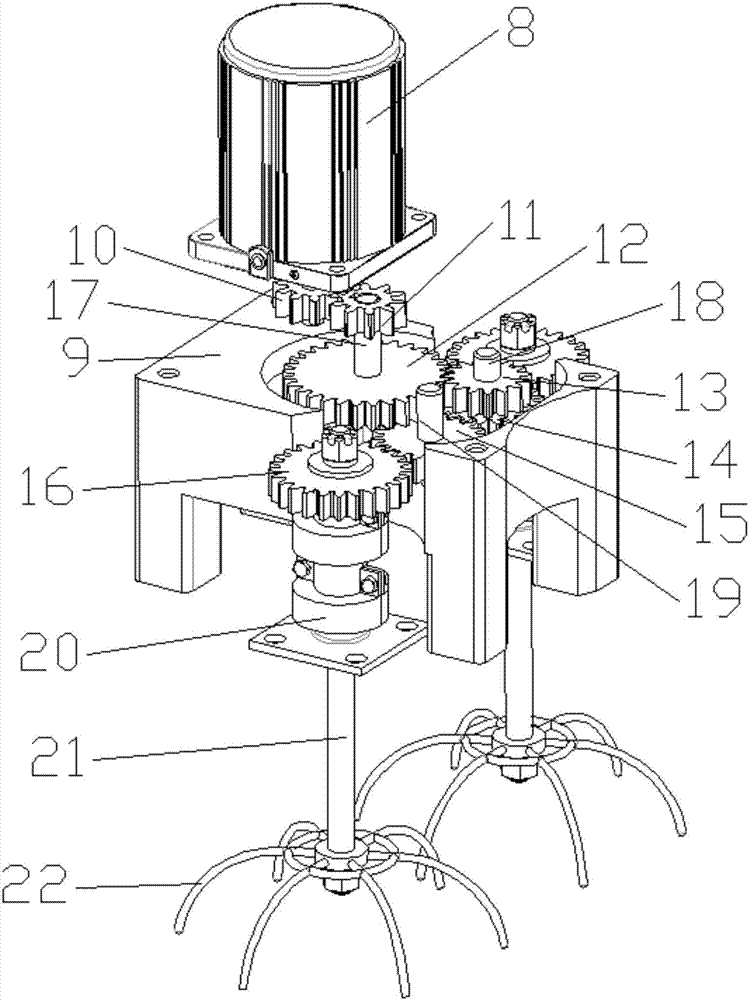

Automatic weeding robot and its control method

InactiveCN106973572BAvoid accumulationRealize small radius turnsSoil-working equipmentsDrive shaftEngineering

The invention discloses an automatic weeding robot and a control method thereof. The rice field weeding control has the effects of promoting the growth of rice and saving fertilizer, and overcomes the problem that the existing weeding devices cannot remove the weeds between the plants. The automatic weeding control robot comprises a marching mechanism, an inter-row weeding mechanism, an inter-plant weeding mechanism, a machine frame and a camera. The marching mechanism comprises a first stepper motor, a motor seat, a first bushing, an axle and marching wheels. The inter-row weeding mechanism comprises a first direct current motor, a gear box, a first drive shaft, a second shaft, a third shaft, a second bushing, an inter-row weeding shaft and an inter-row weeding claw. The inter-plant weeding control mechanism comprises a second direct current motor, a fourth transmission shaft, a first pulley, a bearing box, a swinging central shaft, a second stepper motor, a bearing, a swinging arm, a second pulley, a swinging box, a drive belt, an inter-plant weeding shaft and an inter-plant weeding claw. When in the working process, the automatic weeding control robot can ensure that the rice is not damaged when removing the grasses between the plants.

