Wheel and running equipment with same

A wheel and equipment technology, applied in the field of wheels and walking equipment with the wheels, can solve problems affecting the safety and life of use, poor environmental adaptability, tire burst or damage, etc., achieve reliable pulse continuous rotation, and improve motion stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

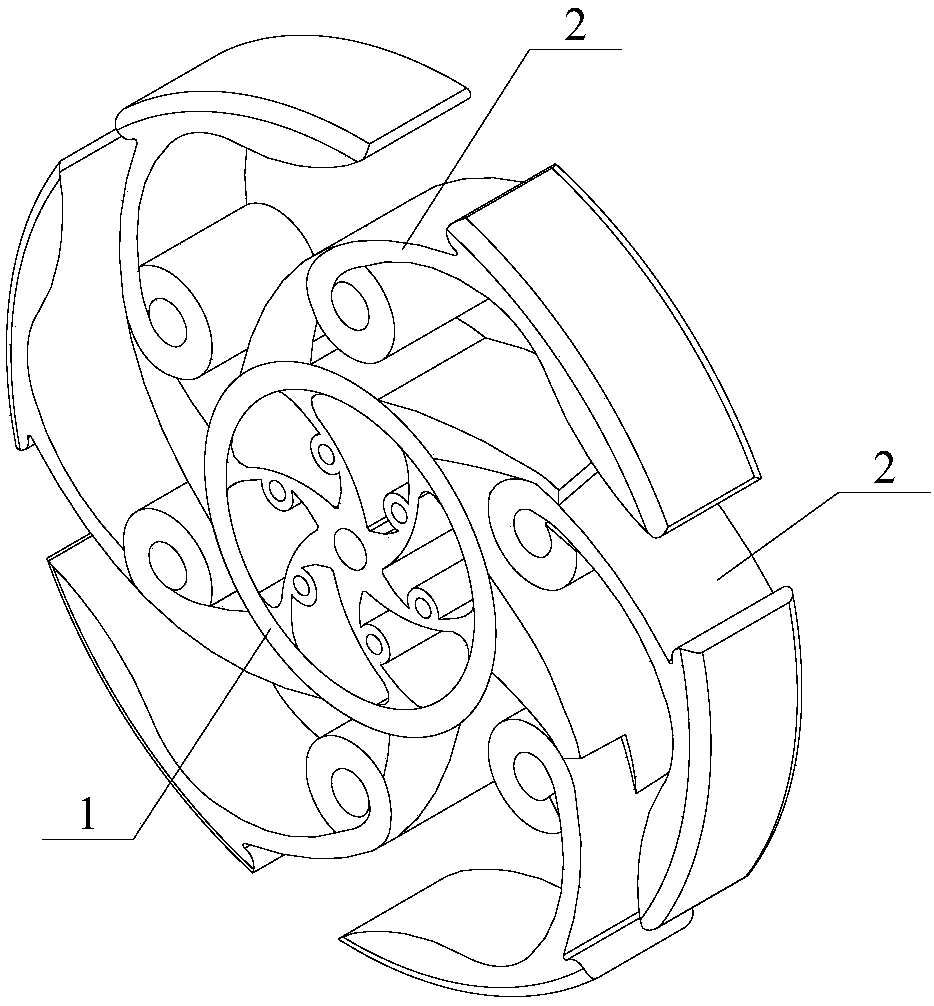

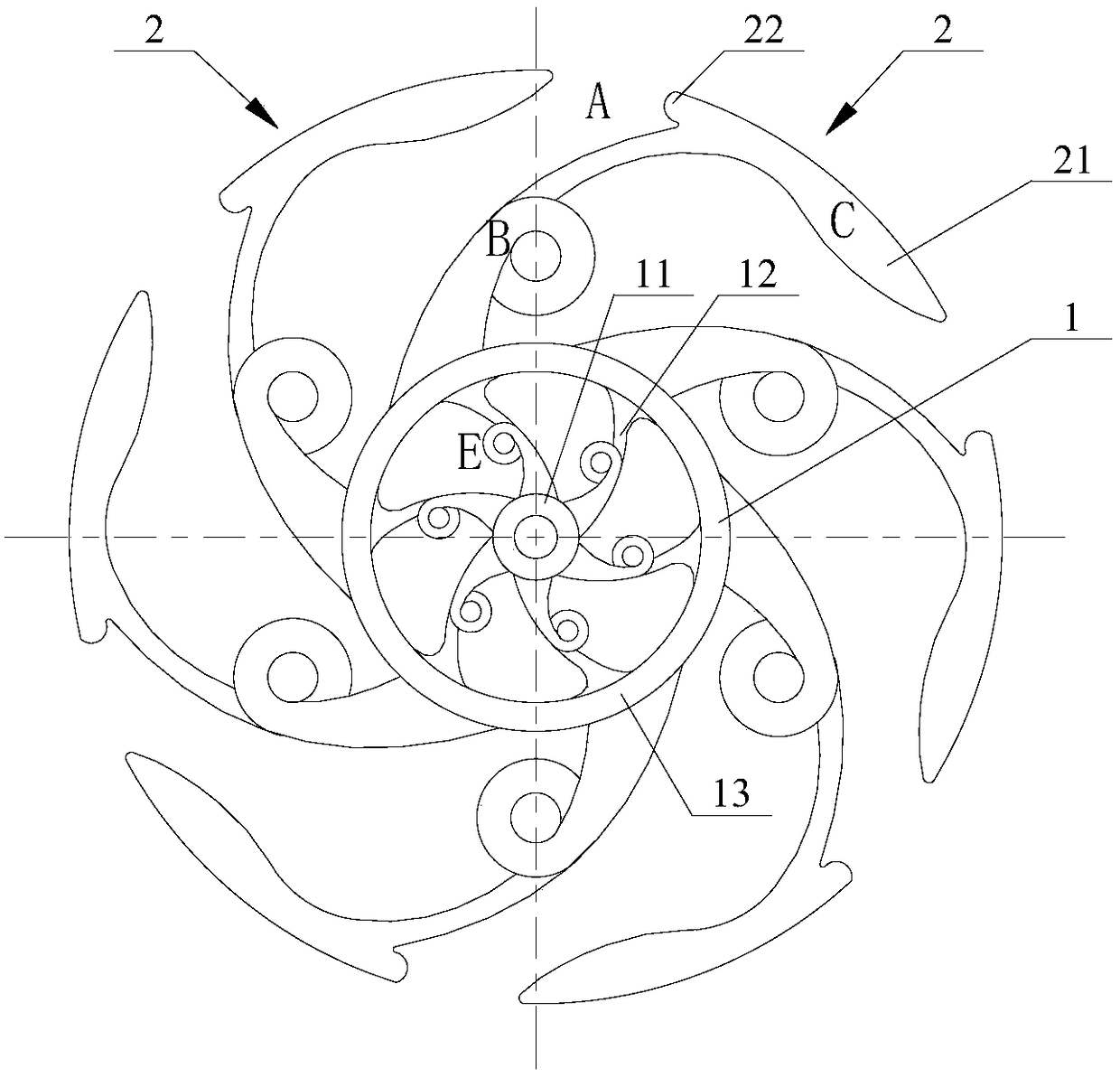

[0039] See figure 1 with figure 2 ,among them, figure 1 Is a three-dimensional schematic diagram of the wheel of this embodiment, figure 2 The front view of the wheel.

