Crystallizer for continuous casting

一种结晶器、铸坯的技术,应用在结晶器领域,能够解决热处理欠缺均匀性等问题,达到增大接触表面、提高最终质量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

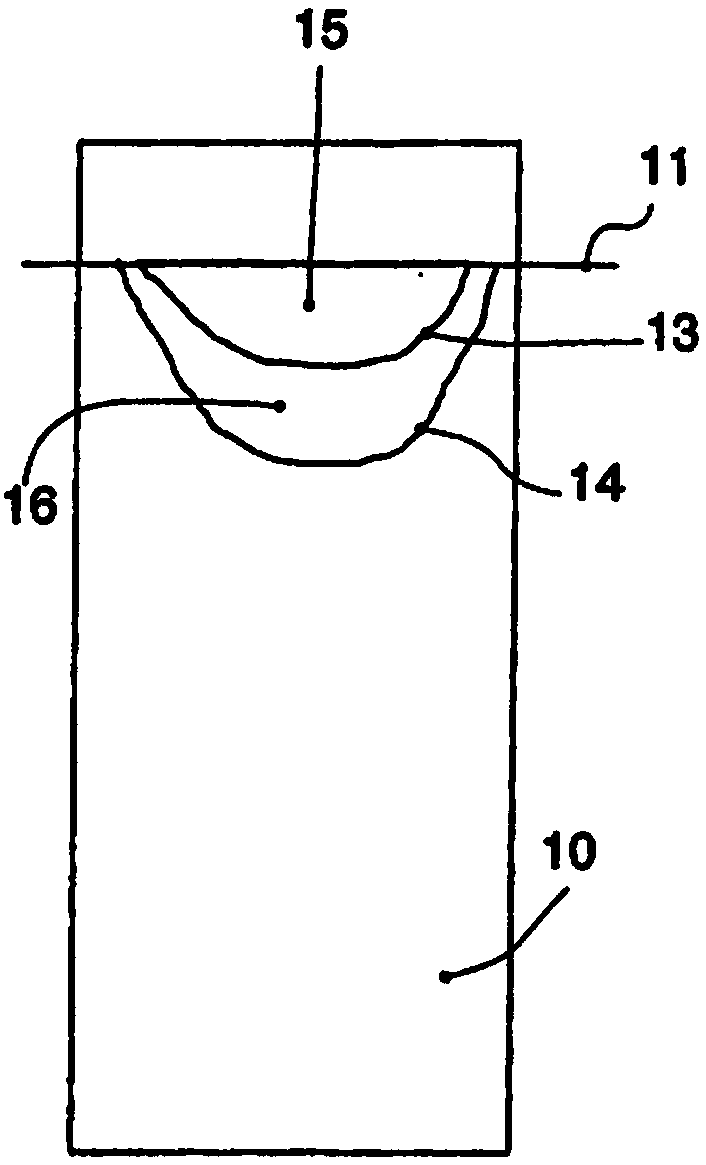

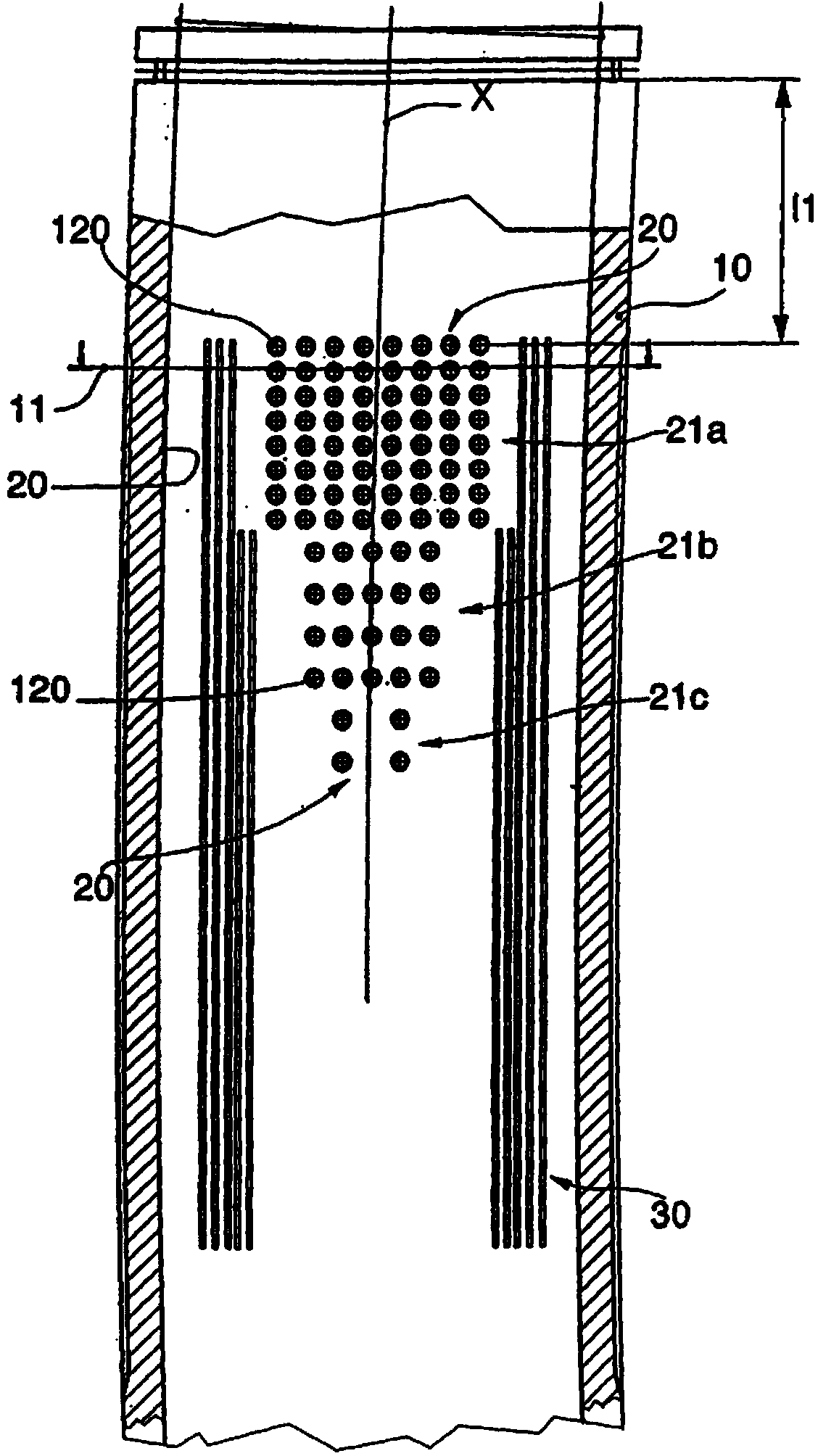

[0037] A mold 10 for continuous casting of long products is shown schematically at figure 1 , wherein reference numeral 11 basically indicates the nominal line of the meniscus of the liquid metal.

[0038] In this type of mold 10 for long products such as blooms or billets 12, the isotherms (with the same temperature) on the inner surfaces of the mold 10 have an elliptical or parabolic development, Such as figure 1Line 13 