Owner:永新县绿欣农业科技有限公司

Directional drilling execution mechanism based on three-speed drill bit

ActiveCN106837175ADrilling GuaranteeImprove universal applicabilityDrilling rodsConstructionsUniversal jointWell drilling

Owner:泰安泰山科技有限公司

Vehicle dynamic information feedback equipment based on Internet-of-vehicles

ActiveCN112208455AAvoid submersionImprove cooling effectVehicle componentsVehicle dynamicsDust control

The invention relates to vehicle dynamic information feedback equipment based on Internet-of-vehicles. The vehicle dynamic information feedback equipment comprises a box body, a cavity is formed in the box body, fixing blocks are fixed to the front inner wall and the rear inner wall of the cavity, a fixing box is fixed to the upper sides of the fixing blocks, and a fixing cavity with an upward opening is formed in the fixing box. According to the equipment, a GPS can be stably fixed on the vehicle. The cooling fan can effectively cool, remove dust and rotate coaxially and reversely, torque generated by rotation can be counteracted, meanwhile, the cooling fan has the function of removing dust of a filter screen, automatic closing can be achieved under the condition that an automobile is flooded, water flooding is prevented, damage is reduced due to a damping device, the vehicle dynamic information feedback equipment can move to the outer side of the box body under the condition that signals are weak, therefore the signals are enhanced. And the device can realize effective dust prevention, heat dissipation, water prevention and shock absorption.

Owner:广州新程北斗信息科技有限公司

Flapping rotor wing device capable of ascending, half-rotating and descending

InactiveCN112407276AEasy to liftReasonable designOrnithoptersRotocraftFlight vehicleClassical mechanics

The invention discloses a flapping rotor wing device capable of ascending, half-rotating and descending. Theflapping rotor wing device comprises a supporting assembly, a rotating assembly, a driving assembly and a rotor wing assembly which are in linkage fit. Therefore, the technical effect that an autorotation main shaft of the flapping rotor wing device can autorotate while revolving along witha revolution main shaft is achieved, the rotating surface of the rotor wing assembly can be kept parallel to the horizontal plane all the time in the descending process of the rotor wing assembly, andthen vertically-upward lifting force is provided for an aircraft; the rotor wing assembly can keep the rotating surface of the rotor wing assembly vertical to or approximately vertical to the horizontal plane in the descending process, so that the resistance generated in the ascending process of the rotor wing assembly is reduced, the offset of the lifting force generated in the ascending and descending processes of the rotor wing assembly is avoided, and a continuous and stable lifting force is provided for the take-off and hovering of the aircraft. The flapping rotor wing device is reasonable in design, simple in structure, easy to operate, convenient to control, energy-saving, efficient and good in application prospect.

Owner:GUANGDONG GUOSHIJIAN TECH DEV CO LTD

Servo motor with protection structure

ActiveCN114785048AReal-time speed detectionReduce the temperatureMechanical energy handlingStructural associationRatchetGear wheel

The invention discloses a servo motor with a protection structure, and relates to the technical field of driving motors, and the servo motor comprises a motor body assembly, a heat dissipation and cooling assembly and a rotation speed detection assembly. The heat dissipation cooling assembly comprises a rear-end inner ratchet wheel, a rear-end outer ratchet wheel, a front-end inner ratchet wheel, a front-end outer ratchet wheel, a rear-end gear set, an outer-end gear ring, a large gear and a rear-end heat dissipation fan, the rear-end gear set, the outer-end gear ring and the large gear are all rotationally installed on the rear machine base, and the rear-end inner ratchet wheel and the front-end inner ratchet wheel are fixedly installed on a motor shaft in a stacked mode; the rear-end inner ratchet wheel is meshed with the rear-end outer ratchet wheel, the input end of the rear-end gear set is in gear fit with the rear-end outer ratchet wheel, and the output end of the rear-end gear set is in gear fit with the outer-end gear ring; the rear-end cooling fan is fixedly connected with the outer-end gear ring and can rotate together with the outer-end gear ring, the temperature of the motor in an actual power environment is reduced through rotation of the rear-end cooling fan, the demagnetization threshold value is increased, and demagnetization is reduced.

