Patents

Literature

53results about How to "Reduce input torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

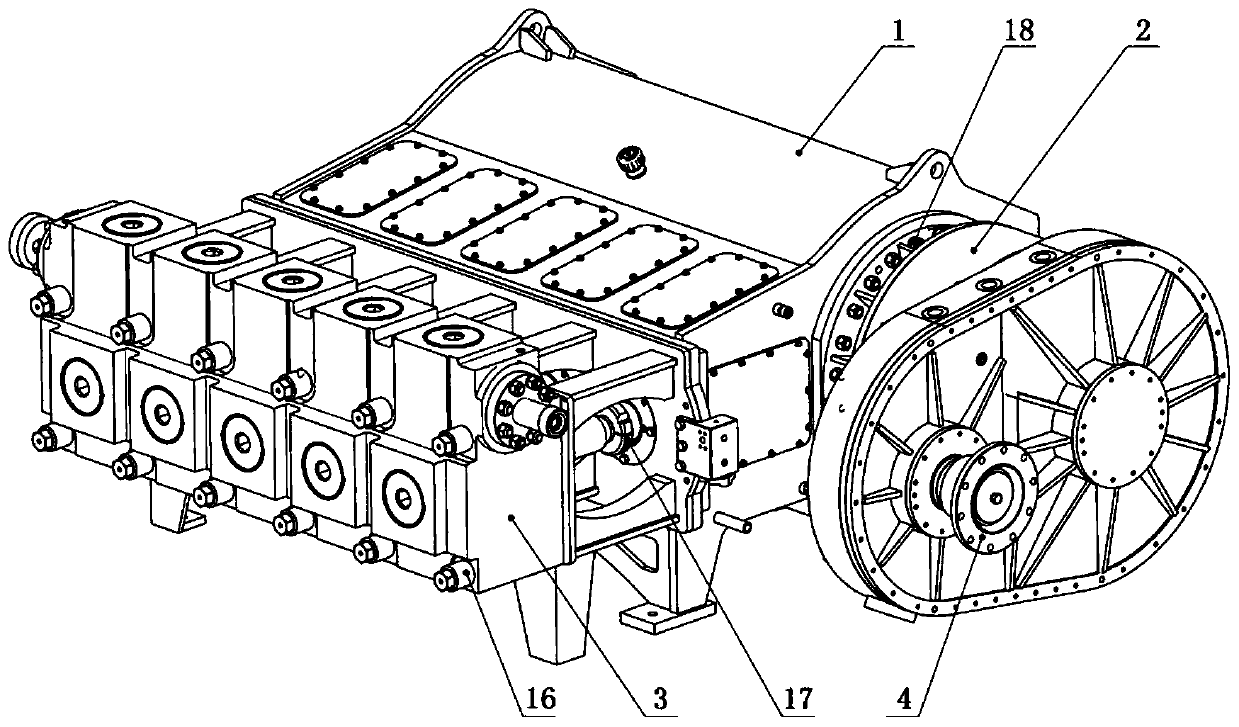

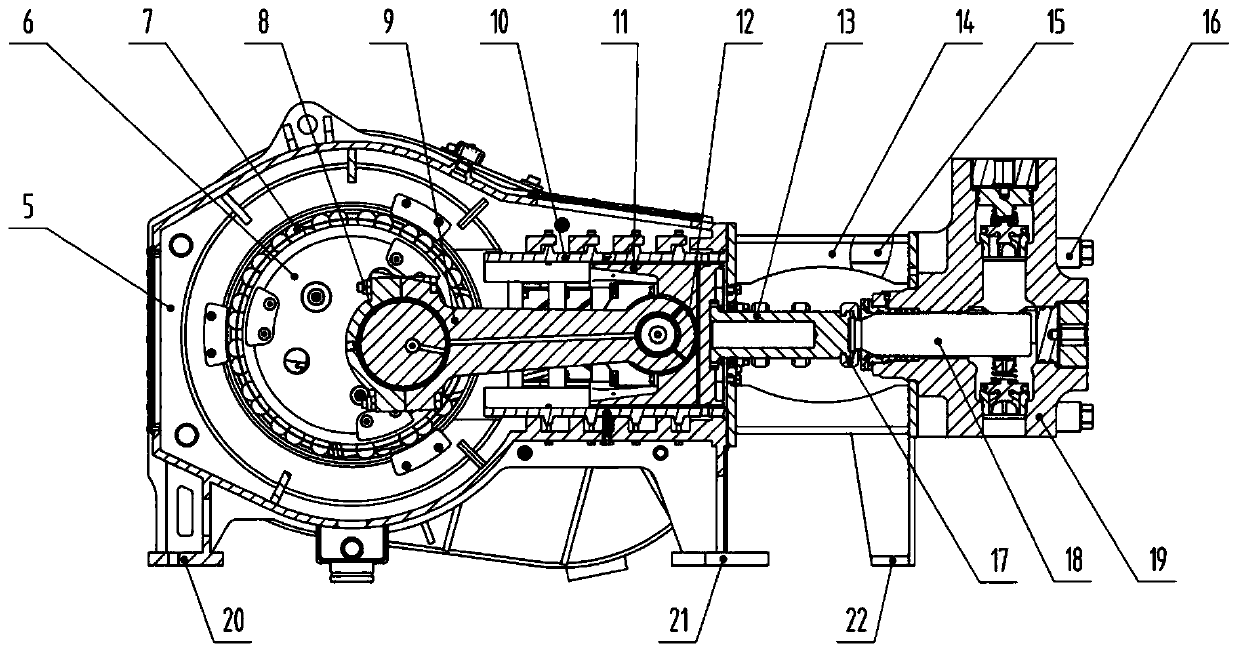

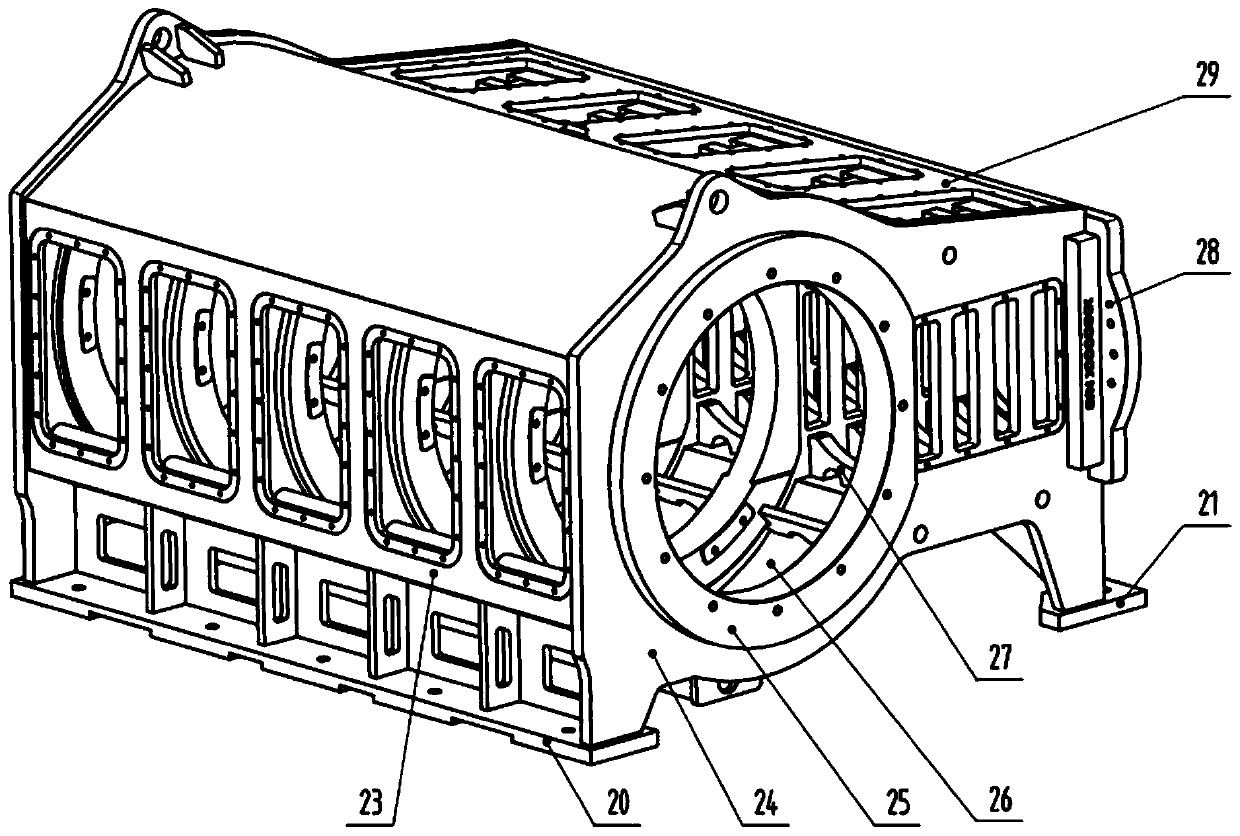

Five-cylinder plunger pump with integral power end structure

PendingCN110617318AExtended service lifeLow strokeCrankshaftsConnecting rod bearingsCrankcaseHigh load

The invention discloses a five-cylinder plunger pump with an integral power end structure. According to the five-cylinder plunger pump, an integral welding structure is adopted for a crankshaft box body and a crosshead box body in a five-cylinder plunger pump power end assembly, so that the structural strength of the power end assembly is higher, the supporting stability is better, and the whole pump vibration can be reduced; the cylinder spacing is 13-14 inches, the bearing area of connecting rods, crossheads and bearing bushes is increased, a guarantee is provided for the output of the high-power of the five-cylinder plunger pump, the high-power five-cylinder plunger pump can effectively solve the problem that the shale gas fracturing well site area is narrow and the required fracturingequipment is relatively large, the use of equipment can be reduced, and the wellsite arrangement is facilitated; the 11-inches long-stroke design can better realize large-displacement operation requirements and improve the operation efficiency; and according to the multi-point supporting design of crankcase bodies, crosshead box bodies and the hydraulic end assembly, the supporting strength of thefive-cylinder plunger pump can be improved, the vibration is reduced, the high-load operation is better guaranteed, and the operation is more stable.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

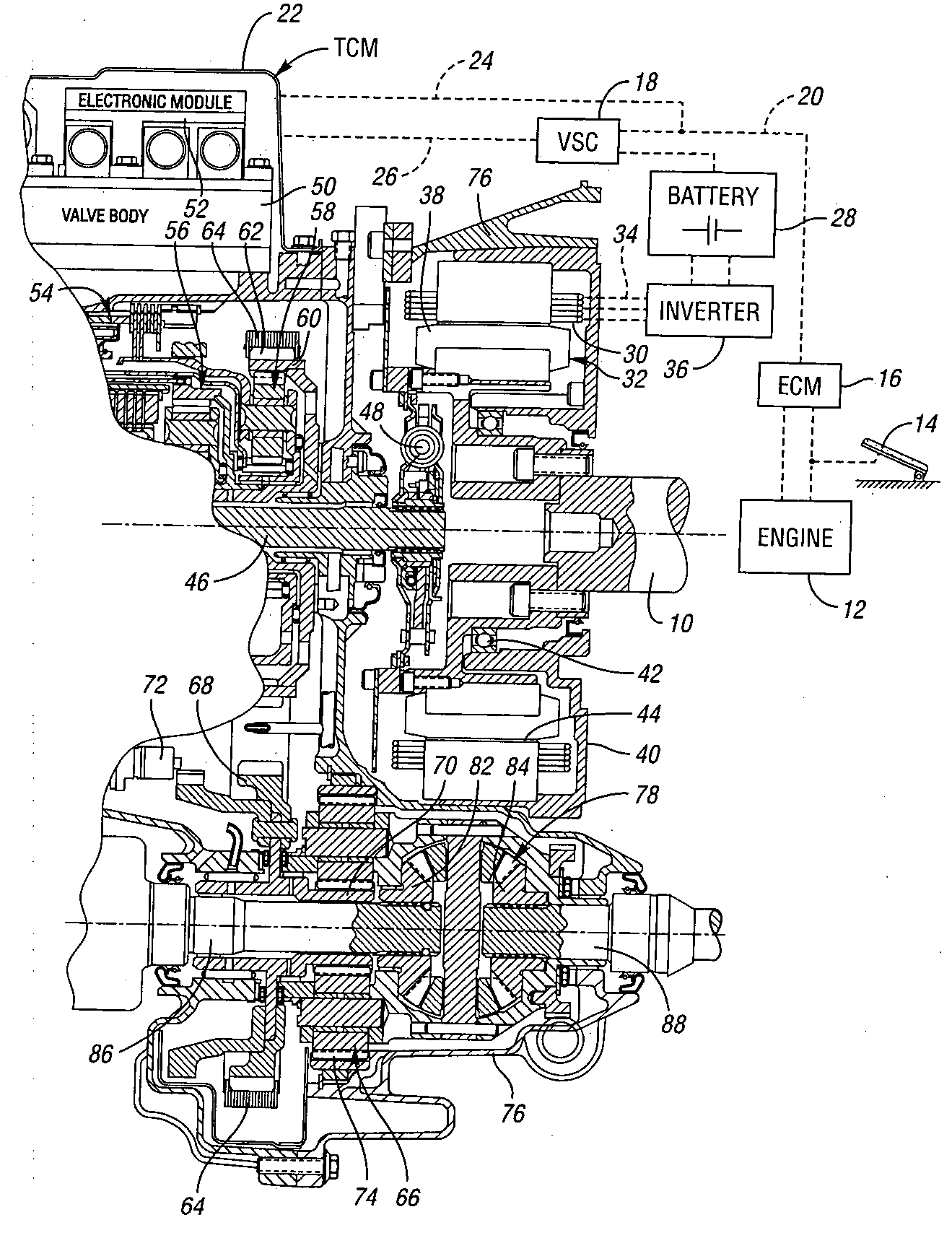

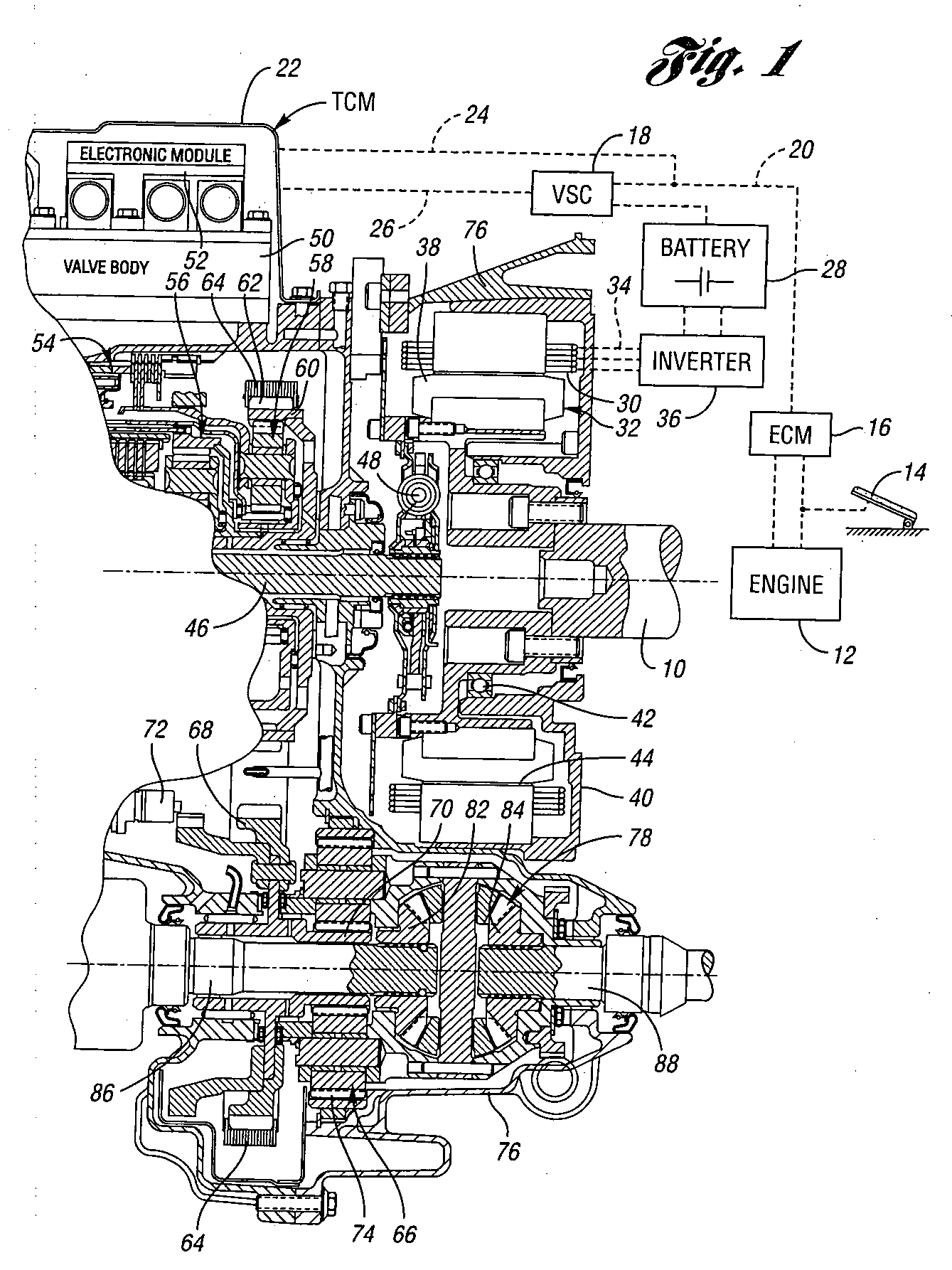

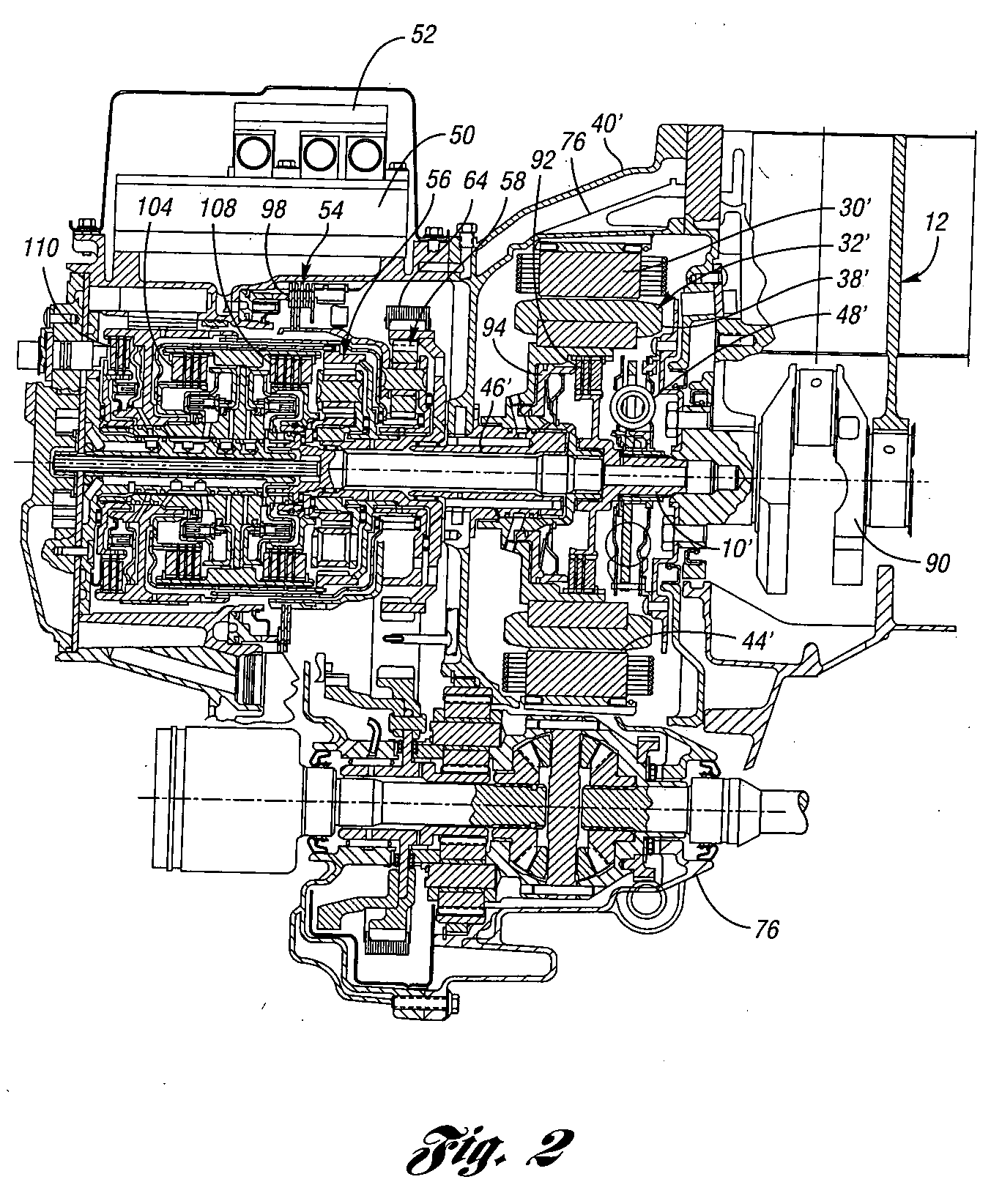

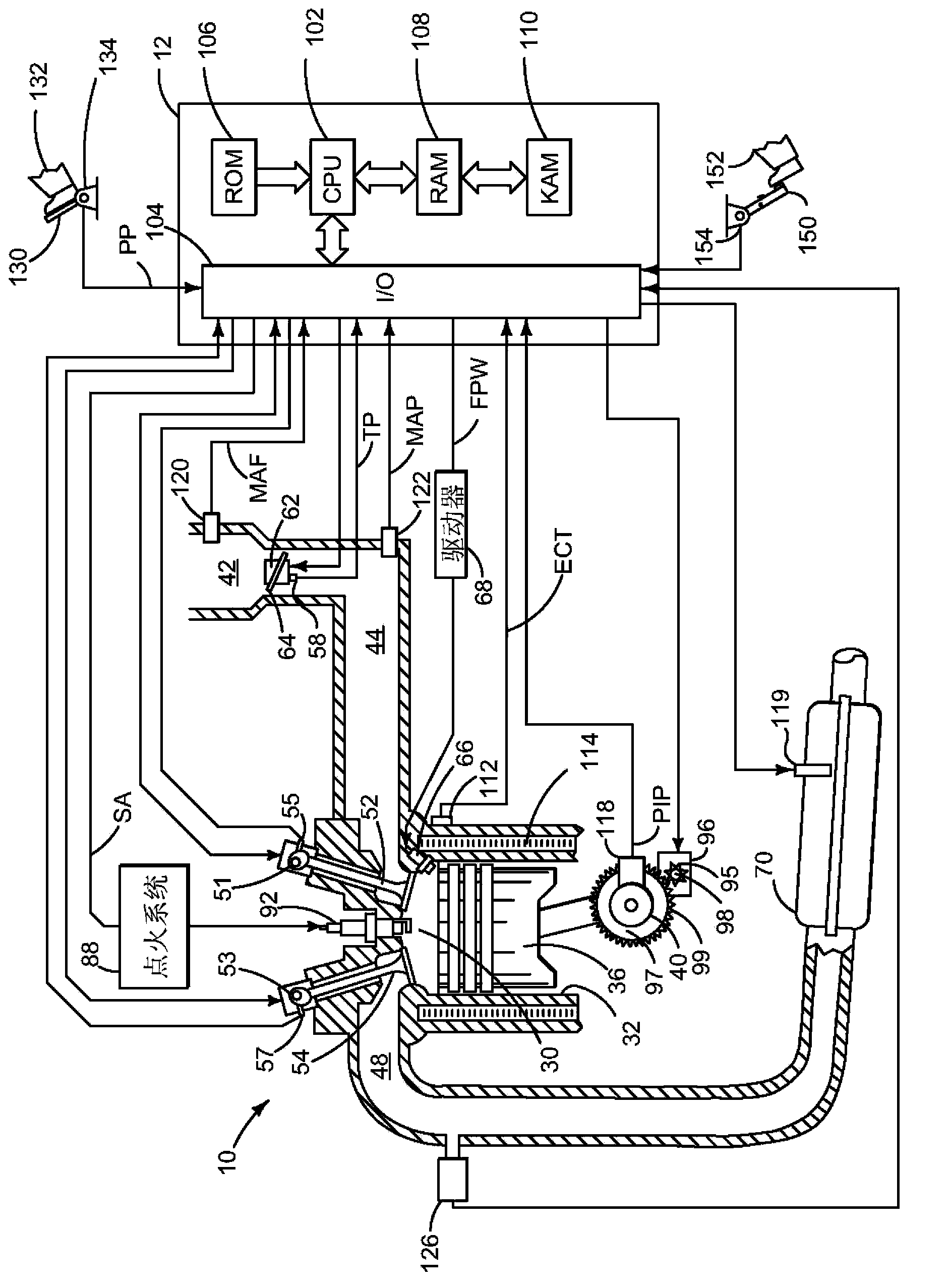

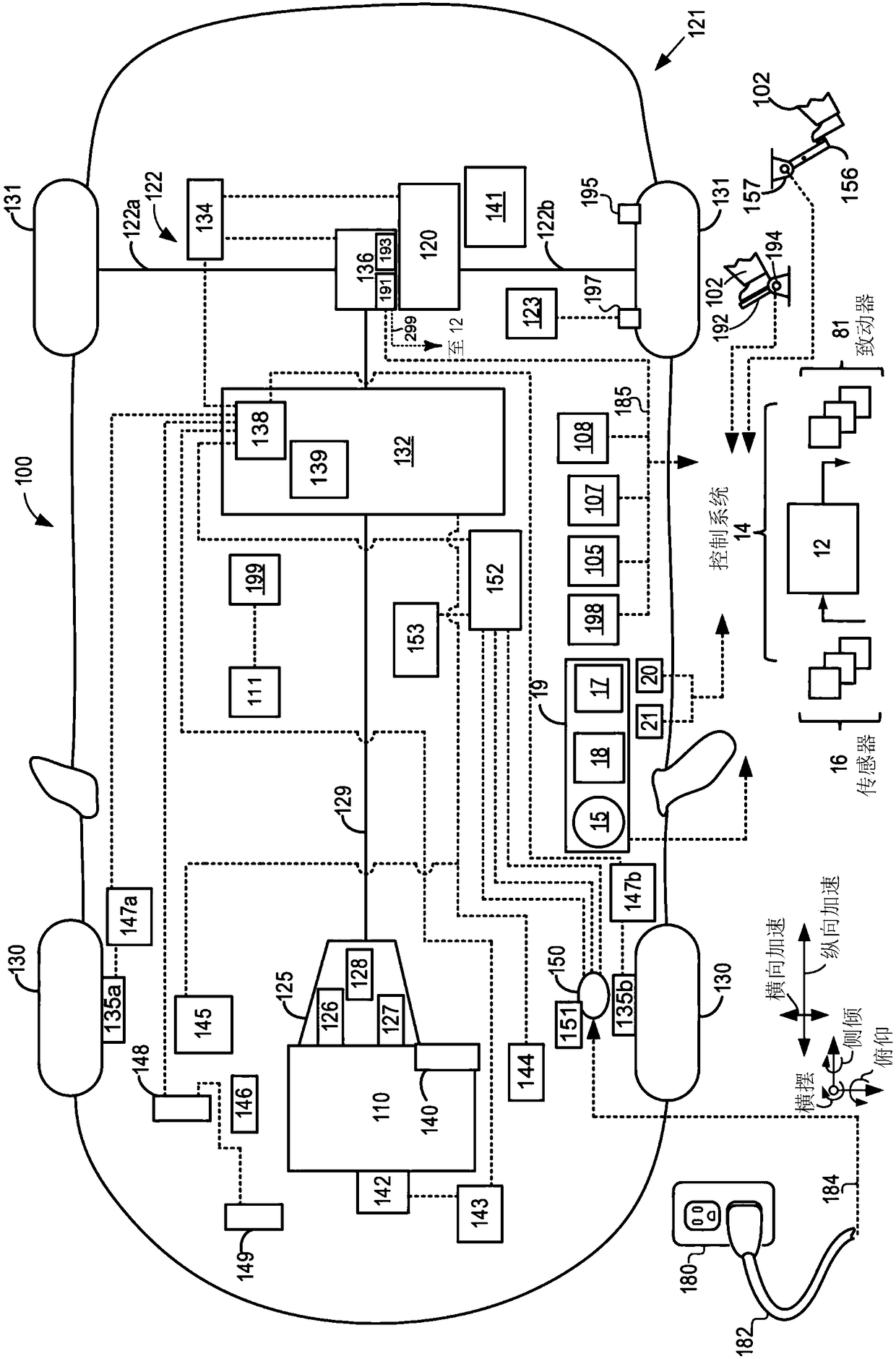

Control of power-on downshifts in a multiple-ratio powertrain for a hybrid vehicle

InactiveUS20060142117A1Reduce dynamic torque disturbanceReduce input torqueGearing controlConjoint controlElectric vehicleHybrid vehicle

A method for controlling engagement and release of friction clutches in a multiple-ratio transmission for a hybrid electric vehicle powertrain uses electric motor torque to augment engine torque as a power-on downshift is commanded. Near the end of a downshift event, total powertrain torque is modulated or reduced to reduce torque disturbances.

Owner:FORD GLOBAL TECH LLC

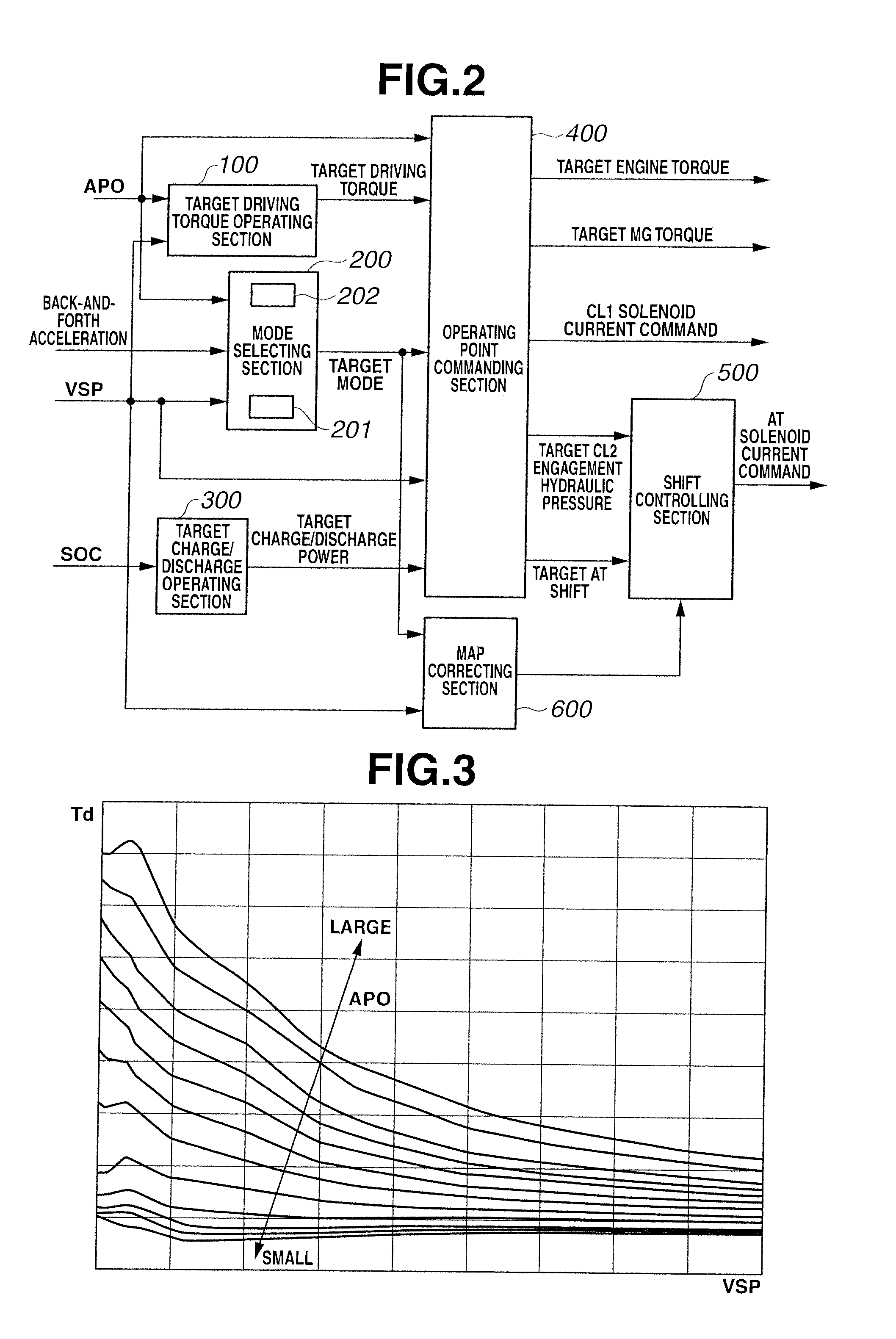

Hydraulic control apparatus for vehicle

ActiveUS20120109478A1Suppress feverReduce transmissionHybrid vehiclesDigital data processing detailsTarget engagementDrive wheel

The hydraulic control apparatus calculates a target engagement hydraulic pressure of a frictional engagement element, controls the frictional engagement element so that a revolution speed at a driving source side of the frictional engagement element is higher than a revolution speed at a driving wheel side of the frictional engagement element, outputs a command current to a solenoid valve on the basis of a map having a relationship between the target engagement hydraulic pressure and the command current, and decreases the engagement hydraulic pressure when a vehicle speed is equal to or less than a predetermined vehicle speed at which the vehicle is judged to be vehicle stop during execution of the slip control. Further, the hydraulic control apparatus corrects the map so that a variation of the command current with respect to a variation of the target engagement hydraulic pressure is small when decreasing the engagement hydraulic pressure.

Owner:JATCO LTD +1

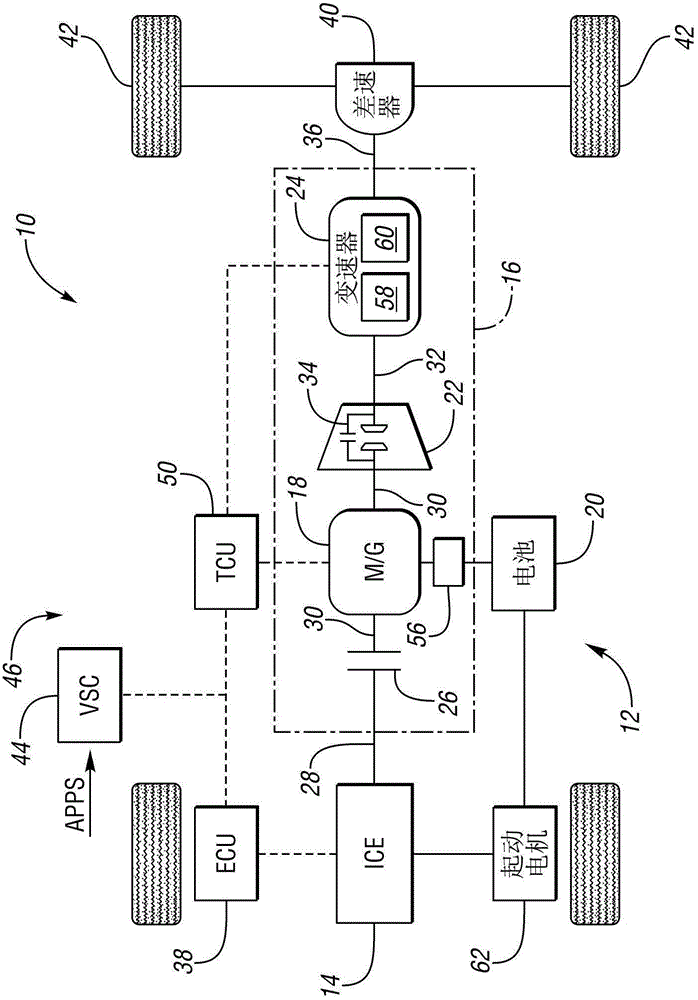

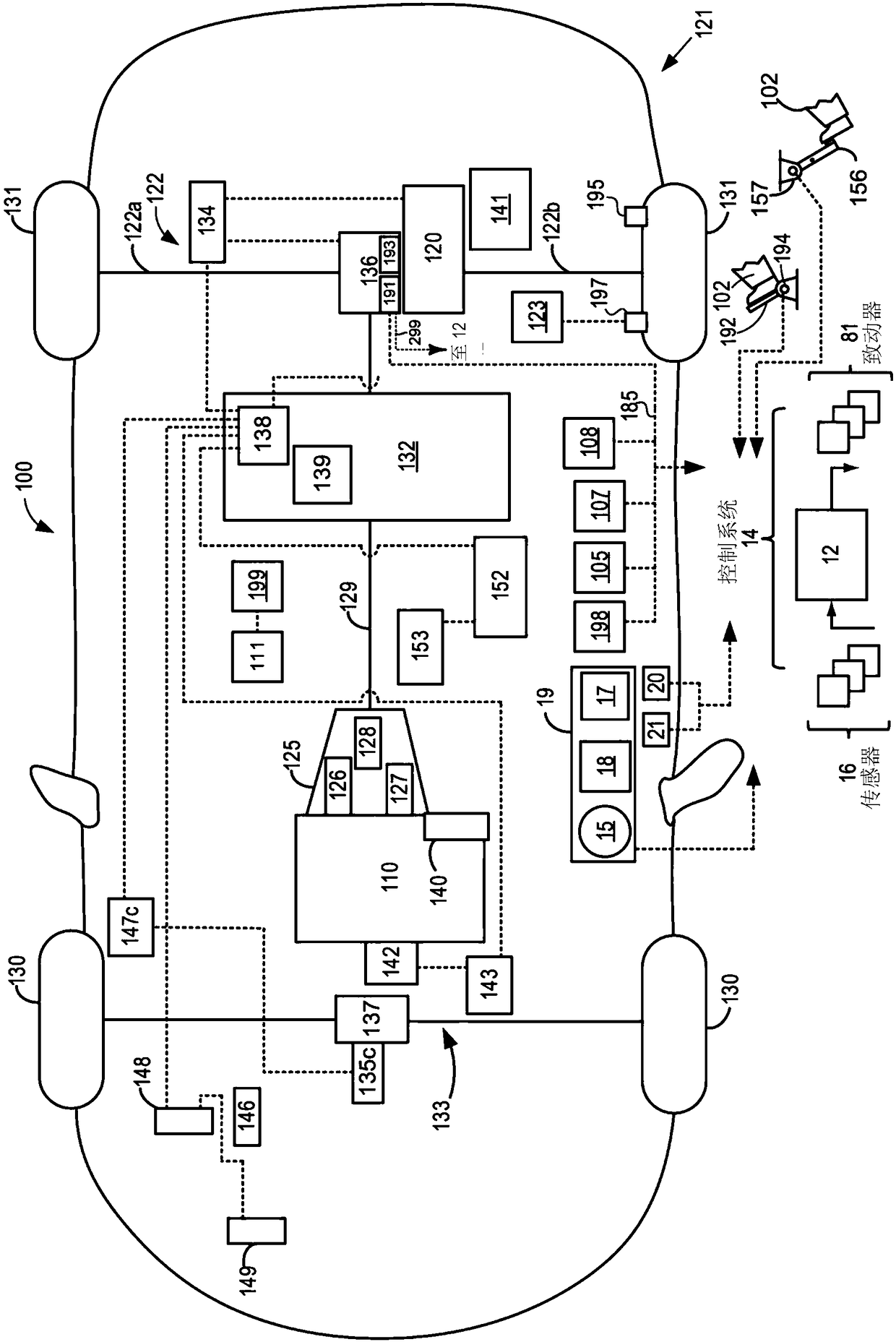

Hybrid vehicle

ActiveCN104627183ASmall rotational inertiaReduce input torqueHybrid vehiclesSpeed controllerElectricityElectric machine

A hybrid vehicle has an engine, an electric machine connected to the engine by an upstream clutch, a transmission gearbox connected to the electric machine by a downstream clutch, and a controller. The controller is configured to, in response to a commanded upshift of the gearbox, modulate a pressure of the upstream clutch. A method for controlling a vehicle includes, in response to a commanded upshift of a gearbox, controlling an upstream clutch to a first nonzero speed differential corresponding to a first inertia connected to and upstream of the gearbox to reduce inertia torque during the upshift. A method for controlling a vehicle includes, in response to a commanded upshift of a gearbox when the vehicle is beyond an electrical limit and a fast path torque reduction limit, slipping an upstream clutch and reducing torque outputs of an engine and an electric machine.

