Polishing disk trimming device of polishing machine

A dressing device and polishing disc technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, abrasive surface adjustment devices, etc., can solve the problems of increased load, high equipment cost, increased motor power, etc. Equipment operation mode, optimizing equipment energy consumption, reducing the effect of rotational inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following examples are only specific examples of the present invention. In order to make the purpose, technical solutions and advantages of the present invention clear at a glance, the present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The scope of protection of the present invention is not limited by the examples. limit.

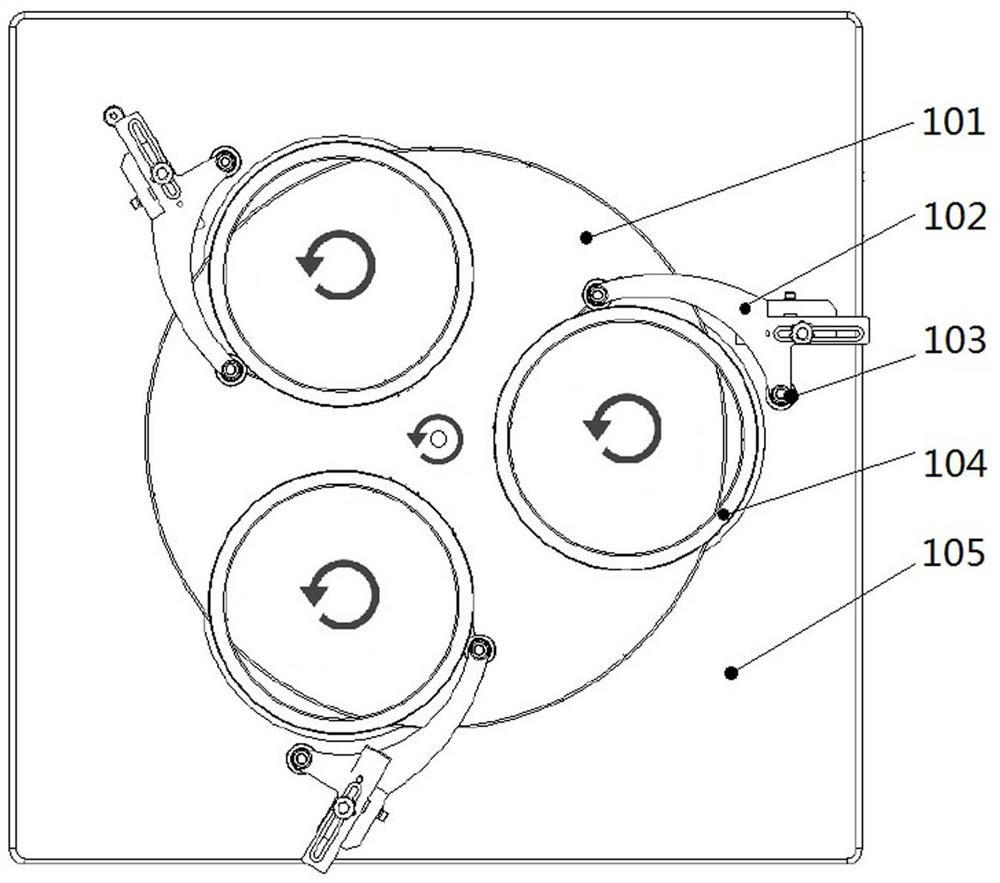

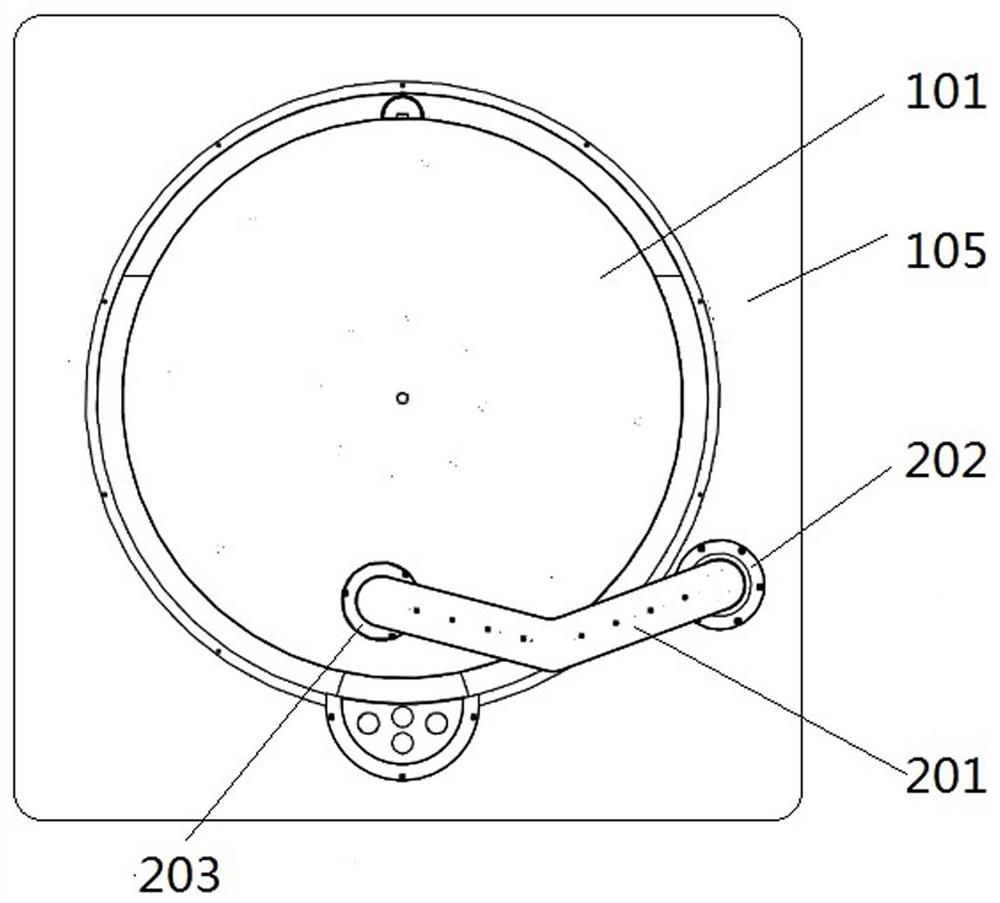

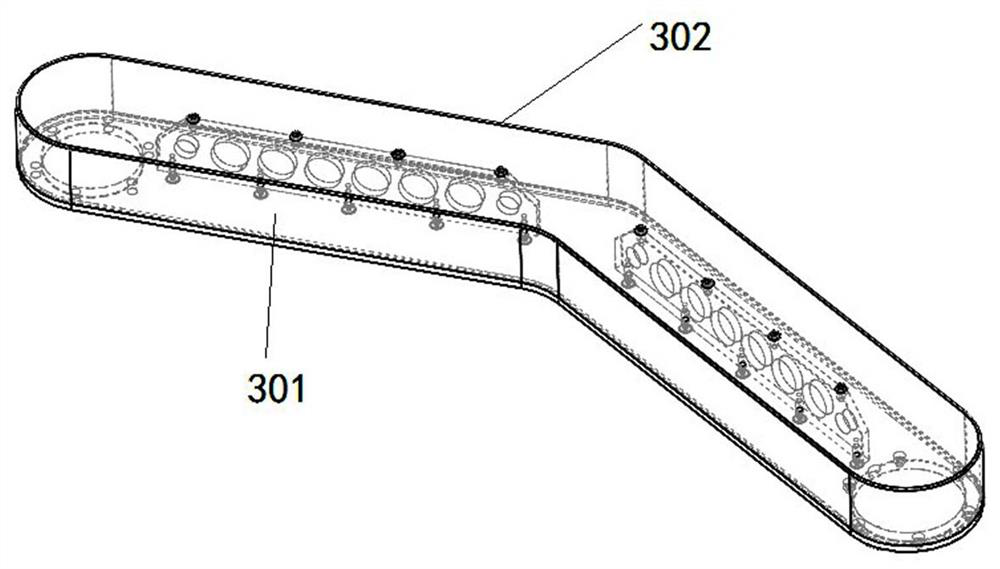

[0034] like figure 2 As shown, the present invention is a polishing disc dressing device for a polishing machine, which is composed of a rotating arm assembly 201 , a driving assembly 202 and a disc dressing spindle assembly 203 . The driving assembly 202 is fixed on the workbench 105 by screws uniformly distributed around the circumference, one end of the rotating arm assembly 201 is fixed on the rotating flange 412 of the driving part 202 by the screws uniformly distributed around the circumference, and the other end of the rotating arm assembly 201 is fixed on the rotating f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com