Low input torque rotor for vane pump

a vane pump and low input torque technology, applied in the direction of positive displacement liquid engines, piston pumps, liquid fuel engines, etc., can solve the problem of achieve the effect of reducing the shear force of the fluid and reducing the required input torqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]As used herein, those skilled in the art will appreciate that a vane-type fluid displacement unit encompasses both vane-type pumps and motors.

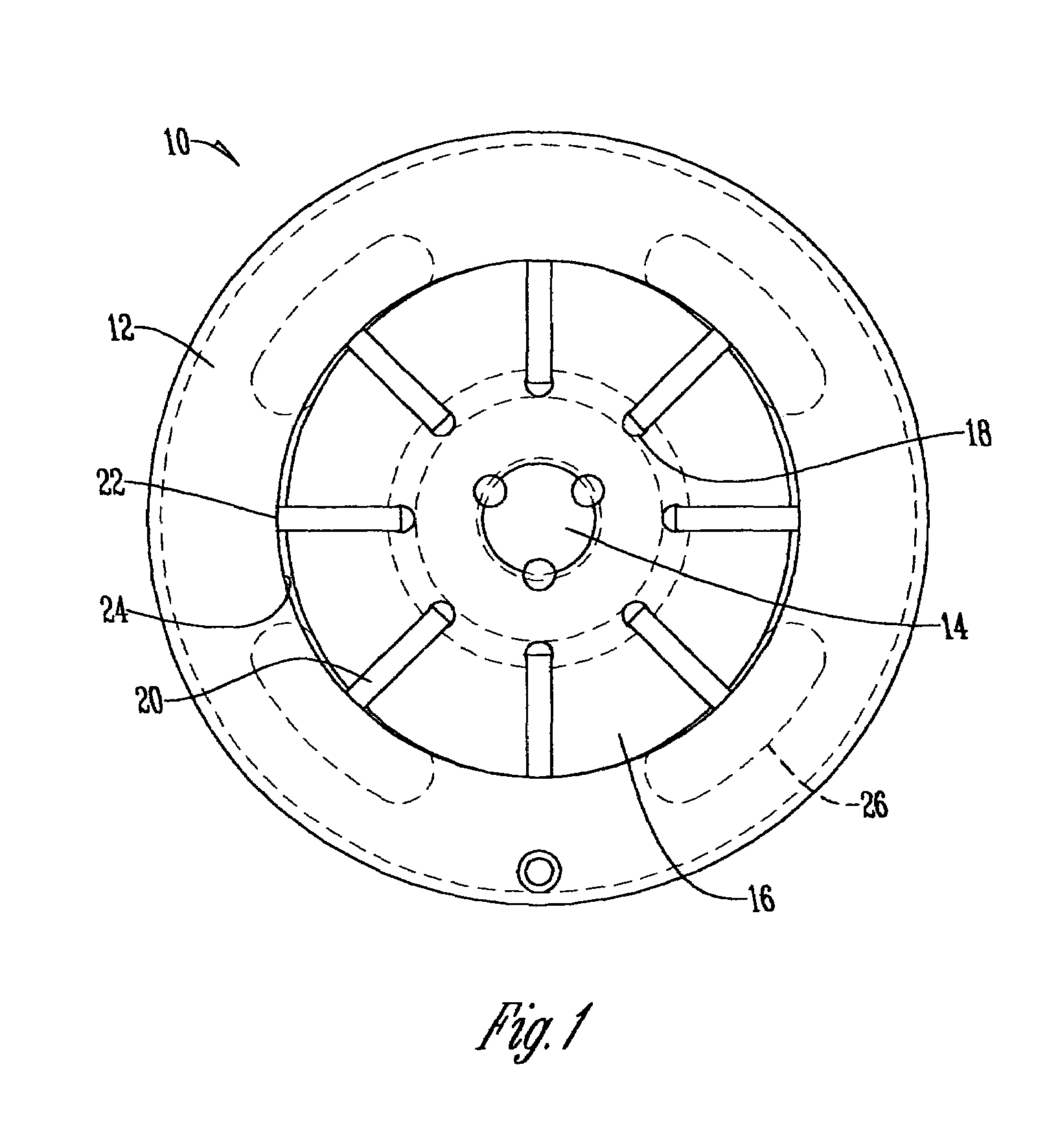

[0016]With reference to FIG. 1, a typical vane-type fluid displacement unit 10 is shown having a cam ring or housing 12, a drive shaft 14 extending through the housing 12, a rotor 16 secured to the drive shaft 14 and having slots 18 for receiving vanes 20. Fluid pressure within the slots 18 forces the vanes 20 radially outward such that the tips 22 of the vanes engage with the inner diameter 24 of the housing 12. In this manner, the vanes 20 sweep fluid compressed between the rotor 16 and inner diameter 24 of the housing 12 between inlet / outlet ports 26, as is well known in the art.