Owner:FORD GLOBAL TECH LLC

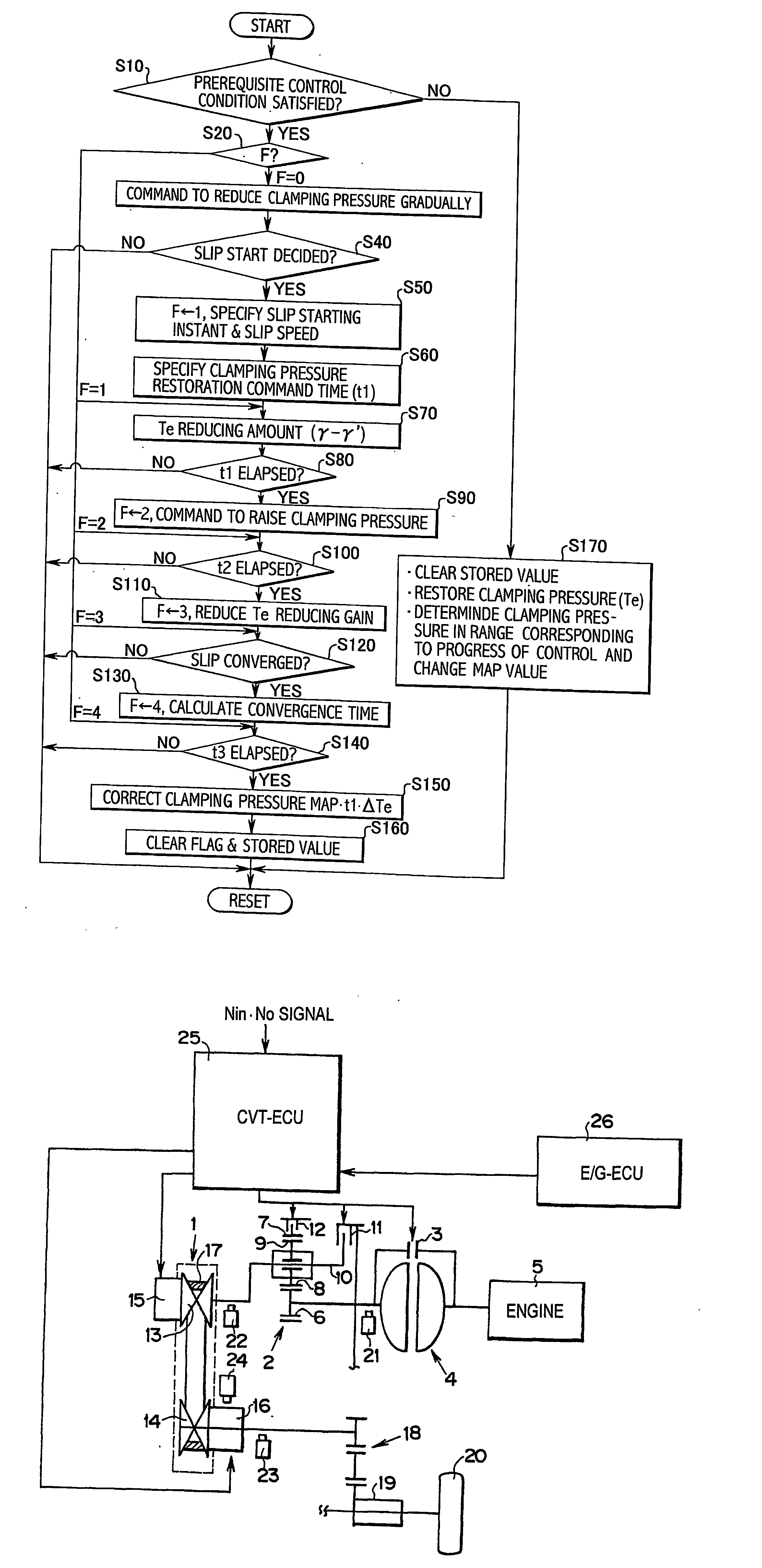

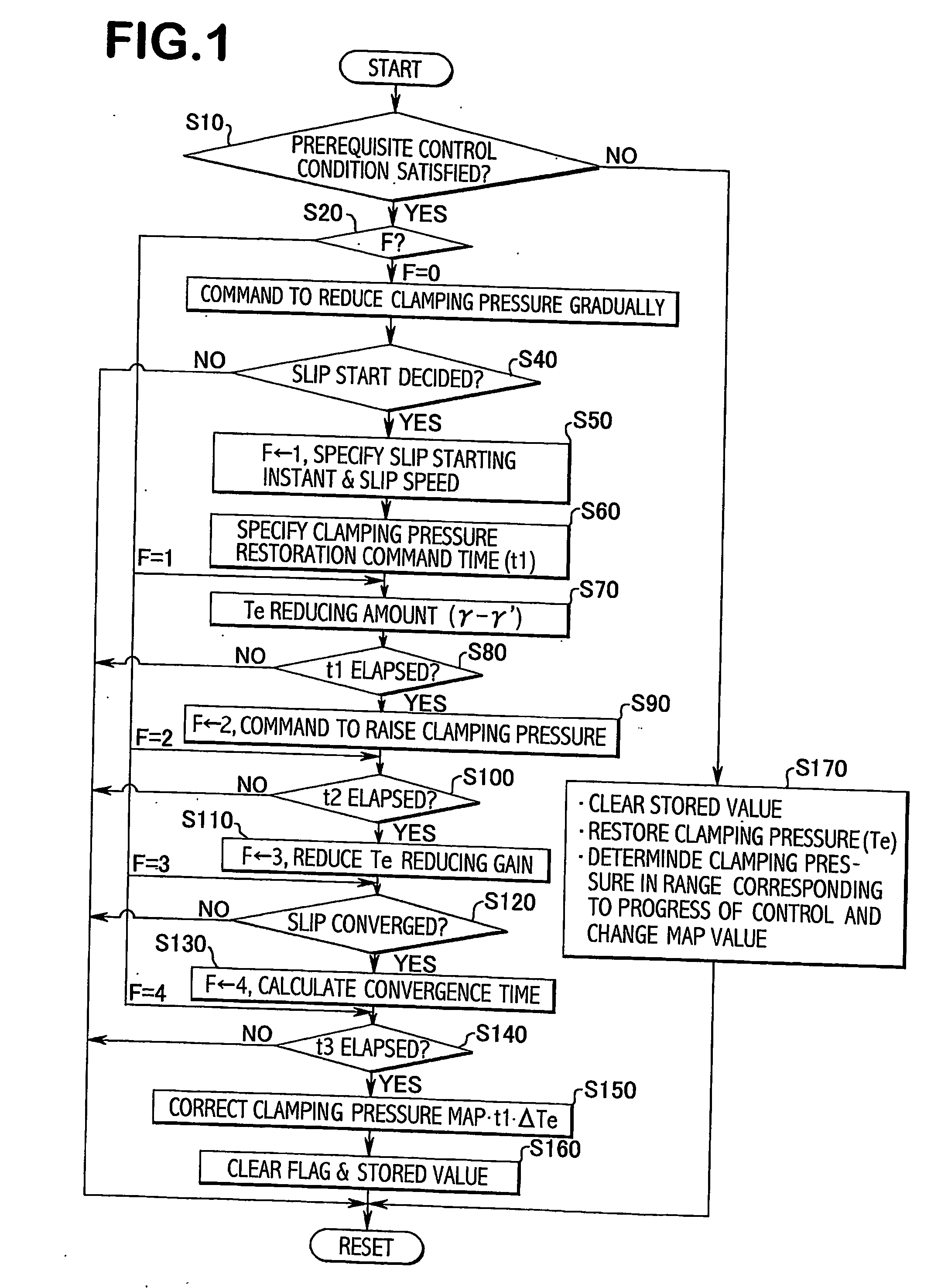

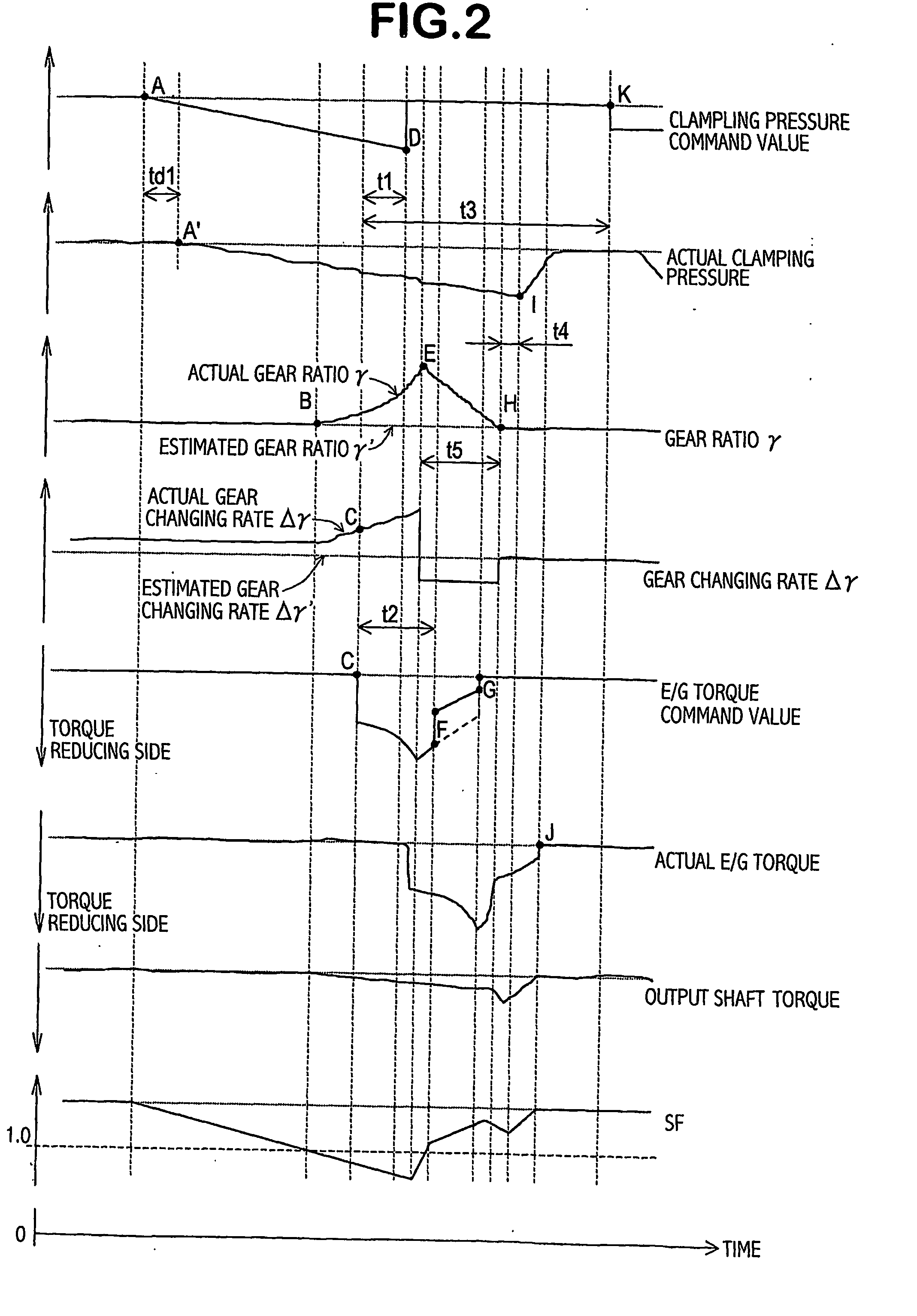

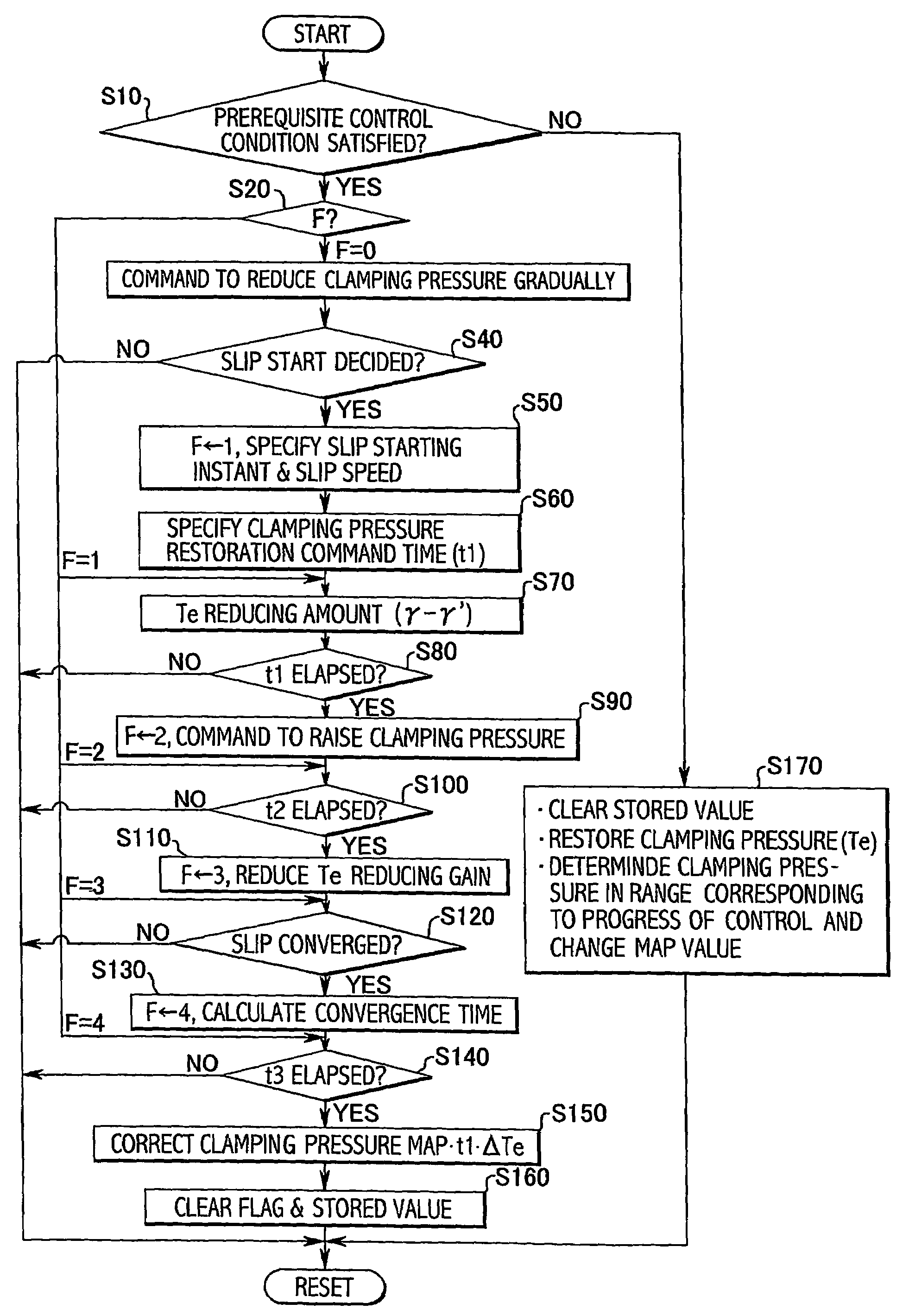

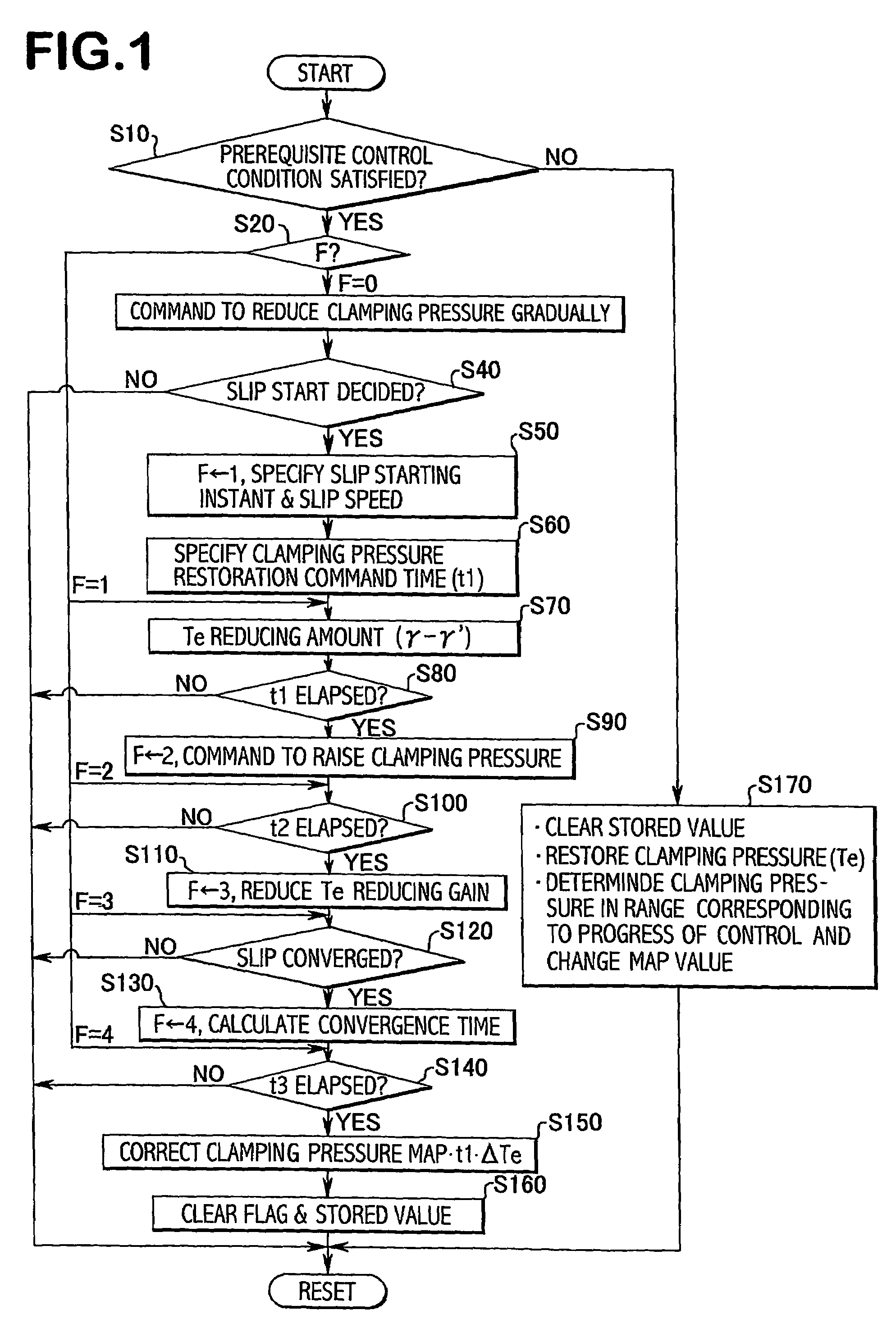

Cooperative control system for prime mover and continuously variable transmission of vehicle

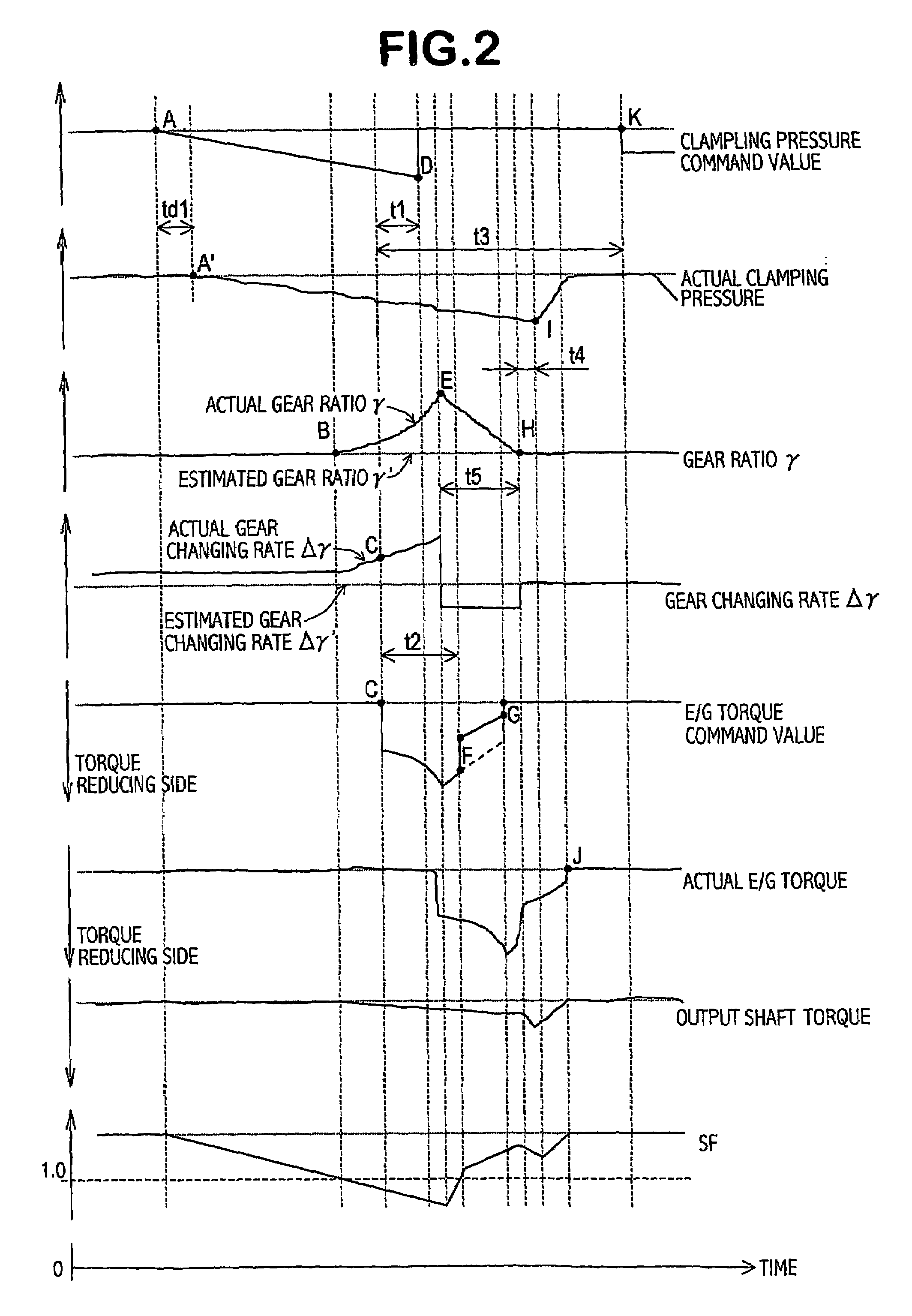

InactiveUS20060234828A1Avoid feeling uncomfortableUncomfortable feelingGearingGearing controlControl systemExecution control

A cooperative control system for a prime mover and a continuously variable transmission of a vehicle, in which the continuously variable transmission is connected to an output side of the prime mover for generating a driving force for running, and in which a clamping pressure to set a torque capacity of the continuously variable transmission is raised and an input torque to the continuously variable transmission is lowered on the basis of a decision of the slip in the continuously variable transmission. A clamping pressure / input torque sequential control raises an actual pressure of the clamping pressure at or after a deciding instant of the slip convergence, and executes a control to complete a restoration of an actual torque of the lowered input torque afterward.

Owner:TOYOTA JIDOSHA KK

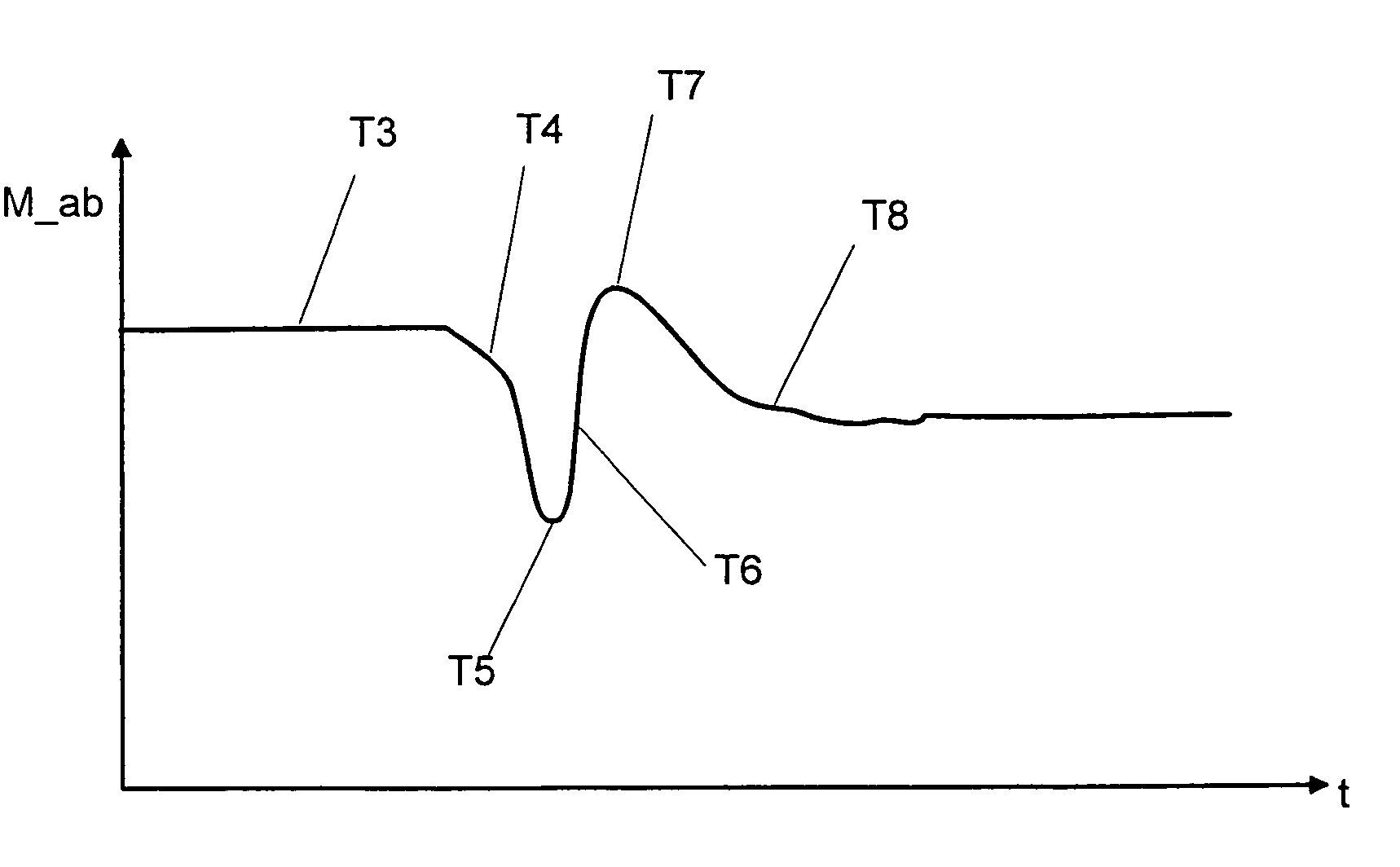

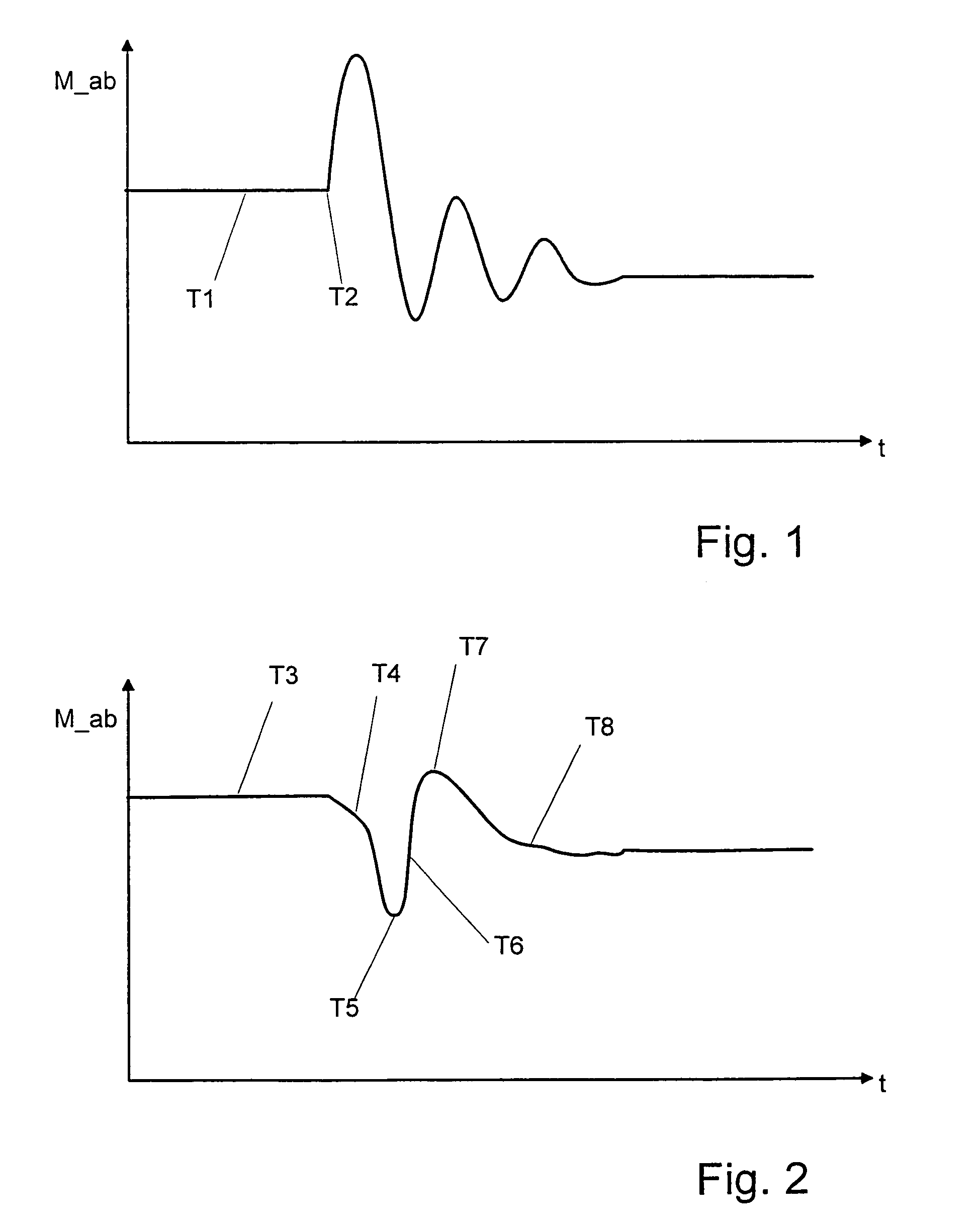

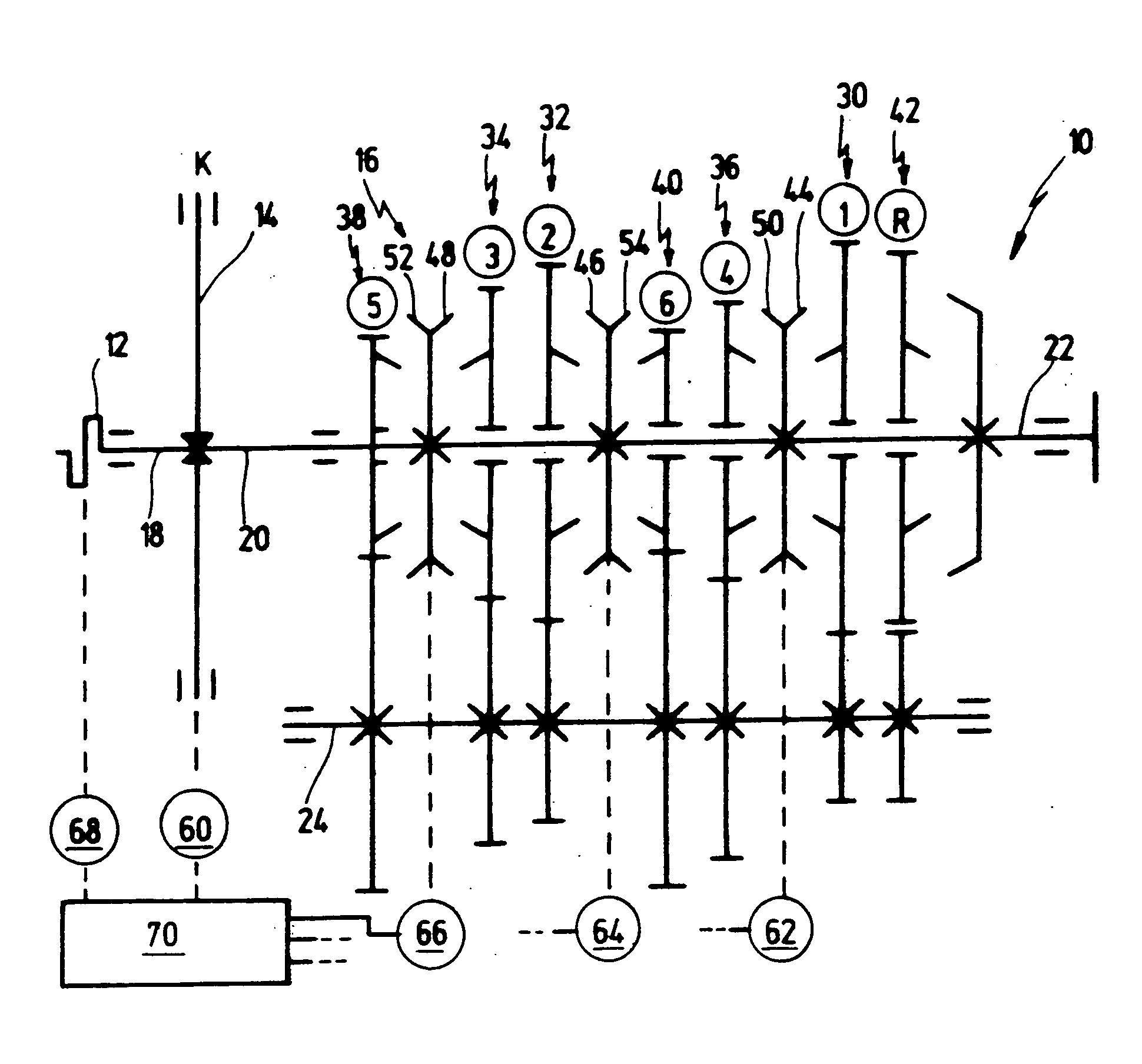

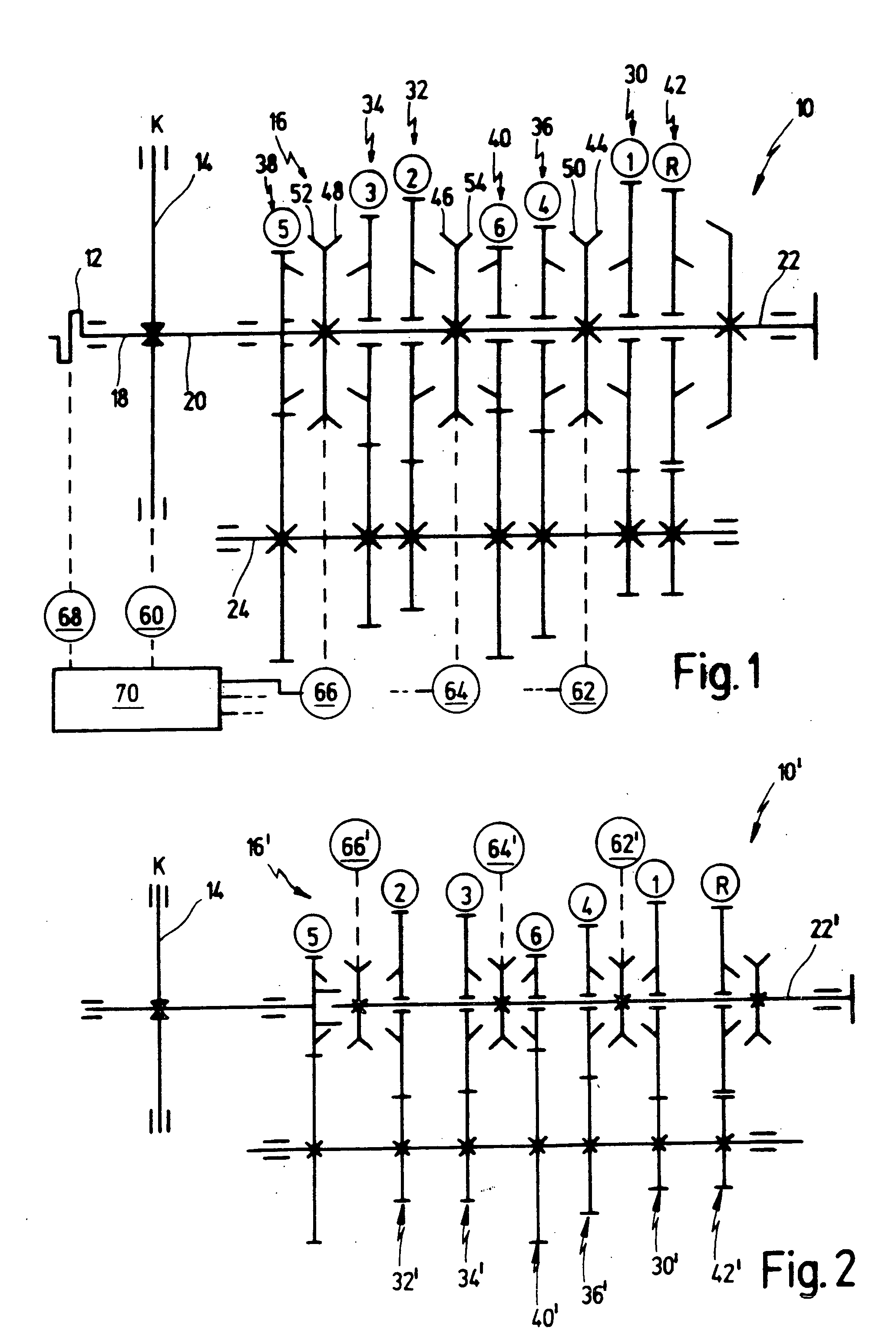

Method for controlling and regulating a drive train

InactiveUS6969338B2Avoid disturbanceIncrease loadElectrical controlToothed gearingsFreewheelGear wheel

Described is a method for controlling and regulating a drive train of a vehicle comprising one drive unit, one transmission and one output unit. The transmission has controllable free-wheel device corresponding with toothed wheel pairs for disconnecting or connecting an old or a new gear and located on the input side one clutch. In the presence of a shifting signal for carrying out a higher traction shift, an input torque of the drive unit is quickly reduced so that a first vibration is induced in the drive unit. During a subsequent shifting, an operative connection is abruptly created between a free-wheel device and a toothed wheel pair corresponding therewith in a manner such that a second vibration counteracting the first vibration is produced in the drive train. With the engagement of the new gear the operative connection of the old gear is canceled as a result of a torque reversal from a pull torque to a push torque.

