Flat stepping motor

A stepper motor, flat technology, applied in electrical components, electromechanical devices, etc., can solve the problems of large axial size, difficult to use stepper motor, large axial size, etc., achieve small moment of inertia, improve control performance, Responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

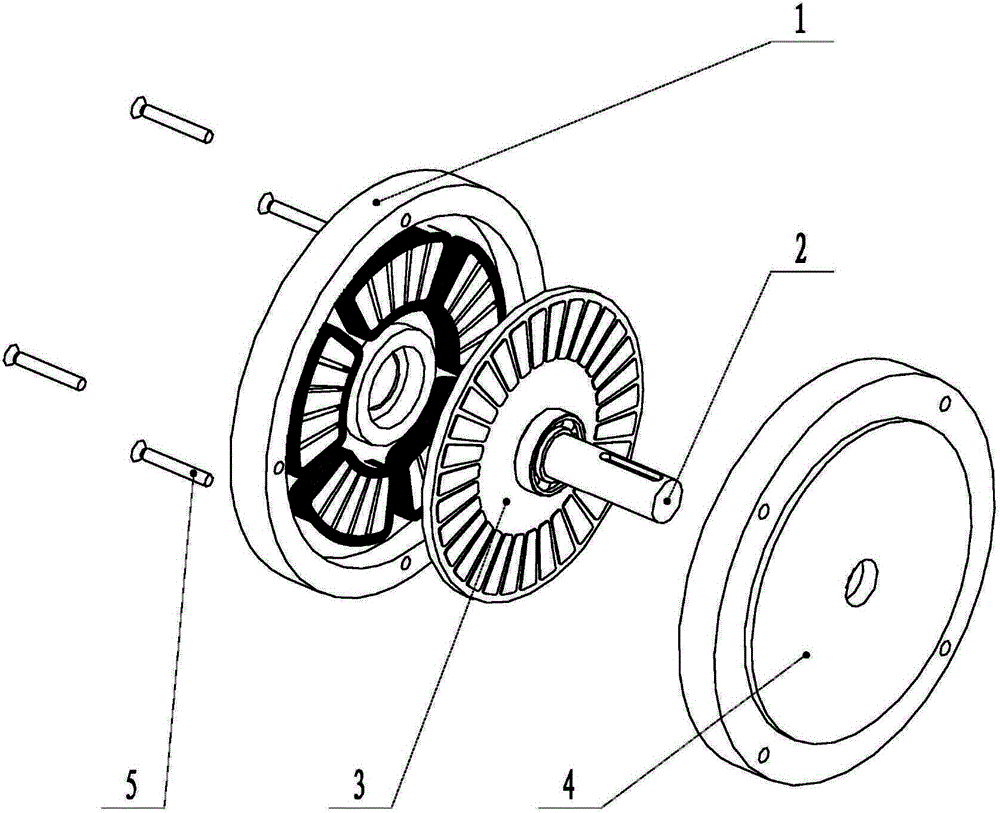

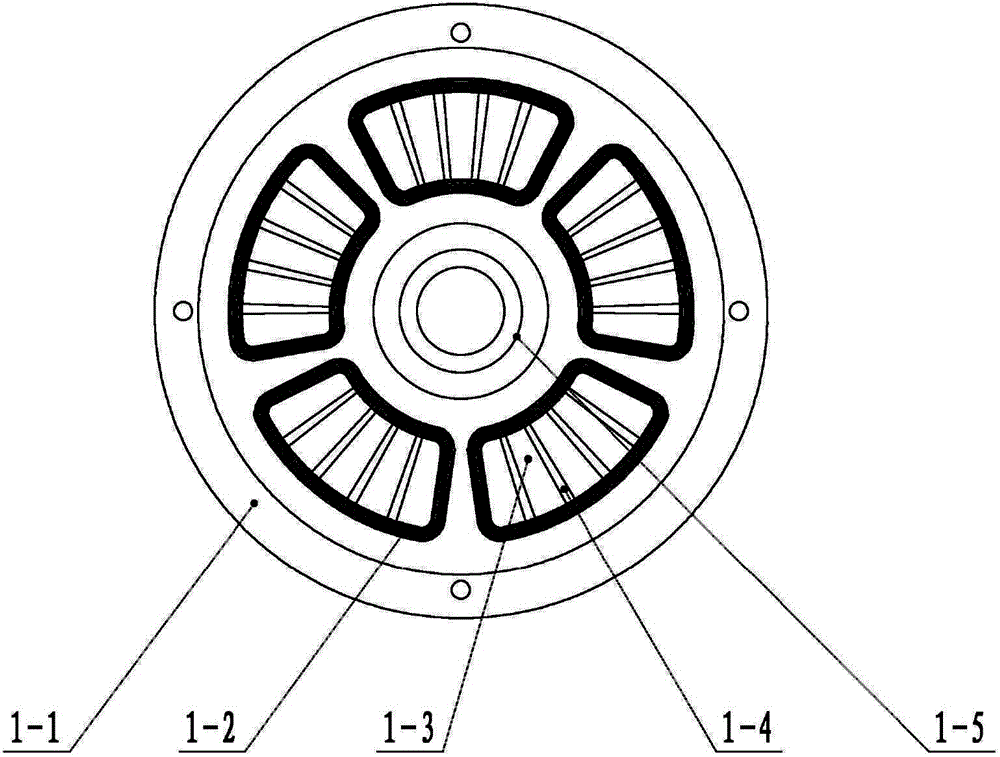

[0020] Embodiment of this flat stepper motor figure 1 , Figure 4 As shown, it includes a front end cover 1, a rotor 3, an output shaft 2 and a rear end cover 4.

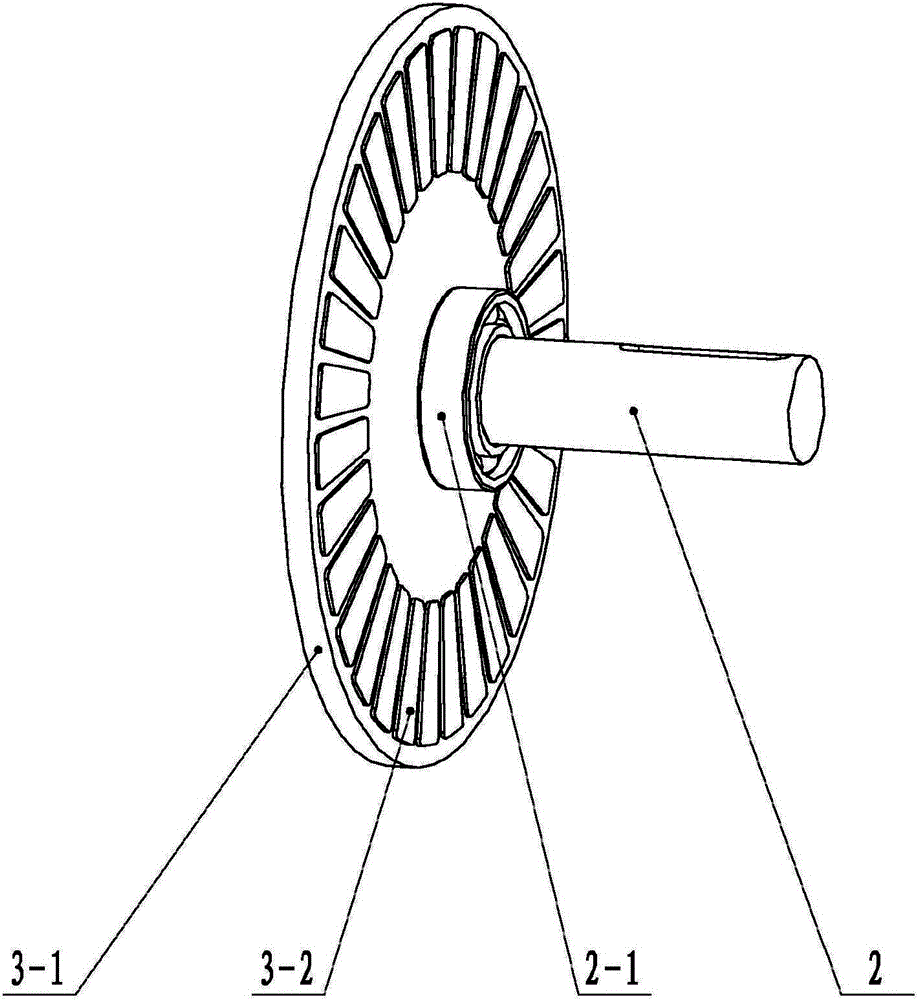

[0021] Rotor structure such as image 3 As shown, it includes a turntable 3-1 and a magnetic steel 3-2. The turntable 3-1 is disc-shaped, and 31 magnets of the same shape and size are evenly fixed and fixed on the disc surface of the turntable 3-1 with the center as the center. 3-2. This example magnetic steel is fan-shaped. The turntable 3-2 has a thickness of 5mm, and the magnetic steel 3-2 has a thickness of 6mm. The disk surface of the rotating disk 3-1 is evenly provided with 31 holes with the same shape and size as the magnetic steel 3-2 with the center as the center, and the distance between the inner edge of the hole and the center of the rotating disk 3-1 is 1 / 2 of the radius of the rotating disk. The magnetic steel 3-2 is firmly embedded in the hole. The magnetic field direction of each magnetic stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com