Bogie for freight car and freight car

A technology for bogies and trucks, which is applied in the direction of bogies, trucks, devices for lateral relative movement between the chassis and the bogie, and can solve the problem of the reduction of the effective load of the truck, the increase of the overall weight of the truck, and the increase of the weight of the bolster, etc. problems, to achieve the effect of improving running stability, optimizing structure and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

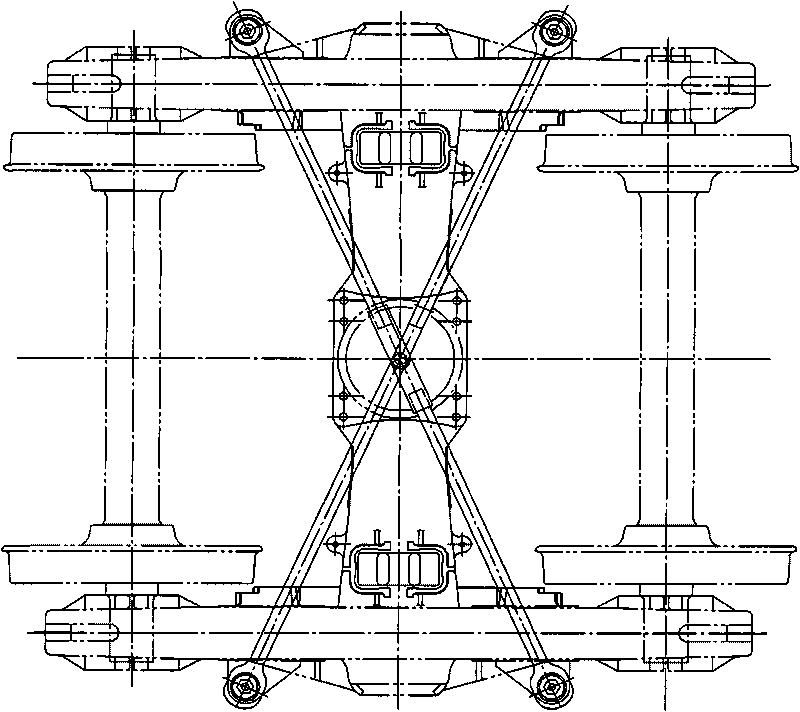

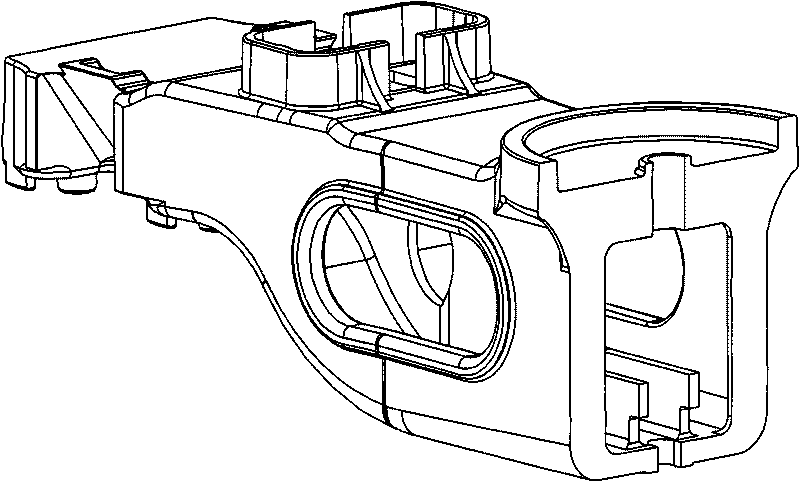

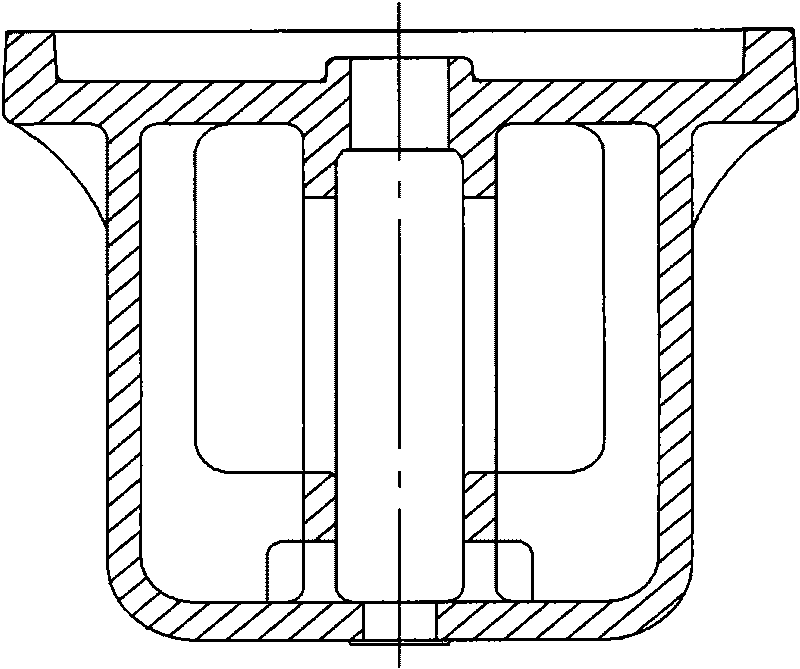

[0042] The invention provides a truck bogie, comprising: two wheel pairs, two side frames arranged outside the wheel sets, and a bolster fixedly connected to the center of the two side frames, the truck bogie also includes: K Type support device, the K-type support device passes through the reserved holes on both sides of the bolster abdomen, the first upper end and the second upper end, the first lower end and the second lower end of the K-type support device are respectively connected with the two The two side frames are elastically connected, and the first upper end and the second upper end, the first lower end and the second lower end are respectively symmetrical about the center line of the bolster. The invention adopts the K-shaped supporting device passing through the reserved holes on both sides of the bolster belly, which can prevent the bogie from rhomboid deformation and improve the running stability of the vehicle; the K-shaped supporting device passes through the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com