Owner:ZF FRIEDRICHSHAFEN AG

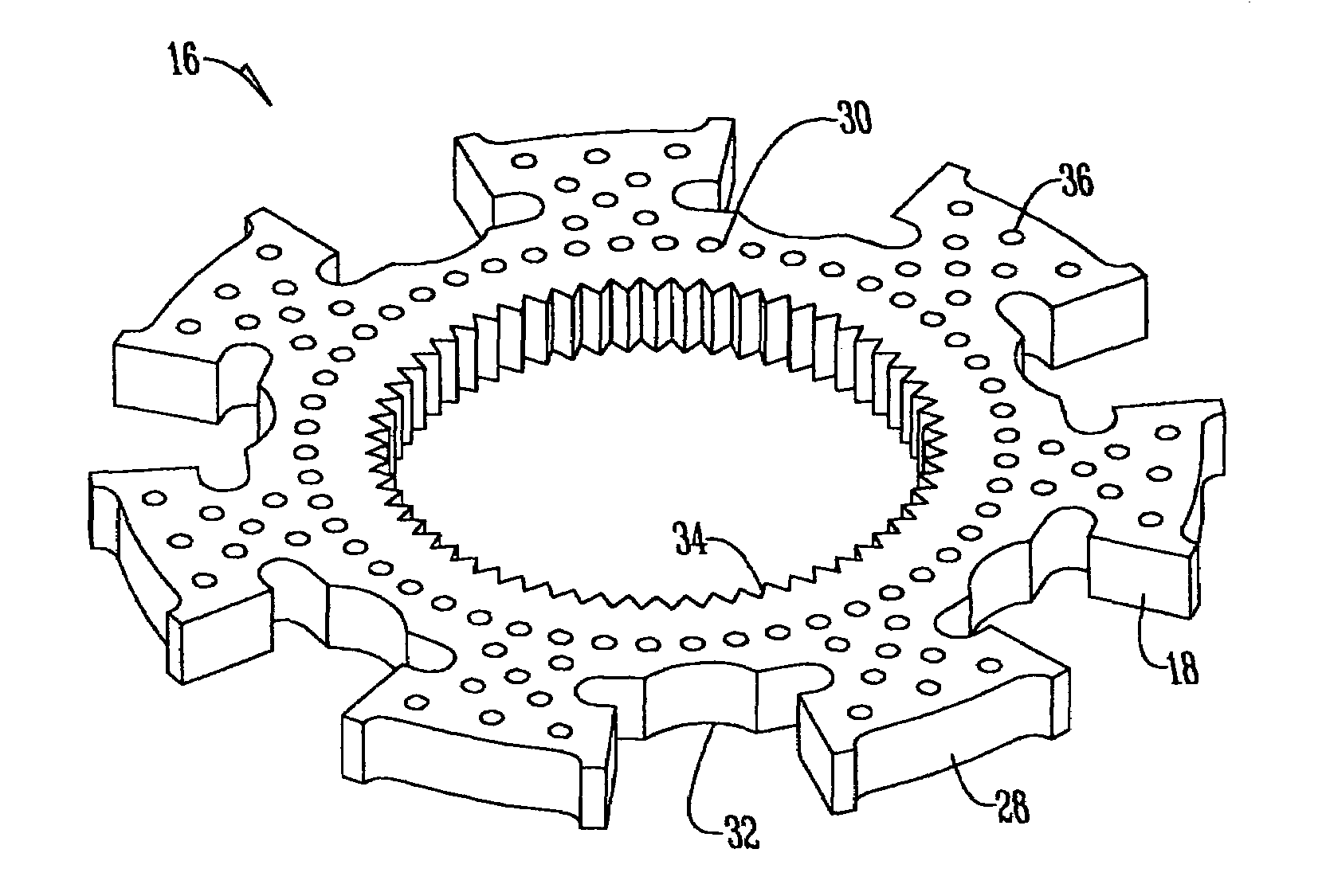

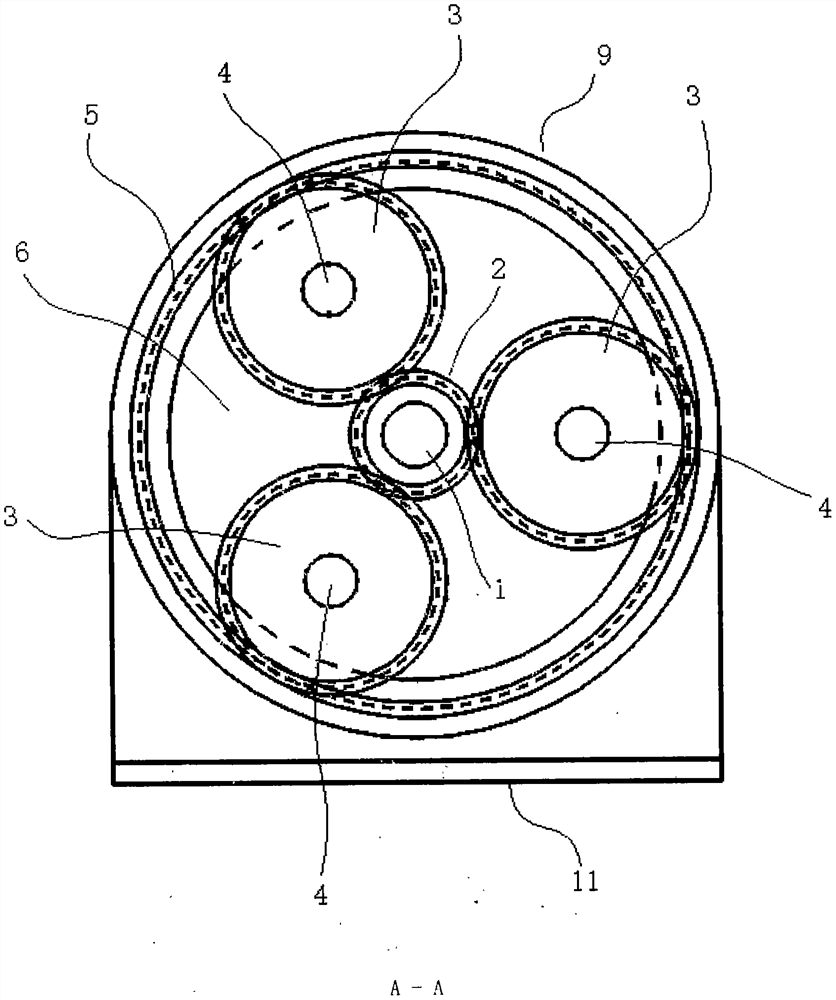

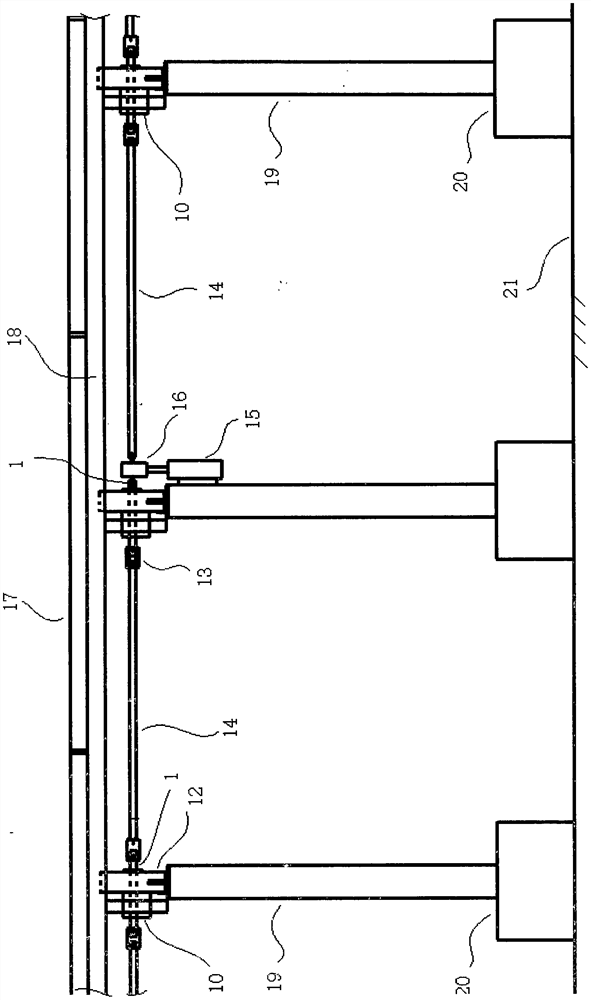

Low input torque rotor for vane pump

InactiveUS7467935B2Reduce shear forceReduce input torqueOscillating piston enginesRotary piston pumpsDrive shaftLow input

Owner:DANFOSS POWER SOLUTIONS INC

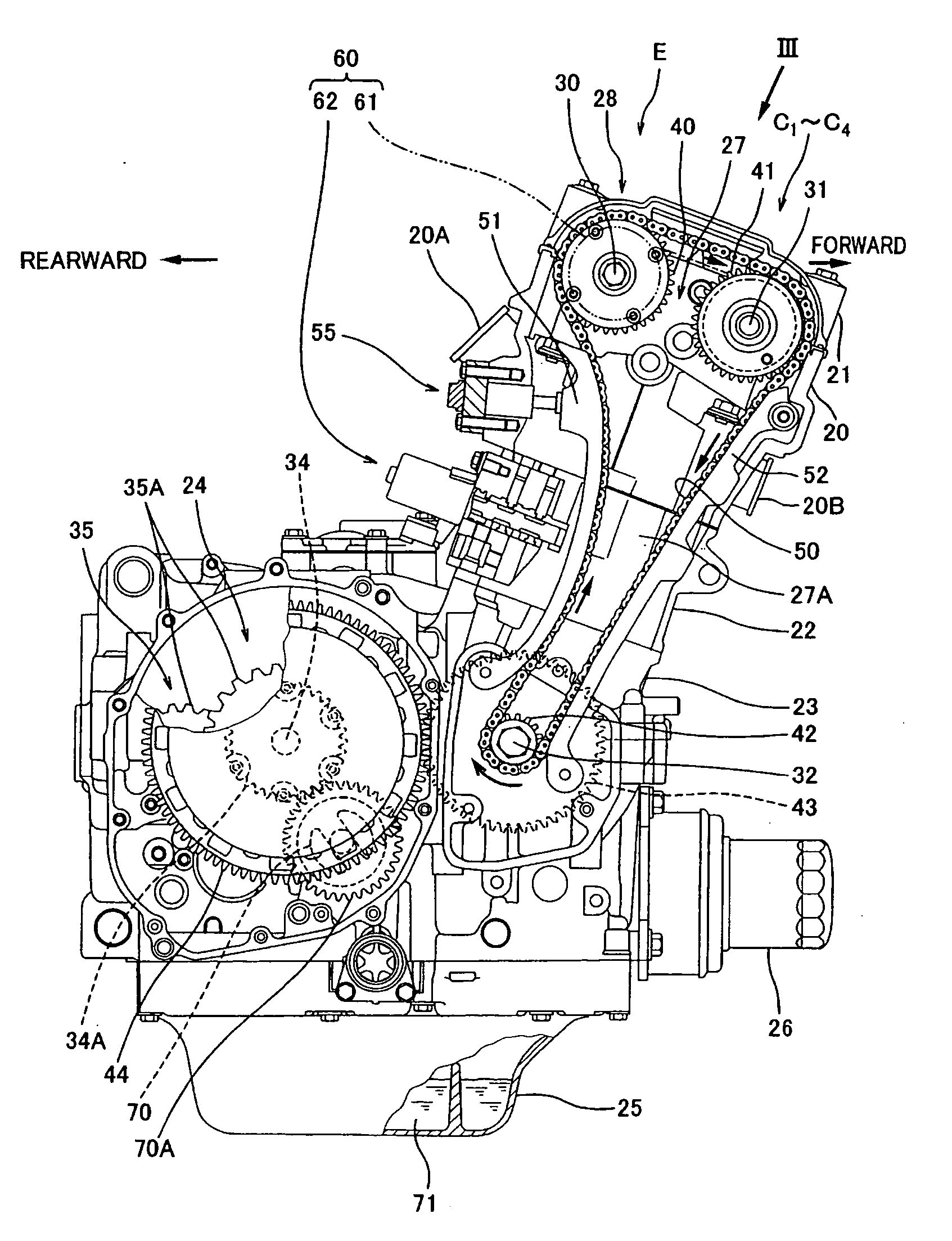

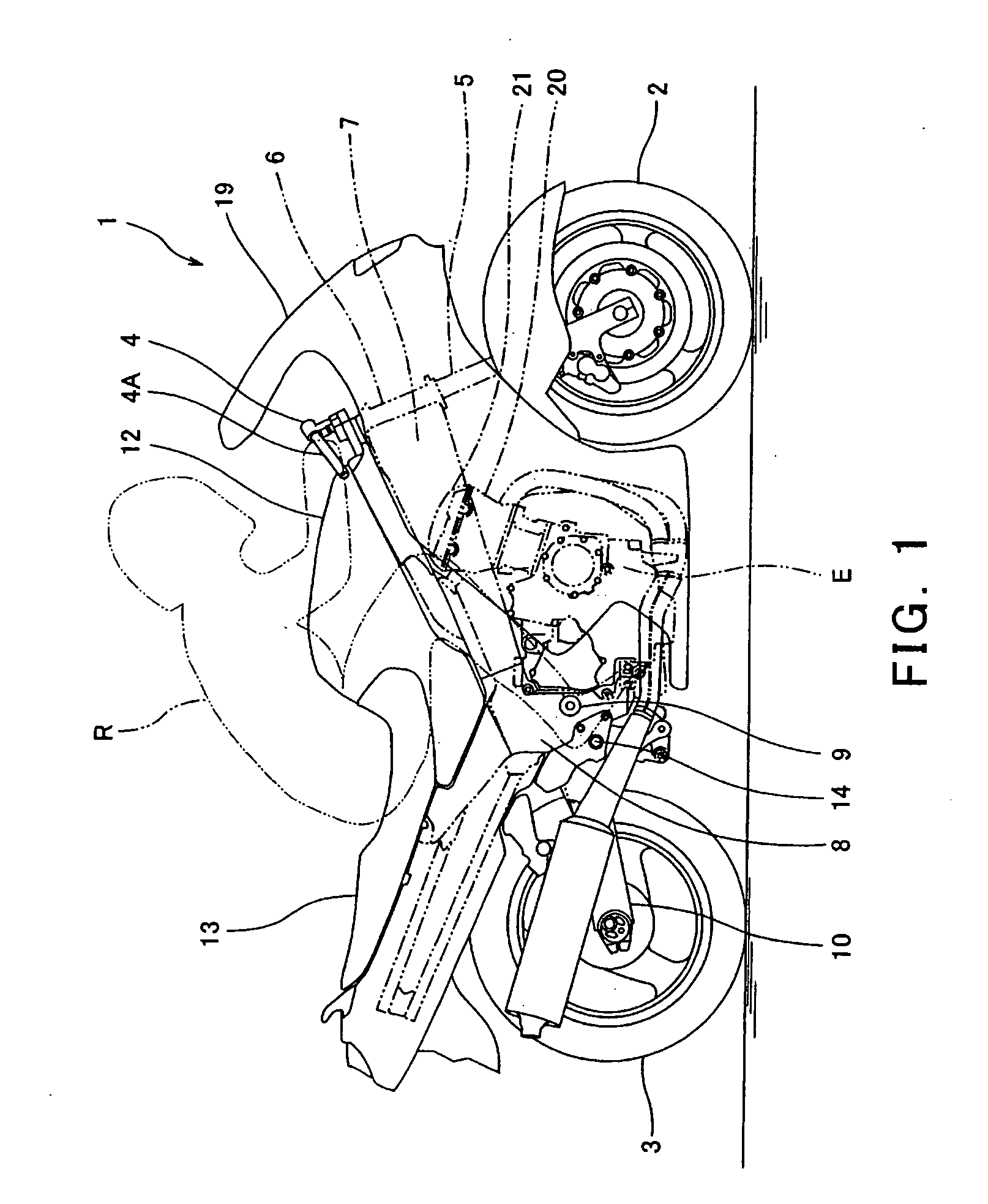

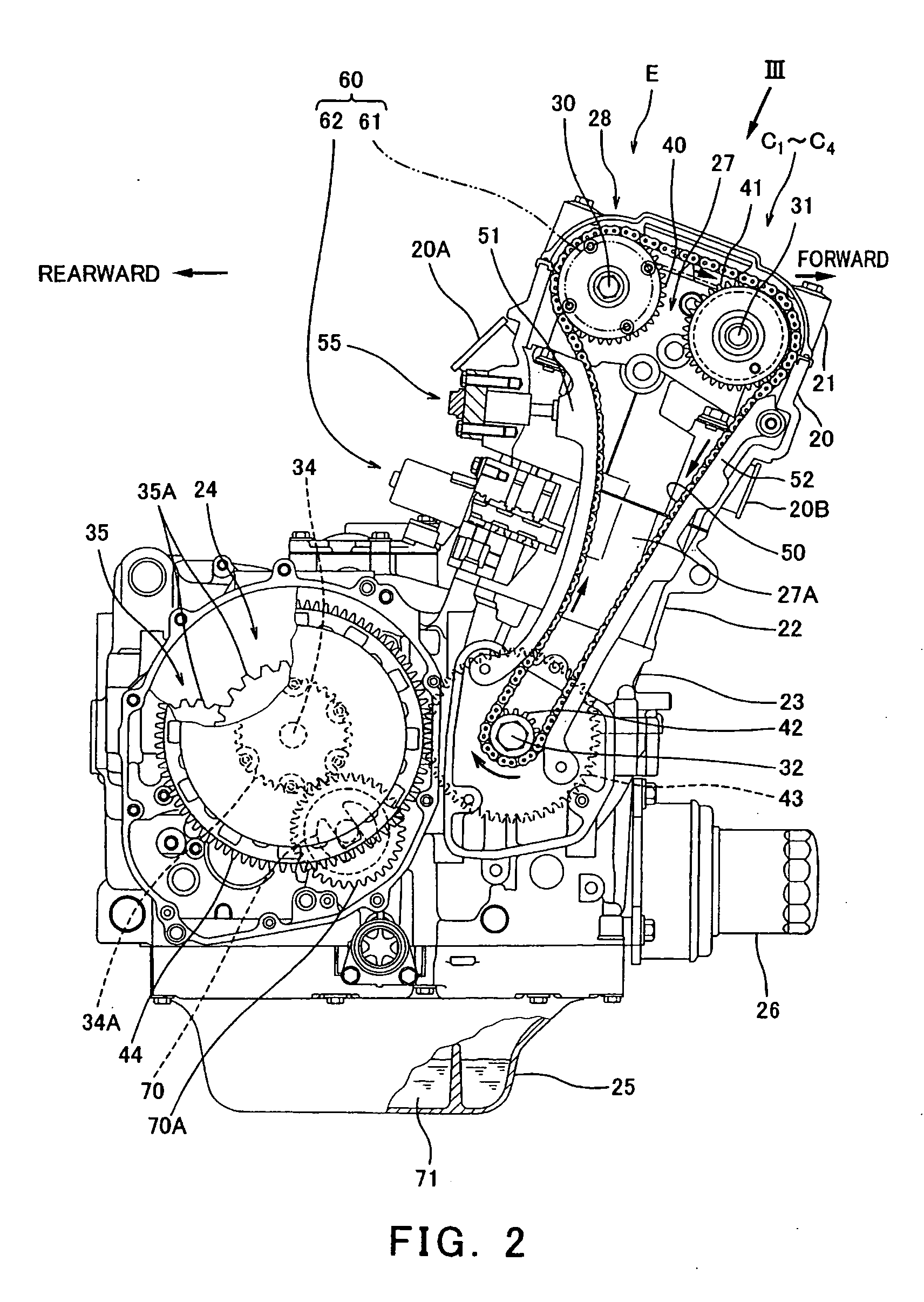

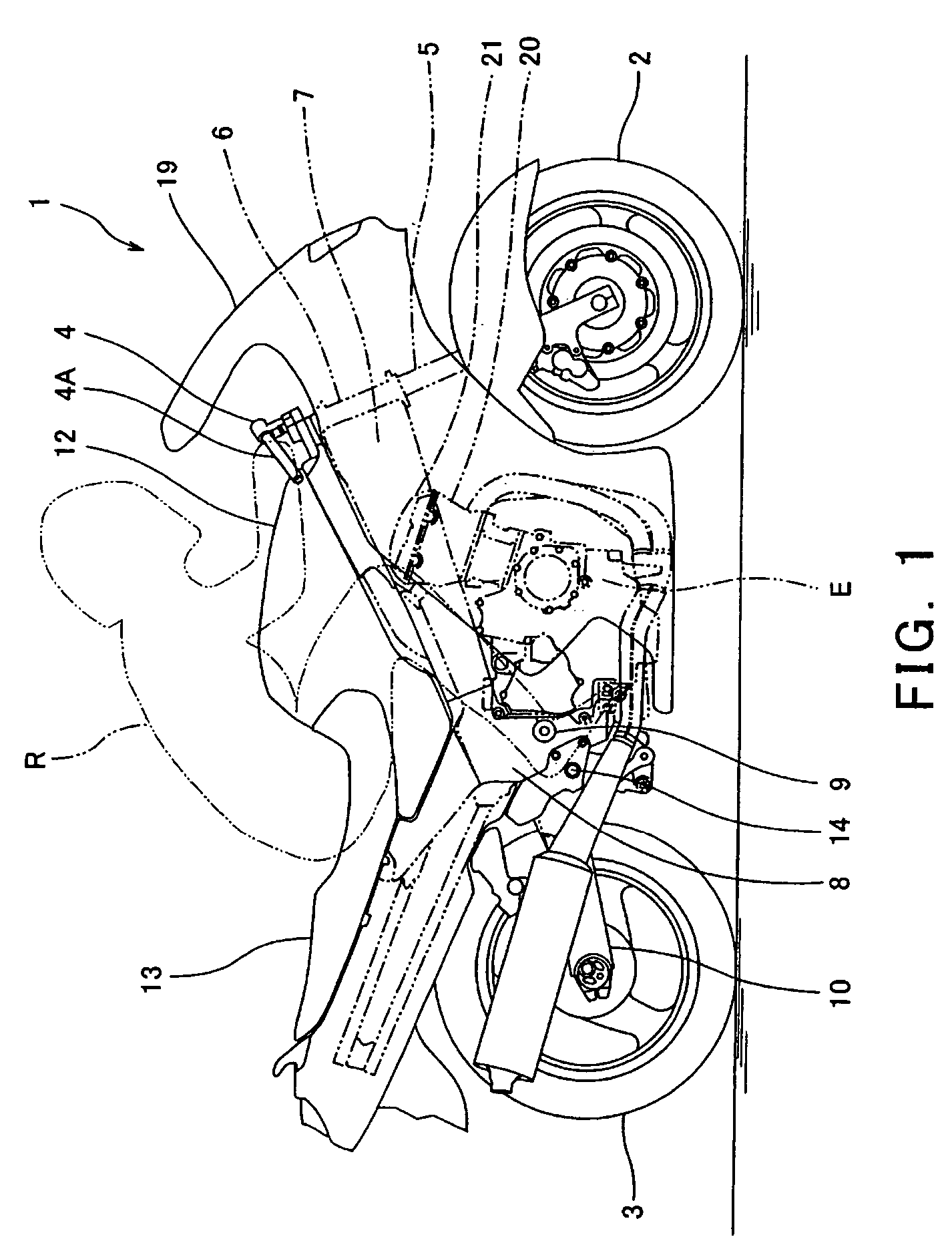

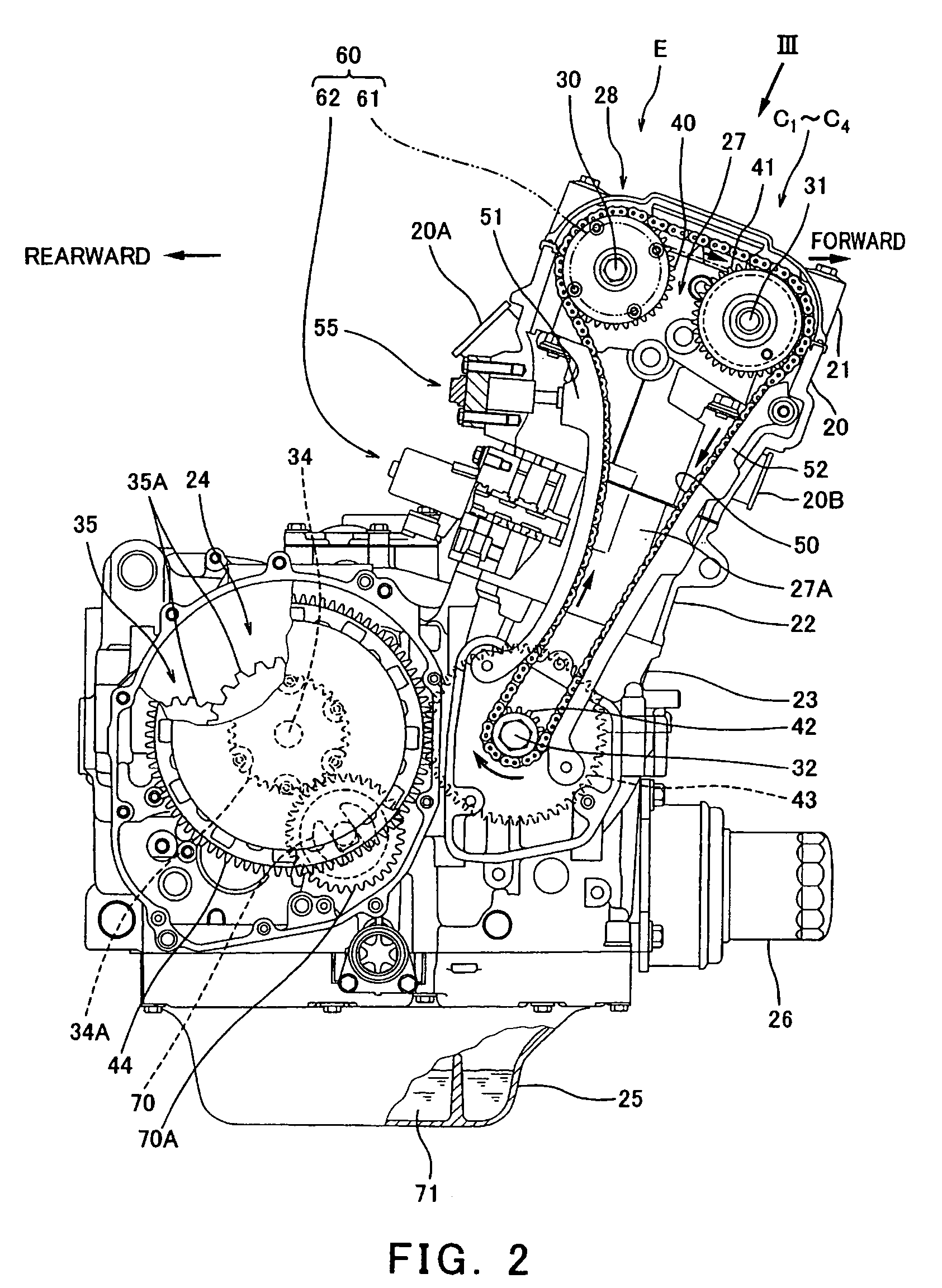

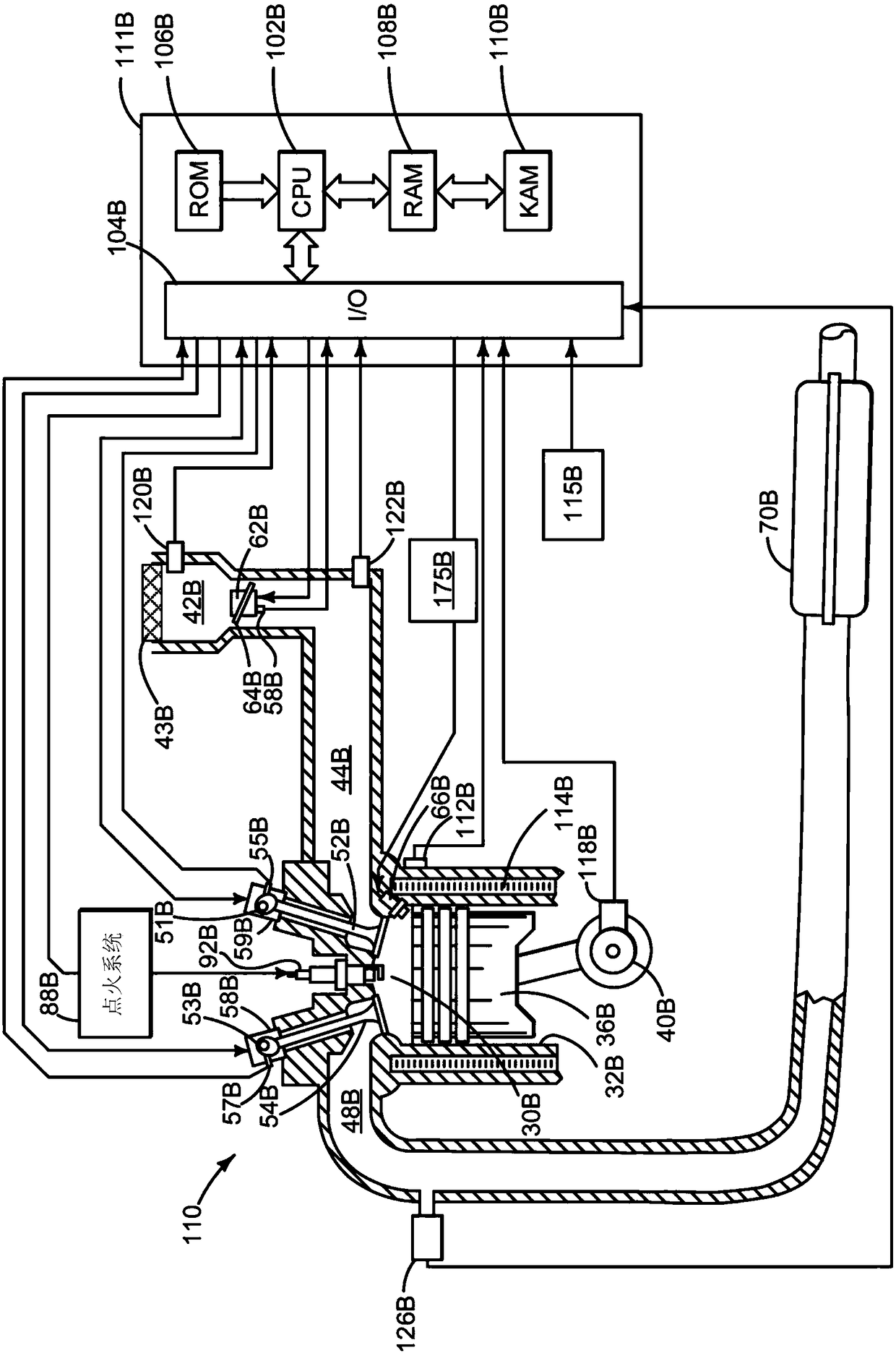

Engine

ActiveUS20070157900A1Reduce total pressure lossLower oil temperatureLubrication of auxillariesValve drivesPetroleum engineering

An engine including an oil passage through which oil output from an oil pump flows, an oil cooler mounted to the oil passage, and a branched oil passage for a hydraulically-powered device of the engine that is configured to branch in a location of the oil passage extending from the oil pump to the oil cooler to deliver the oil to the hydraulically-powered device.

Owner:KAWASAKI MOTORS LTD

Method and system for improving gear shift of gear box

InactiveCN103381816ASmall torqueKeep acceleratingVehicle sub-unit featuresGearing controlControl theoryHybrid vehicle

