Levelling device for large shell type component

A technology of leveling device and housing, which is applied in the direction of workbench, manufacturing tools, etc., can solve the problems of inconvenient operation, long time for leveling, unstable lifting, etc., achieve good lifting stability, convenient operation, and save working time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

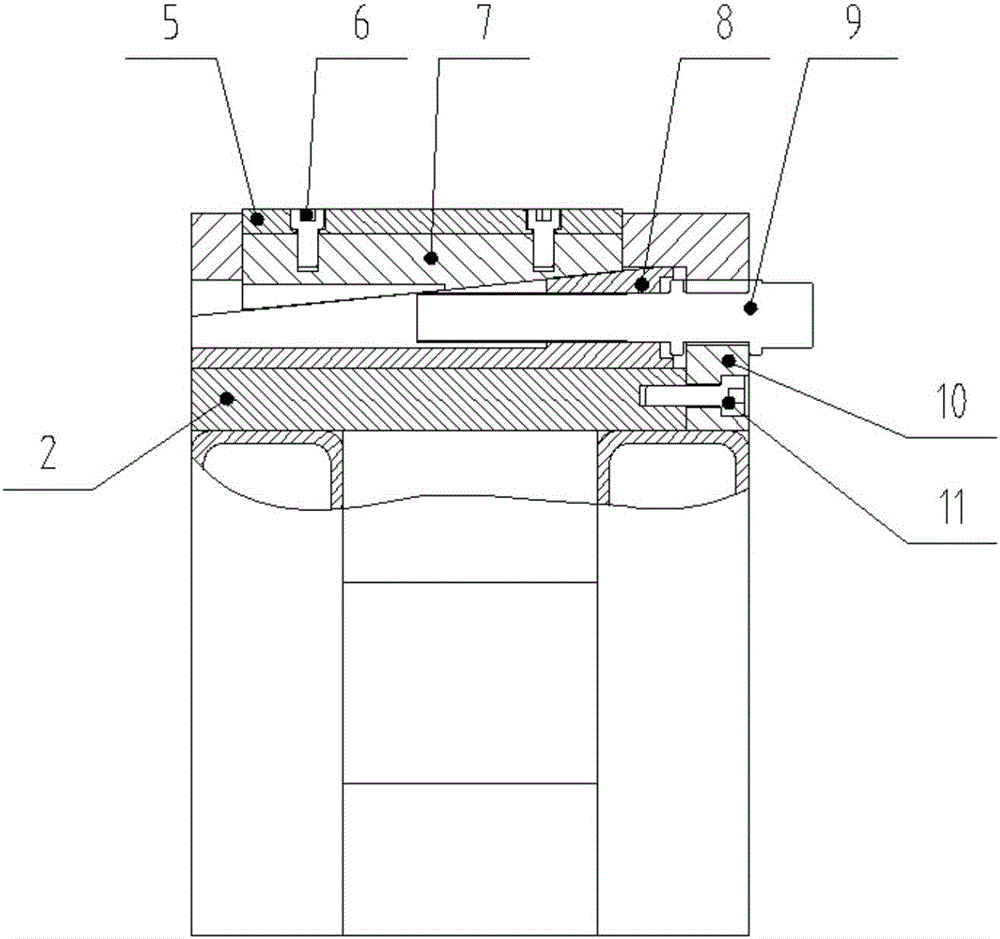

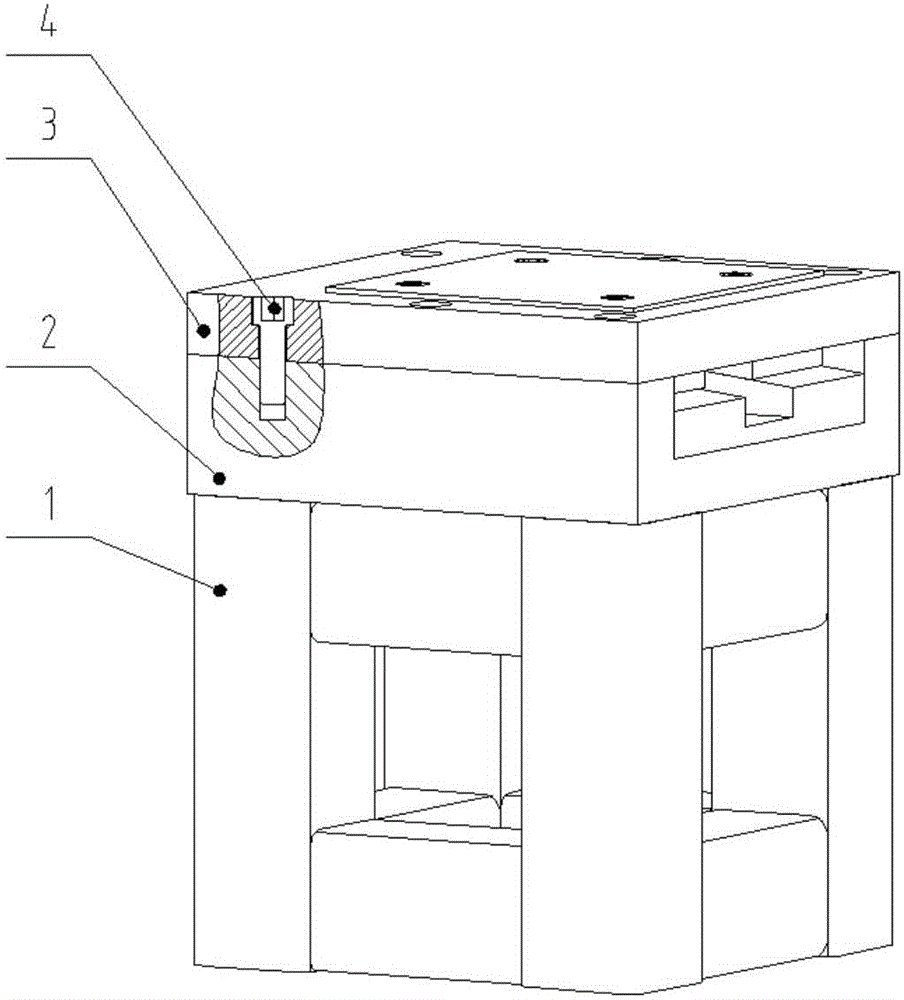

[0019] Such as figure 1 , 2 As shown, a leveling device for large shell parts includes a support base 1, a base 2, a pressure plate 3, a bolt 4, a rubber pad 5, a bolt 2 6, a lifting italic body 7, a thrust italic body 8, a power screw rod 9, spacer 10 and bolt three 11,

[0020] The base 2 is a concave body whose upper surface is provided with transparent grooves at both ends, and the base 2 is welded above the support seat 1;

[0021] The spacer 10 is located above the support seat 1, and the spacer 10 is connected to one side of the bottom of the base 2 through the bolts 11;

[0022] The upper part of the thrust slant 8 is a slope, the thrust slant 8 is located in the groove of the base 2, and the higher end of the thrust slant 8 faces the pad 10, and the thrust slant 8 is from the upper The side of the high end has a horizontal hole towards the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com