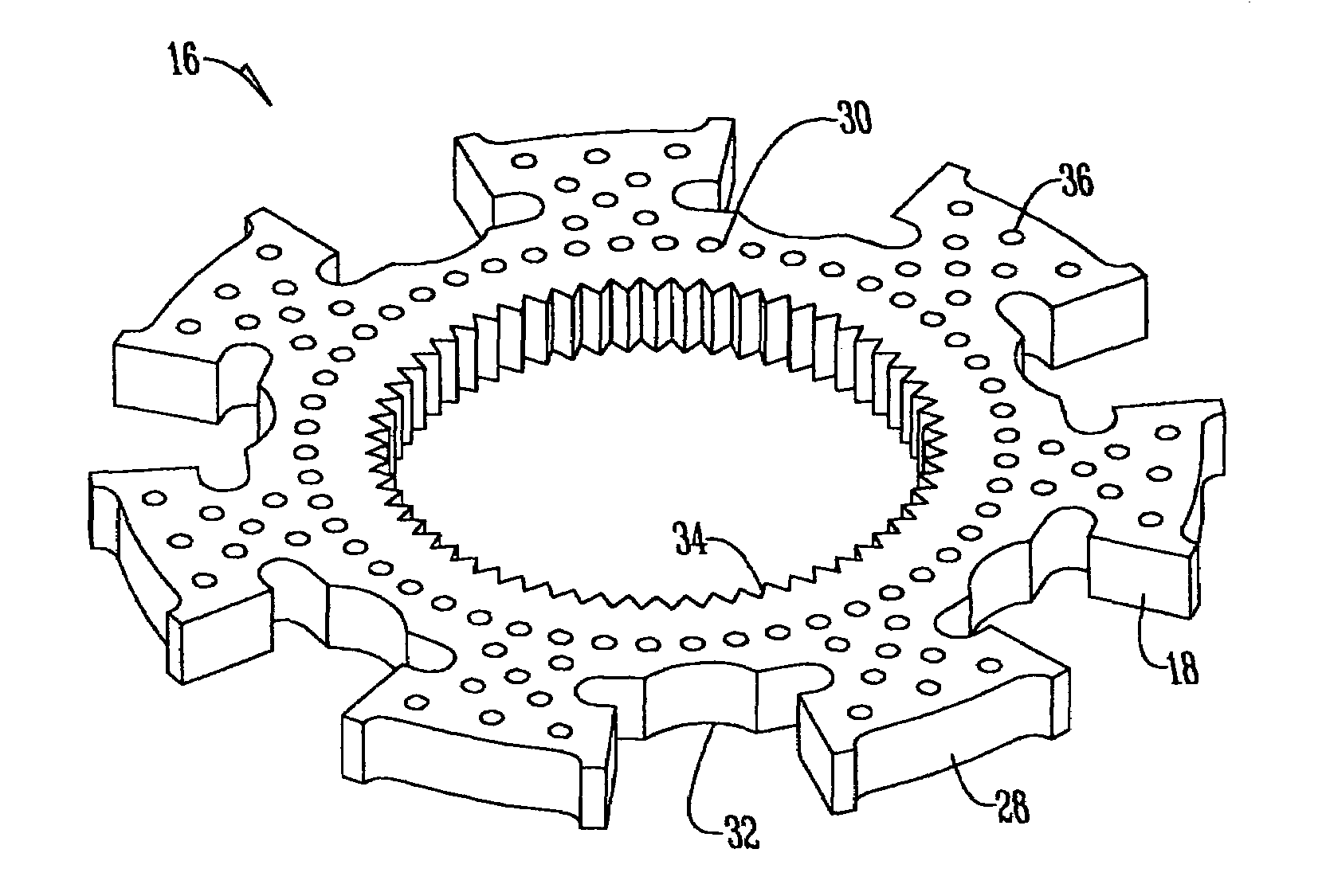

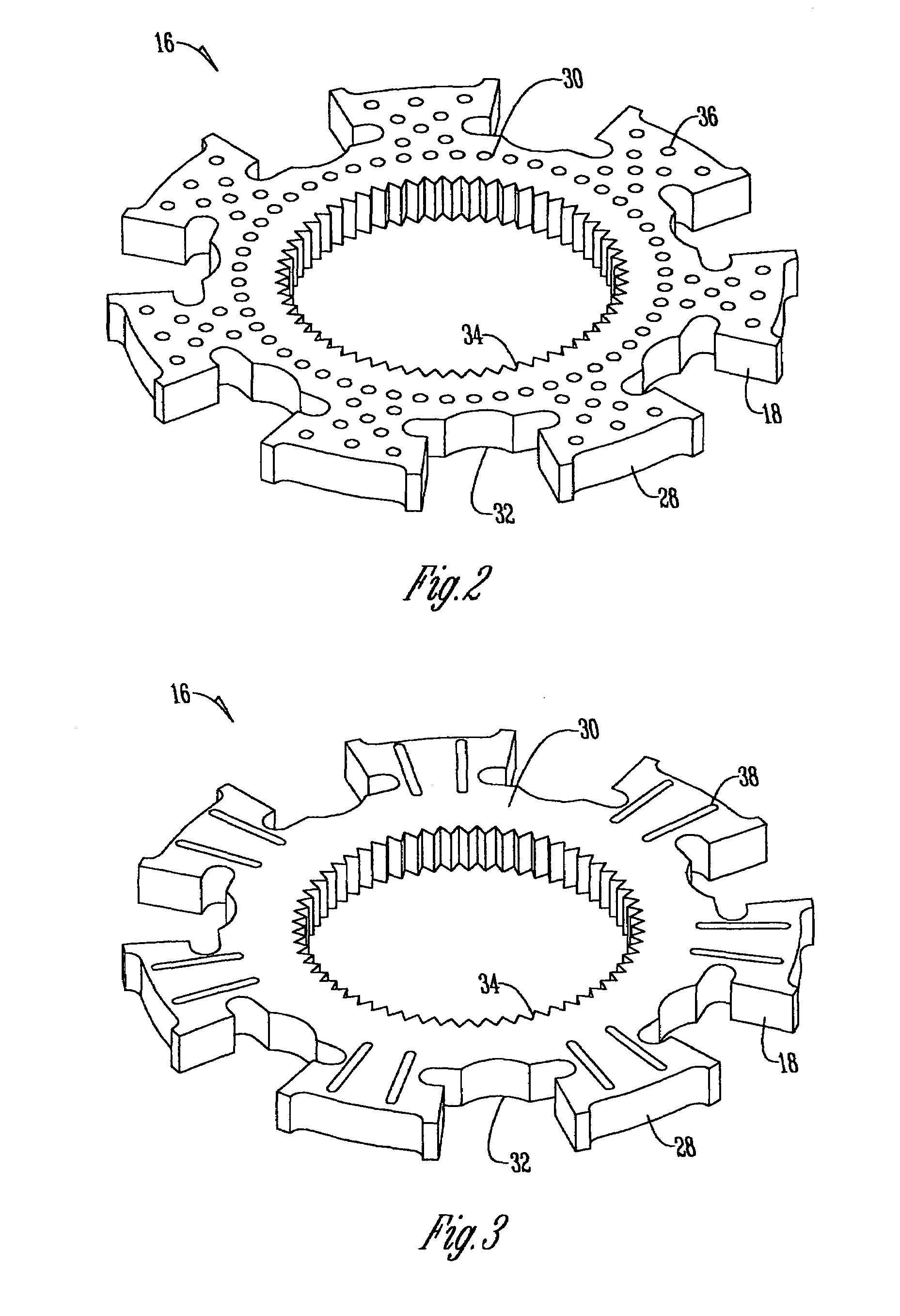

[0017]With reference to FIGS. 2-6, the rotor 16 is generally circular in shape with an outer side surface 28 and a top surface 30 opposite a bottom surface 32. Rotor 16 further includes a central aperture 34 to matingly receive the drive shaft 14. As shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com