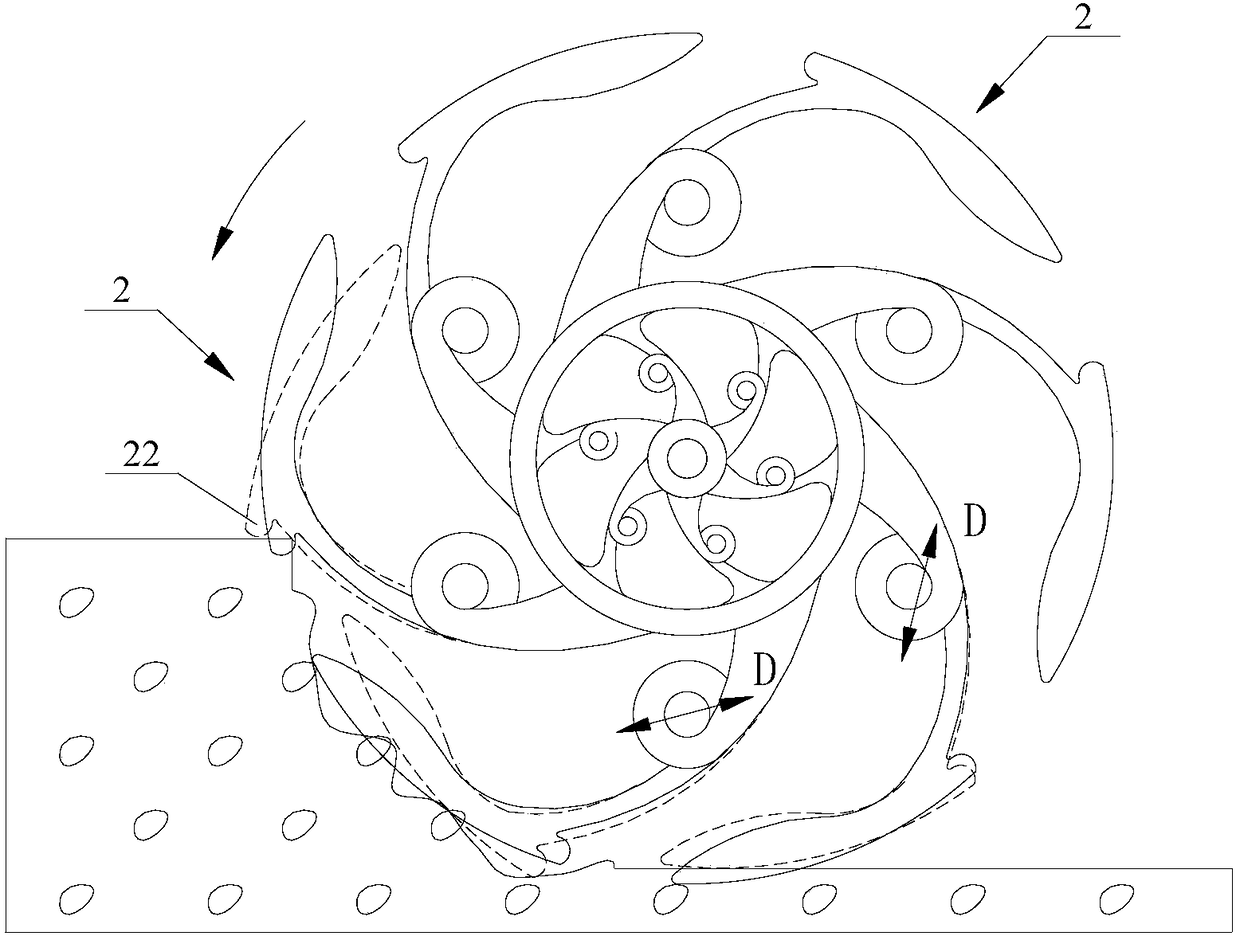

[0040] The wheel mainly includes a hub 1 adapted to a rotating shaft (not shown in the figure) of walking equipment and an elastic support 2, and a plurality of elastic supports 2 are evenly distributed on the outer peripheral surface of the hub 1 in a circumferential direction. Here, the multiple elastic support members 2 have both the functions of the spokes and rim of a traditional wheel, and the outer tire is eliminated based on its own rigidity and flexibility.

[0041] As shown in the figure, the body of the elastic support member 2 extends outward to form an end outer arc section 21. The outer arc sections 21 of a plurality of elastic support members 1 are arranged at intervals in the circumferential direction, and two adjacent outer arc sections form Discontinuous opening area A. And each outer arc segme...

Embodiment 2

[0051] The difference between this solution and the first embodiment lies in the change in the structure of the hub and the addition of the optional adapter 14, which can be applied to the temporary replacement function of another walking device. See Figure 5 This figure shows a schematic diagram of the assembly relationship of the wheel in another use state of this embodiment. In order to clearly show the difference and connection between this embodiment and Embodiment 1, the same functional components in the figure are indicated by the same symbols.

[0052] Specifically, the inner ring portion 11 and a plurality of inner elastic support portions 12 are integrated into one body, and can be detachably connected with the outer ring portion 13, such as threaded connection or snap connection; that is, the inner ring portion 11 and the inner elastic support portion The part 12 can be detached from the outer ring part 13, wherein the optional adapter 14 can also be detachably connect...

Embodiment 3

[0055] The difference between this solution and Embodiment 1 or Embodiment 2 is that the wheel is additionally provided with a rubber coating layer 3, which covers a plurality of elastic support members 2, and the overall outer contour is a continuous disc shape, forming Whole coating. See Figure 8 This figure is a schematic diagram of the wheel described in the solution. In order to clearly show the difference and connection between this embodiment and the first and second embodiments, the same functional components in the figure are indicated by the same symbols.

[0056] That is to say, the gap (opening) is connected by flexible materials, and the appearance of the wheel is like a traditional wheel. That is, the rigid and flexible characteristics of the disc structure are composed of an elastic skeleton and a highly elastic covering material. The circle is coherent, further improving its smooth operation. Here, the rubber coating layer 3 can be made of foamed silicon rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com