Four-shaft harmonic speed reducer numerical control swing head

A harmonic reducer, swing head technology, applied in metal processing machinery parts, metal processing, drive devices and other directions, can solve the problems of low torque, small transmission, and poor transmission accuracy, to improve accuracy, reduce The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

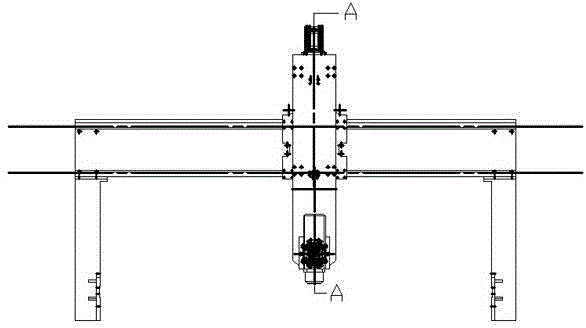

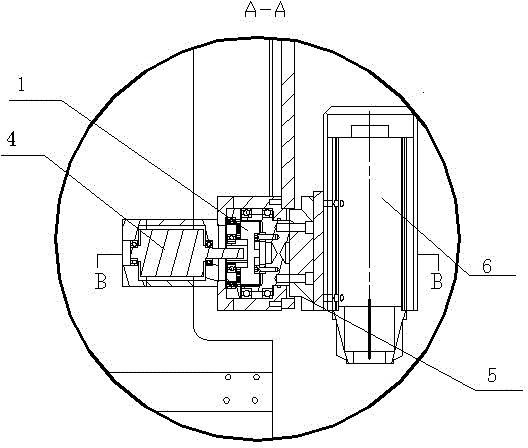

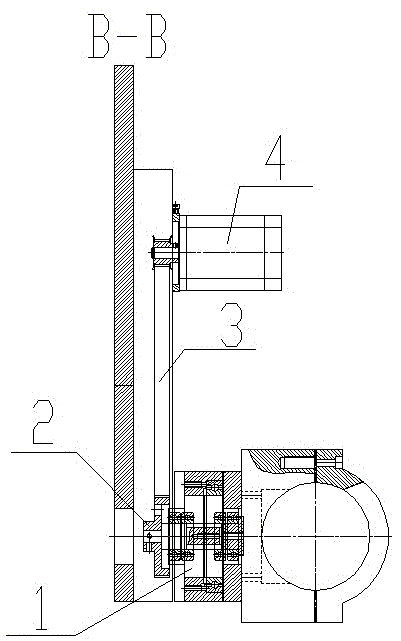

Image

Examples

Embodiment Construction

[0011] As shown in the figure: a four-axis harmonic reducer CNC swing head, including harmonic reducer 1, synchronous wheel 2, synchronous belt 3, transmission motor 4, connecting plate 5, electric spindle 6, transmission motor 4 is connected through synchronous belt 3 The synchronous wheel 2, the synchronous wheel 2 is connected to the harmonic reducer 1, and the harmonic reducer 1 is connected to the electric spindle 6 through the connecting plate 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com