Automatic cell culture equipment

A cell culture and equipment technology, which is applied in tissue cell/virus culture devices, biochemical equipment and methods, biochemical instruments, etc. Single and other problems, to achieve the effect of simple and easy operation, avoiding large changes in heat, and high degree of refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0187] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described The embodiments are only some of the embodiments of the present invention, not all of them.

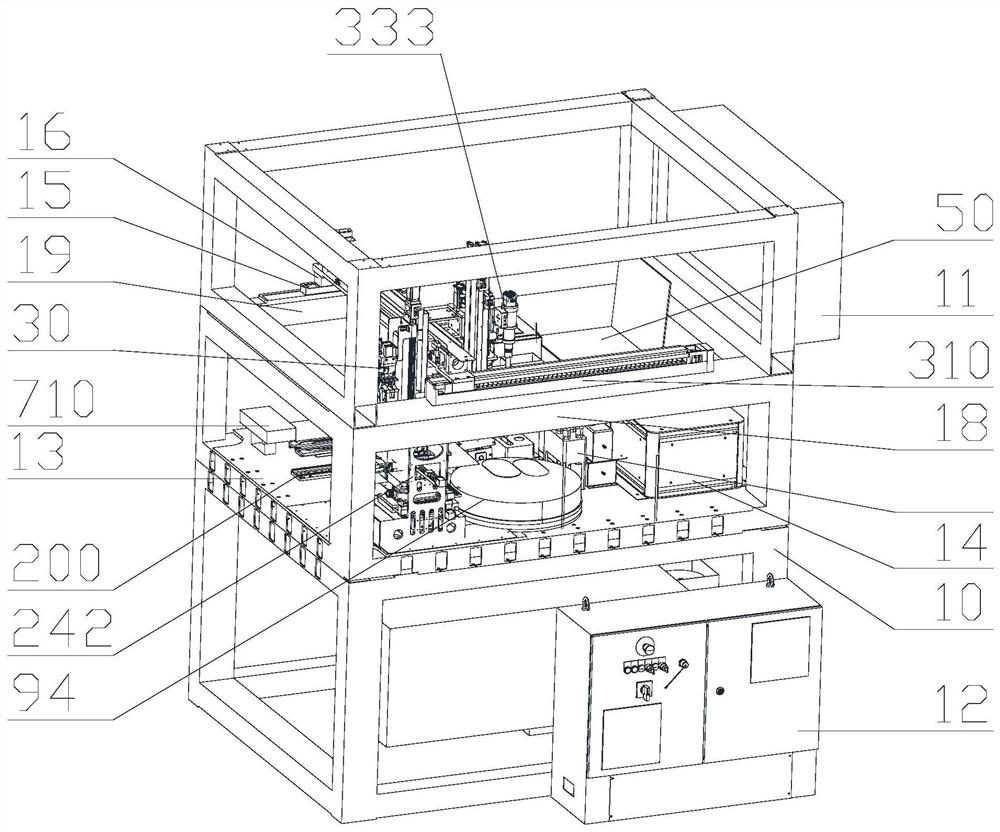

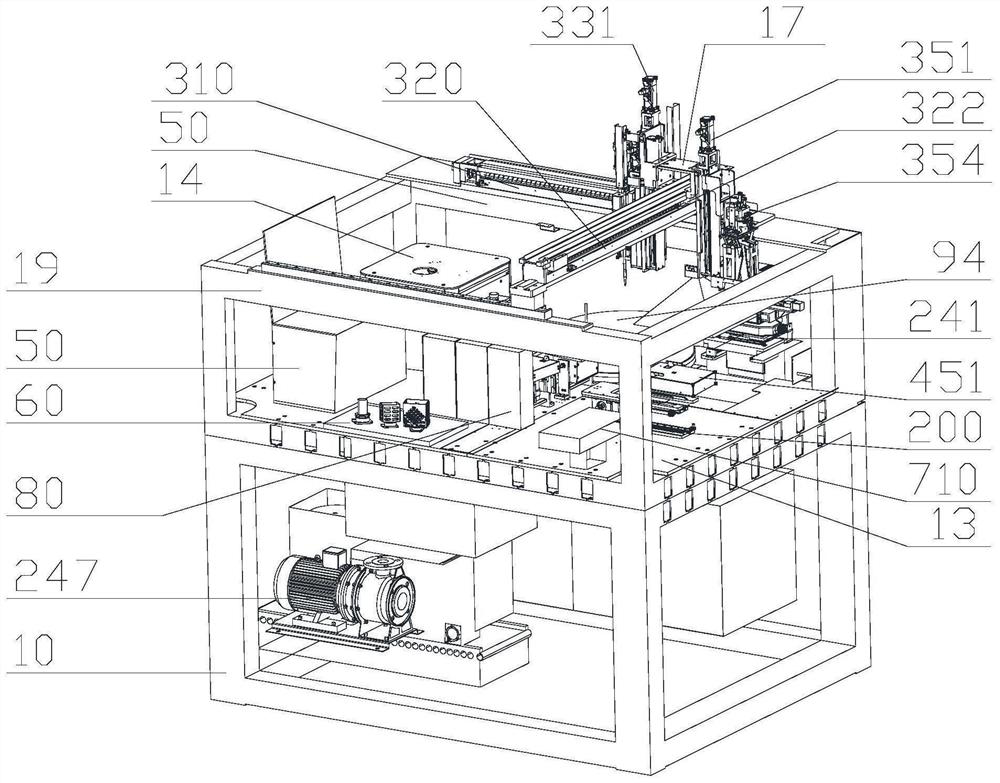