Owner:FORD GLOBAL TECH LLC

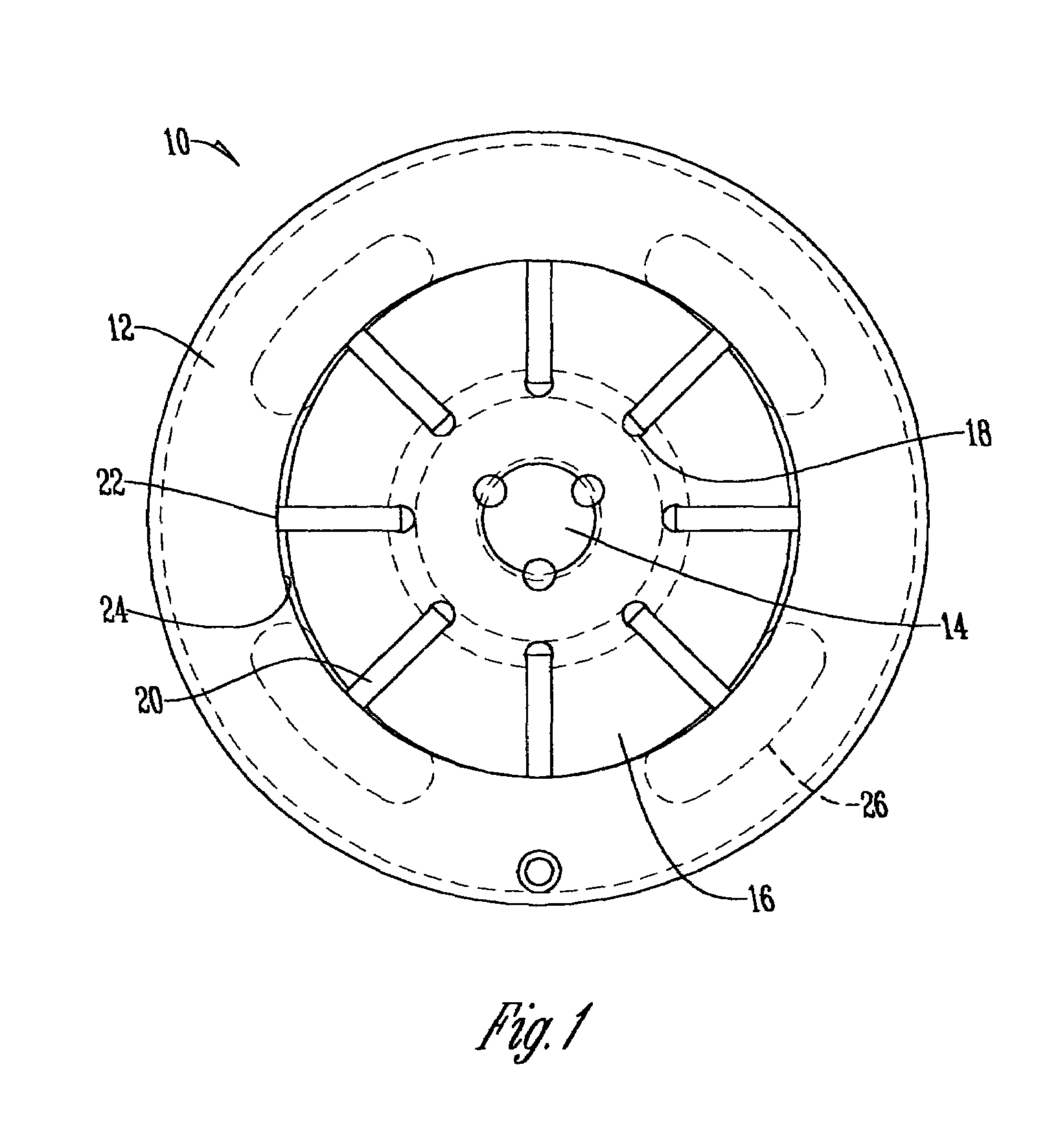

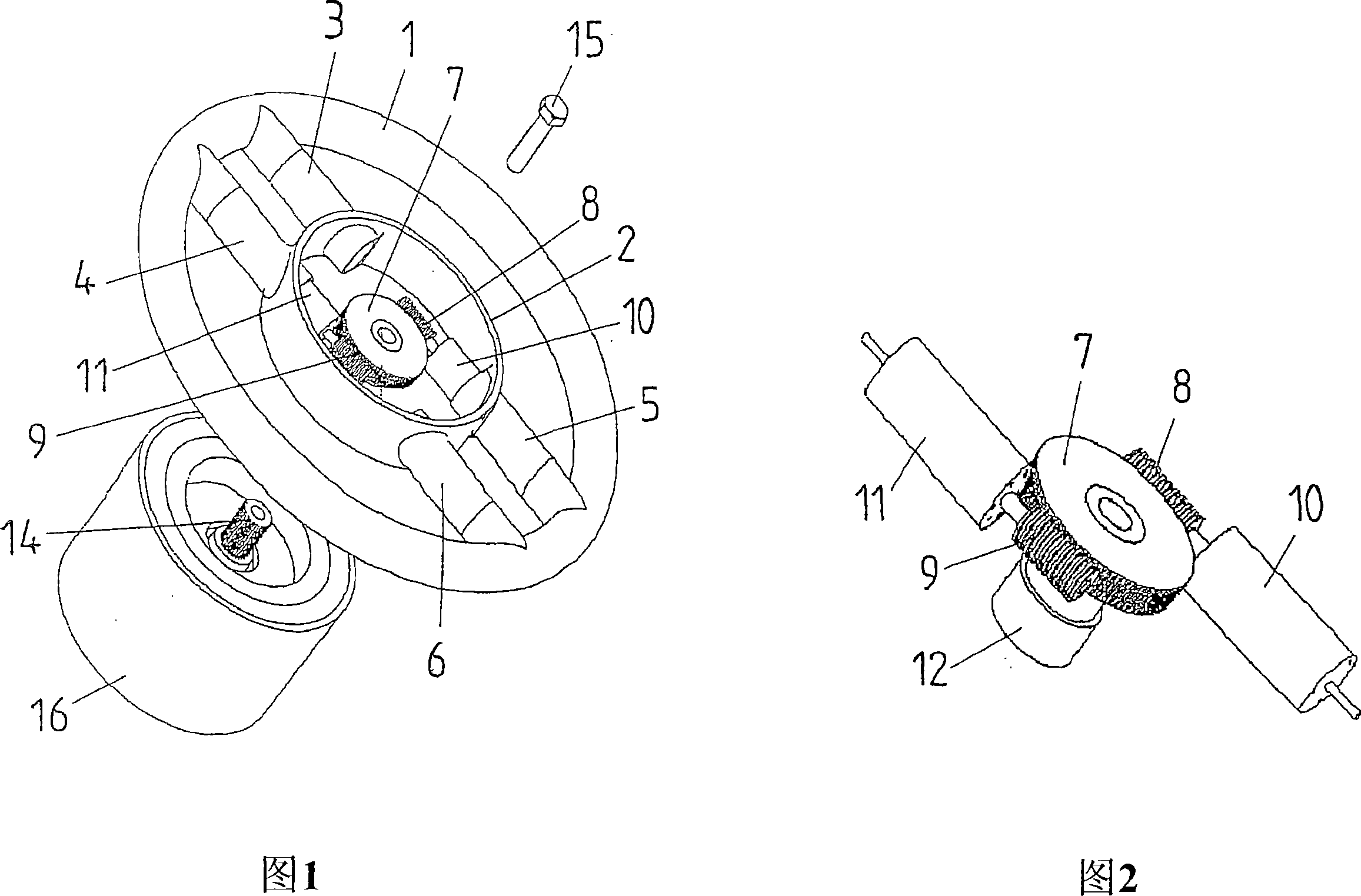

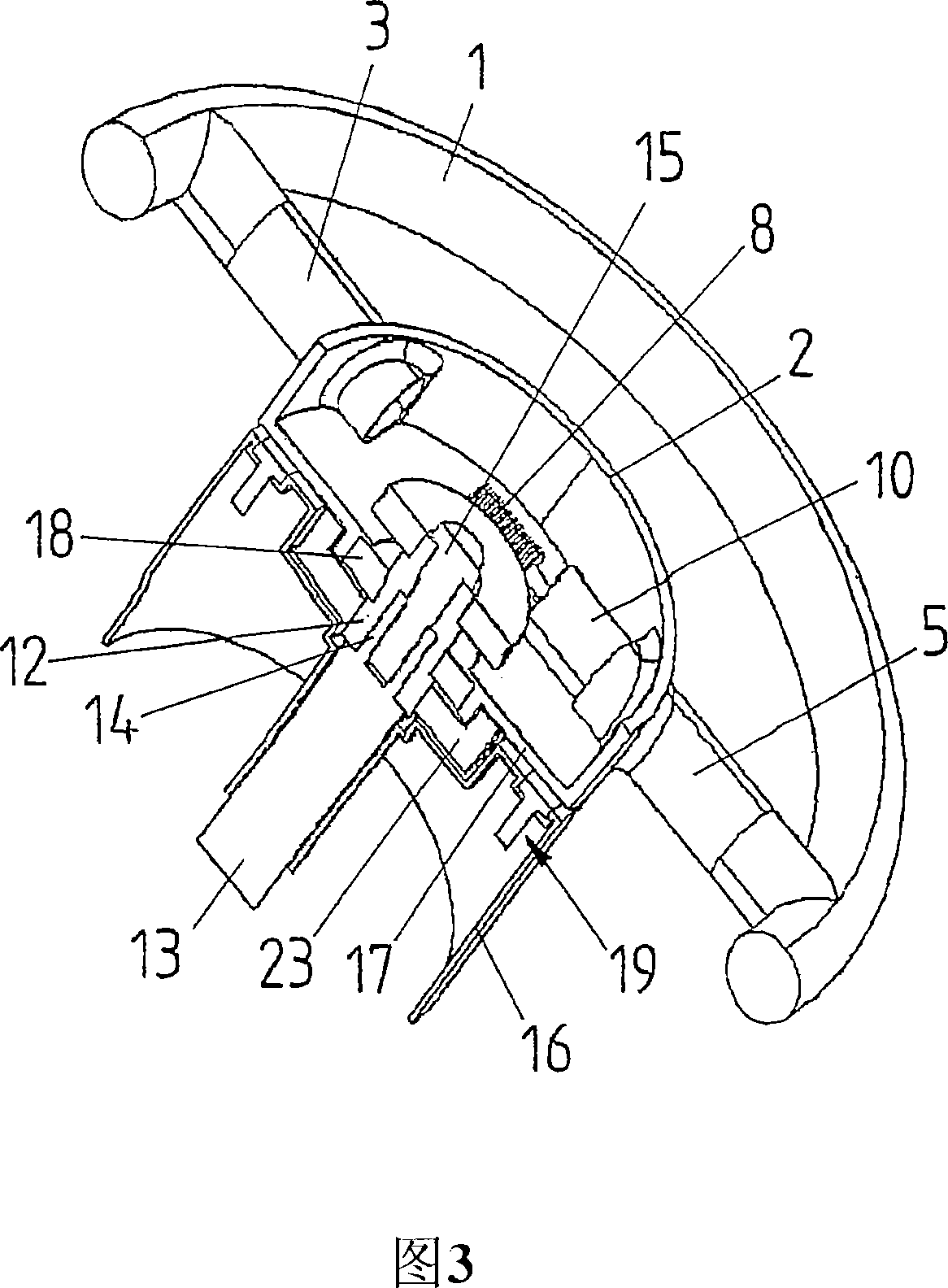

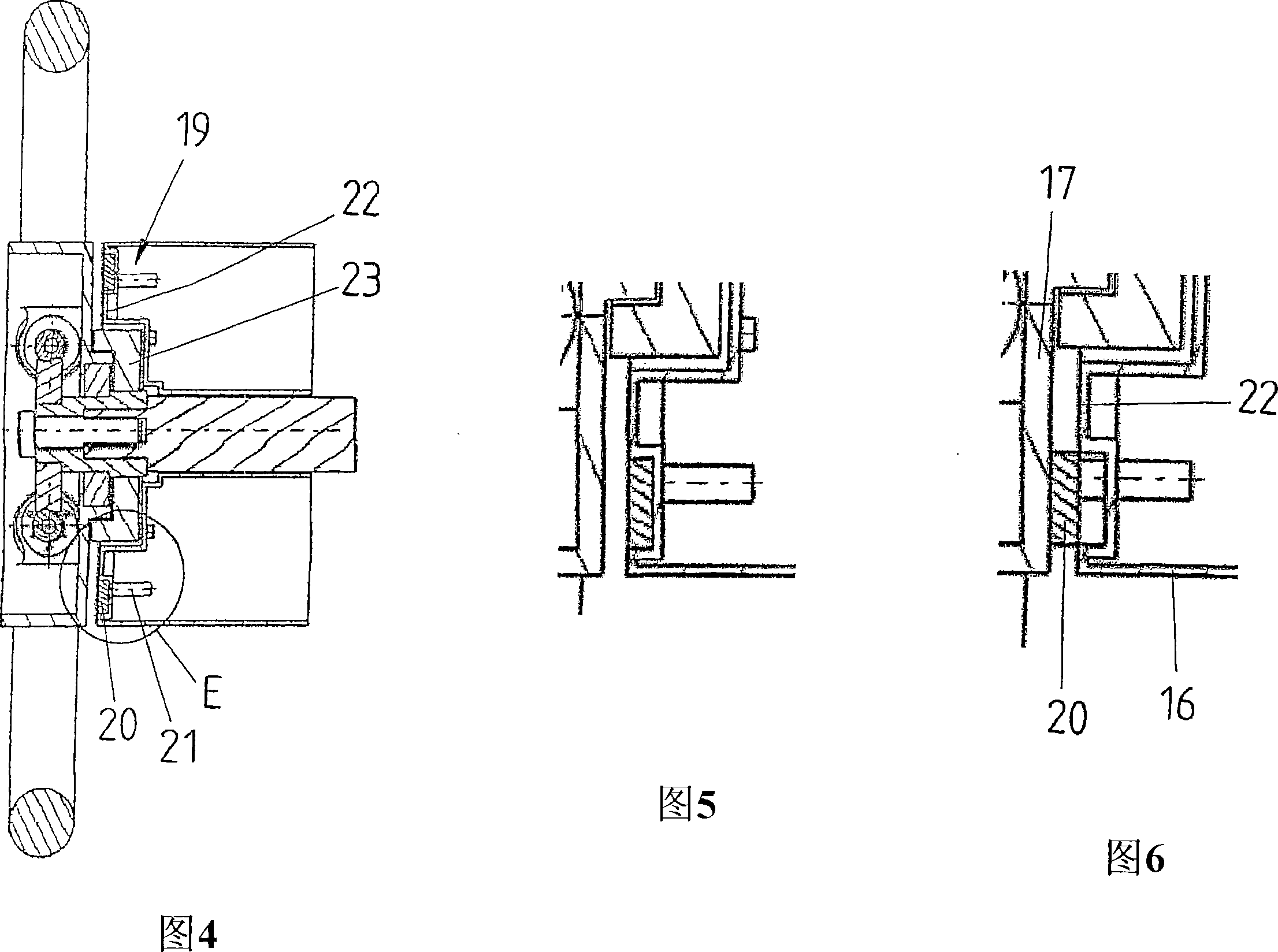

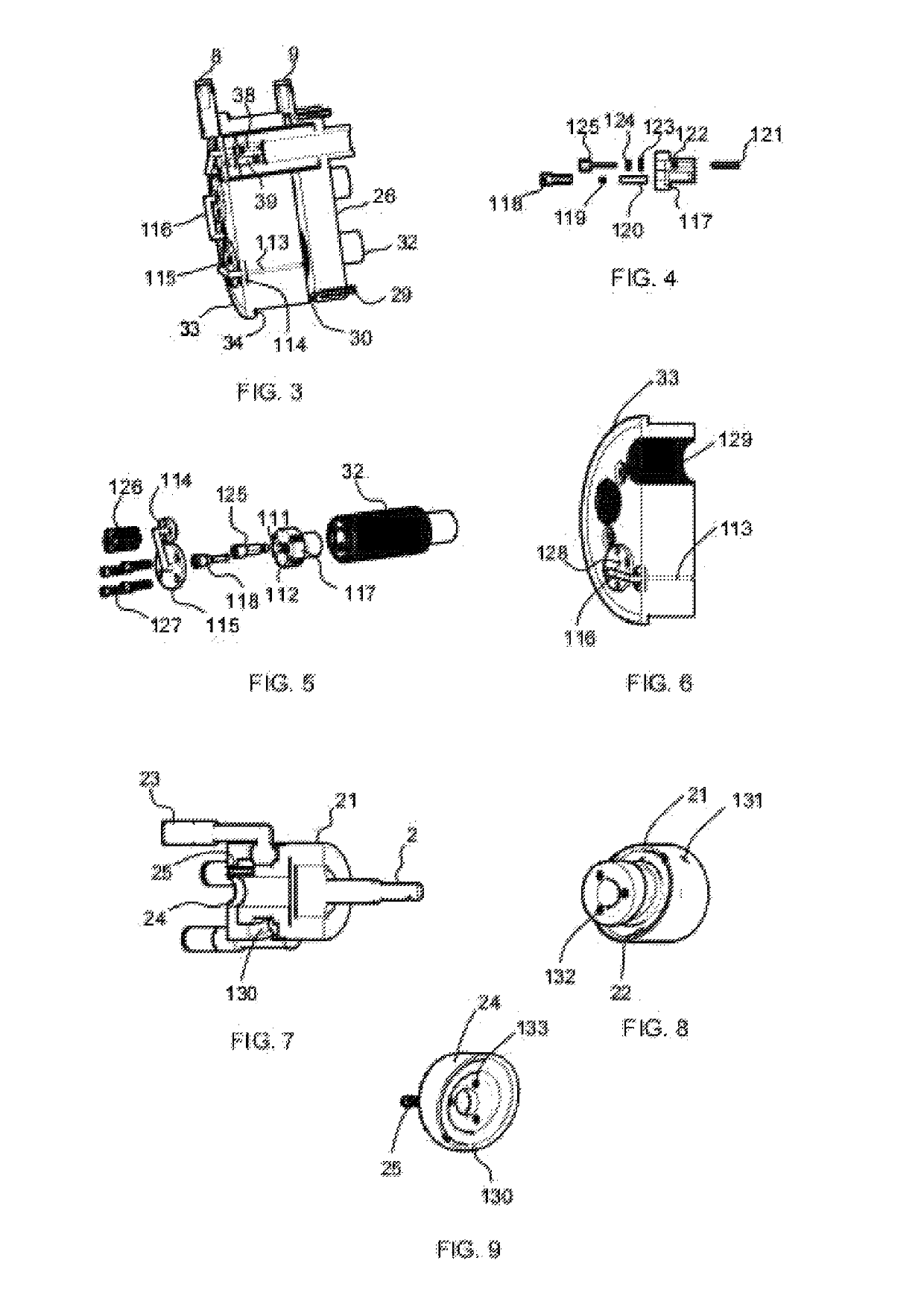

Steering device for a superposition steering system

ActiveCN101198508AImprove bindingLarge leadHand wheelsElectrical steeringSteering columnSteering wheel

The invention relates to a steering device for a superposition steering system using at least one actuator. The invention is based on the object of producing a superposition steering system which requires no additional installation space in the steering column. According to the invention, the actuator (7-11) for the superposition steering system is therefore arranged in the steering wheel (1, 2).

Owner:JOYSON SAFETY SYST GERMANY GMBH

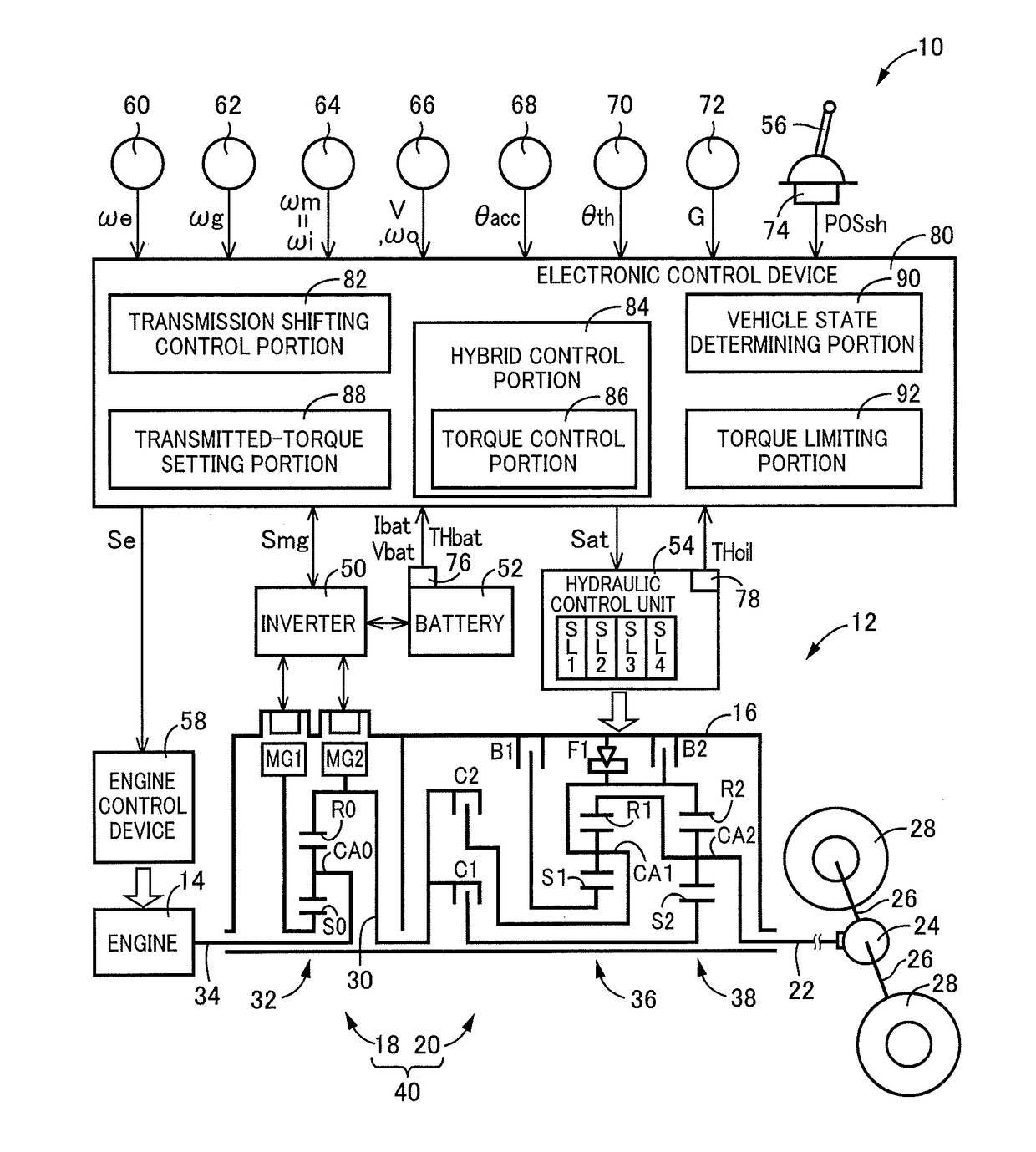

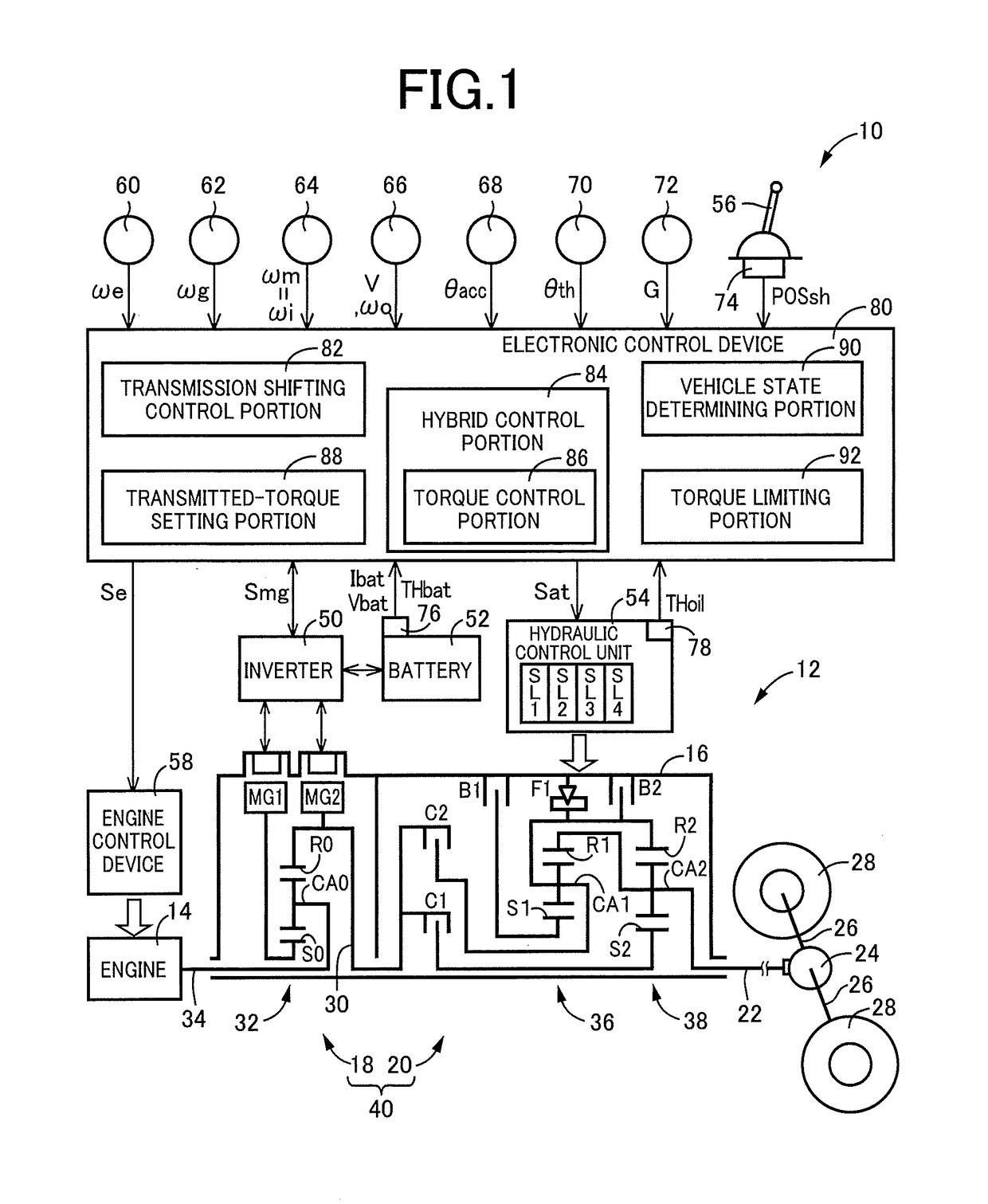

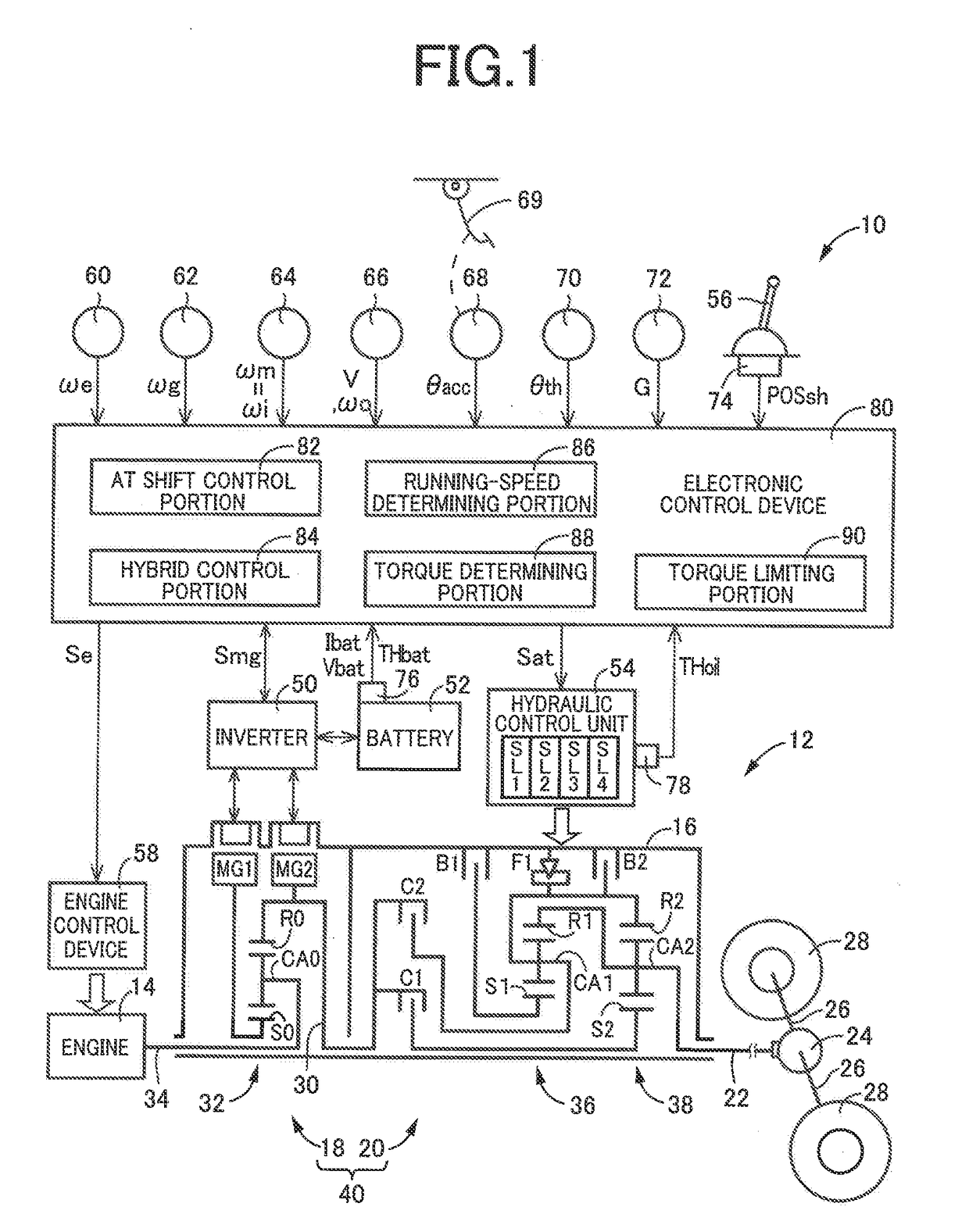

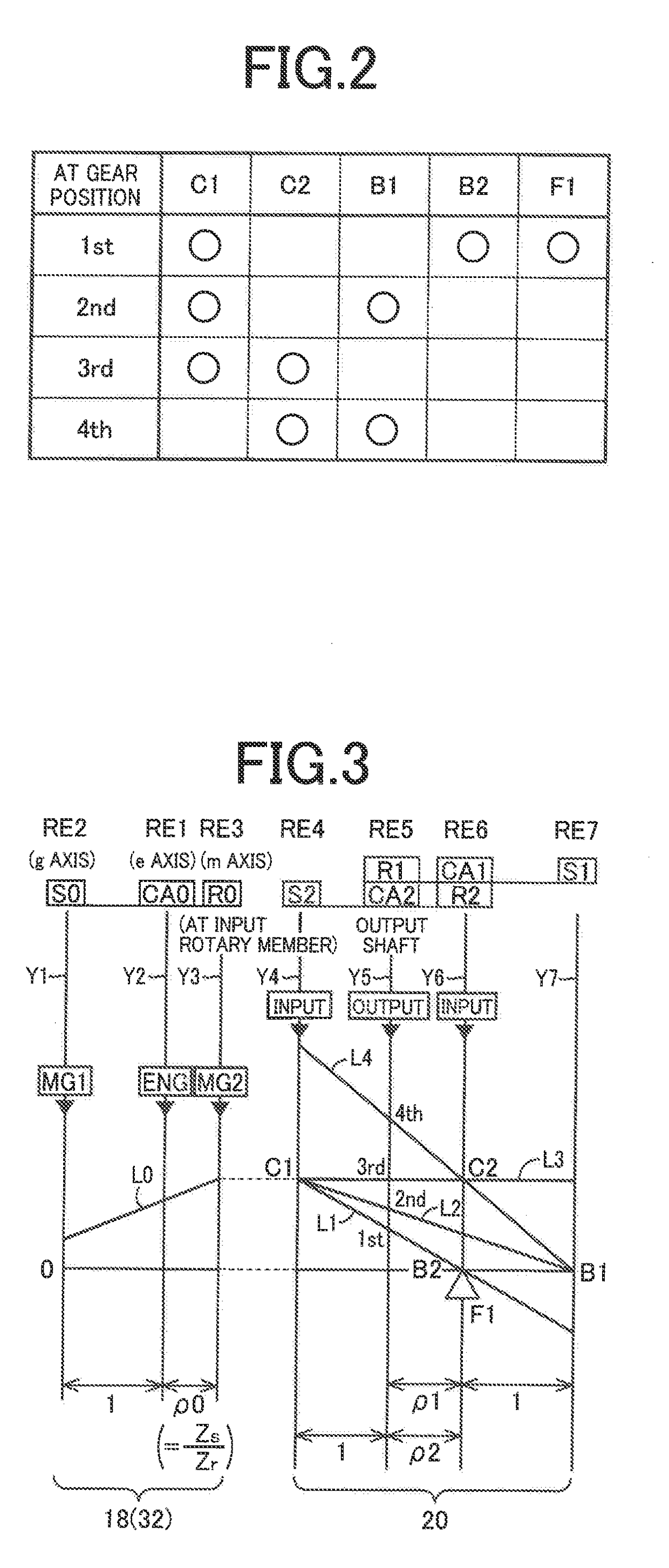

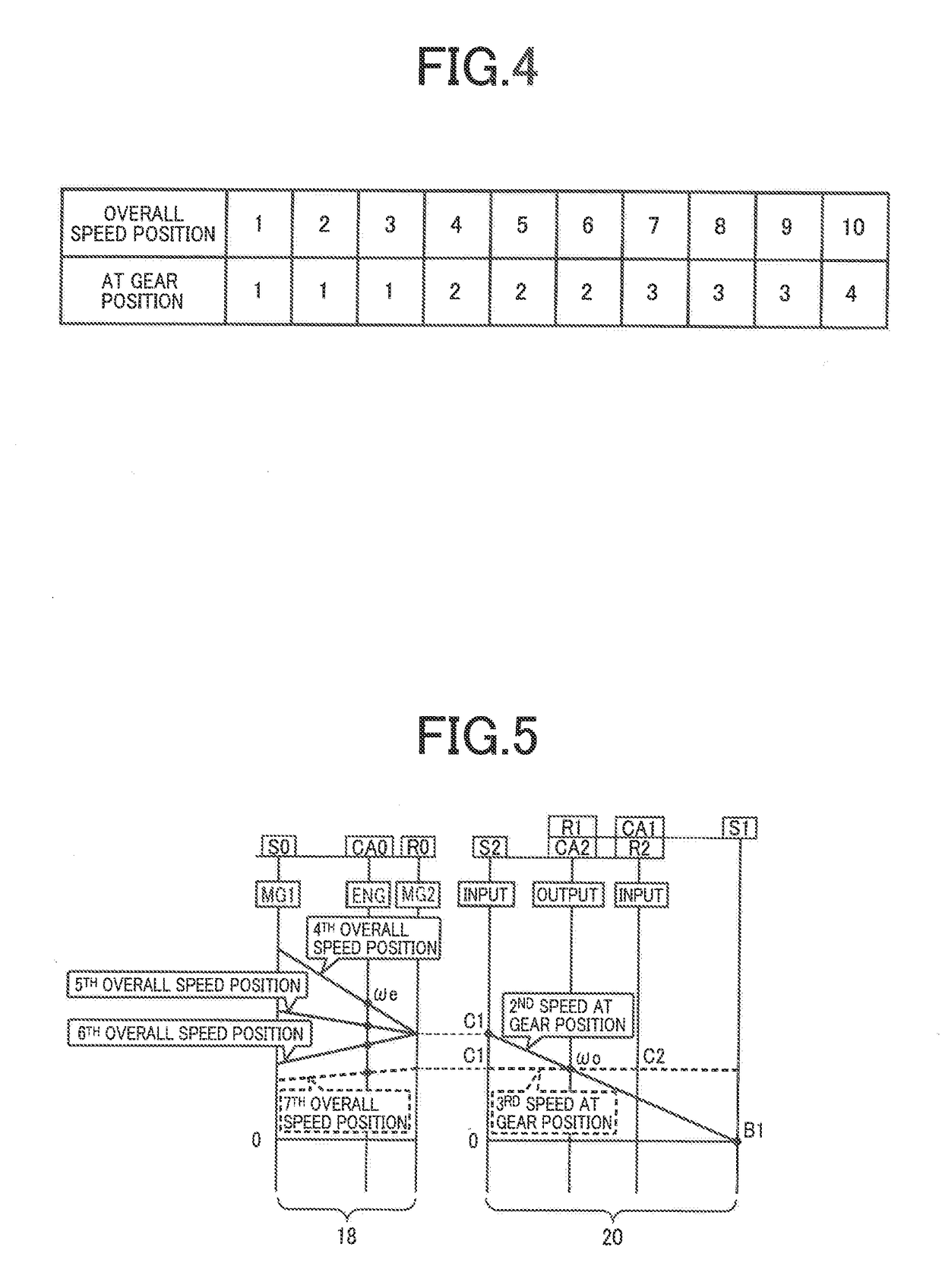

Vehicle control apparatus

ActiveUS20180170390A1Reduce riskReduce the amount requiredHybrid vehiclesPropulsion using engine-driven generatorsLower limitDrive wheel

A control apparatus (80; 122) for a vehicle provided with a motor / generator (MG2; MG) functioning as a drive power source, and a step-variable transmission (20; 110) which constitutes a part of a power transmitting path between the drive power source and drive wheels (28; 116) and which is placed in a selected one of a plurality of speed positions with engagement of a selected one or ones of a plurality of coupling devices (CB). The control apparatus includes: a torque control portion (86) configured to control an output torque (Ti) of the drive power source (MG2) during a shifting action of the step-variable transmission (40; 110) from one of the speed positions to another of the speed positions, on the basis of a required vehicle drive torque (Tidem) corresponding to an operation amount (θacc) of an accelerator pedal, such that a value representing a state of a rotary motion of an input rotary member (30) of the step-variable transmission coincides with a target value; and a torque limiting portion (92) configured to limit the required vehicle drive torque to a predetermined lower limit value (Tif) in the process of a shift-up action of the step-variable transmission which is performed by placement of the accelerator pedal in an operated position.

Owner:TOYOTA JIDOSHA KK

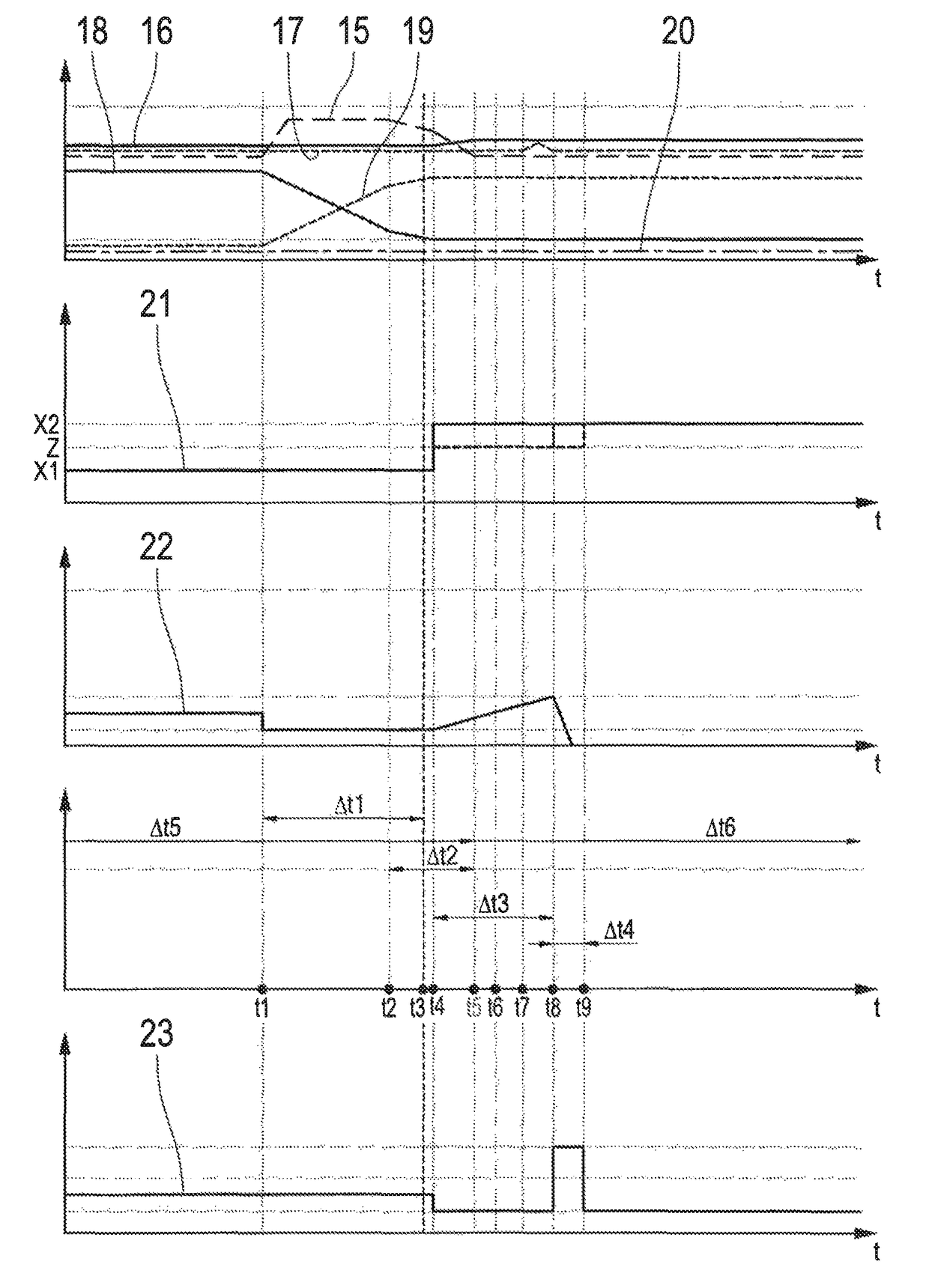

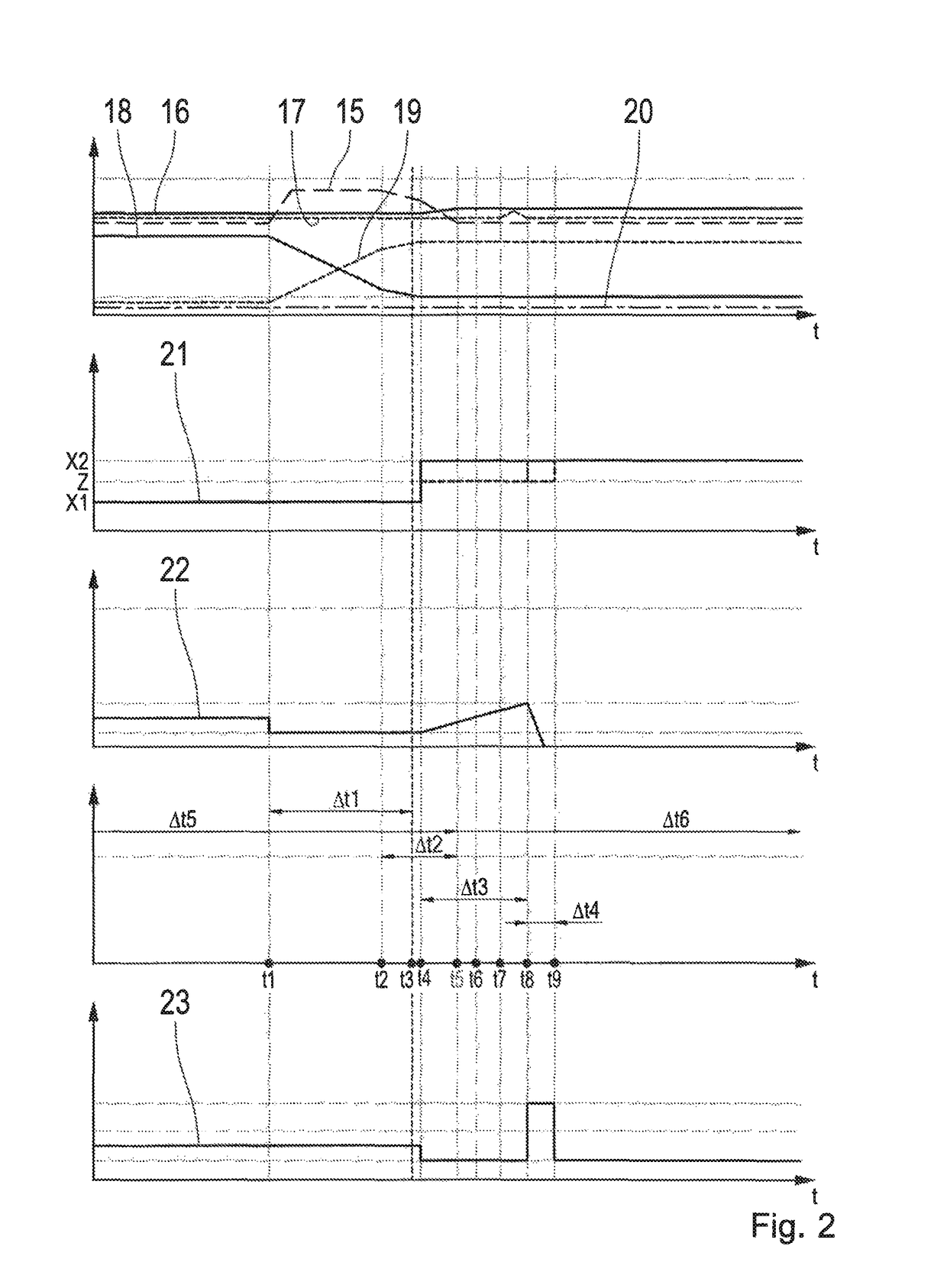

Method for executing a gearshift in an automatic transmission

ActiveUS9625032B2Increase operating pressureReduce risk of damageToothed gearingsGearing controlAutomatic transmissionEngineering

A method is provided for executing a gearshift in an automatic transmission with several shifting elements. Upon the execution of the gearshift, a first frictional-locking shifting element is opened and a second positive-locking shifting element is closed. If, upon the execution of the gearshift, an input torque of the automatic transmission is less than a threshold value, after at least partially opening the frictional-locking shifting element and after releasing the positive-locking shifting element, there is a monitoring of whether the positive-locking shifting element is transferred into its end position. If it is then determined that the positive-locking shifting element is not in its end position, a torque transferred by the partially open frictional-locking shifting element initially increases. If, despite the increase in torque transferred by the frictional-locking shifting element, the positive-locking shifting element is not in its end position, the operating pressure of the positive-locking shifting element is then increased.

