Beveling machine for cutting pipeline

A pipe cutting and beveling machine technology, applied in the beveling machine field, can solve the problems of unguaranteed pipe mouth quality and low equipment efficiency, and achieve the effects of reducing the risk of stuck teeth and short teeth, convenient operation, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

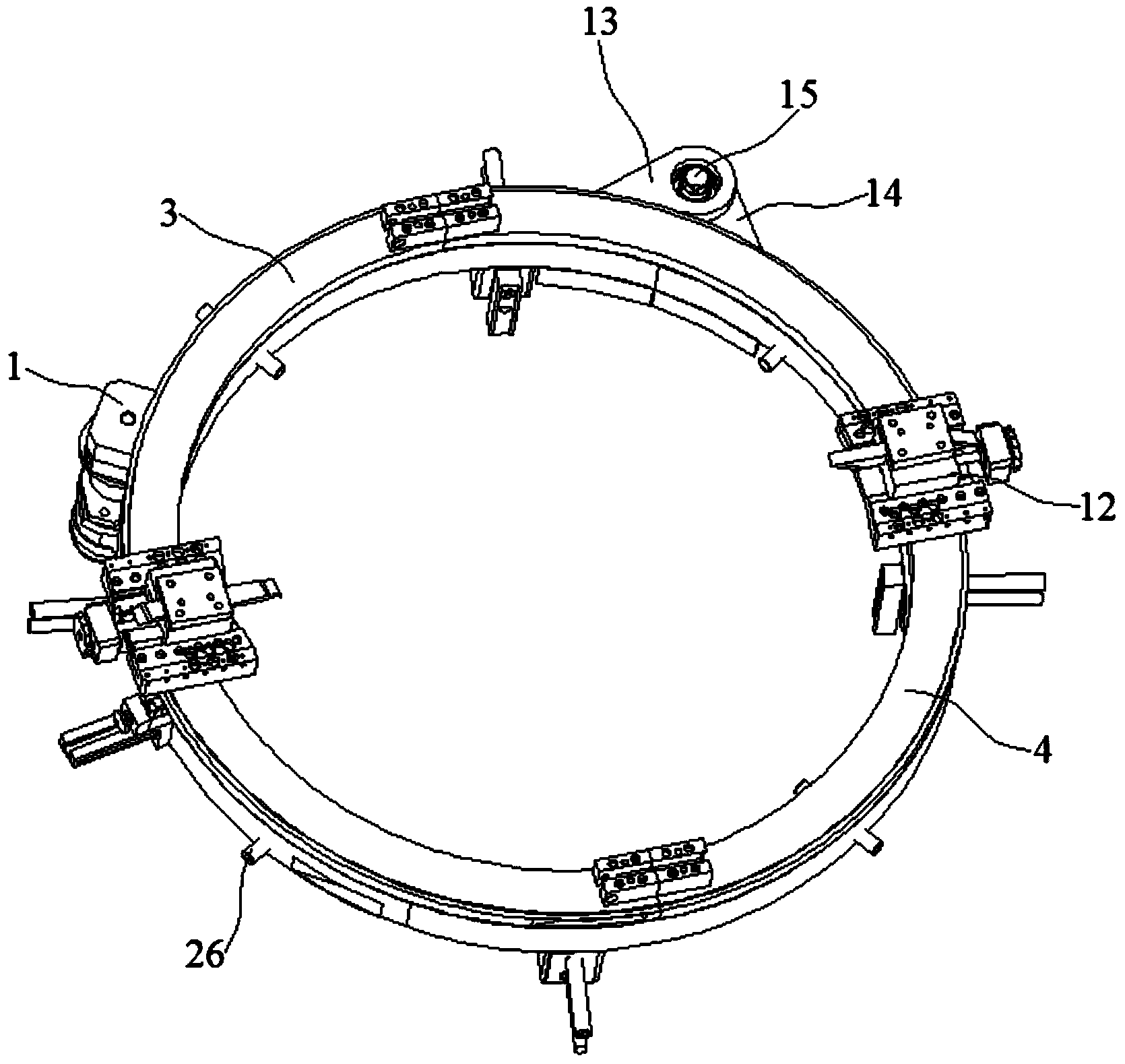

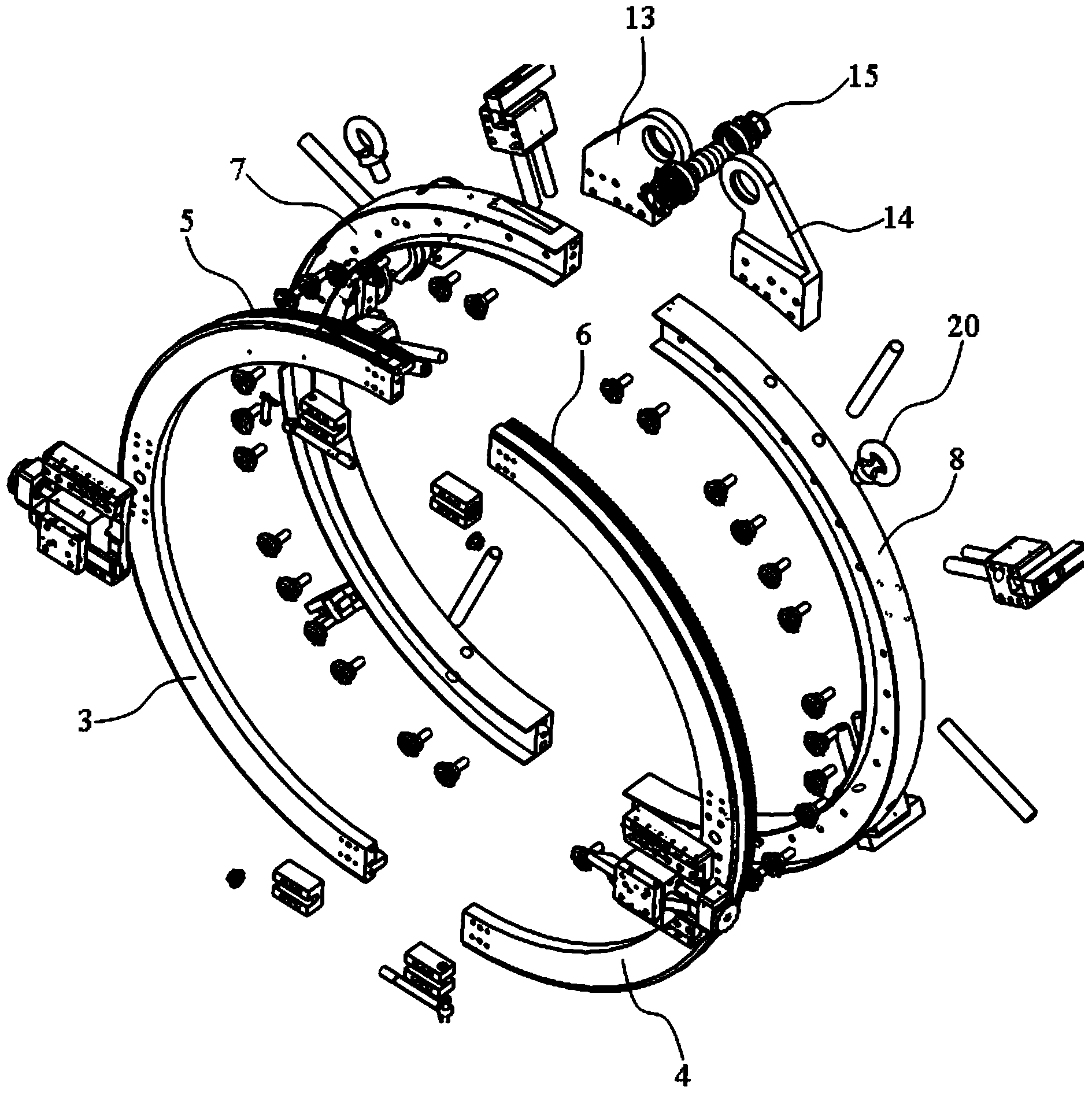

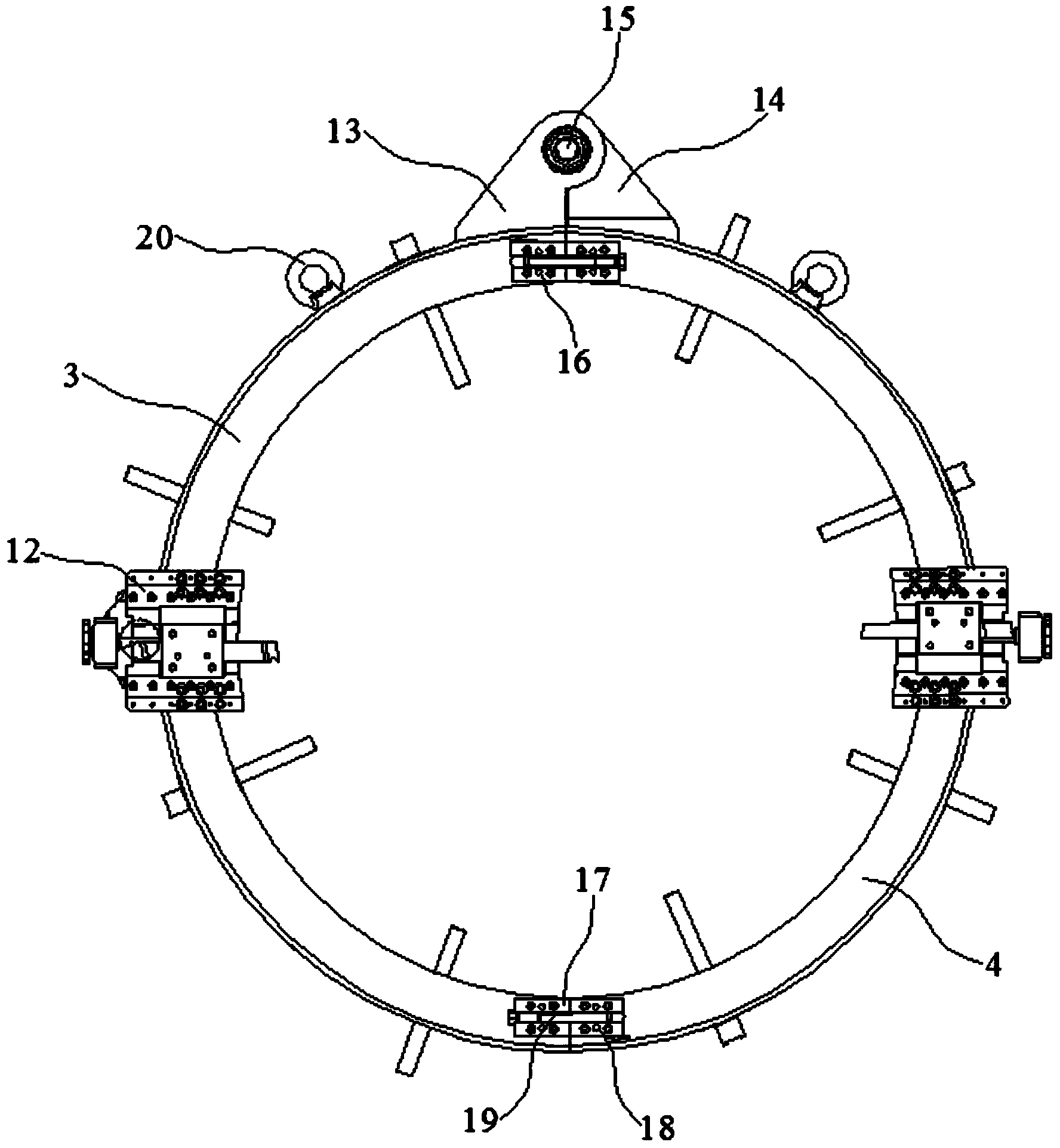

[0026] Embodiment: A beveling machine for pipe cutting, including power mechanism 1, driving gear 2, left and right moving coils 3, 4, left and right ring gears 5, 6 and left and right fixed coils 7, 8 ; The left and right moving coils 3 and 4 are respectively fixedly installed on the left and right ring gears 5 and 6;

[0027] Several eccentric shafts 9 are respectively fixed on the left and right fixed rings 7 and 8 along the circumferential direction. The eccentric shaft 9 includes a shaft body 91 and a cylindrical protrusion 92 arranged at one end of the shaft body 91. The shaft body 91 Parallel to the axis of the cylindrical protrusion 92 and not coincident, the shaft body 91 of the eccentric shaft 9 is fixed on the left and right fixed rings 7, 8, a roller bearing 10 is installed on the cylindrical protrusion 92, and several of the The roller bearing 10 is movably embedded in the groove 11 located on the inner side of the left and right ring gears 5 and 6;

[0028] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com