and Line 14 are shown. Therein, the crystallizer 10 has a polygonal shape, preferably a quadrangular shape, even more preferably a rectangular or square shape, and has thin walls and is cooled by an external jacket.

[0039] In particular, the region indicated by the reference number 15 is the region with the maximum temperature, since it corresponds to the region of the meniscus; The adjacent area indicated by marker 16 has a lower temperature.

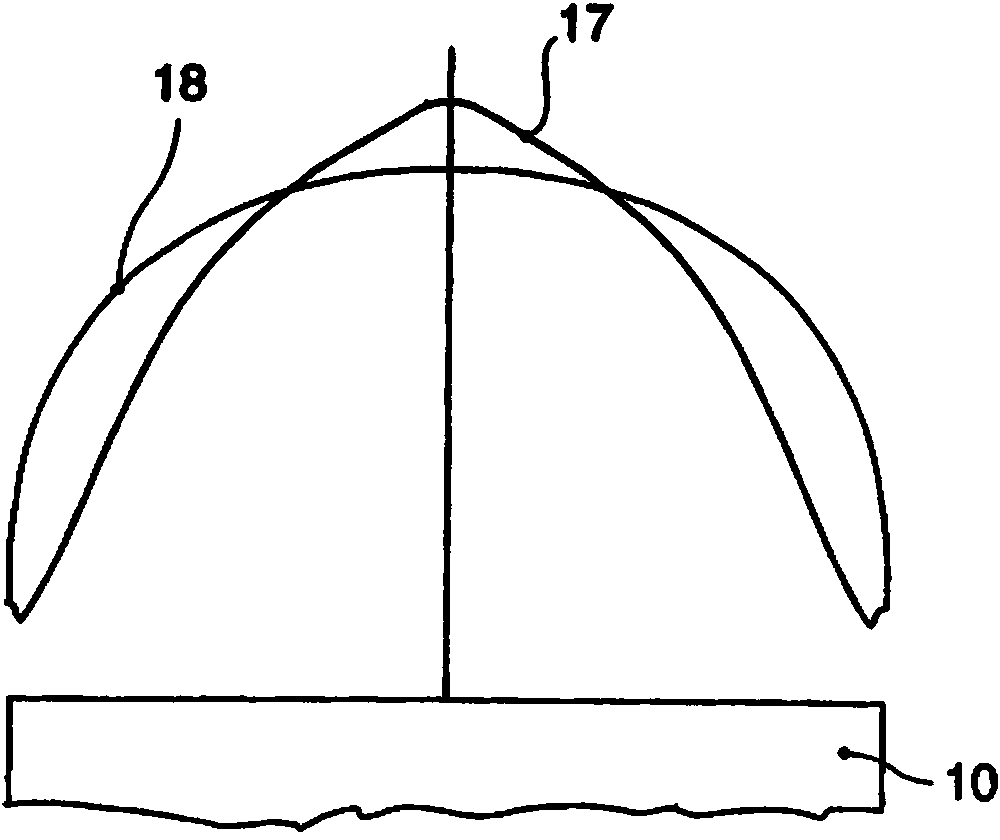

[0040] exist figure 2 , the development of heat flow along one surface of the crystallizer 10 just below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com