Owner:ZF FRIEDRICHSHAFEN AG

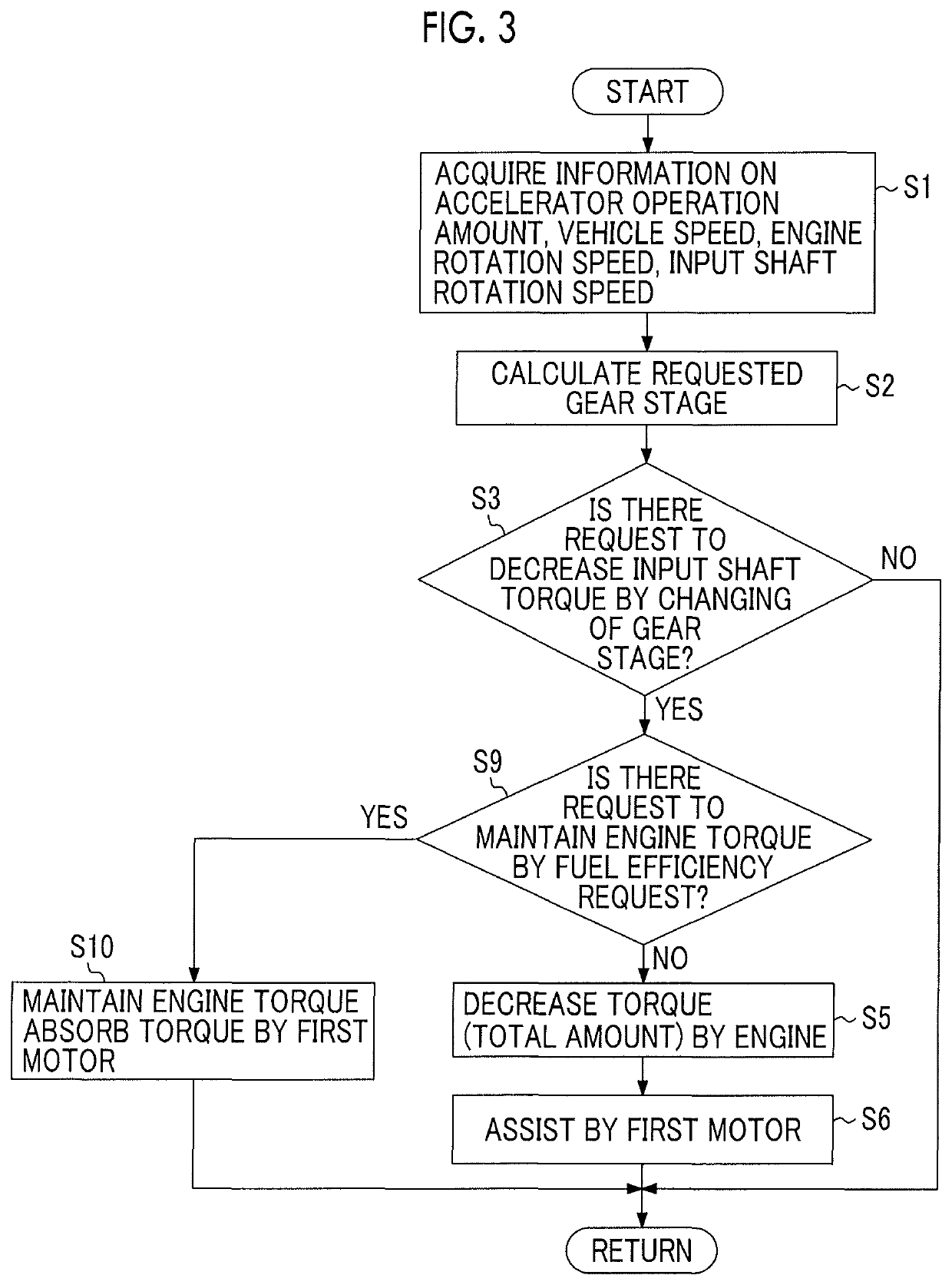

Vehicle control apparatus

ActiveUS20190061738A1Reduce detection accuracyImprove responsivenessHybrid vehiclesGas pressure propulsion mountingControl theoryVehicle control

A vehicle control apparatus selects one of a power-on control and a power-off control for execution of a shift-down action in a transmission of a vehicle, and implements the selected power-on or power-off control. When a running speed of the vehicle is not lower than a predetermined value, the control apparatus selects one of the power-on control and the power-off control, based on a target input torque that is to be inputted to the transmission. When the vehicle running speed is lower than the predetermined value, the control apparatus selects one of the power-on control and the power-off control, based on an actual input torque that is actually inputted to the transmission.

Owner:TOYOTA JIDOSHA KK +1

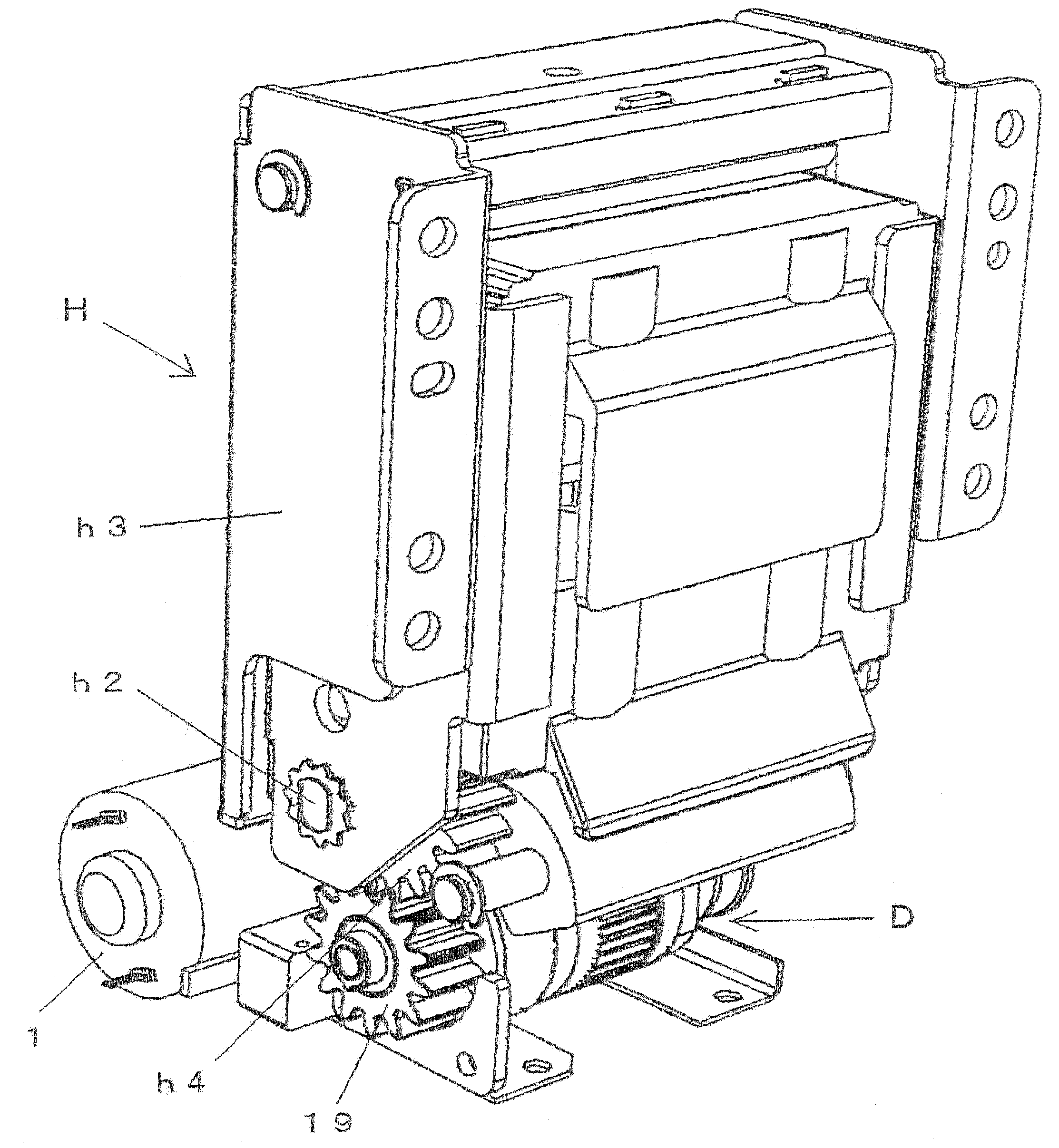

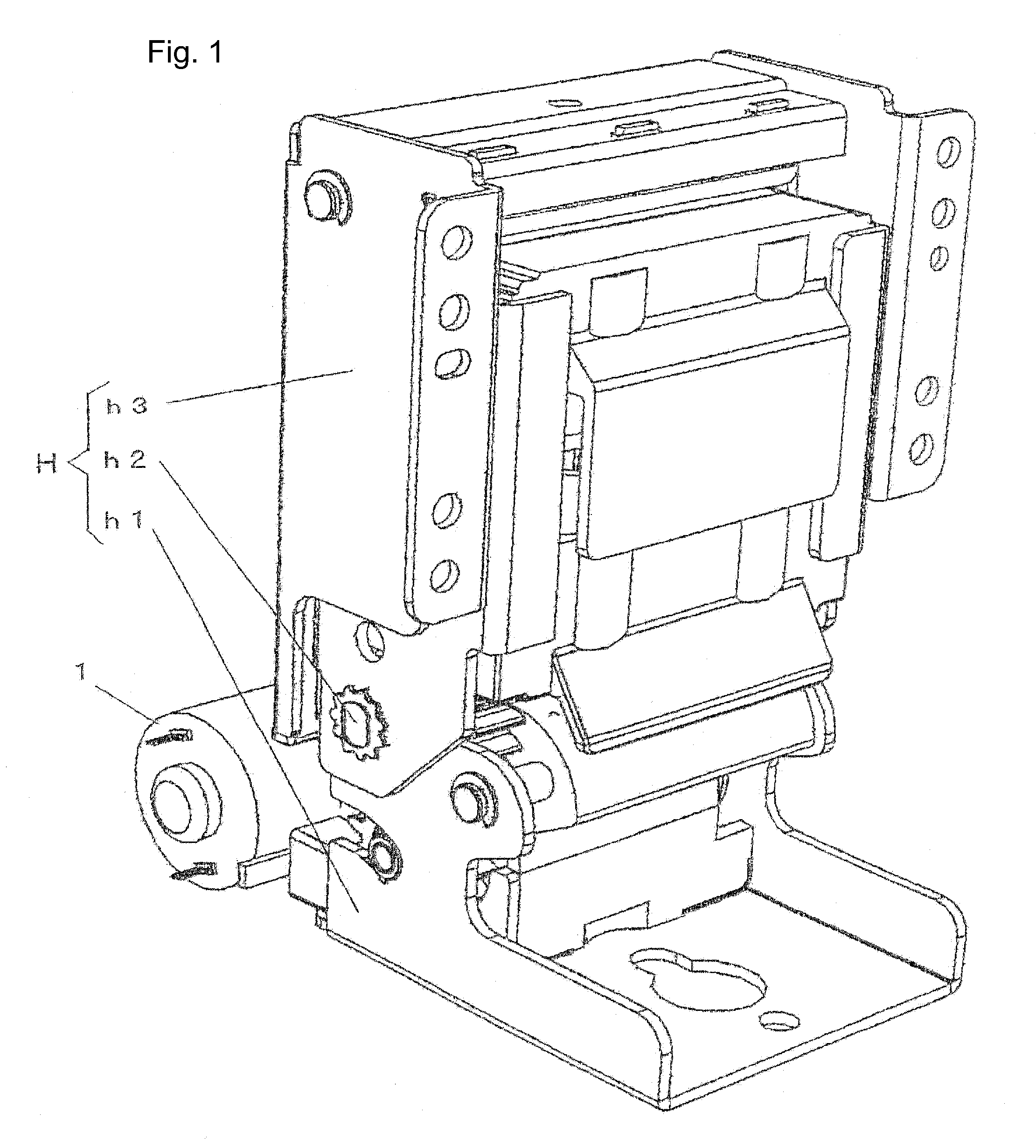

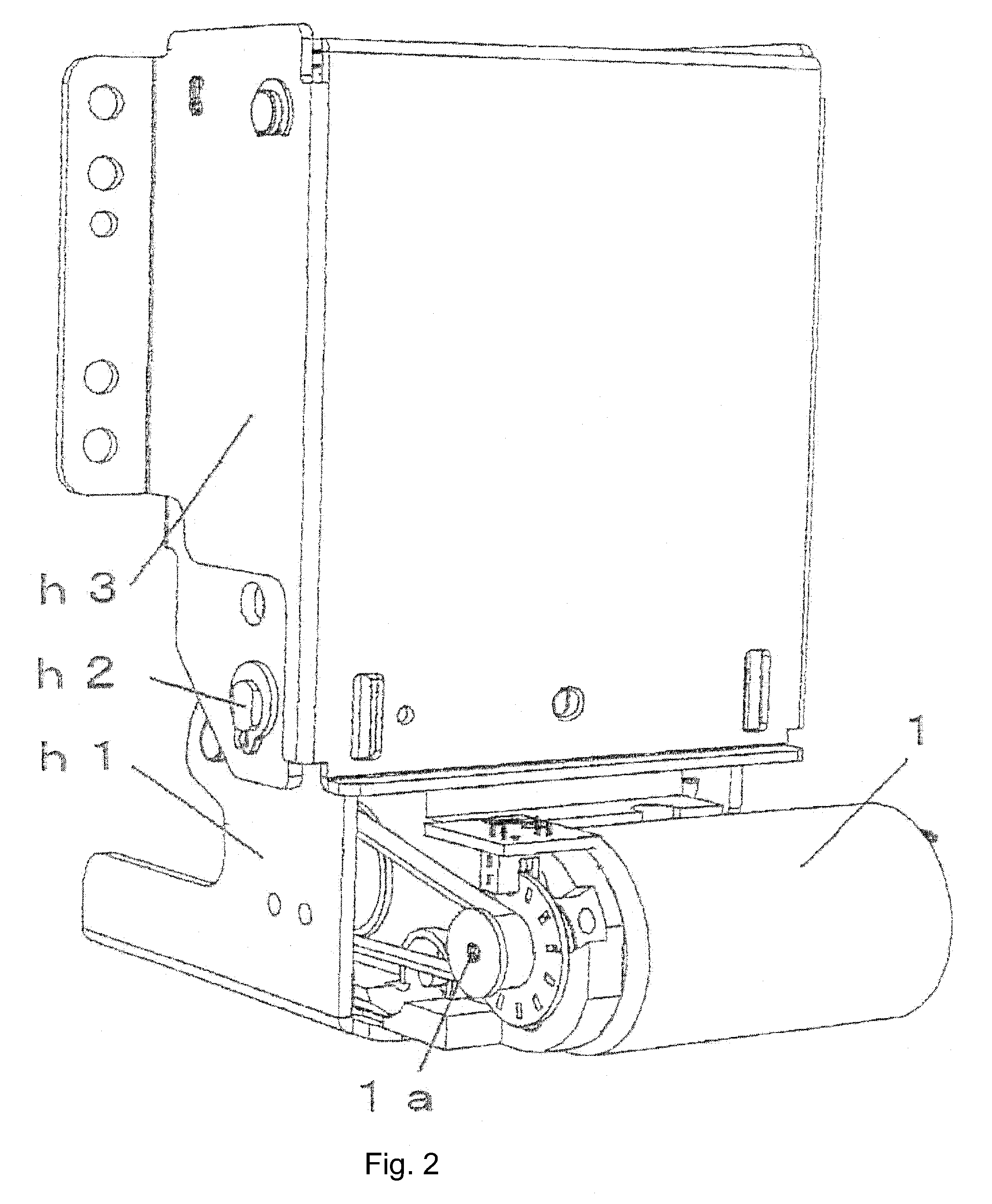

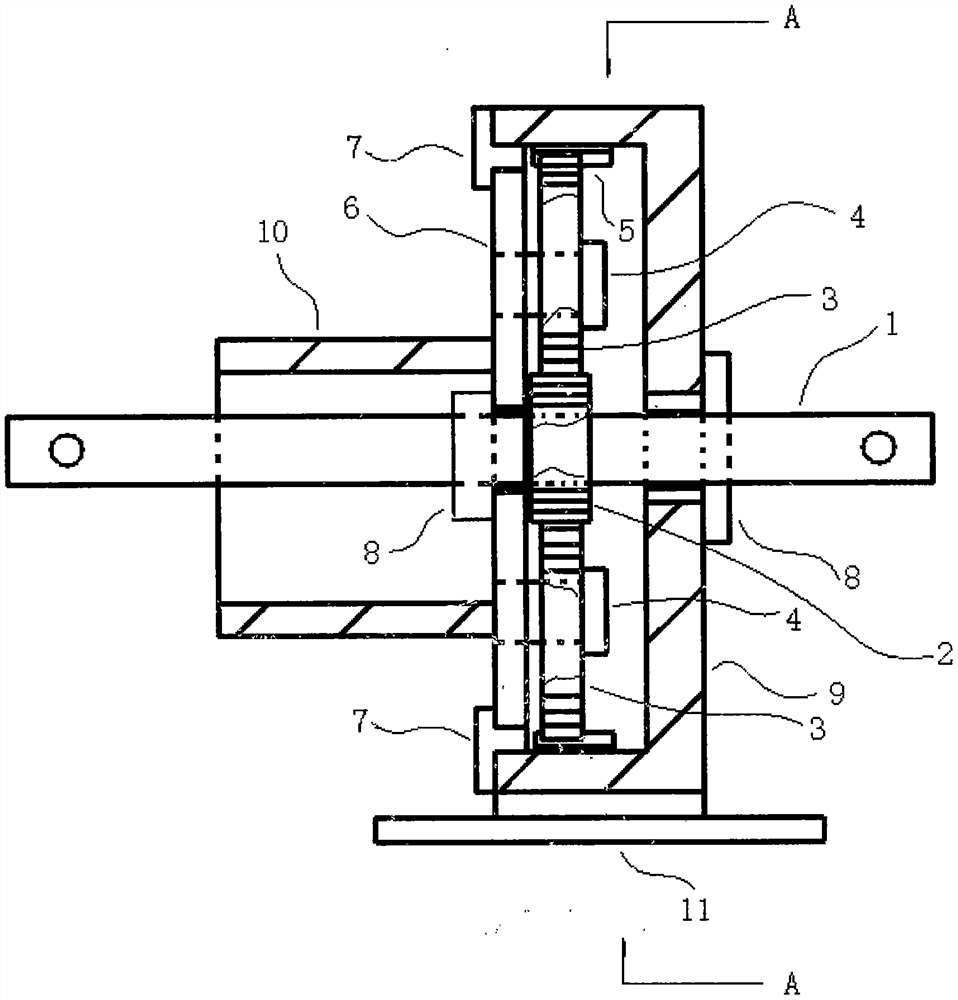

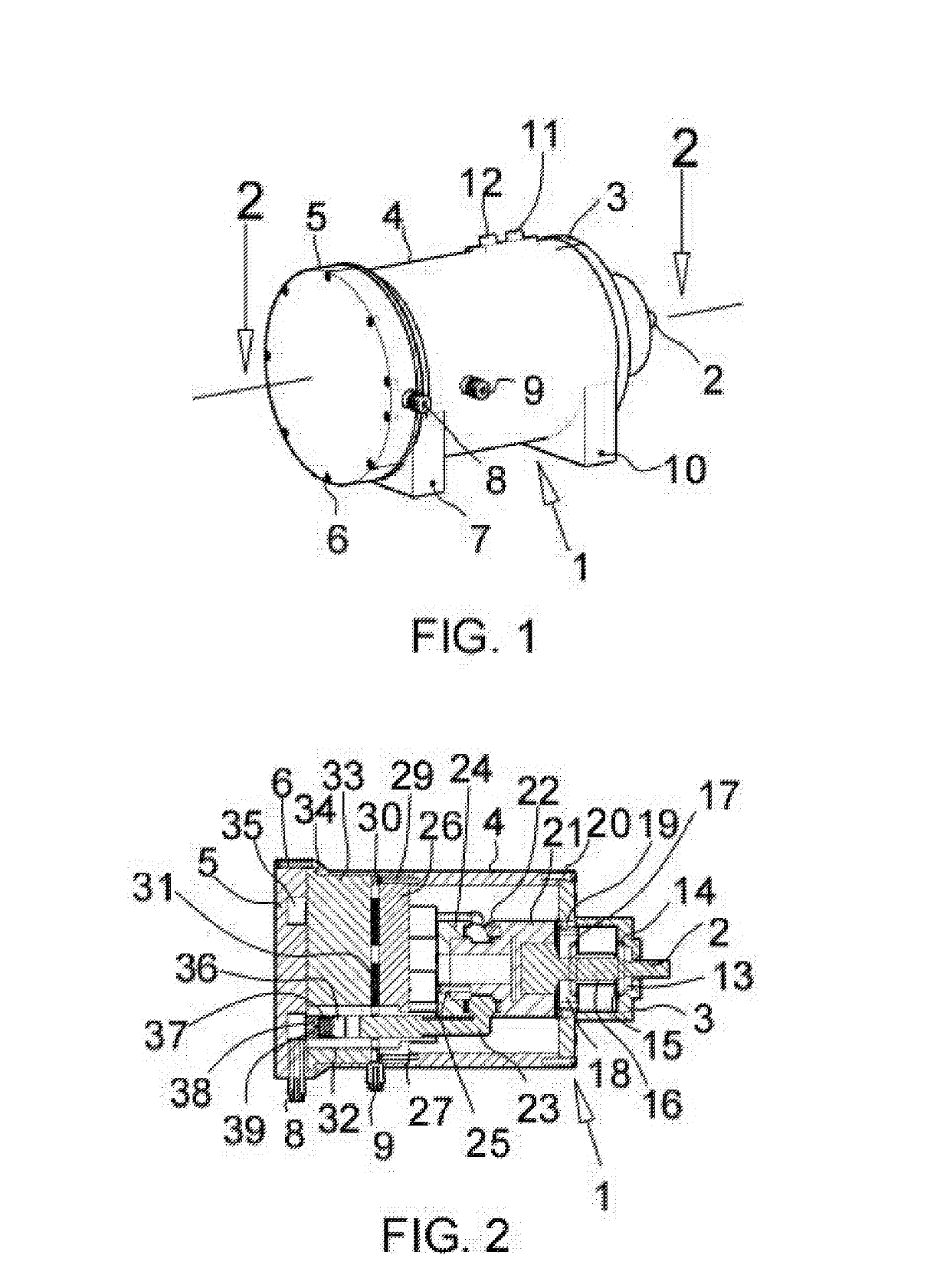

Cover closer

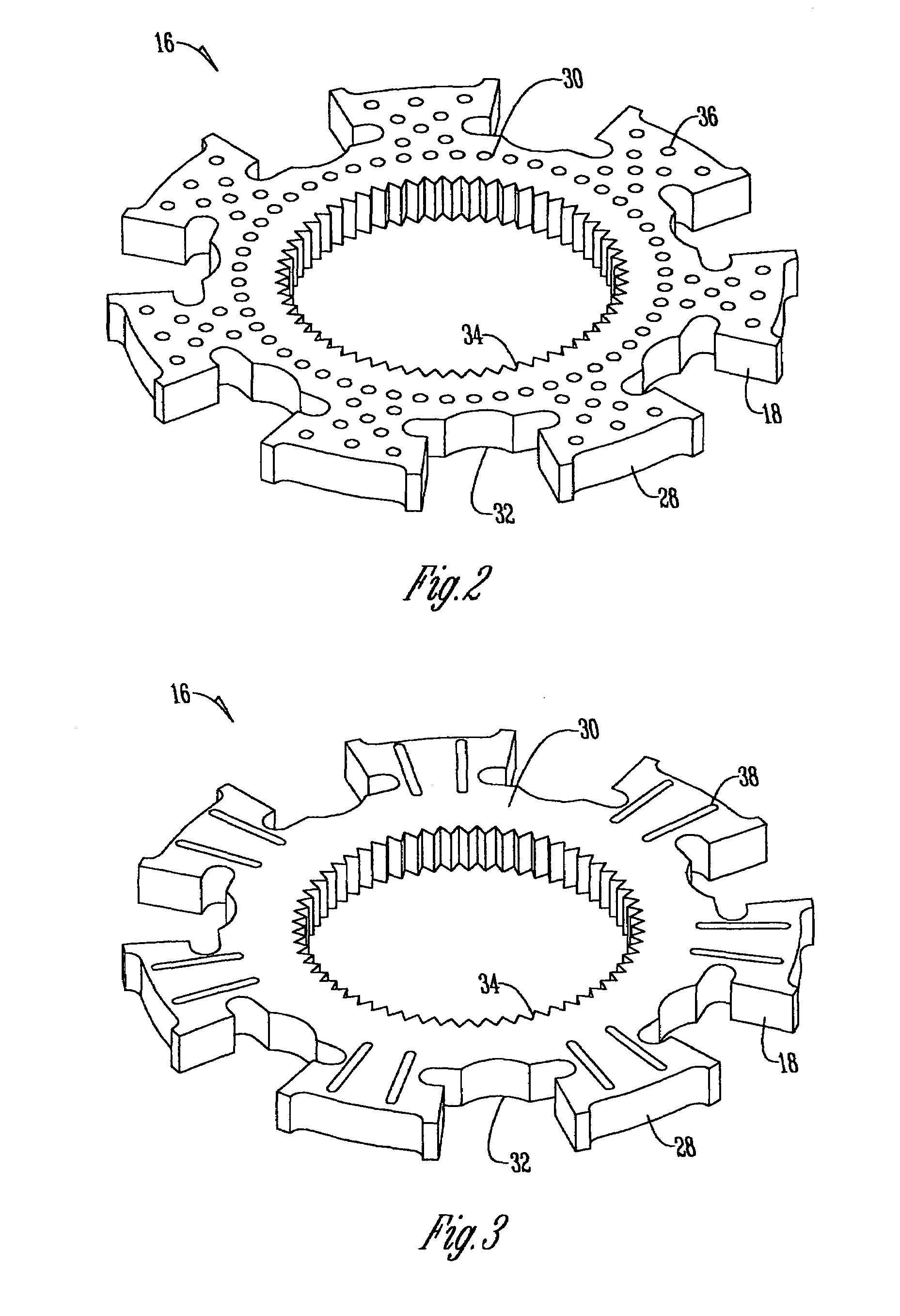

InactiveUS20100097745A1Reduce input torqueReduce rateDigital data processing detailsCasings/cabinets/drawers detailsEngineeringReduction ratio

A cover closer having a drive unit for electrically opening and closing a cover of a copying machine or the like is described. The cover closer can ease the burden of manipulation of the cover and minimize the constraints on designing the main body of the copying machine and the like. The cover closer is provided with a compact drive unit having a high reduction ratio by the use of planetary gears which reduce the input torque necessary for opening and closing the cover, so as to downsize an electric motor used in the drive unit. The drive unit can therefore be installed within the hinge structure of the cover closer.

Owner:SHIMONISHI GIKEN KOGYO KK

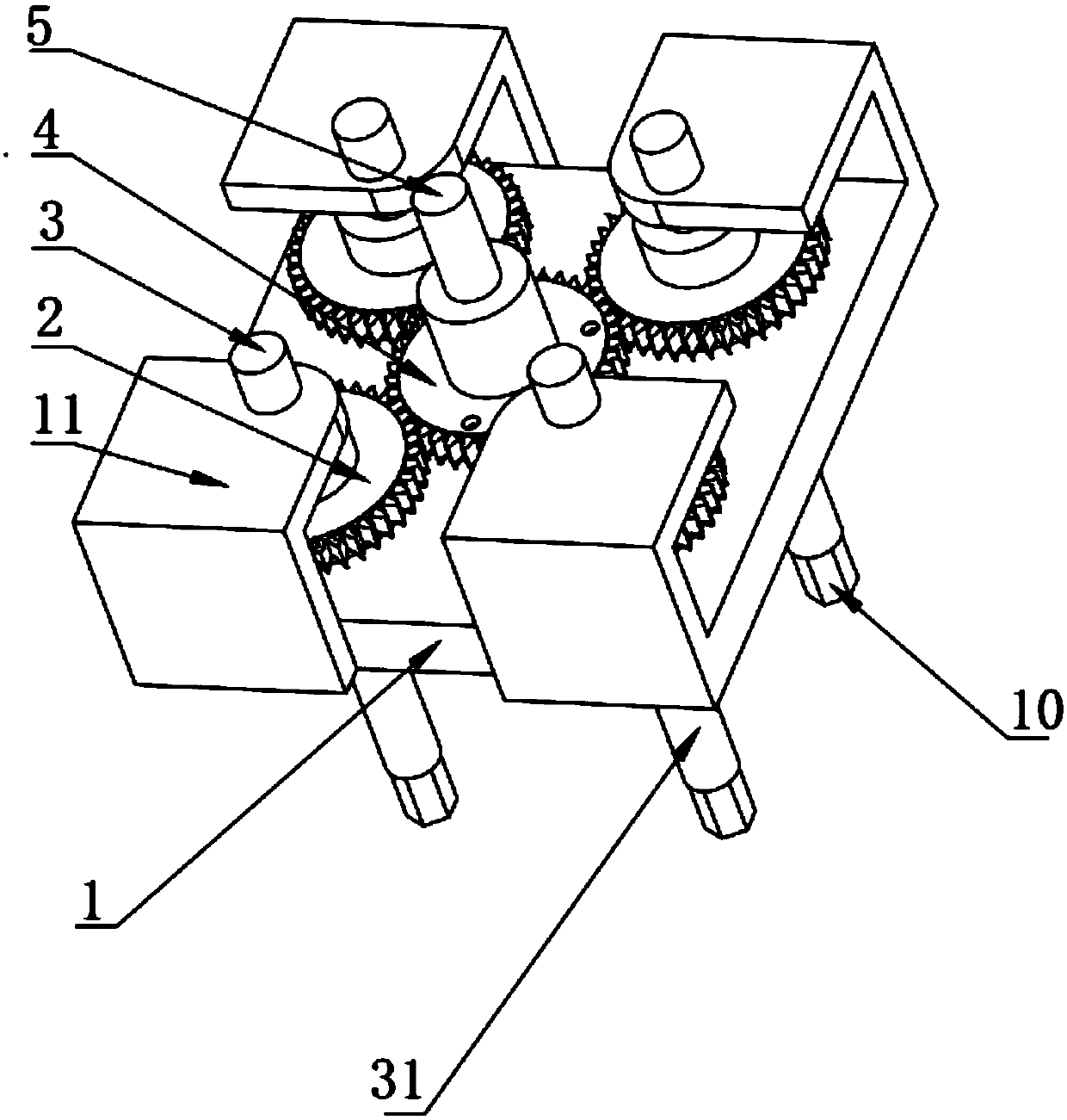

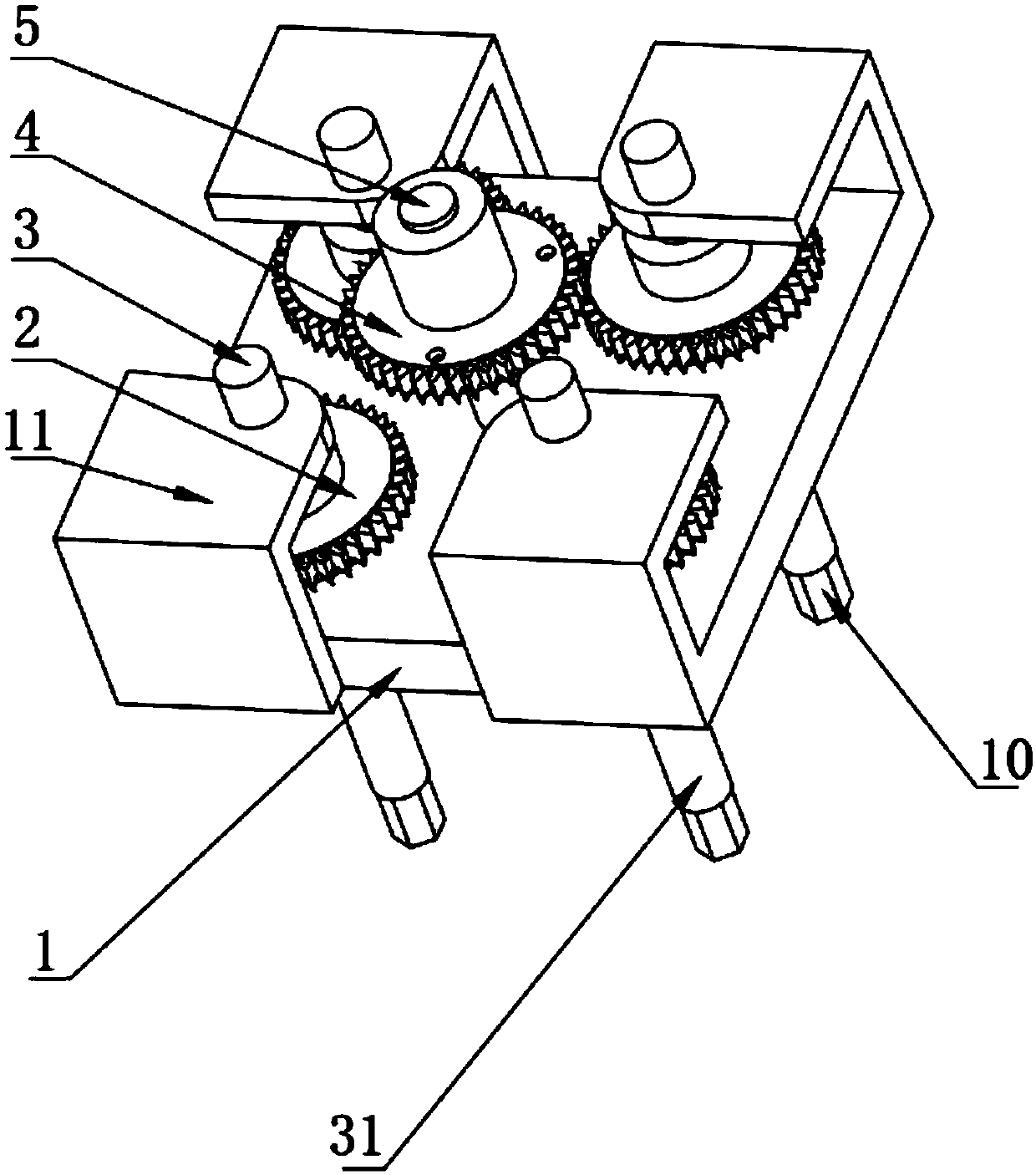

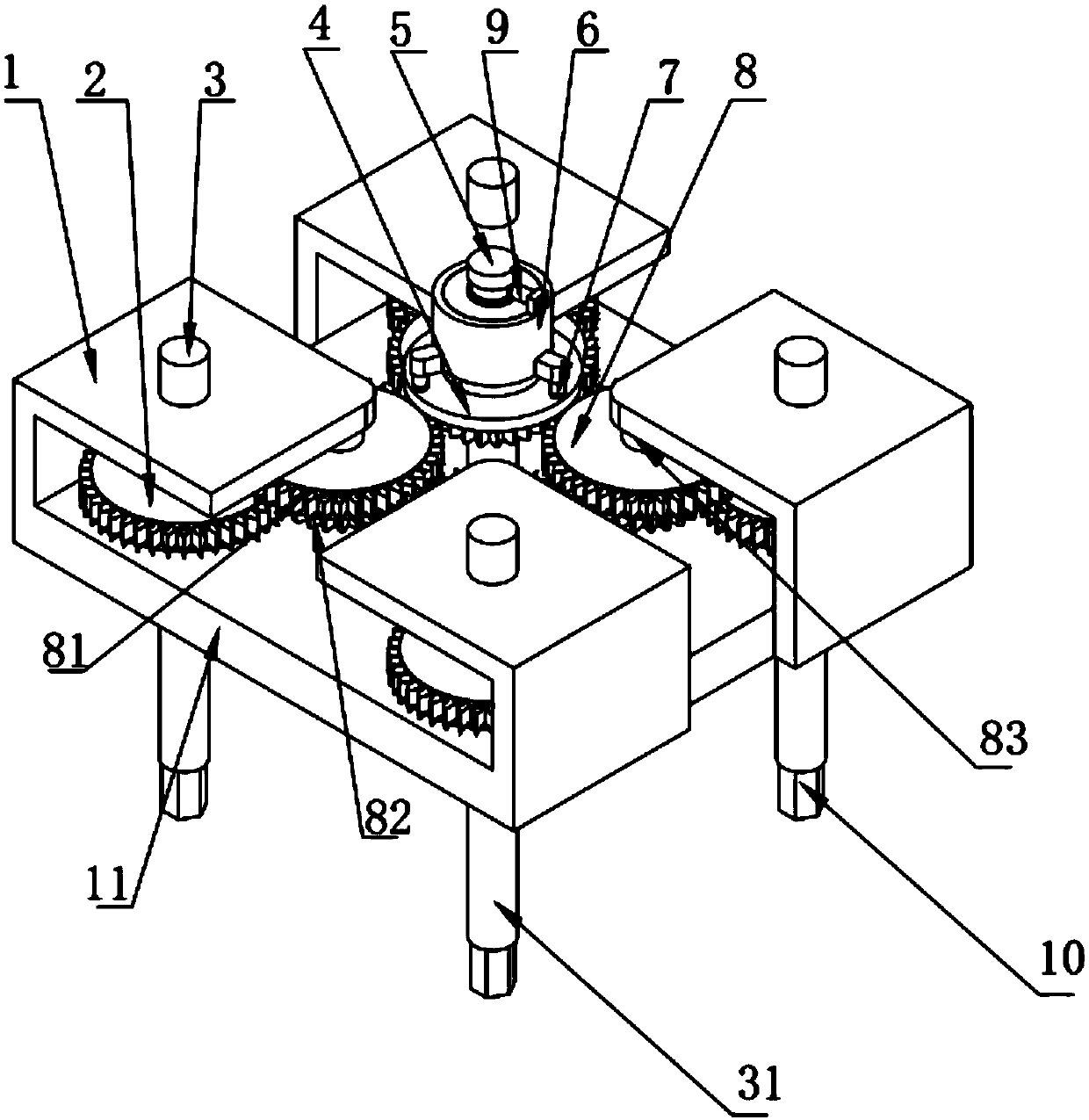

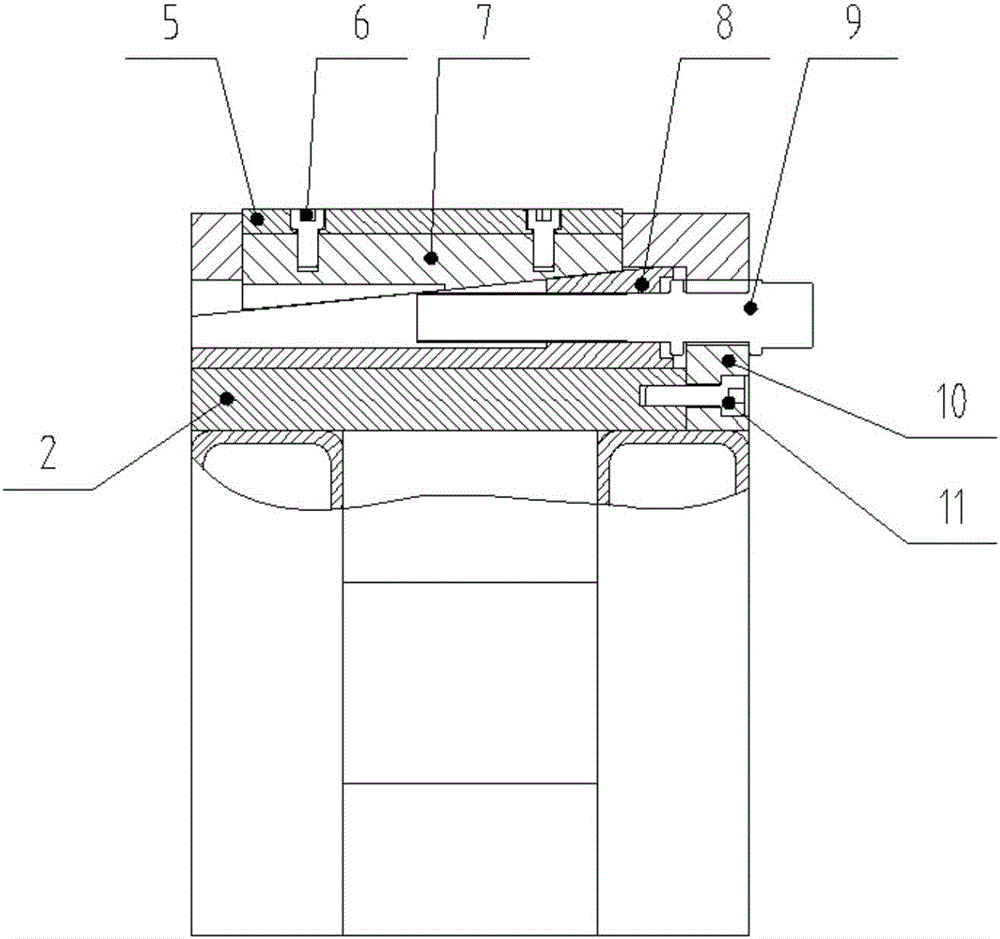

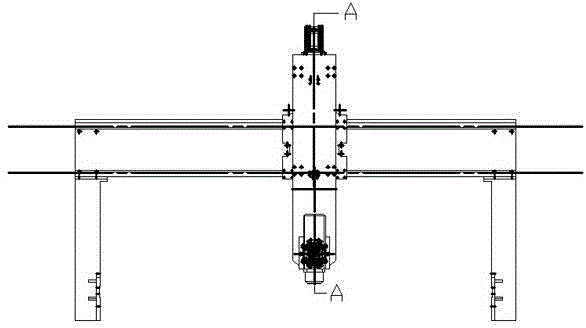

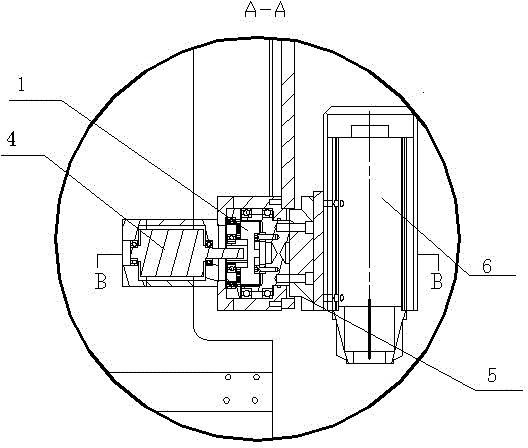

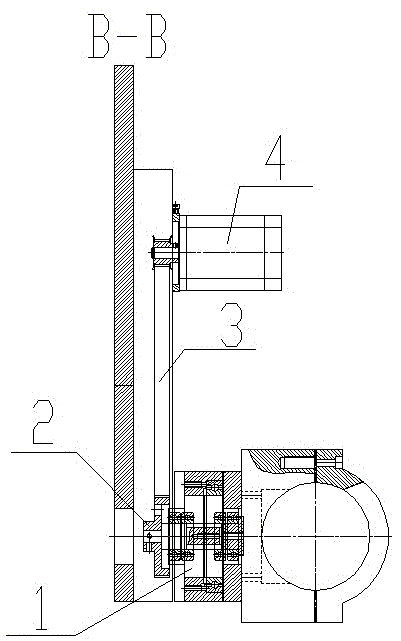

Synchronous fastening device

Owner:BEIJING U PRECISION TECH

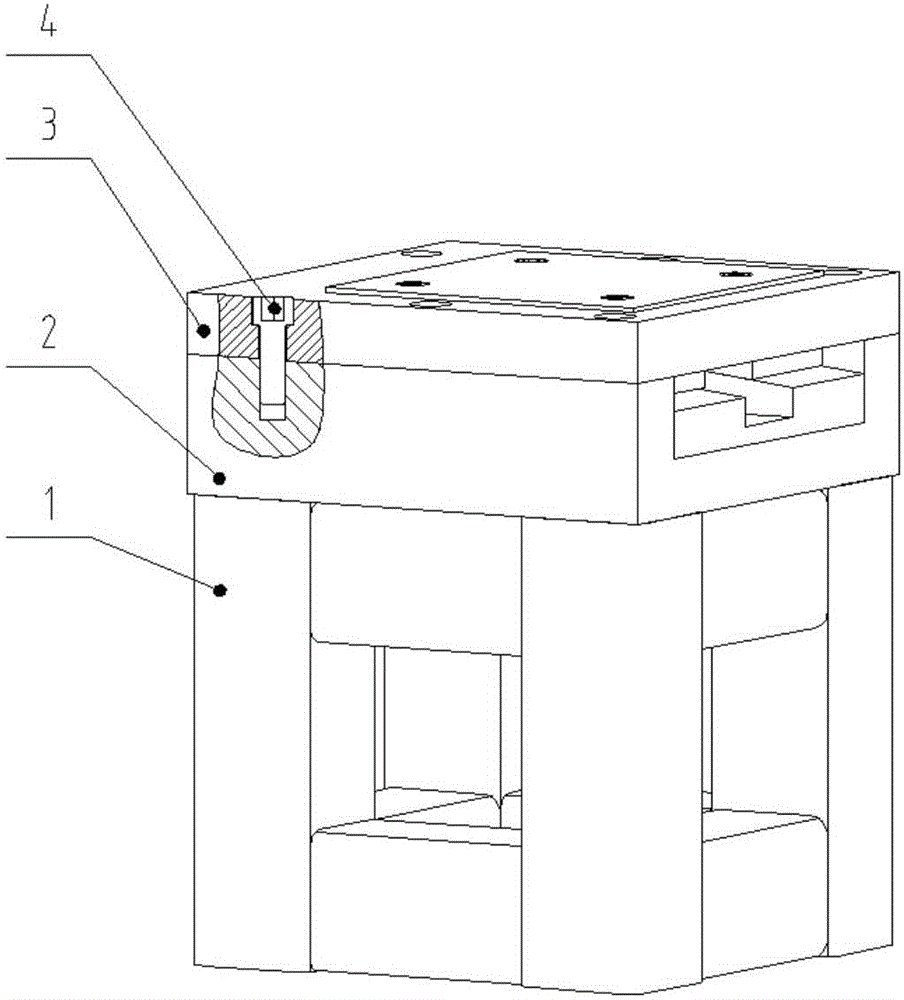

Levelling device for large shell type component

The invention discloses a levelling device for a large shell type component. A pedestal is welded above a supporting seat; a cushion block is positioned above the supporting seat; a thrust oblique body is positioned in a groove of the pedestal and is provided with a horizontal hole; the surface of the cushion block is provided with a lower semicircular groove; a power screw sequentially passes through the lower semicircular groove of the cushion block and the horizontal hole of the thrust oblique body; a lifting oblique body is positioned above the thrust oblique body; a rubber cushion is fixedly arranged at the upper surface of the lifting oblique body through a bolt II; a pressing plate passes through the rubber cushion body and is used for covering the upper portion of the pedestal; an upper semicircular groove of the pressing plate is capable of covering the upper portion of the power screw. According to the levelling device disclosed by the invention, a lifting platform pushed by a screw is designed, and the screw is applied with a torque by two mutually-matched oblique bodies so that stable lifting of the lifting platform can be realized. The levelling device is capable of satisfying levelling of a large shell, also small in input torque, convenient to operate, good in lifting stability, and capable of improving the levelling efficiency for the large shell and shortening the working time for levelling the shell.

