Method and device for controlling an automatic transmission

A technology of automatic transmission and braking clutch, applied in transmission control, components with teeth, gear vibration/noise attenuation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

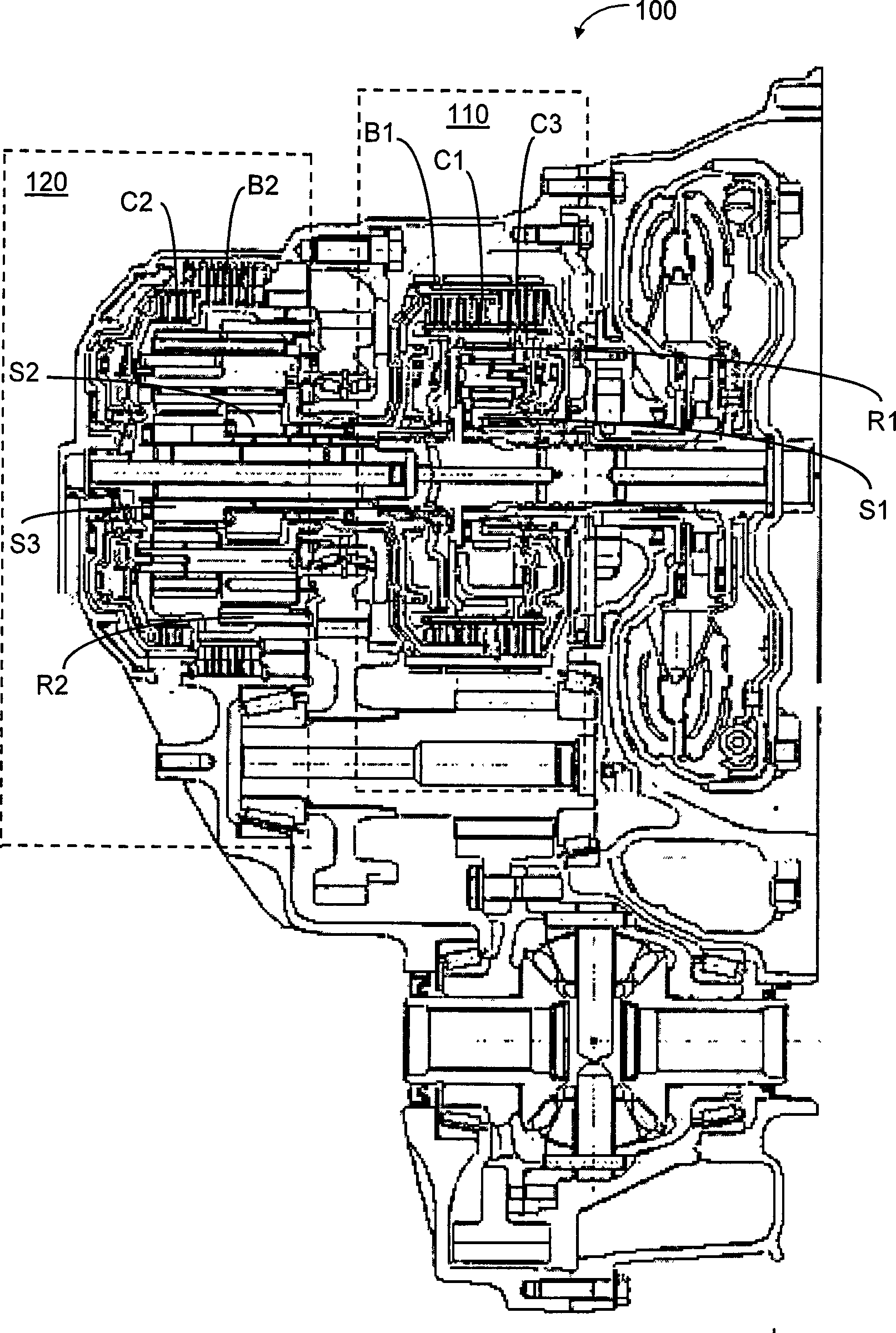

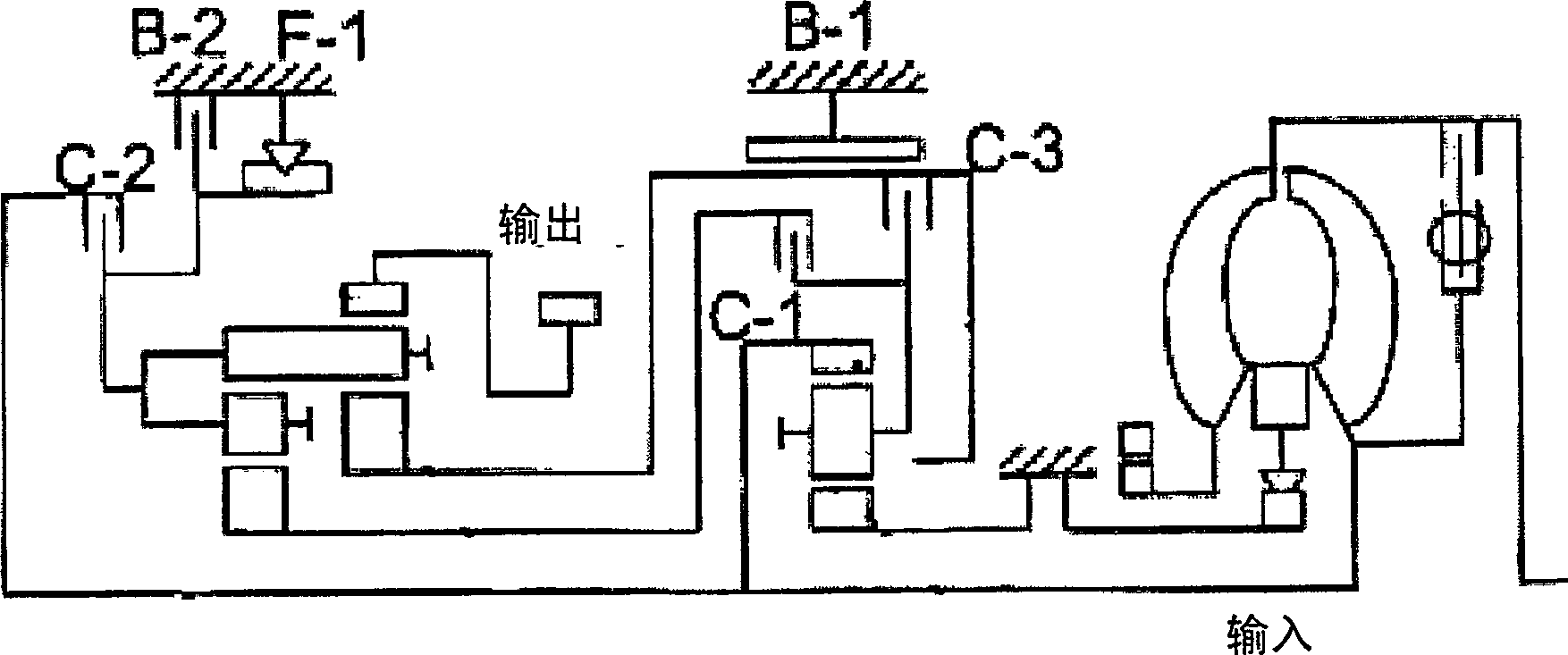

[0025] The method and device for controlling the automatic transmission of the present invention are specifically realized as schematically in figure 1 with figure 2 A six-speed automatic transmission 100 is shown in FIG. 1 , which combines a single-stage planetary gear mechanism 110 with a double-stage planetary gear mechanism or Ravigneaux-type planetary gear mechanism 120 . This existing structure is also referred to as the "Lepe Laijie" type planetary gear mechanism.

[0026] figure 1 A structural sectional view of the transmission is shown here, figure 2 A schematic diagram of a gear mechanism is shown.

[0027] exist figure 1 In the shown structure, the single-stage planetary gear mechanism 110 is used as a reduction transmission or a reduction transmission, and has a sun gear S1, a ring gear R1, planetary gears, and a planetary carrier. The sun gear S1 is permanently fixed. The ring gear R1 is connected to the turbine shaft.

[0028] A double-stage planetary ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com