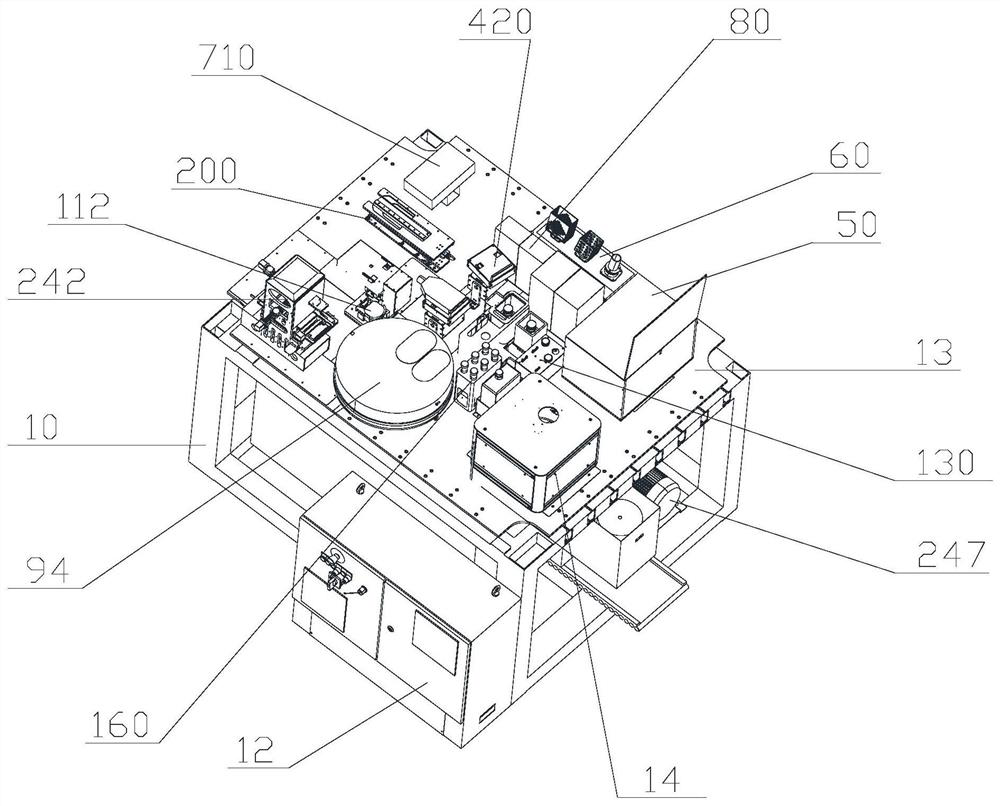

[0188] Please refer to Figure 1-Figure 70 As shown, the automated cell culture equipment includes a support frame 10, a mechanical arm 30 moving in three-dimensional space, functional components, an air filter device 11, and an electronic control system. The air filter device used in this embodiment is a HEPA high-efficiency air filter , The air filter device has the function of filtering particles, dust and suspended solids, keeping the environment inside the equipment clean and preventing impurities from polluting the culture medium. Air filtering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com