Owner:TIANJIN TEEK TRANSMISSION

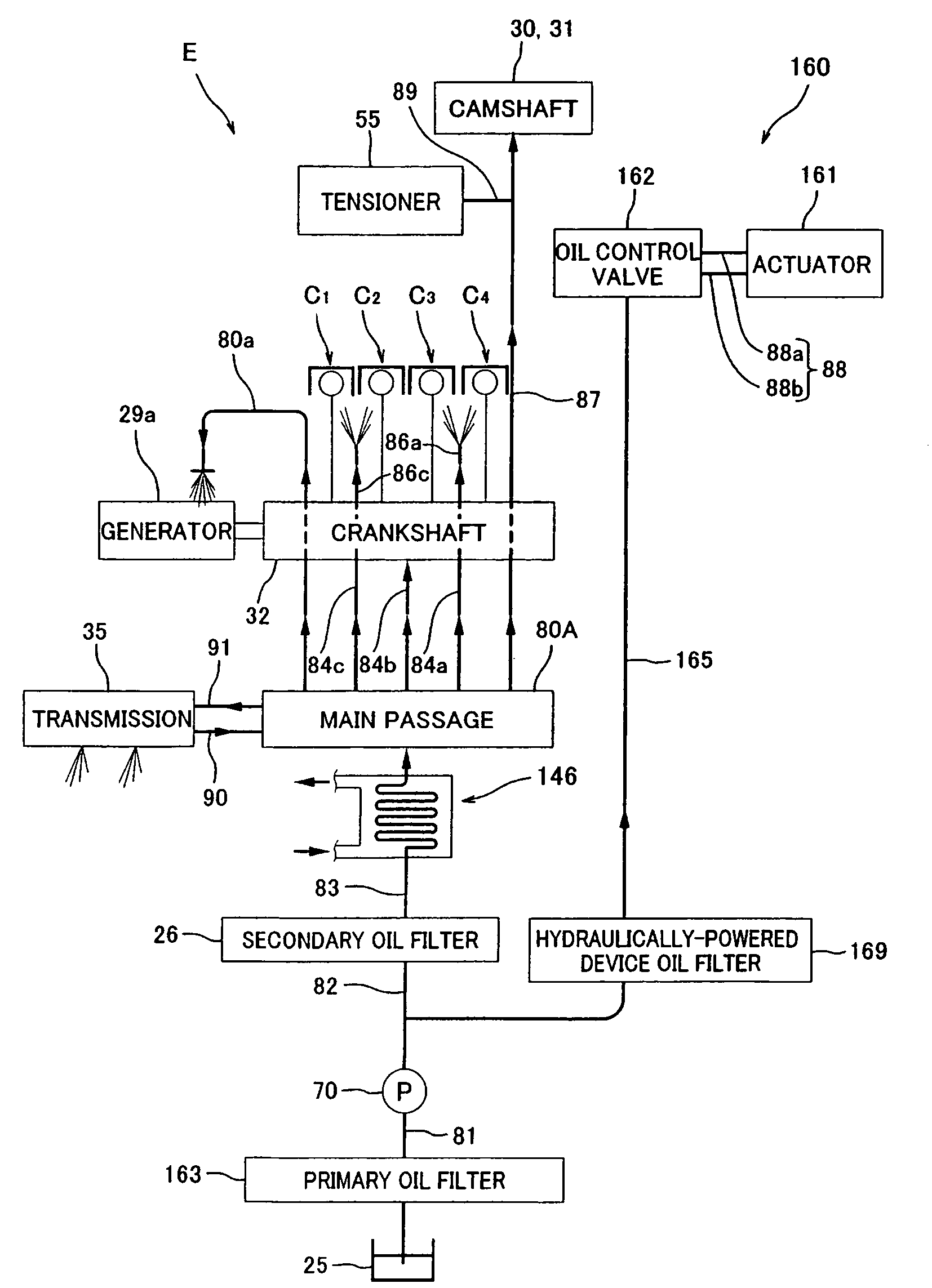

Engine

ActiveUS7434561B2Reduce total pressure lossLower oil temperatureLubrication of auxillariesValve drivesChillerPetroleum engineering

An engine including an oil passage through which oil output from an oil pump flows, an oil cooler mounted to the oil passage, and a branched oil passage for a hydraulically-powered device of the engine that is configured to branch in a location of the oil passage extending from the oil pump to the oil cooler to deliver the oil to the hydraulically-powered device.

Owner:KAWASAKI MOTORS LTD

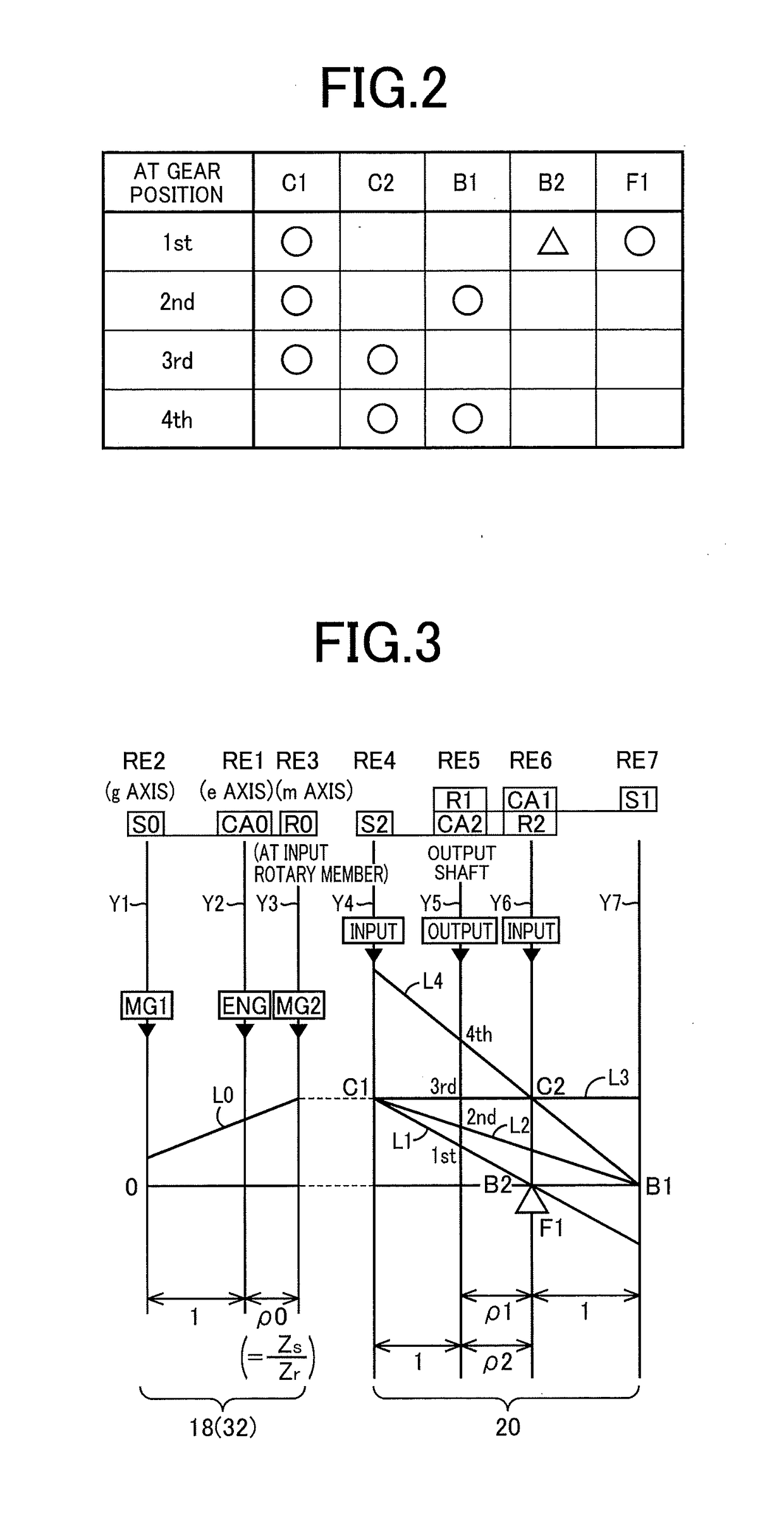

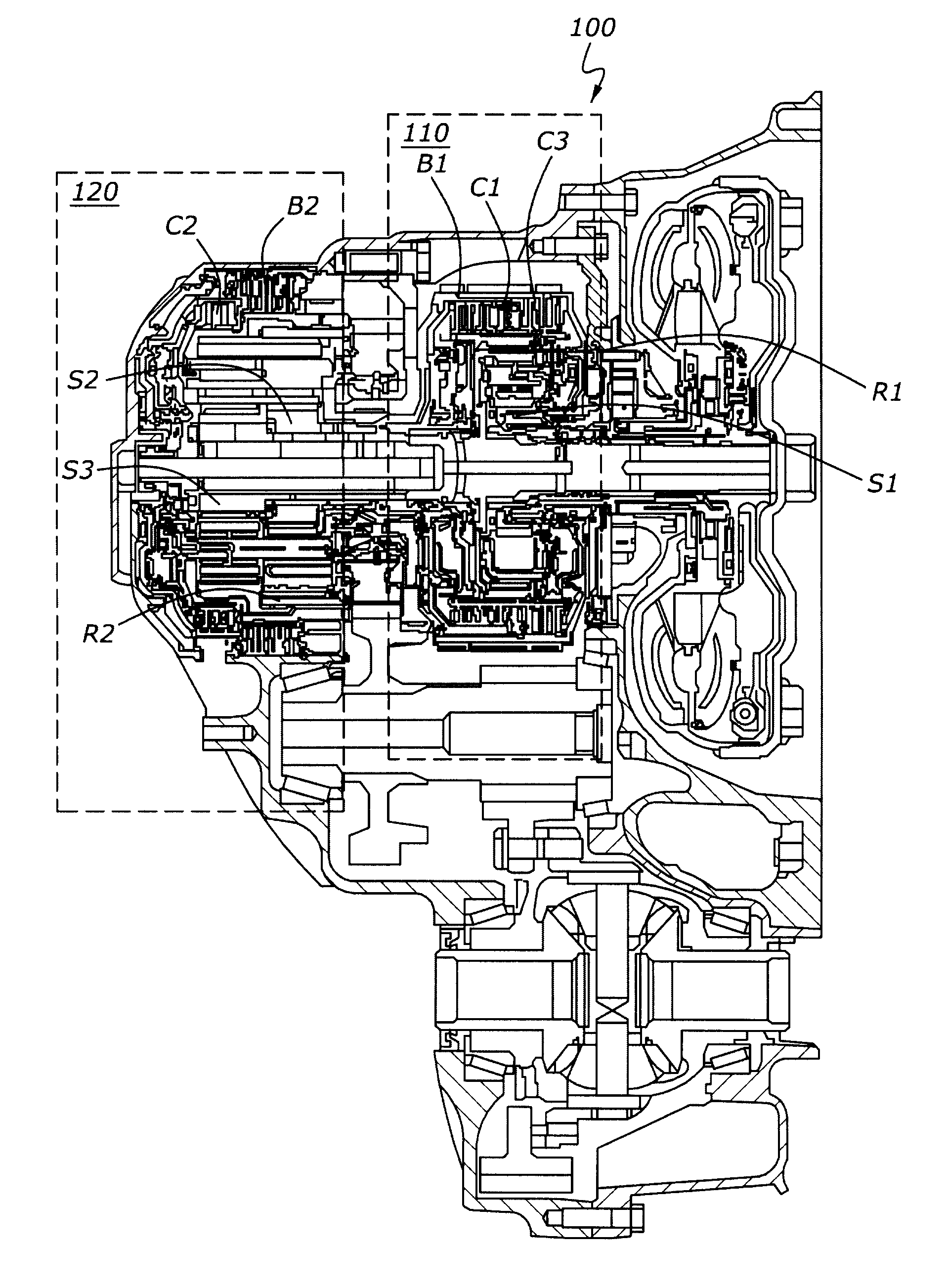

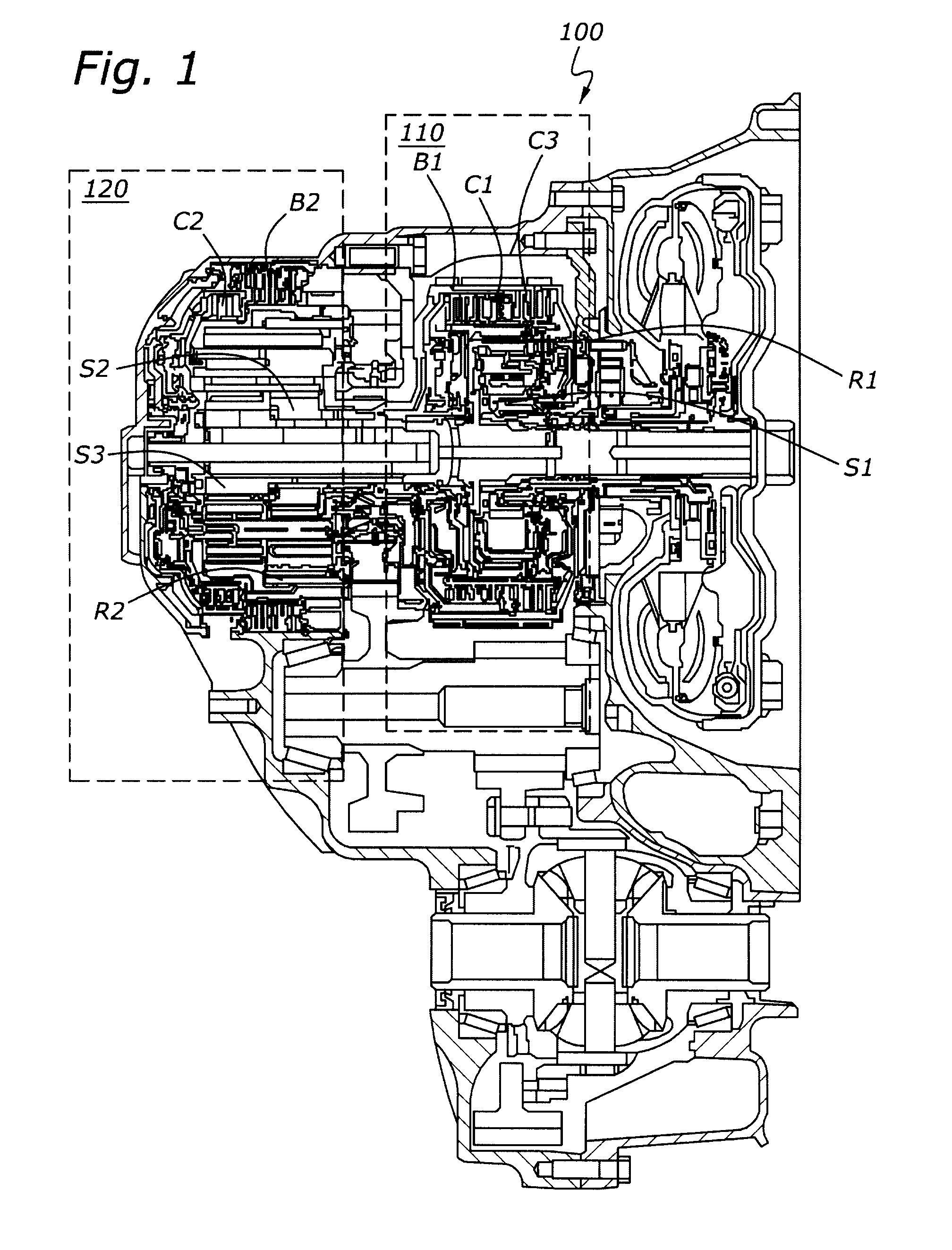

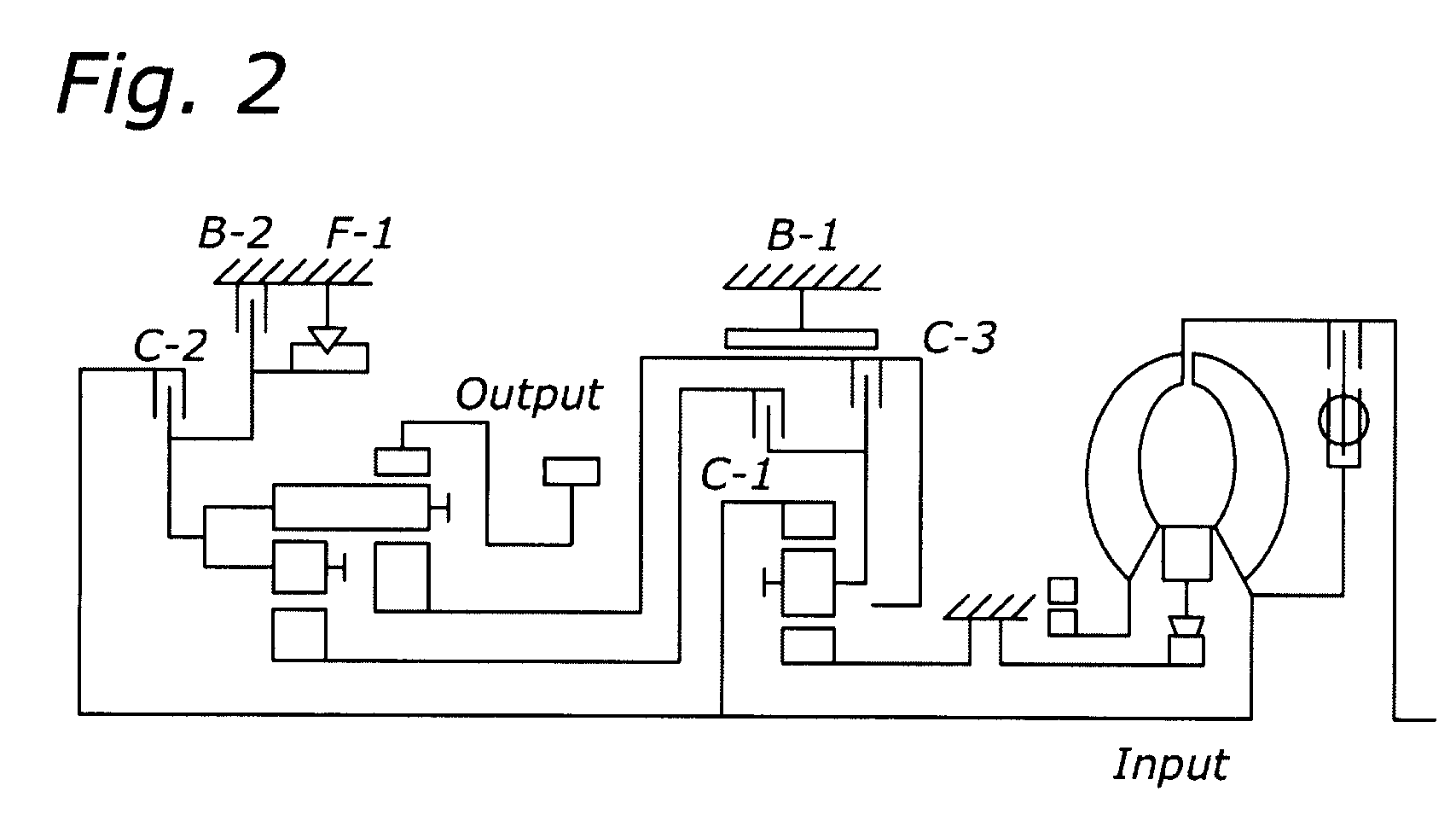

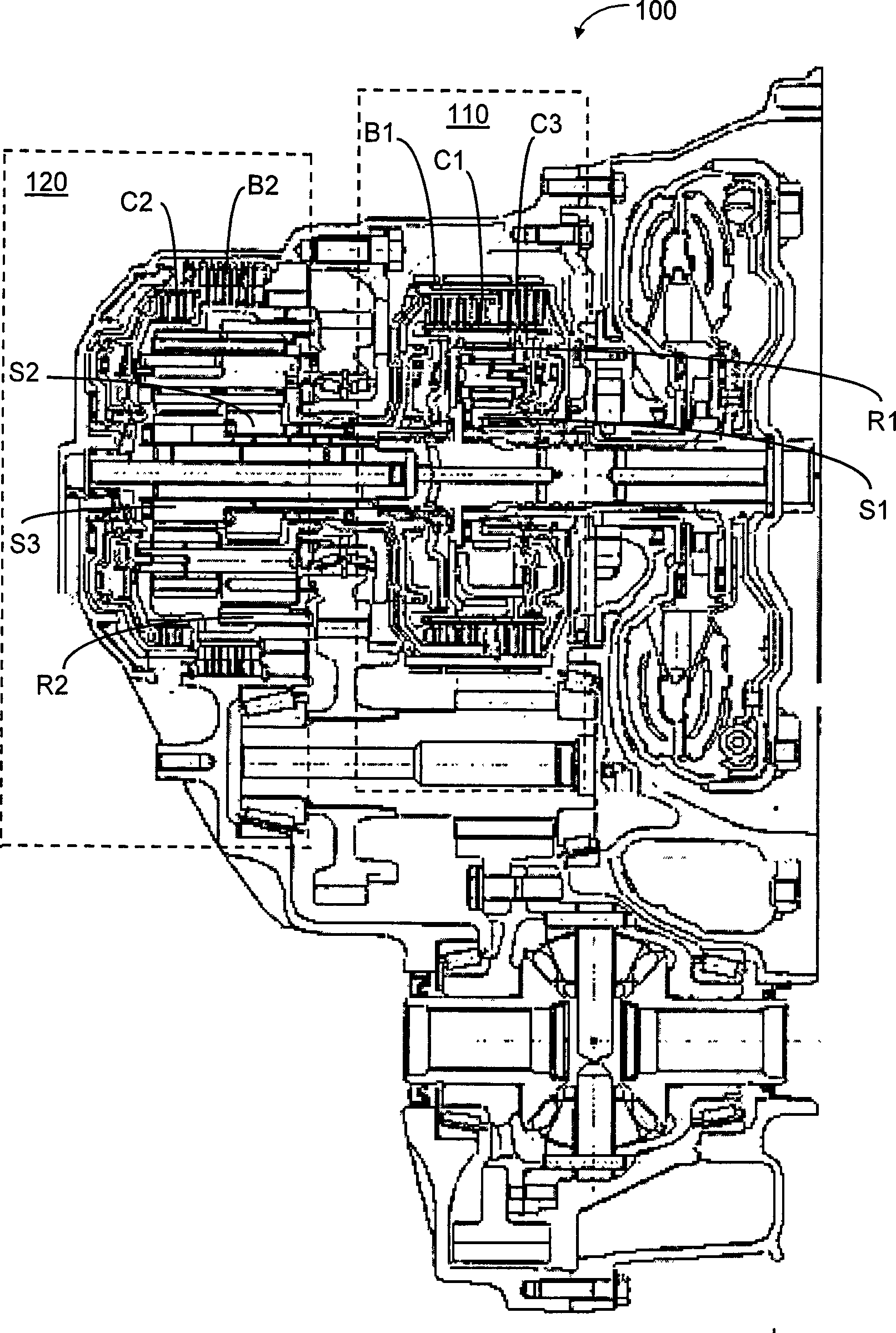

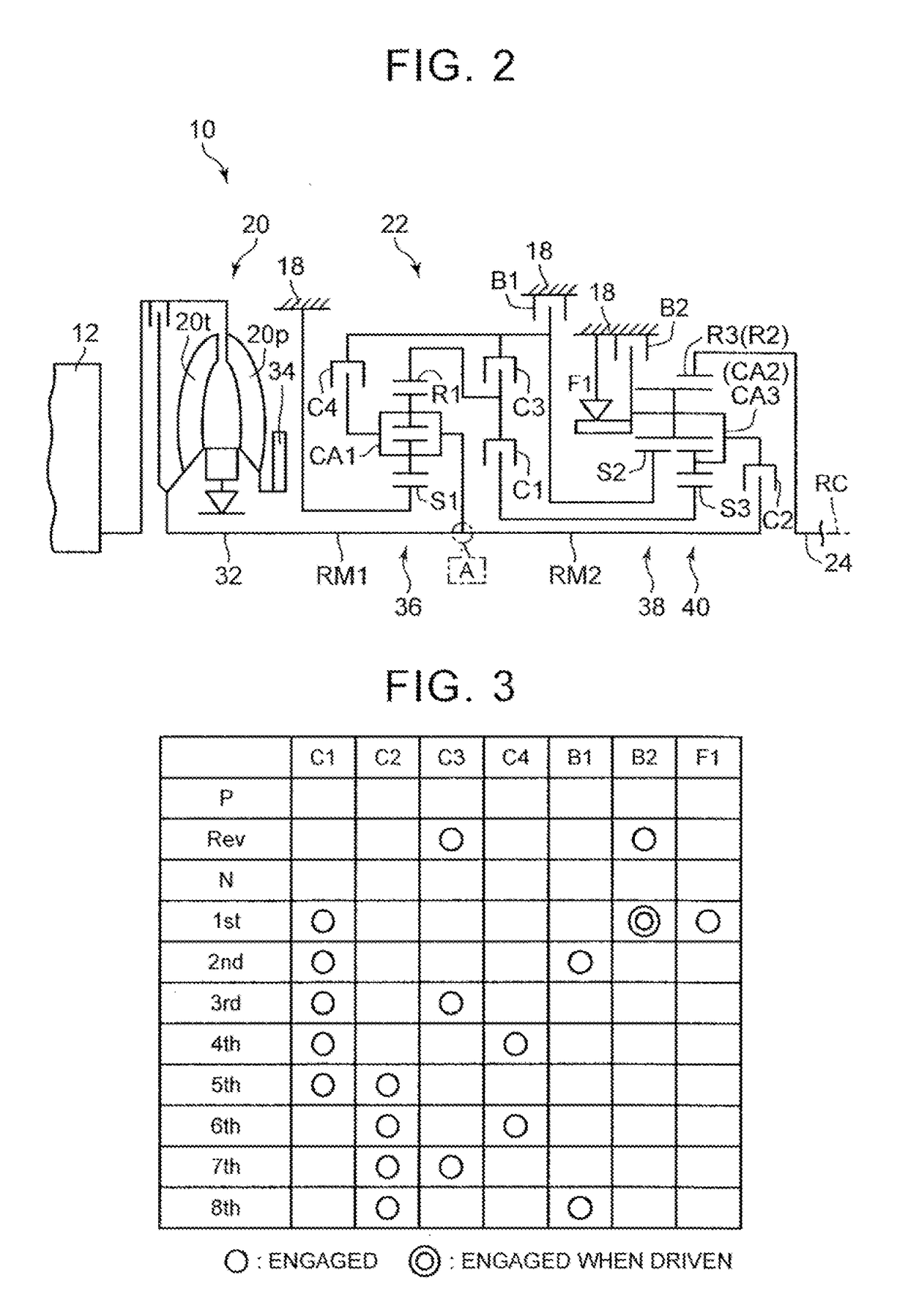

Method and device for controlling an automatic transmission

InactiveUS7946943B2Rapid starting facilityFacility to rotateGearingGear vibration/noise dampingSingle stageAutomatic transmission

The invention relates to a method and a device for controlling an automatic transmission, the automatic transmission (100) comprising a single-stage planetary gear train (110) in combination with a two-stage planetary gear train (120), and provision being made for a brake band (B1) assigned to the large sun gear of the two-stage planetary gear train (110) and a brake coupling (B2) assigned to the planet carrier of the two-stage planetary gear train (120). In order to reduce idling vibrations, the brake band (B1) and the brake coupling (B2) are actuated simultaneously for at least some of the time during an operating state in which the internal combustion engine is idling.

Owner:FORD GLOBAL TECH LLC

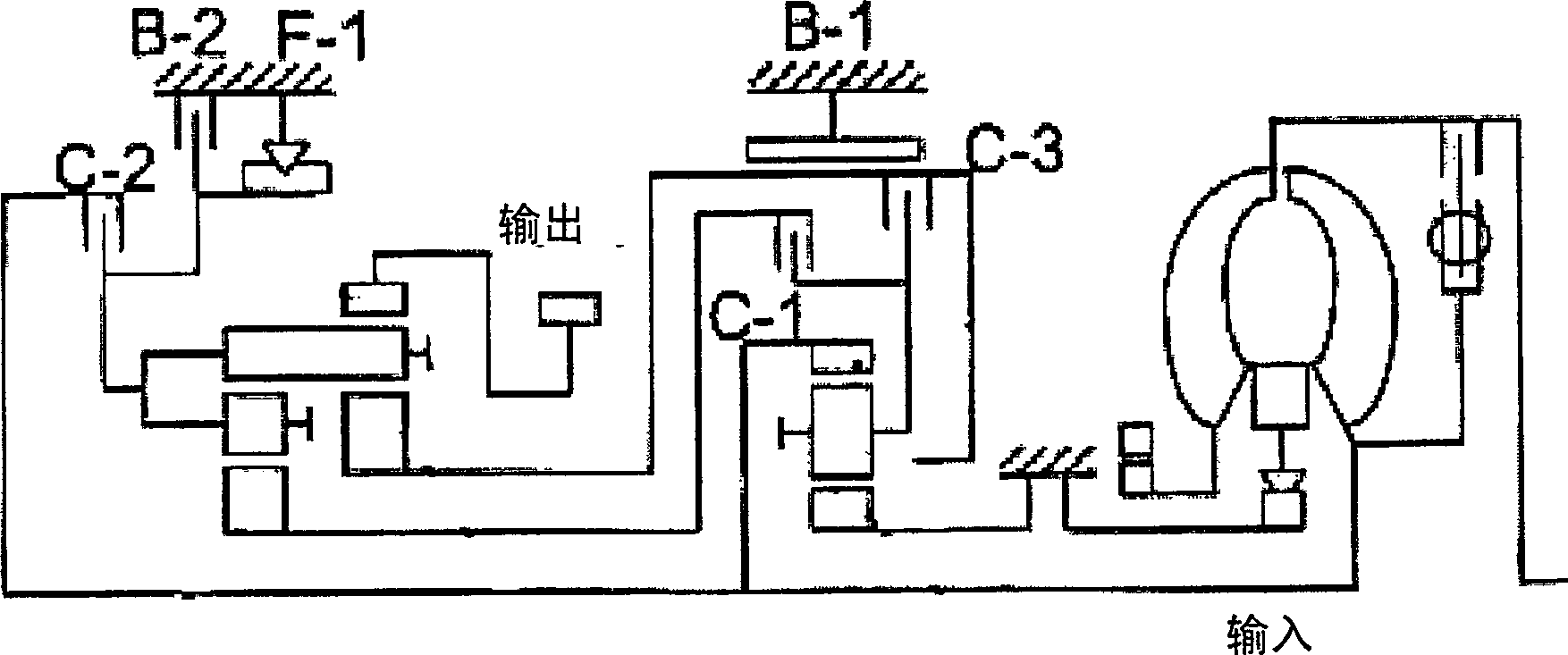

Method and device for controlling an automatic transmission

InactiveCN101398080AReduce torqueReduce vibrationGear vibration/noise dampingGearing controlAutomatic transmissionSingle stage

The invention relates to a method and a device for controlling an automatic transmission, the automatic transmission (100) comprising a single-stage planetary gear train (110) in combination with a two-stage planetary gear train (120), and provision being made for a brake band (B1) assigned to the large sun gear of the two-stage planetary gear train (110) and a brake coupling (B2) assigned to theplanet carrier of the two-stage planetary gear train (120). In order to reduce idling vibrations, the brake band (B1) and the brake coupling (B2) are actuated simultaneously for at least some of the time during an operating state in which the internal combustion engine is idling.