Owner:佛山登奇伺服科技有限公司 +1

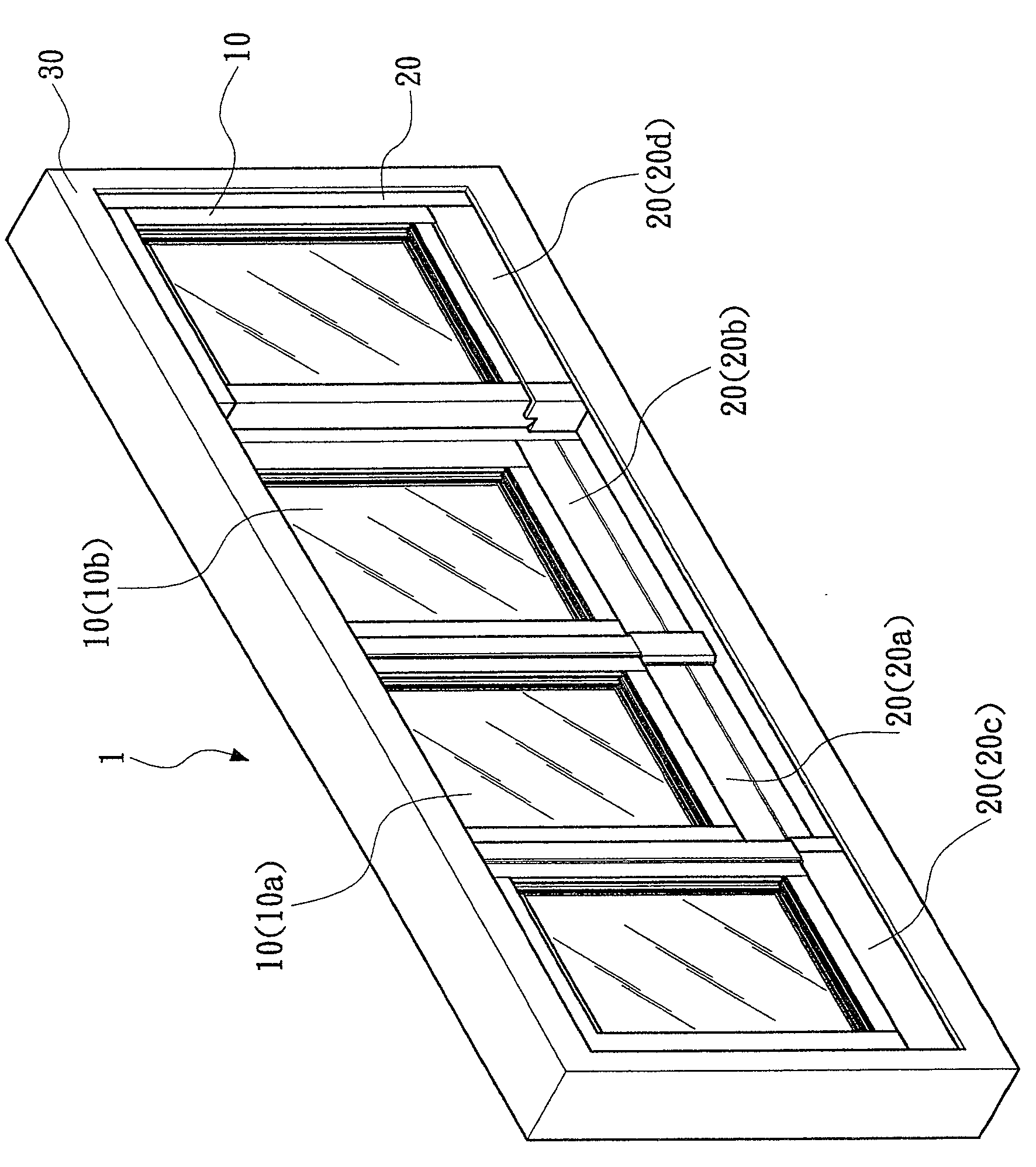

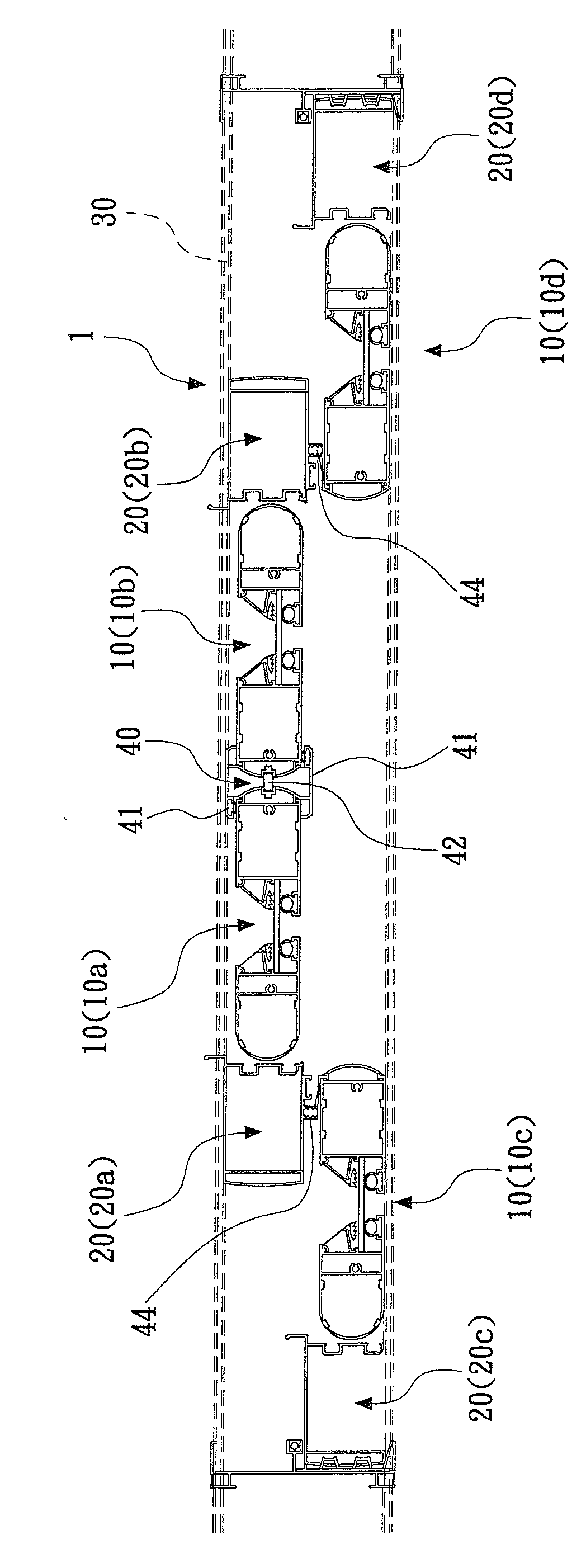

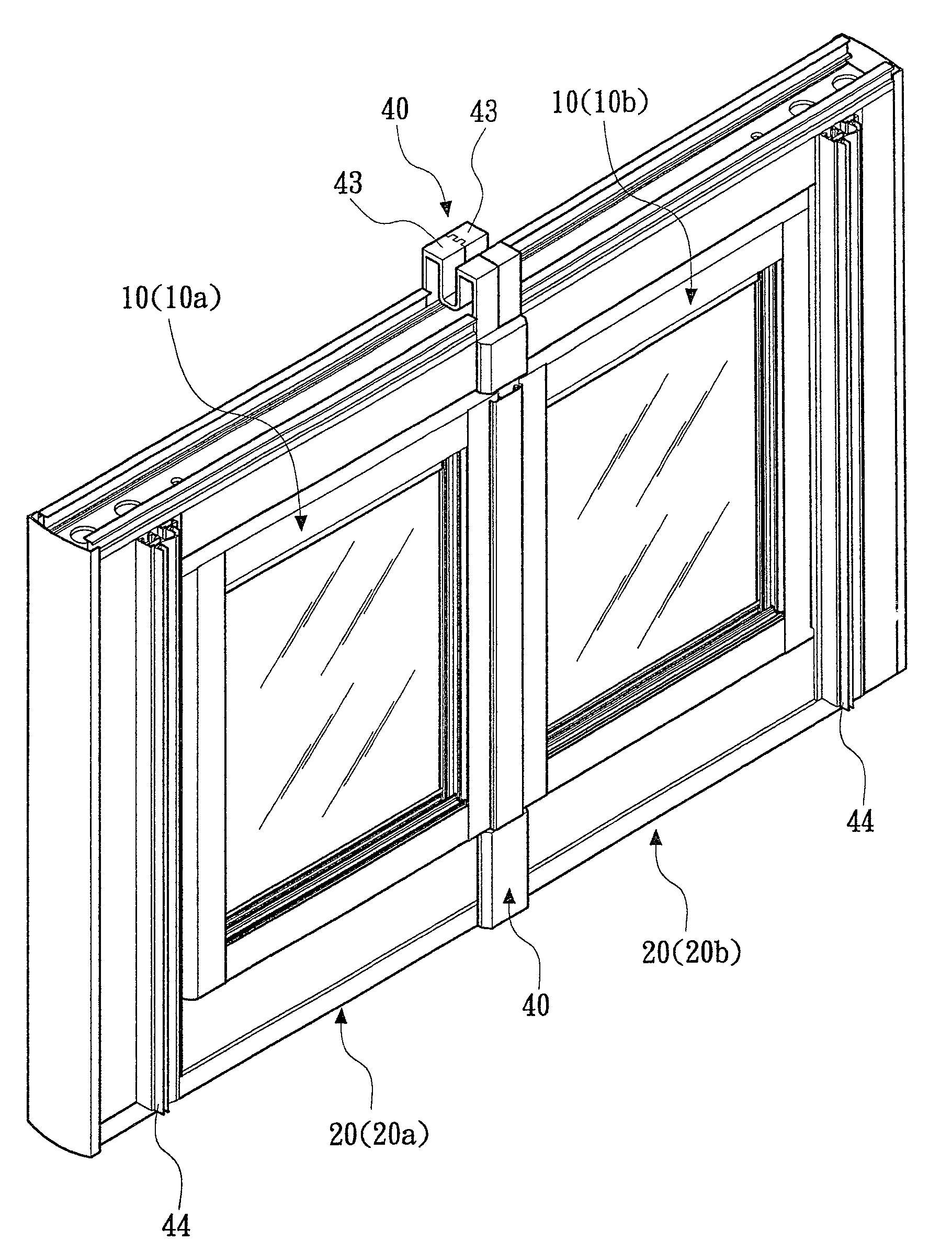

Slide opening and hinge opening two-purpose window structure

InactiveCN100562639CPlay the functionOffset torqueWing arrangementsWing suspension devicesCouplingEngineering

The present invention is a sliding and pivoting dual-purpose window structure. The dual-purpose window includes several inner windows, each of which is pivotally connected to a C-shaped middle frame, and all the middle frames are arranged on an outer window. Several rails of the frame form a window assembly. When in use, each inner window can slide on the slide rails of the outer frame with its C-shaped middle frame, and can be parked at any position and then pushed outward Open, and all the C-shaped middle frames can be slid to the two sides of the outer frame, and all the inner windows on each C-shaped middle frame are pushed outward, so that there is no straight support frame on the entire window. , to present the widest space and field of view, characterized in that: an angle adjustment structure is specially set at the junction of the straight support frame and the transverse support frame of the C-shaped middle frame, so that after the assembly of the inner window and the C-shaped middle frame, The structure can be adjusted by this angle, so that the straight support frame and the lower transverse support frame of the C-shaped middle frame can be pre-adjusted from the general 90-degree connection state to an inclination state of an appropriate angle greater than 90 degrees.

Owner:梁事利

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com