Novel large torque piling machine power head hardened reducer

A hard-tooth surface reducer and high-torque technology, which is applied in the direction of mechanical equipment, transmission devices, transmission device parts, etc., can solve problems that affect normal use and service life, centrifugal force cannot cancel each other, and affect the performance of pile drivers, etc., to achieve Eliminate running influence, improve smooth running performance, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

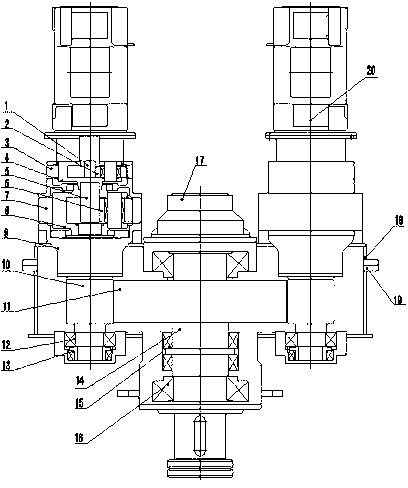

[0015] figure 1 As shown, a new type of high-torque pile machine power head hard tooth surface reducer includes a first-stage sun gear 1, a first-pole planetary gear 2, a first-stage outer ring gear 3, a first-stage planet carrier 4, a first-stage sun gear 5, and a first-stage sun gear. Pole planetary gear 6, stage outer ring gear 7, secondary planet carrier 8, planetary support body 9, helical gear shaft 10, sun gear 11, first roller bearing 12, first plane bearing 13, output shaft 14, second Plane bearing 15 , second roller bearing 16 , grouting device system 17 , body 18 , cover 19 and input motor 20 . The two ends of the output shaft 14 are connected and supported on the machine body 18 and the cover body 19 respectively. The output shaft 14 on one side of the machine body 18 is connected to the grouting device system 17, and the central gear 11 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com