Owner:FORD GLOBAL TECH LLC

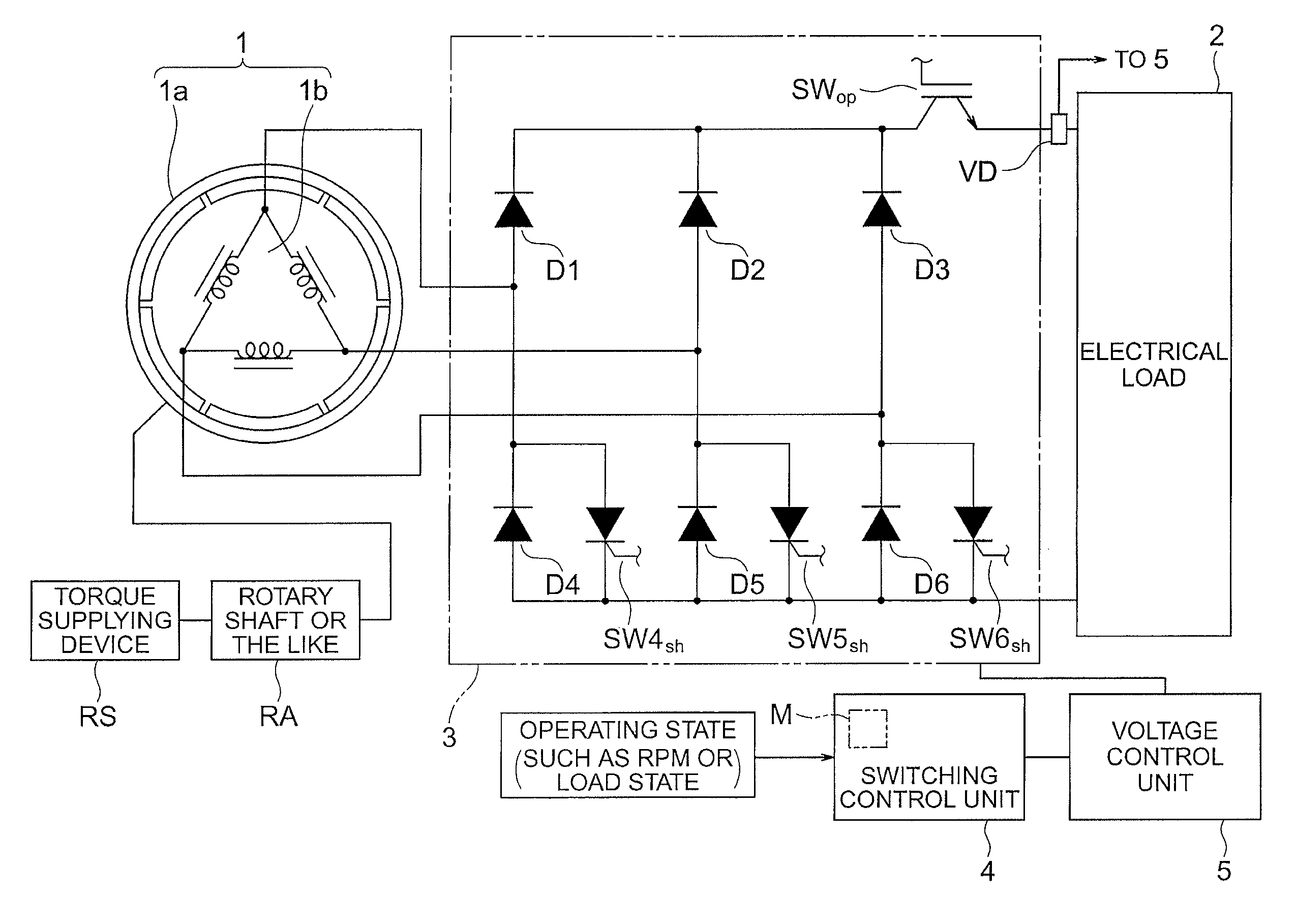

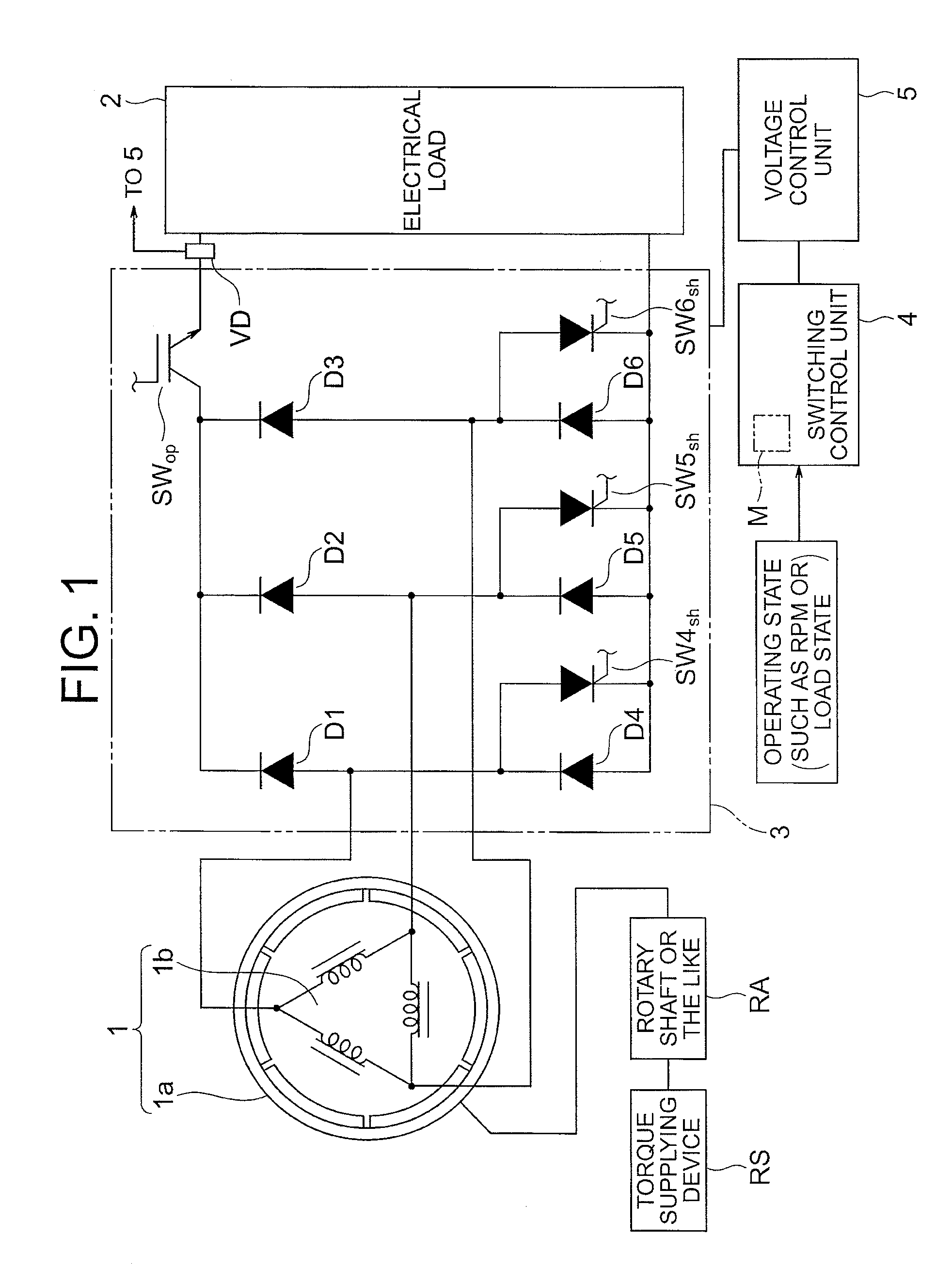

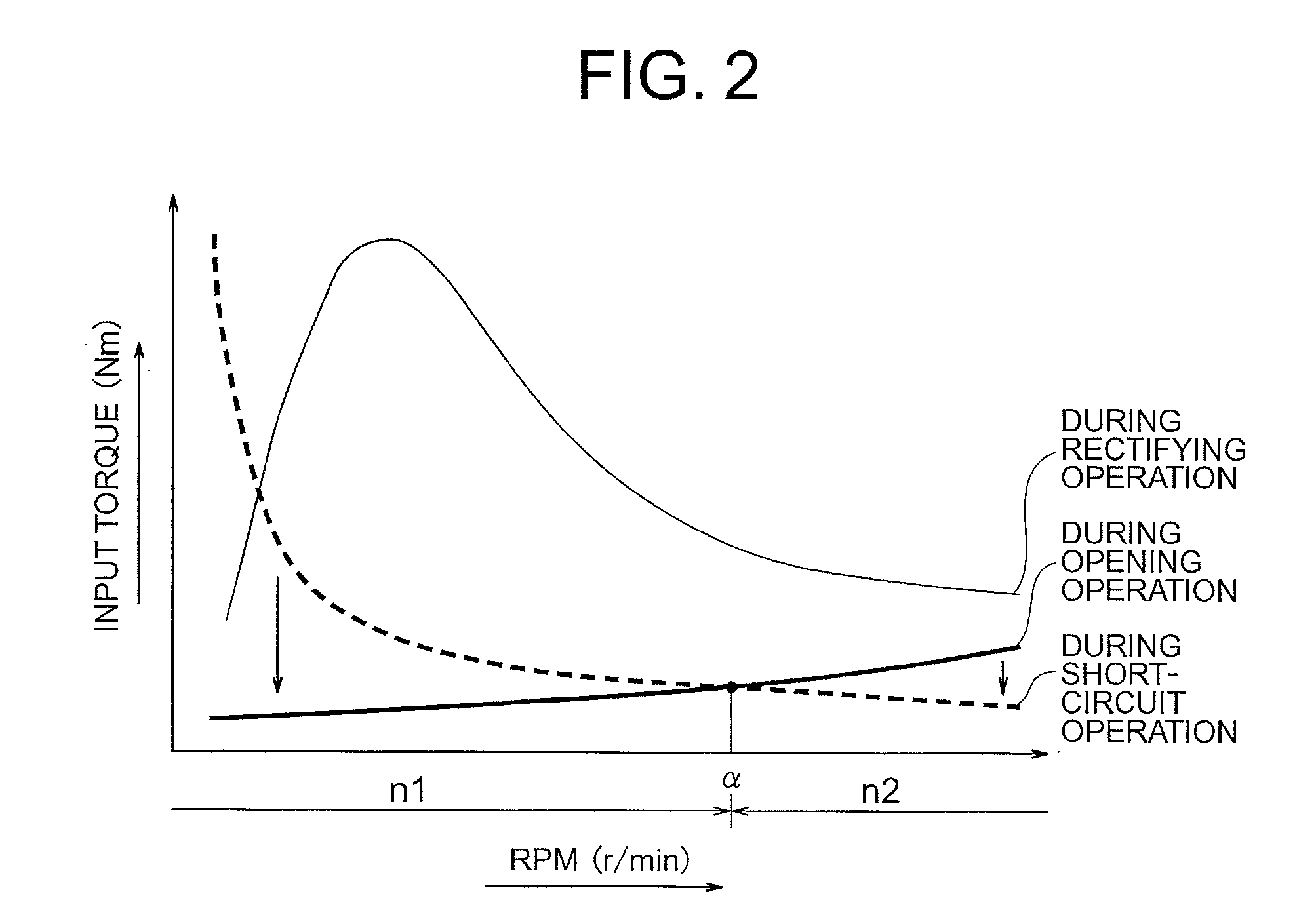

Power supply device

ActiveUS8421422B2Reduce input torqueImprove power generation efficiencyEmergency protective circuit arrangementsDynamo-electric converter controlElectricityAlternating current

A power supply device comprising: a magneto generator including a rotor including a magnet forming a magnetic field; a rectifying unit rectifying an alternating current of the generator to a direct current and supplying to an electrical load; a voltage detection unit detecting a voltage of the electrical load; an opening unit interrupting electrical conduction of an output of the generator; short-circuiting units electrically short-circuiting the output; a torque supplying device supplying torque to the rotor; a voltage control unit selectively performing one of opening-control of controlling on / off switching of the opening unit and short-circuit-control of controlling on / off switching of the short-circuiting units to control the voltage of the electrical load to a predetermined value in accordance with the voltage detected by the voltage detection unit; a switching control unit switching and controlling between the above two controls in accordance with an operating state regarding rotation of the rotor.

Owner:MITSUBISHI ELECTRIC CORP

Self-locking deceleration support bearing for photovoltaic support

PendingCN111835272AReduce manufacturing costEasy to drivePhotovoltaic supportsMechanical energy handlingElectric machineControl theory

The invention provides a self-locking deceleration support bearing for a photovoltaic support. The self-locking and deceleration characteristics are realized; the self-locking characteristic is that the large-scale single-shaft automatic tracking photovoltaic support is integrally locked in case of strong wind. The resonance phenomenon with large destructive power is eliminated; the photovoltaic support is protected; due to the deceleration characteristic, the photovoltaic support can be supported and rotated without a long and heavy rotating beam; accurate coaxial installation is not needed;the construction is easy; the foundation settlement photovoltaic support can still operate, the operation reliability is improved, a small speed reducer and a motor can be used for driving the large single-shaft automatic tracking photovoltaic support according to the deceleration characteristic, the manufacturing cost of the photovoltaic support and the power consumption of the motor are reduced,and the bearing has the advantages of being small in size, light in weight and low in manufacturing cost.

Owner:WUXI HAOSOLAR TECH CO

Cooperative control system for prime mover and continuously variable transmission of vehicle

InactiveUS7300380B2Avoid feeling uncomfortableUncomfortable feelingGearingGearing controlControl systemExecution control

A cooperative control system for a prime mover and a continuously variable transmission of a vehicle, in which the continuously variable transmission is connected to an output side of the prime mover for generating a driving force for running, and in which a clamping pressure to set a torque capacity of the continuously variable transmission is raised and an input torque to the continuously variable transmission is lowered on the basis of a decision of the slip in the continuously variable transmission. A clamping pressure / input torque sequential control raises an actual pressure of the clamping pressure at or after a deciding instant of the slip convergence, and executes a control to complete a restoration of an actual torque of the lowered input torque afterward.

Owner:TOYOTA JIDOSHA KK

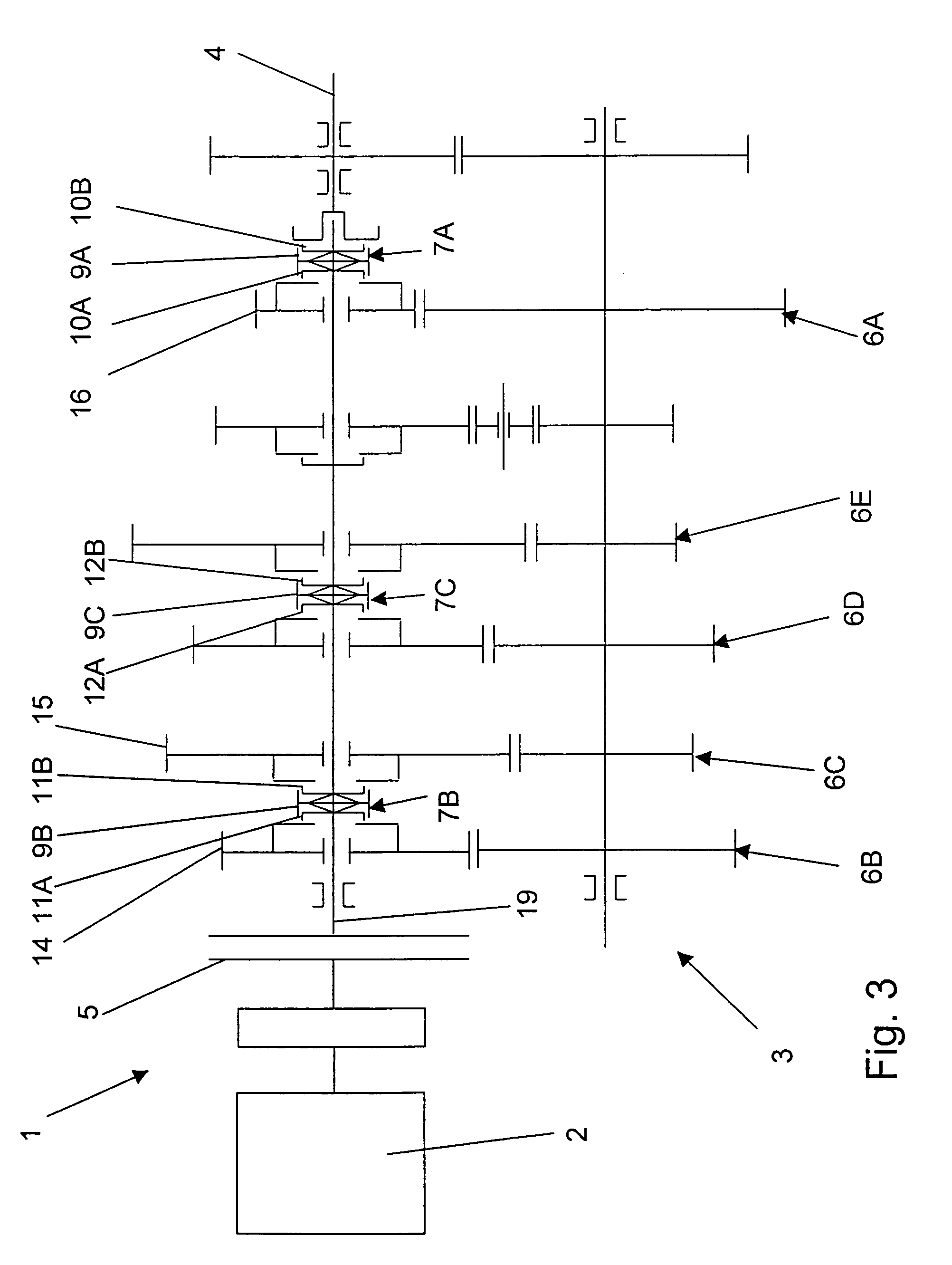

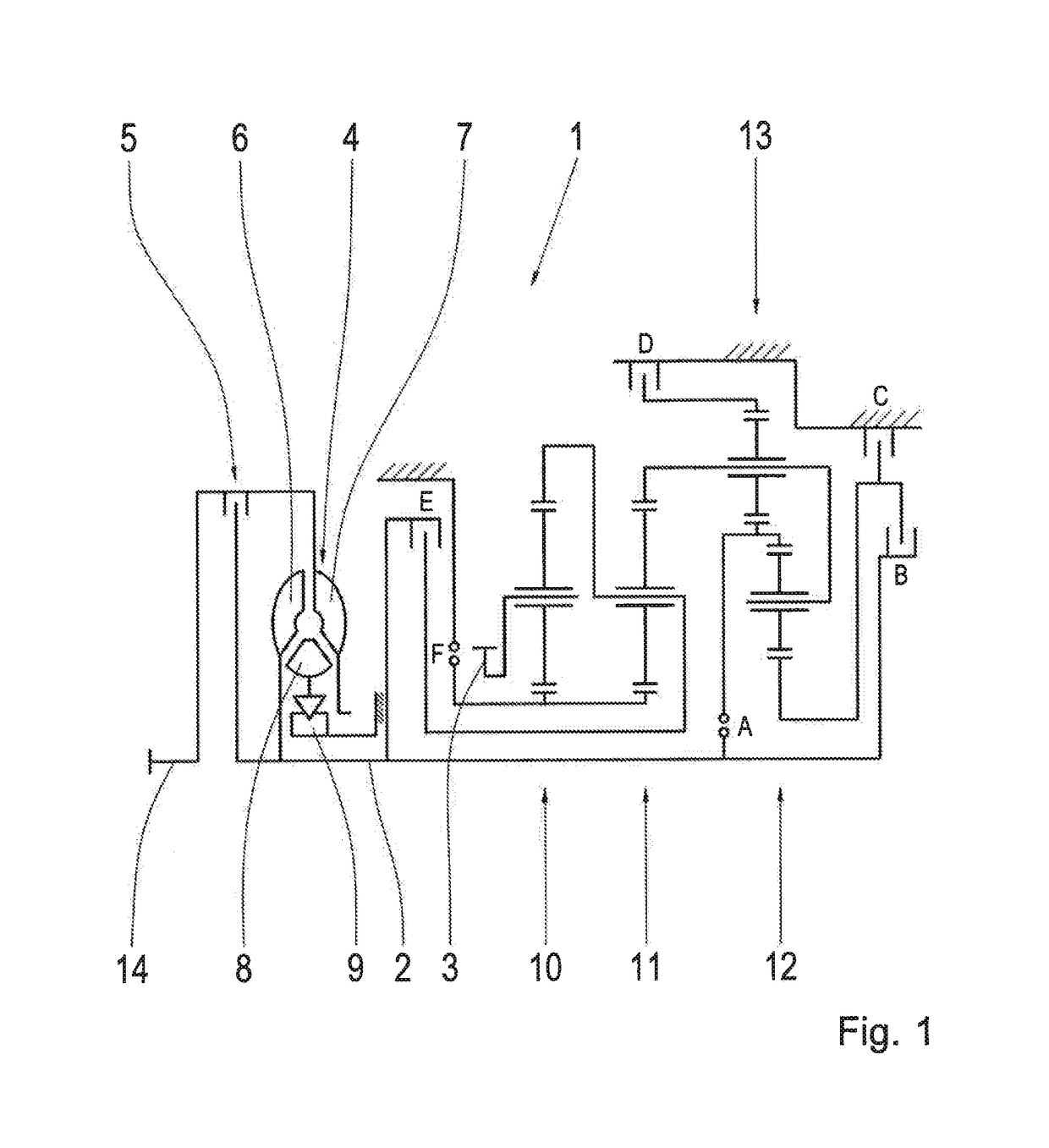

Automated drive train for a motor vehicle and method of controlling a drive train

InactiveUS20050016306A1Reduce investmentReduce input torqueToothed gearingsGearing controlActuatorControl theory

An automated drive train is provided for a motor vehicle comprising a single friction clutch, which is actuatable by a first actuator. A step transmission connected to the output side of the friction clutch comprises wheel sets to engage and disengage forward gears. A plurality of partial load positive gear shift clutches are provided which each include a synchronization means and which are actuatable by means of second actuators for engaging and disengaging the gears. A controller is provided for controlling the actuators such that the drive train is controlled to carry out a gear change under one of the three possible modes (A, B, C) depending on the conditions of the gear change to be made, wherein the three possible modes (A, B, C) of gear changes take place with an opened (C), a closed (B) or with a slipping (A) friction clutch (FIG. 6).

Owner:GETRAG GETTRIEBE UND ZZHNRADFAB +1

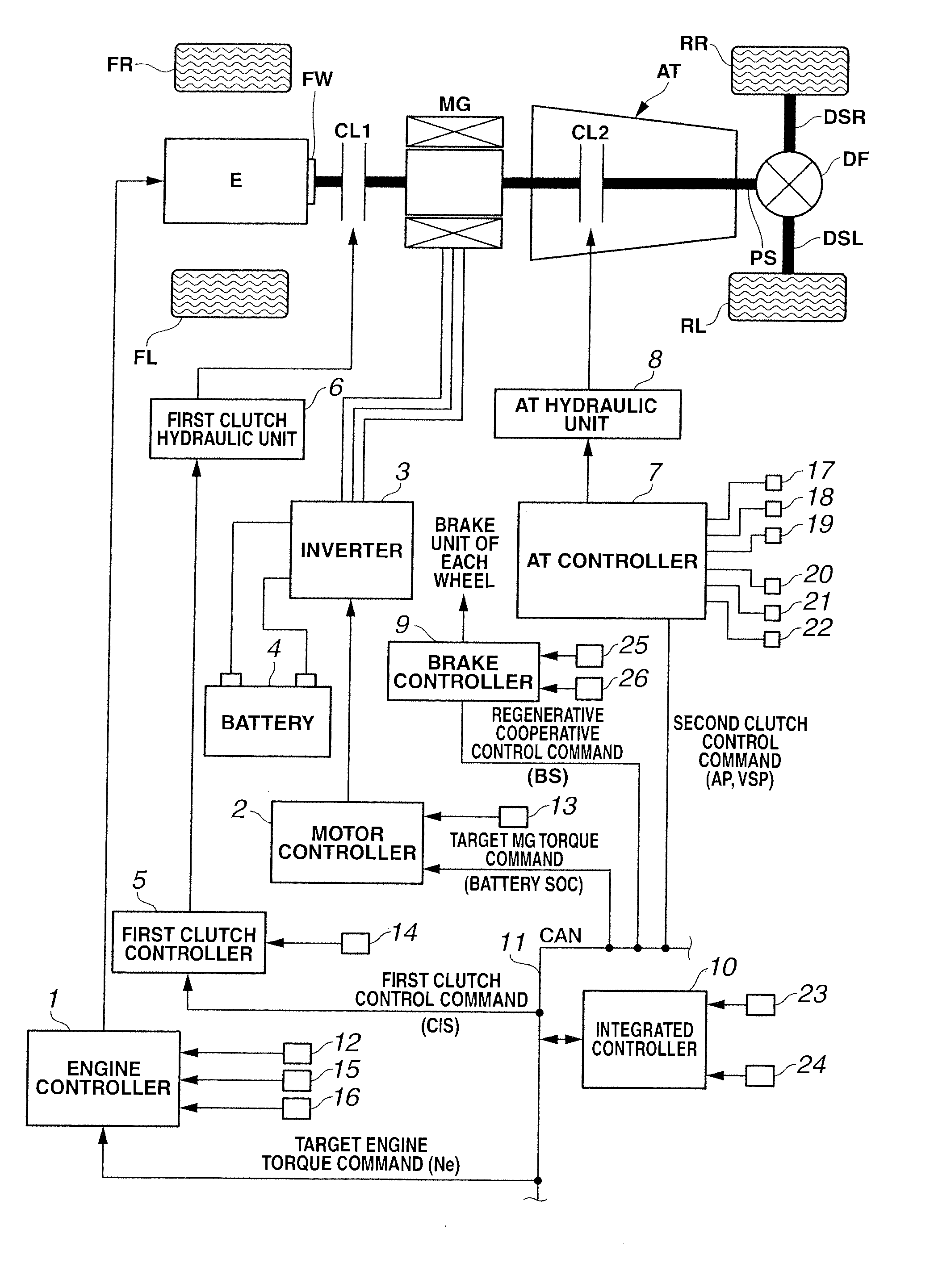

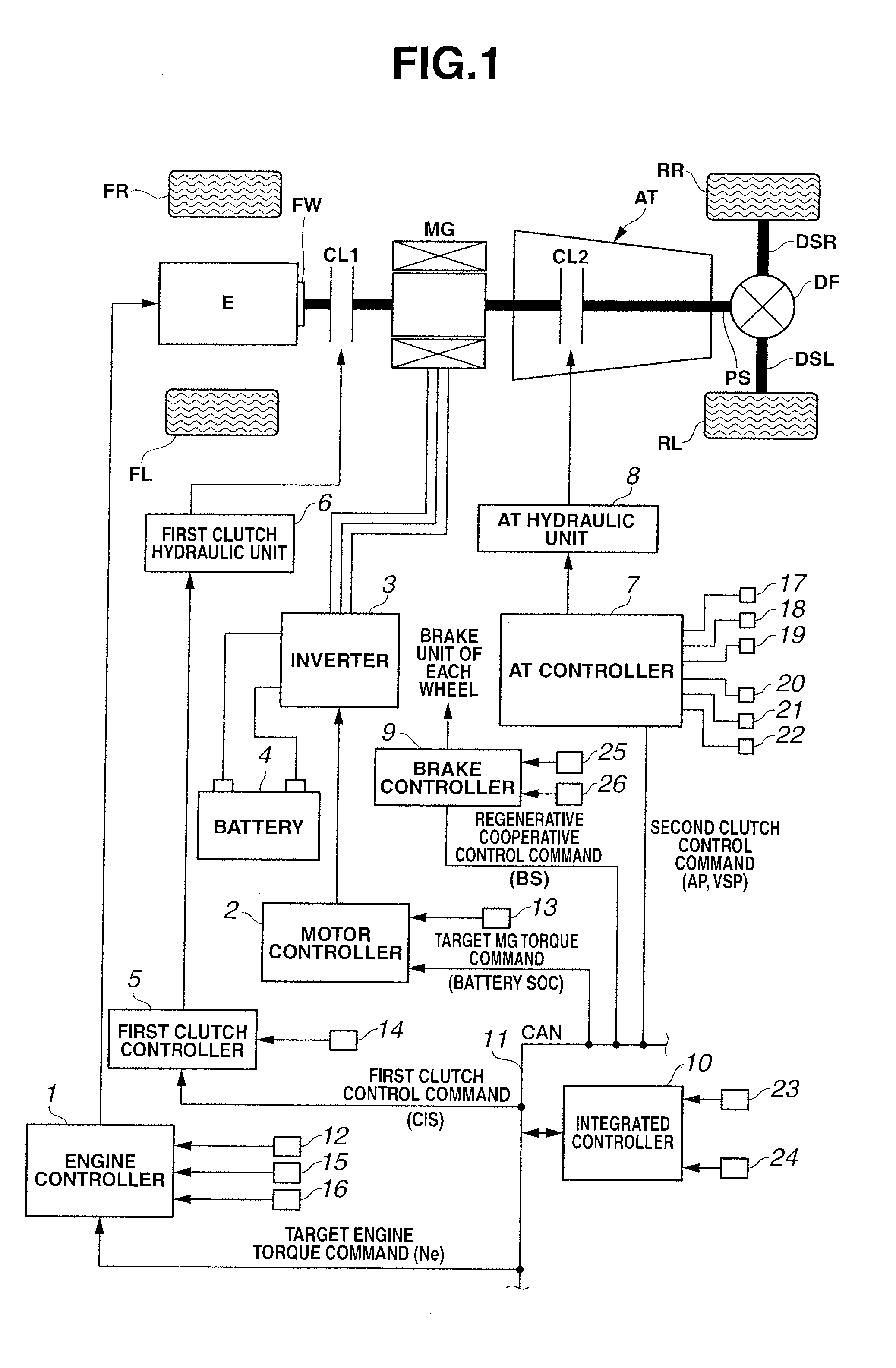

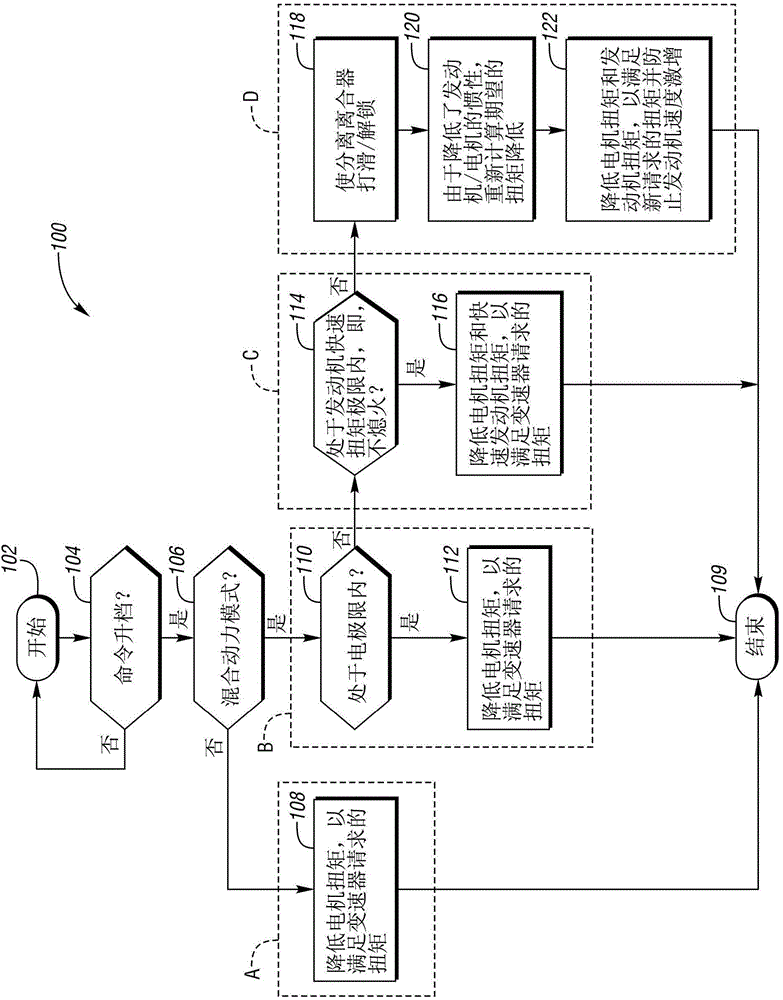

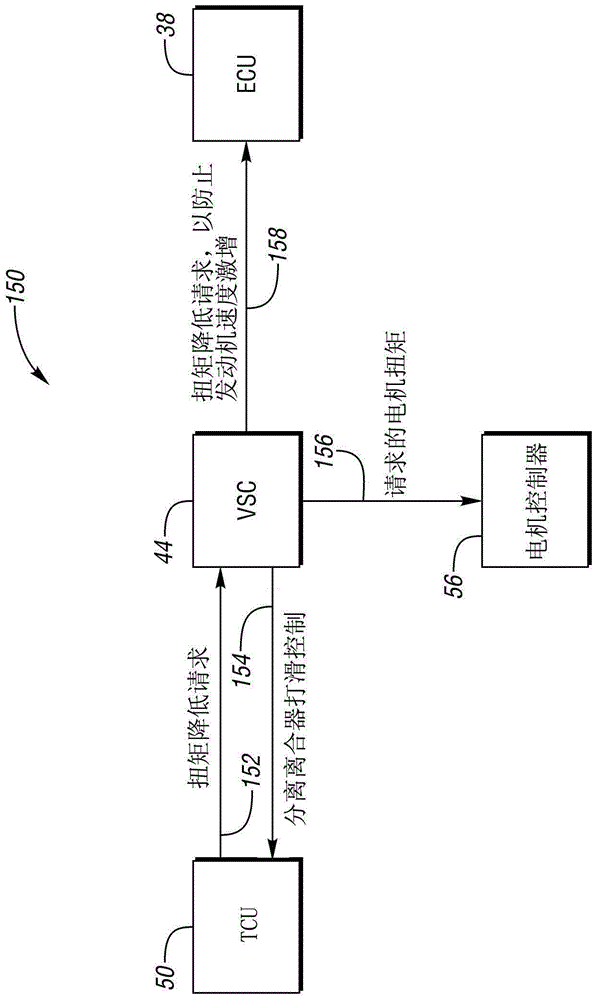

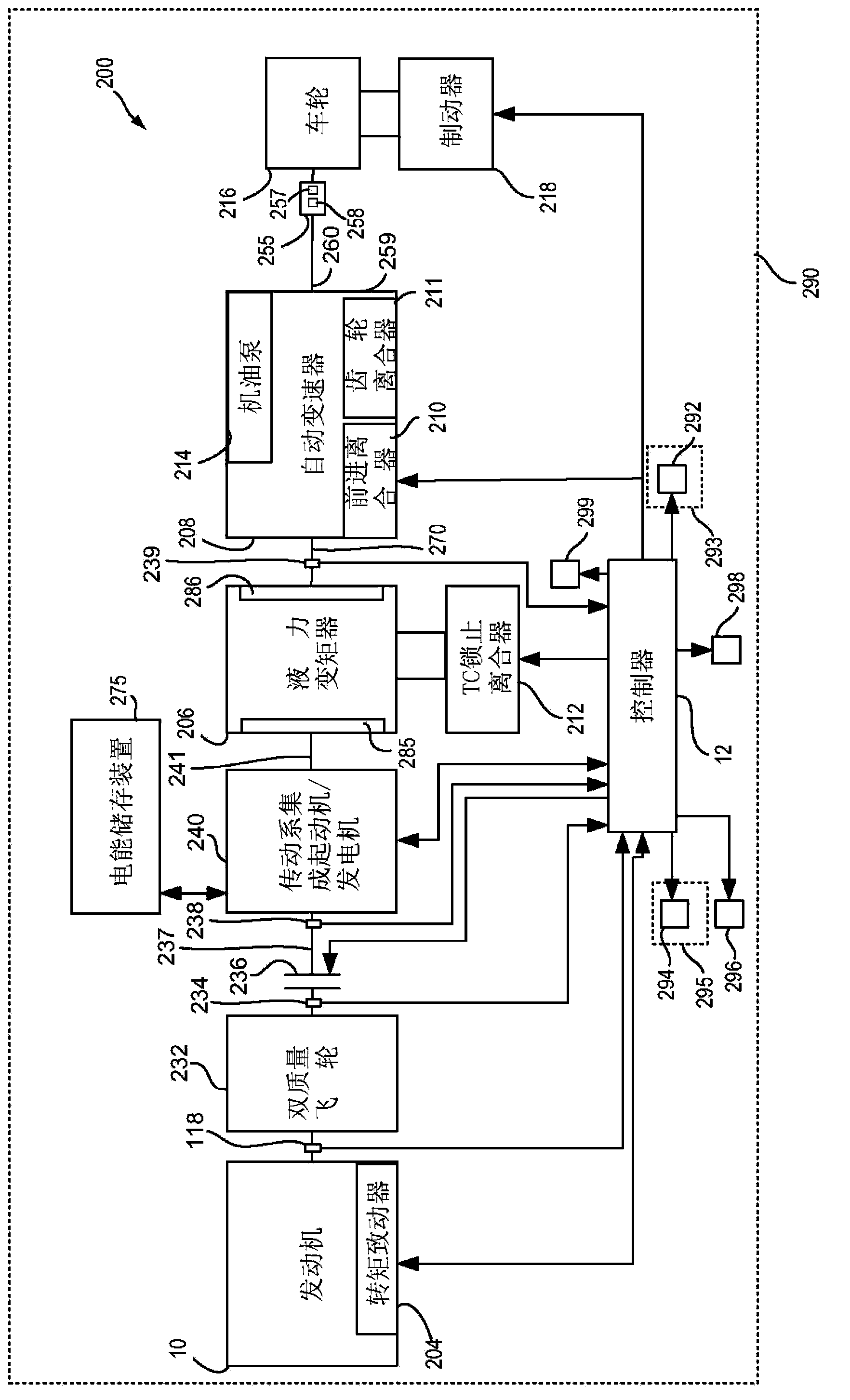

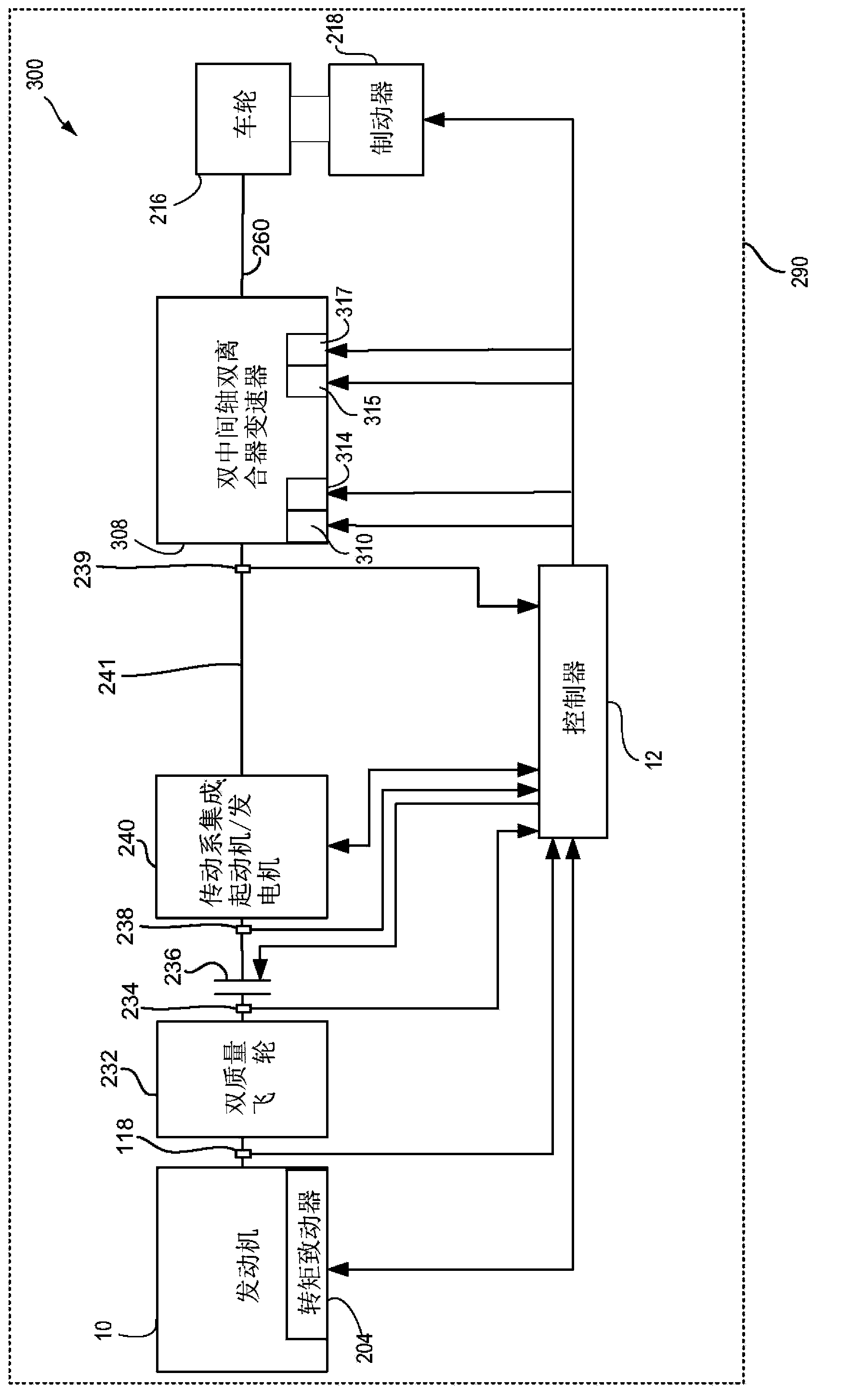

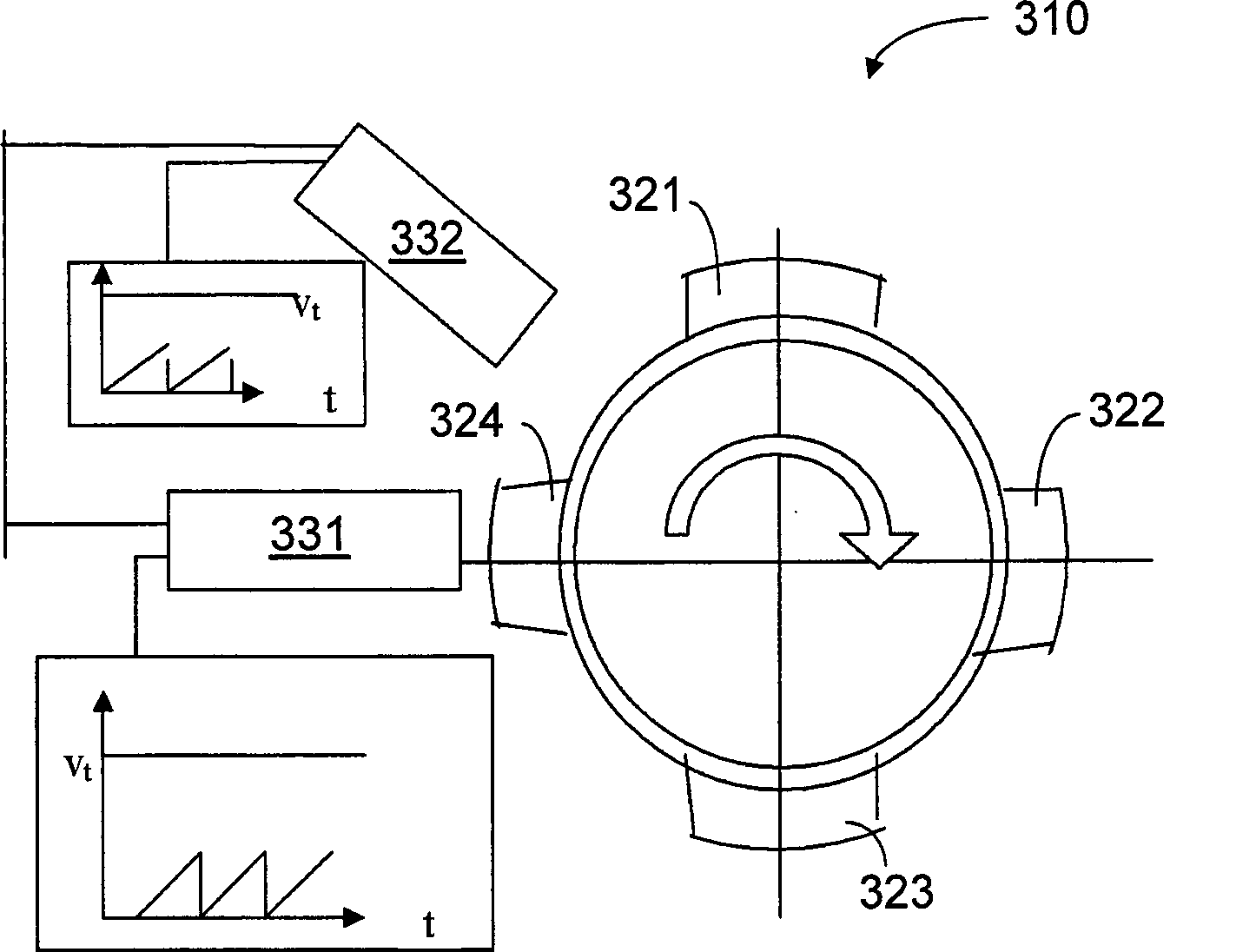

Methods and system for improving hybrid vehicle transmission gear shifting

ActiveCN108583561AReduce input torqueReduce torque disturbanceHybrid vehiclesPlural diverse prime-mover propulsion mountingElectric machineryInternal combustion engine

Methods and systems are provided for operating a driveline of a hybrid vehicle that includes an internal combustion engine, a rear drive unit electric machine, an integrated starter / generator, and a transmission are described. In one example, inertia torque compensation is provided to counter inertia torque during a power-on upshift.

