Automated drive train for a motor vehicle and method of controlling a drive train

a technology of automatic drive train and motor vehicle, which is applied in the direction of gearing control, transmission elements, toothed gearings, etc., can solve the problems of increasing the traction force, so as to reduce the input torque, reduce the torque provided by the motor, and reduce the input torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

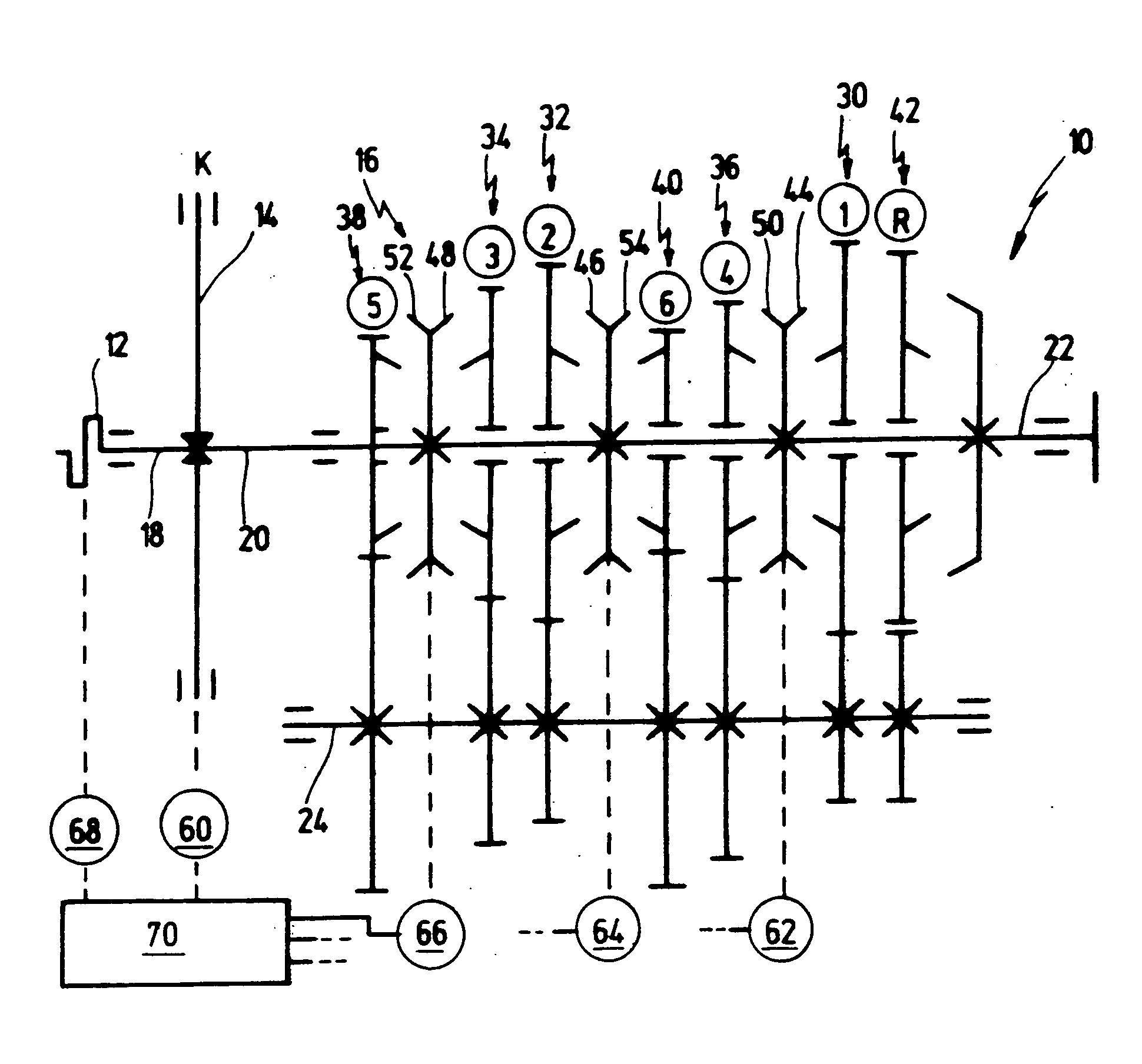

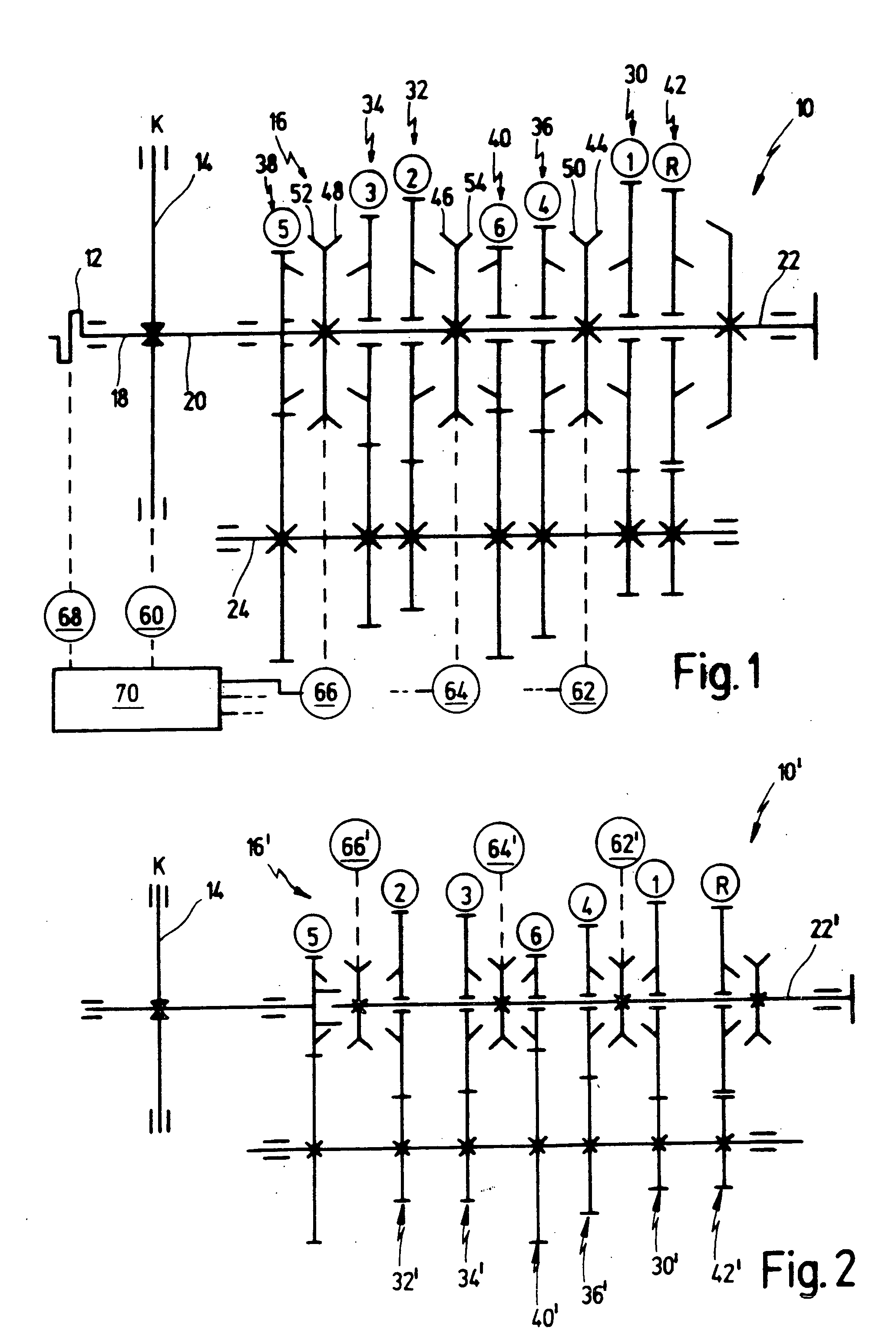

[0053] A drive train for an automobile is shown in FIG. 1 and generally indicated with the numeral 10. The drive train 10 comprises a motor 12, in particular a combustion engine, a single friction clutch 14 configured as a disconnection and starting clutch, and a step transmission (shift transmission) 16.

[0054] A motor drive shaft 18 is connected to an input element (not shown) of the clutch 14. An output element (also not shown) of the clutch 14 is connected to an input shaft 20 of the transmission.

[0055] The shift transmission 16 has the standard construction for longitudinal assembly in a motor vehicle and comprises a transmission output shaft 22 arranged to be concentric with the input shaft 20. Numeral 24 indicates a layshaft (an auxiliary shaft) arranged parallel to the shafts 20, 22.

[0056] The shift transmission 16 comprises seven wheel sets 30, 32, 34. 36.. 38, 40, 42 for the forward gears one to six and a reverse gear R. The wheel set 38 for the fifth gear establishes co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com