Owner:FORD GLOBAL TECH LLC

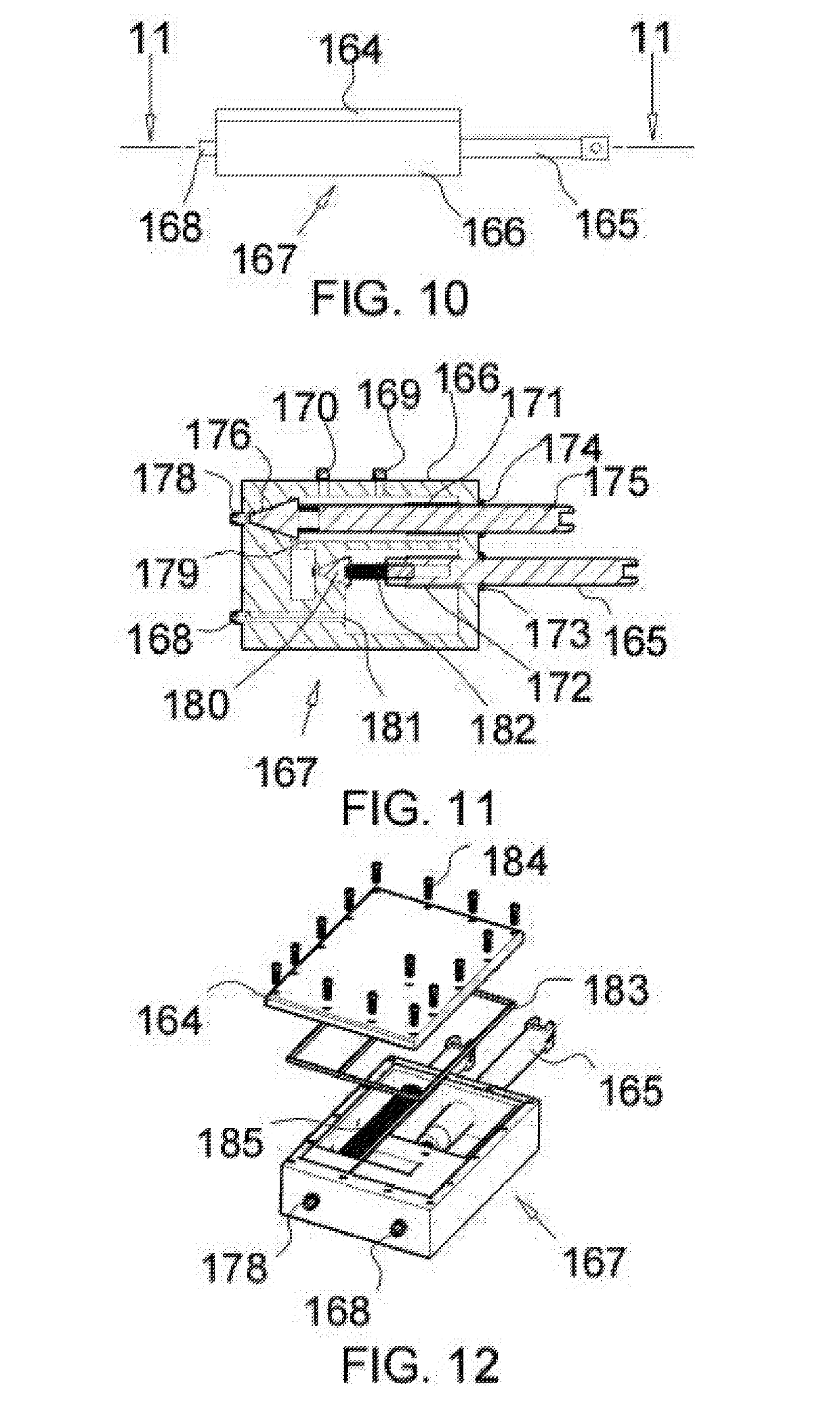

Multi-Hybrid Aircraft Engine

InactiveUS20190186418A1Reduce input torqueGreat driving forceEngine fuctionsJet type power plantsPropellerEngine configuration

A multi-hybrid aircraft engine that includes a primary compressor 1, a multiplier 199 comprising a drive block, a driven block, driven block pistons 54, and primary shafts 78 and 41; an output shaft 105, and a speed regulator 167. The multi-hybrid aircraft engine is configured such that the primary compressor 1 is fluidly connected to the drive block 46 which is mechanically connected to the driven block 57. The primary compressor 1 pumps compressible fluid to the drive block 46 through the speed regulator 167 to drive the drive block 46, which in turn, drives the primary shafts 78 and 41. The primary shafts 78 and 41 drive the driven block 57, which pumps fluid via the driven block pistons 54, to the drive block 46 through the speed regulator 167 to increase the flow rate of compressible fluid within the multi-hybrid aircraft engine. Furthermore, the driven block 57 provides a shaft 68 that is connected to sets of planetary gears 62 connected to an output shaft 105 that drives a propeller 186.

Owner:ROBERT A BINGHAM

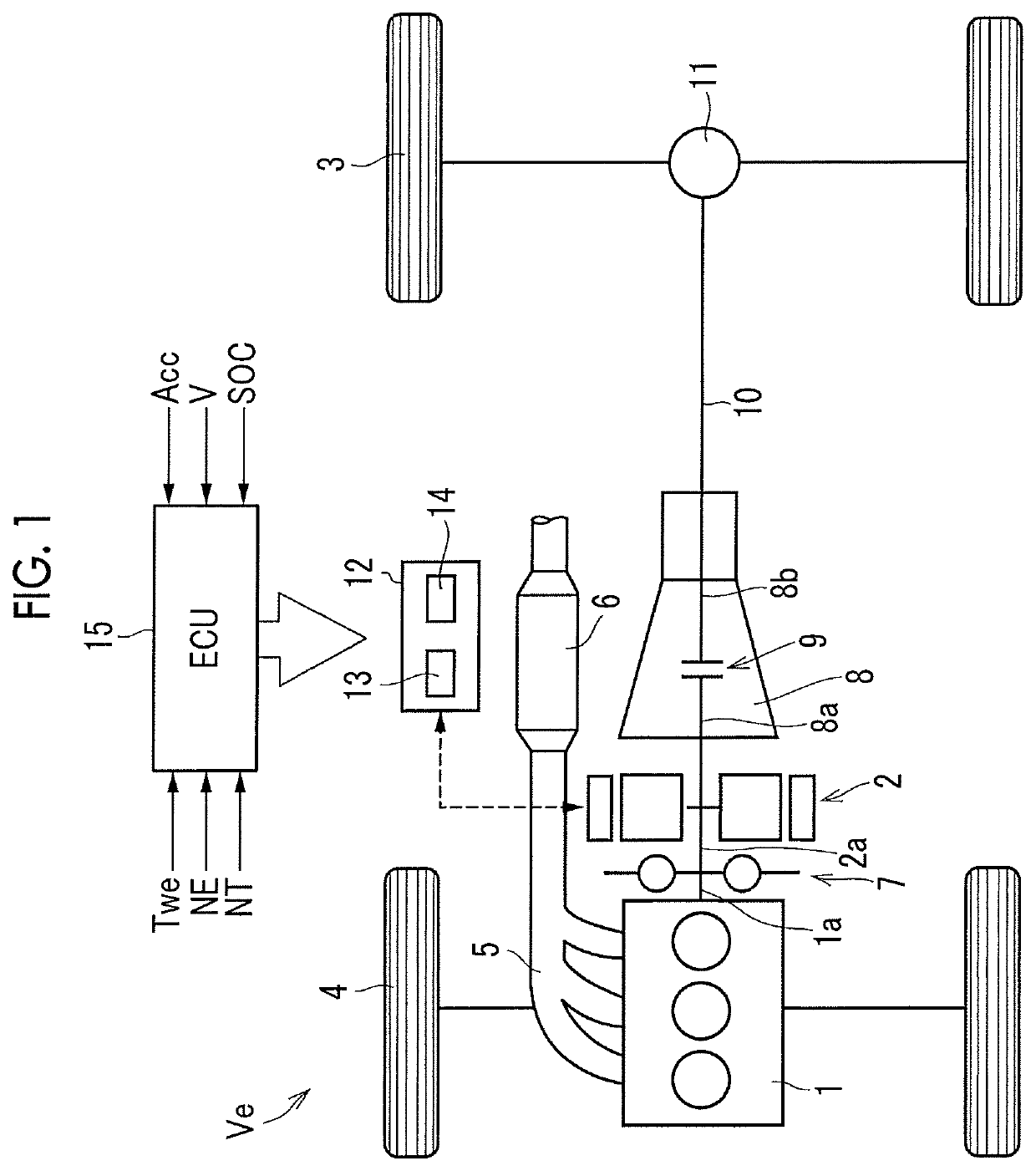

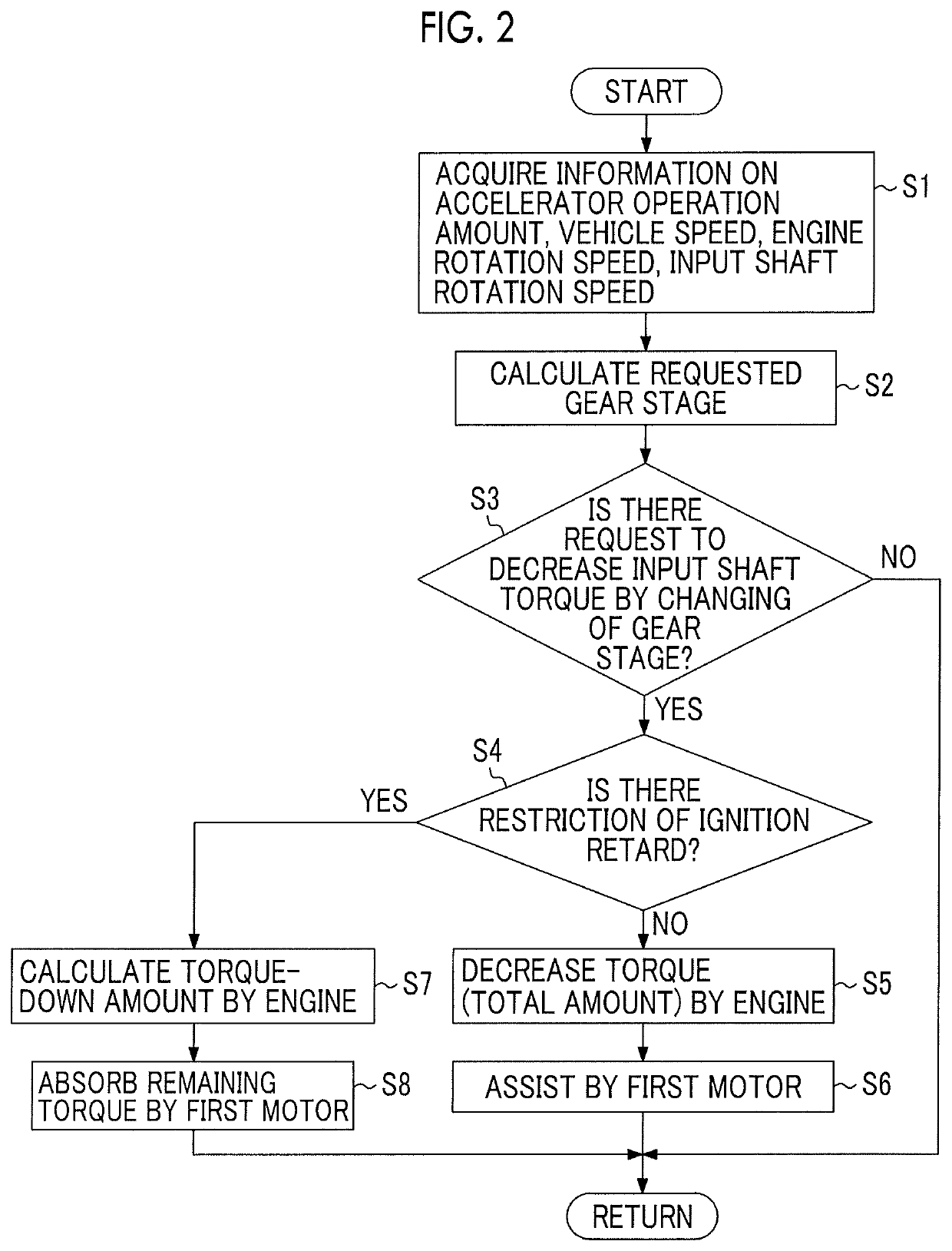

Control device and control method for hybrid vehicle

ActiveUS11247661B2Reduce speedInhibit deteriorationHybrid vehiclesElectrical controlAutomatic transmissionControl engineering

It is provided a control device for a hybrid vehicle including a controller configured to control an engine, a first motor, and an automatic transmission and a control method of the hybrid vehicle. The controller is configured to determine whether or not an operation state of the engine is changeable, when an upshift of the hybrid vehicle is performed, decrease torque of an input shaft of the automatic transmission by outputting negative torque acting to decrease the torque of the input shaft of the automatic transmission from the first motor when a prohibition condition that the operation state of the engine is not changeable is established, and decrease engine torque output from the engine to decrease the torque of the input shaft of the automatic transmission to be decreased accompanied by the upshift when the prohibition condition is not established and the operation state of the engine is changeable.

Owner:TOYOTA JIDOSHA KK

Four-shaft harmonic speed reducer numerical control swing head

InactiveCN104416404AReduce vibrationHigh precisionDriving apparatusMetal working apparatusWheel driveEngineering

The invention discloses a four-shaft harmonic speed reducer numerical control swing head. The four-shaft harmonic speed reducer numerical control swing head comprises a harmonic speed reducer, a synchronous wheel, a synchronous belt, a driving motor, a connecting plate and an electric spindle, wherein the driving motor is connected with the synchronous wheel through the synchronous belt, the synchronous wheel is connected to the harmonic speed reducer, and the harmonic speed reducer is connected to the electric spindle through the connecting plate. According to the four-shaft harmonic speed reducer numerical control swing head, due to the facts that the driving motor is connected with the synchronous wheel through the synchronous belt, and the synchronous wheel drives the harmonic speed reducer to rotate, vibration of the driving motor at a low speed can be effectively reduced, large output torque can be obtained by the driving motor with small input torque, and accuracy of the numerical control swing head can be improved through small rotation gaps of the harmonic speed reducer.

Owner:扬州旺海数控设备科技有限公司

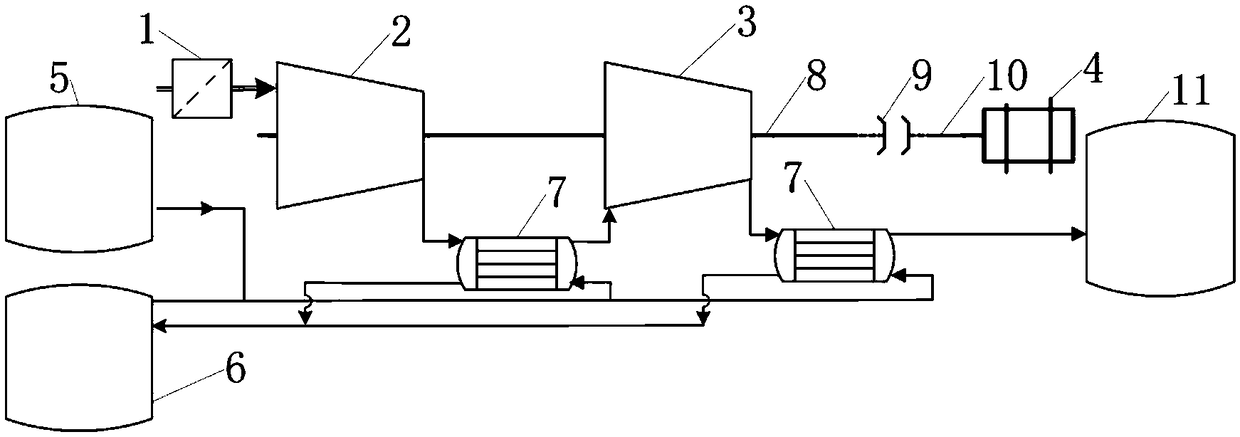

Compressed air energy storage compressor system and control method thereof

PendingCN109441785AReduce input torqueImproving energy storage electricity-to-electricity conversion efficiencyPump controlPiston pumpsFluid couplingThermal energy storage

The invention discloses a compressed air energy storage compressor system and a control method thereof. A hydraulic coupler is connected into the compressed air energy storage compressor system, and amotor is connected with the hydraulic coupler through a motor drive shaft, and the hydraulic coupler is connected with a high-pressure stage compressor through a compressor drive shaft; through the speed adjusting function of the hydraulic coupler, the rotating speed of the compressor can be reduced, and the pressure ratio of the compressor can be adjusted, the pressure of compressed air of compressor outlets can be changed before the compressed air pressure in an air storage tank does not reach the rated pressure, so that the outlet pressure of the compressors is matched with the pressure ofthe air storage tank, and the energy loss of the high pressure compressed air is reduced; and meanwhile, the input torque of the compressors is reduced due to the adjustment of the hydraulic coupler,the motor power is reduced, and the aims that the compressed air energy storage system reduces energy loss and improves electric-electric conversion efficiency are achieved.

Owner:GUIZHOU POWER GRID CO LTD

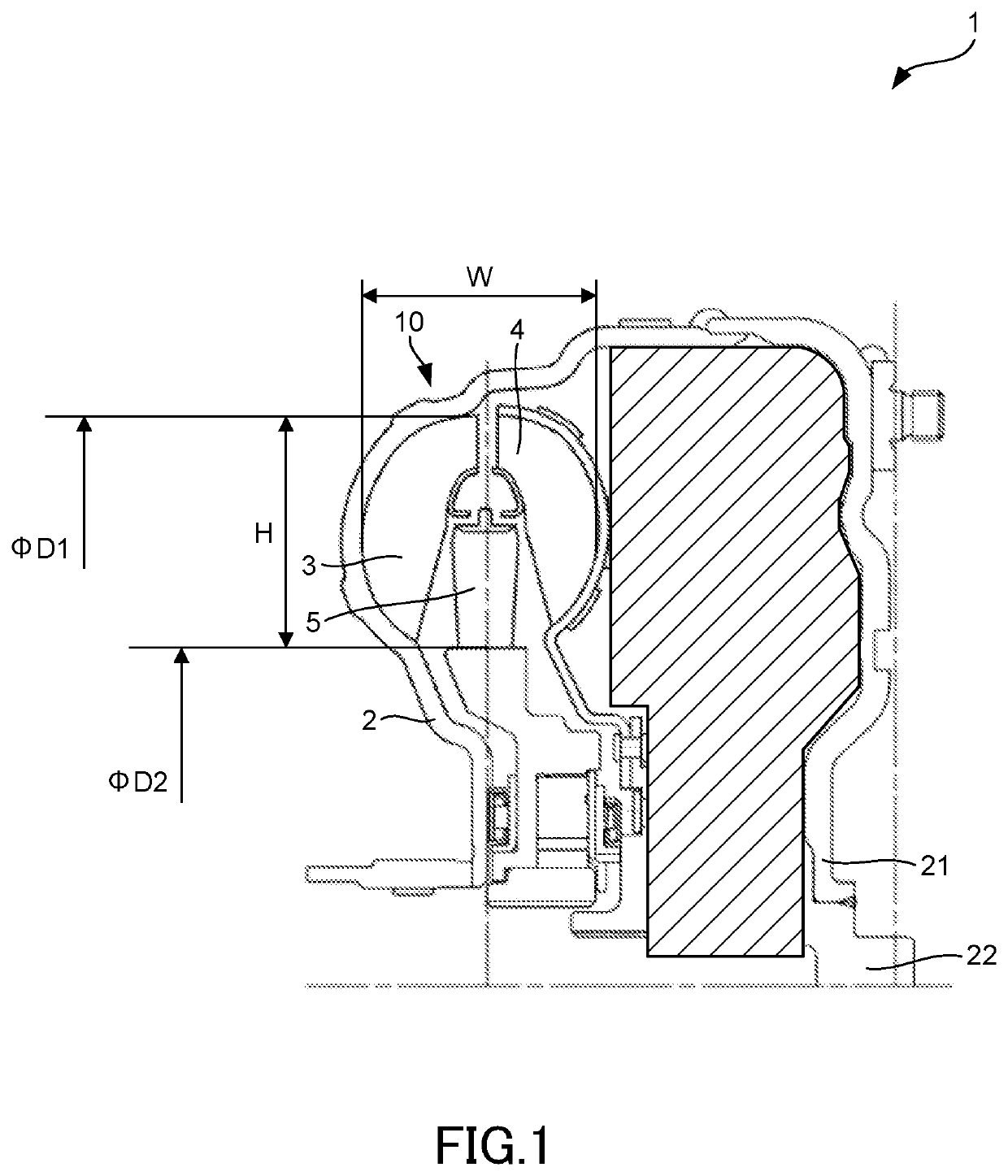

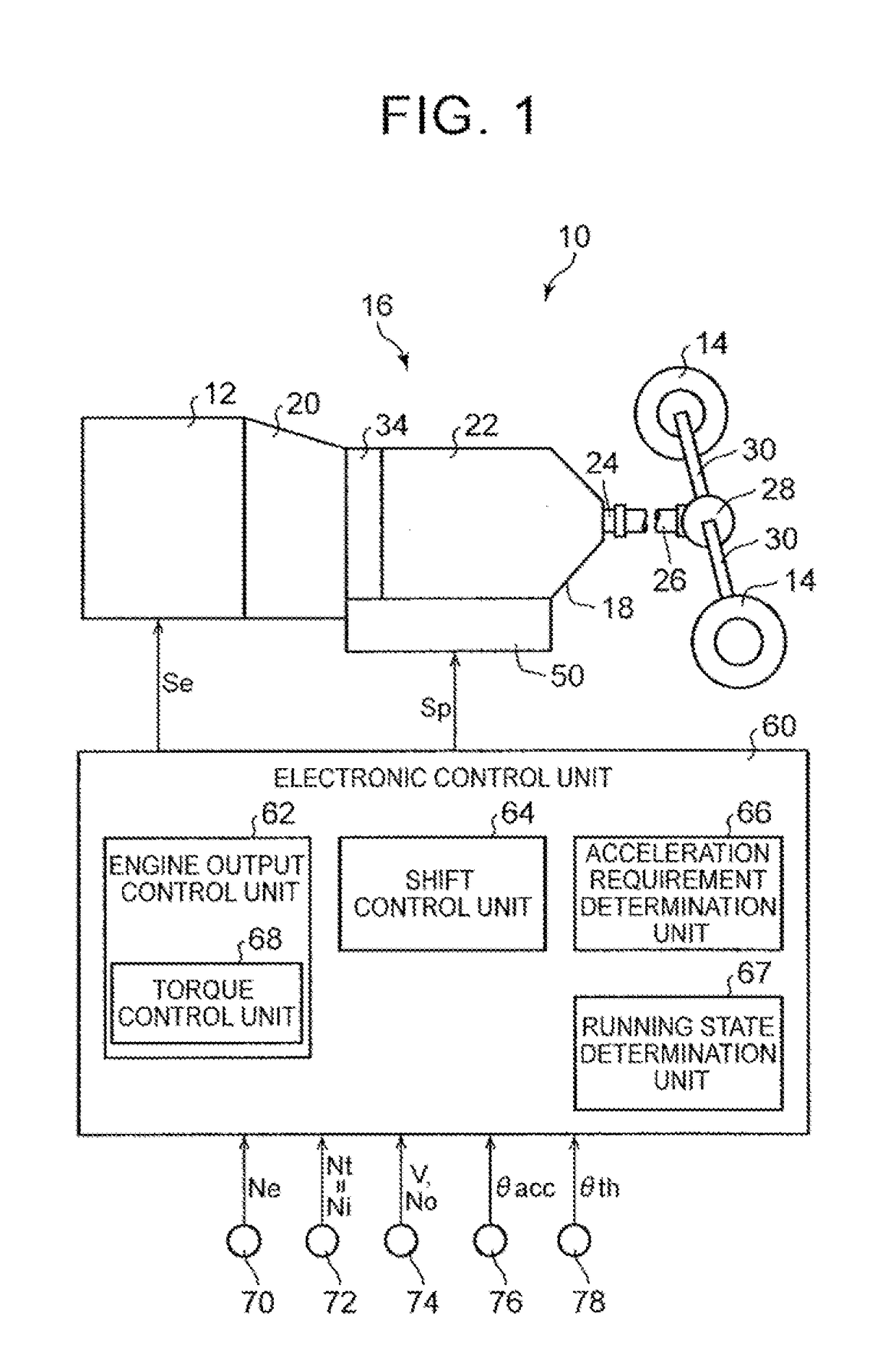

Torque converter

ActiveUS20220025962A1Efficient arrangementSecuring of torque ratioRotary clutchesFluid gearingsEngineeringMechanical engineering

A torque converter has a torus. The torus has a size set based on a flatness ratio obtained by dividing a width of the torus in an axial direction by a width of the torus in a radial direction, a thinness ratio obtained by dividing the width of the torus in the axial direction by an outer diameter of the torus, and an inner diameter ratio obtained by dividing an inner diameter of the torus by the outer diameter of the torus.

Owner:JATCO LTD +1

Control Apparatus and Control Method for Automatic Transmission

ActiveUS20170108117A1Reduce input torquePrevented from feelingToothed gearingsGearing controlAutomatic transmissionIn vehicle

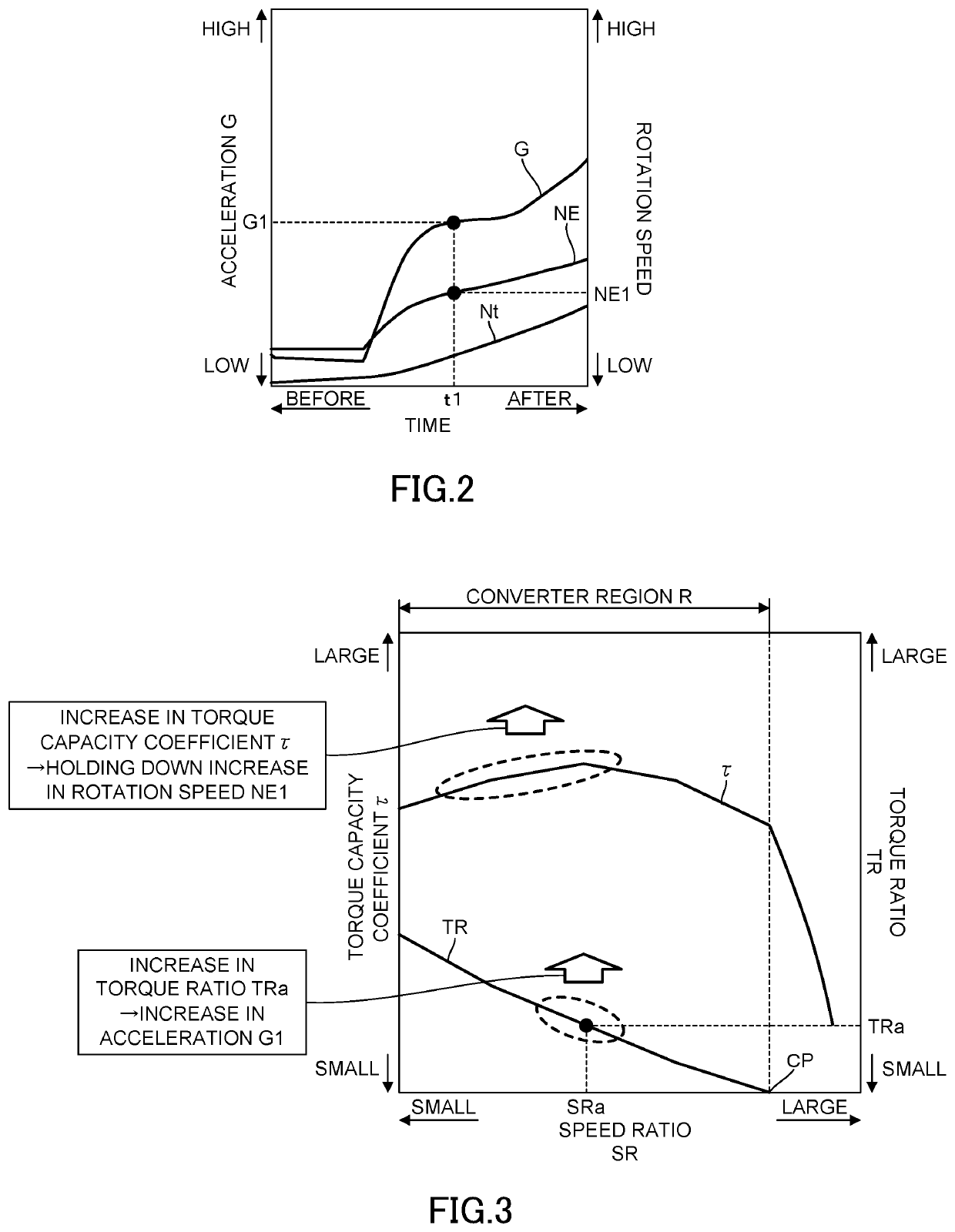

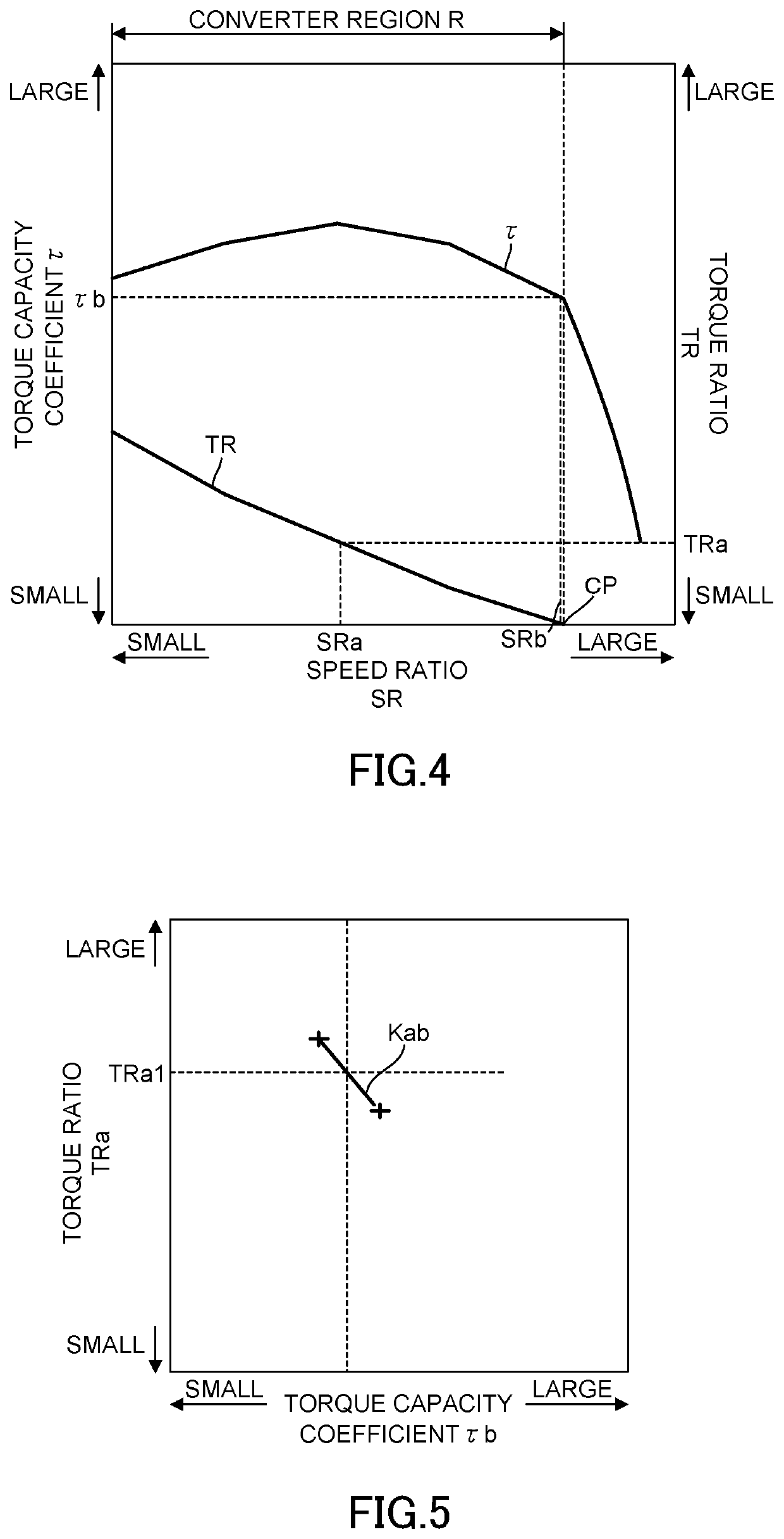

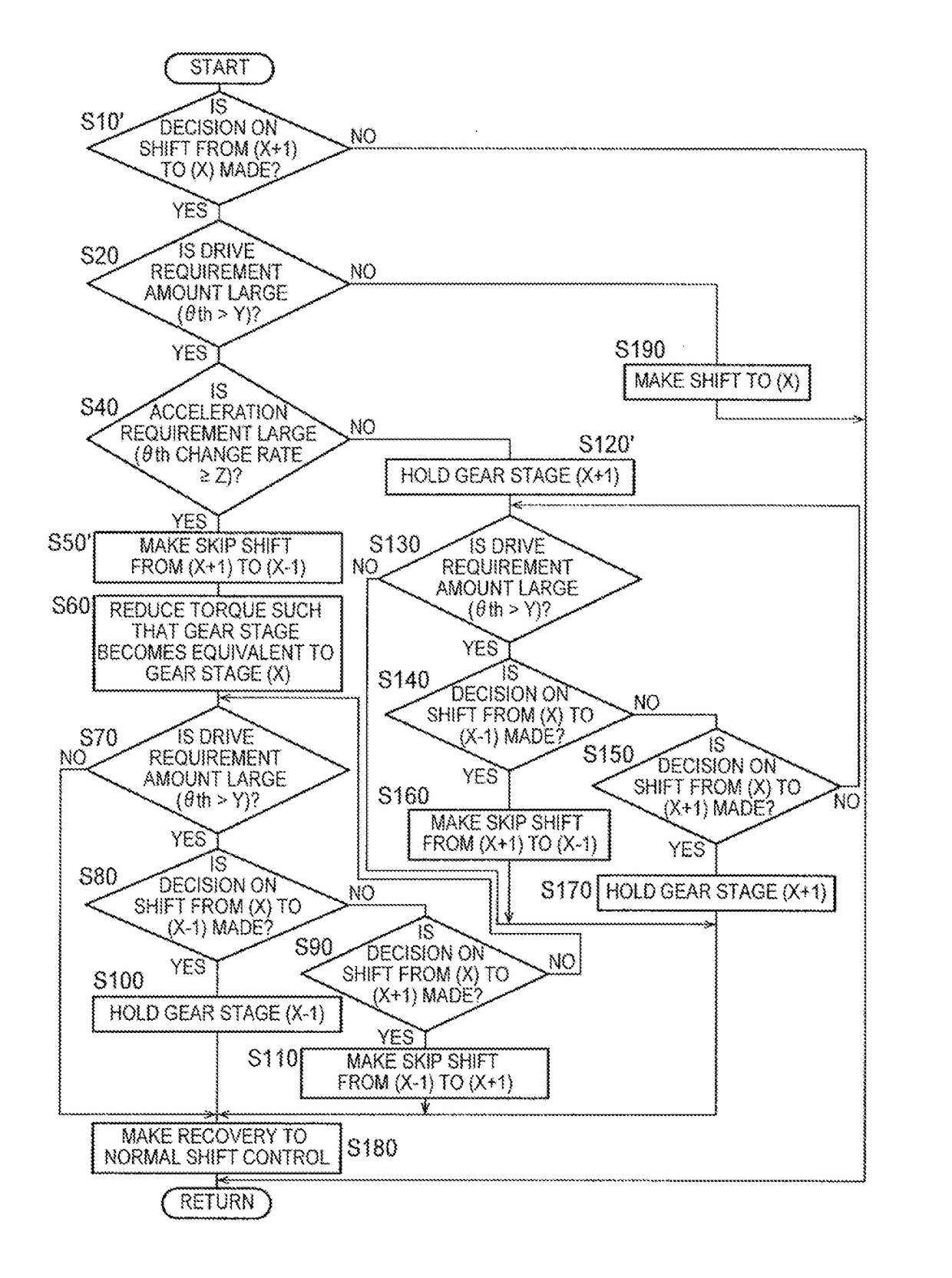

When throttle valve opening degree is larger than predetermined throttle valve opening degree Y in the case where a decision on shift to gear stage at which maximum load is applied to predetermined rotary member of automatic transmission is made, the gear stage is not formed. Therefore, large load is restrained from being applied to the predetermined rotary member of the automatic transmission. Besides, gear stage that is lower in vehicle speed than the gear stage by one stage or gear stage that is higher in vehicle speed than the gear stage by one stage is formed depending on whether acceleration requirement is large or small. Therefore, driving torque corresponding to the acceleration requirement is likely to be obtained. In consequence, the load applied to the predetermined rotary member of the automatic transmission can be reduced, and feeling of strangeness can be restrained from being caused by the driving torque.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com