Patents

Literature

49results about How to "Reduce peripheral speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

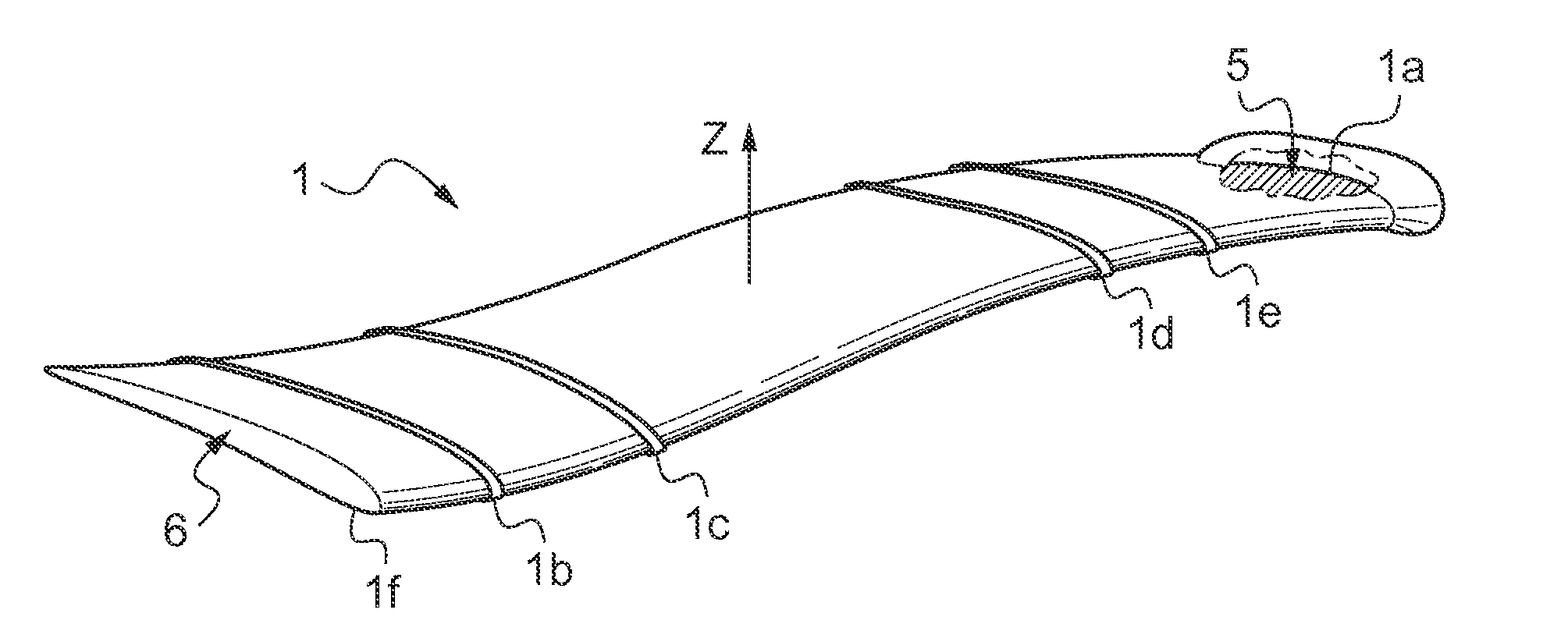

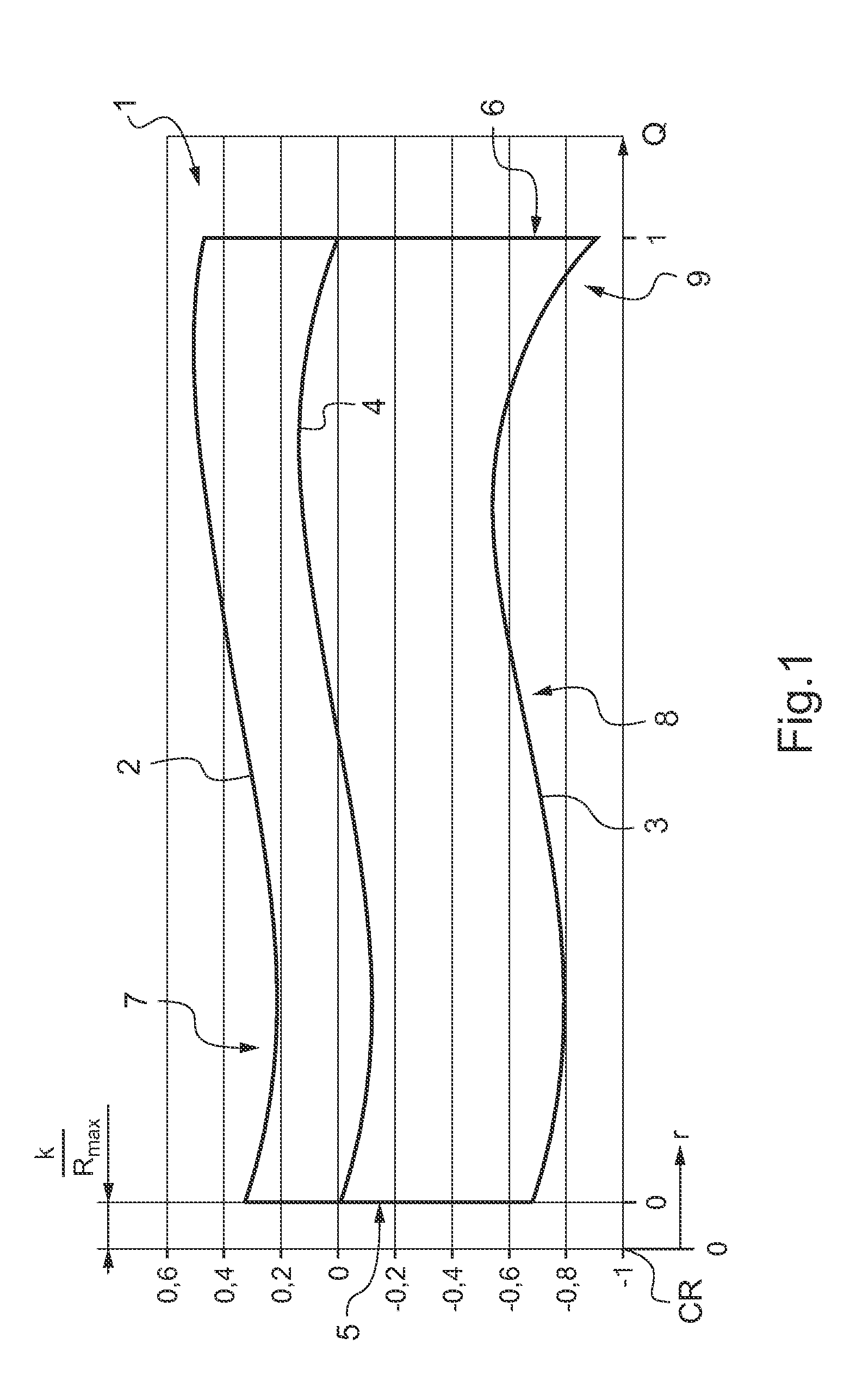

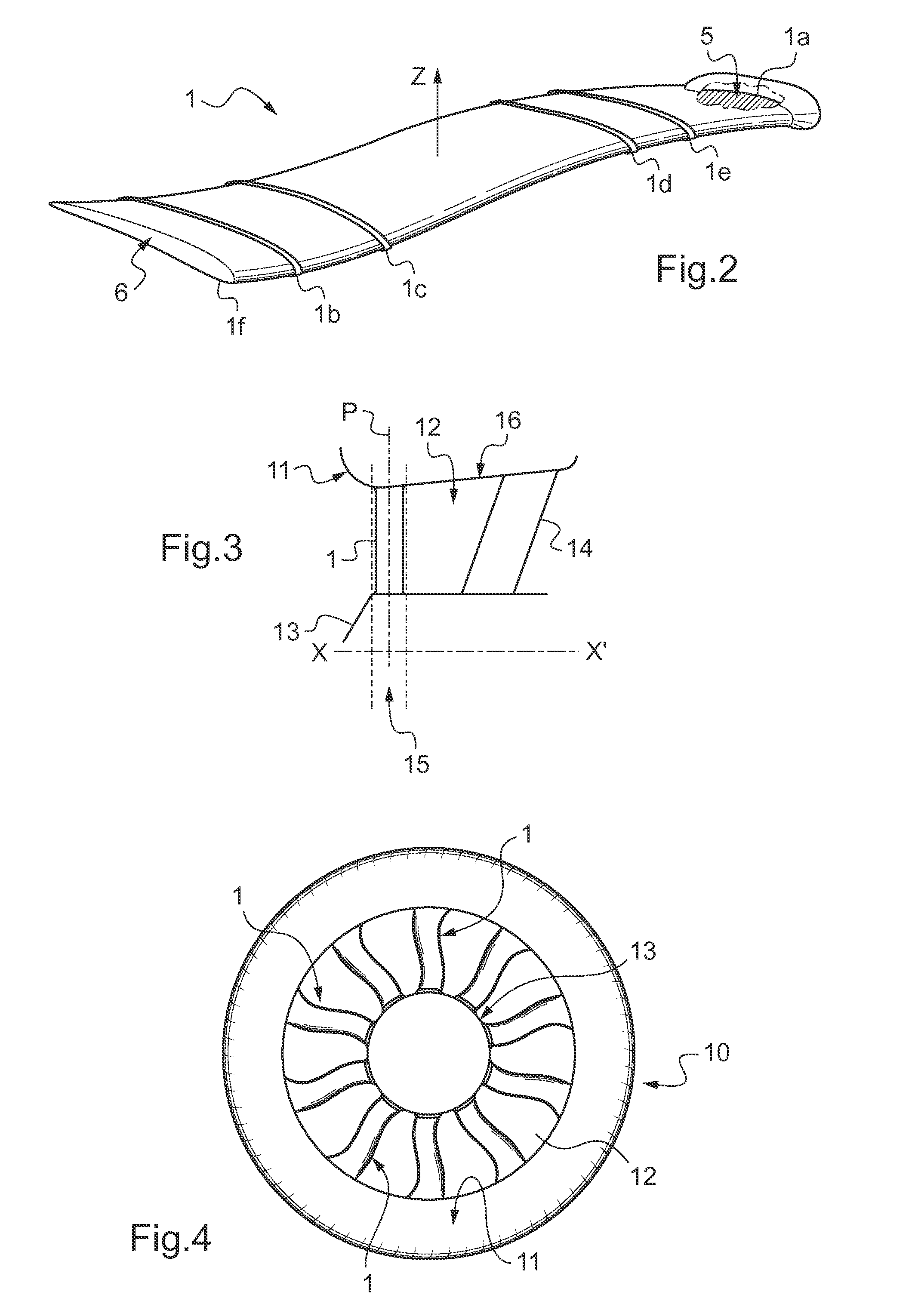

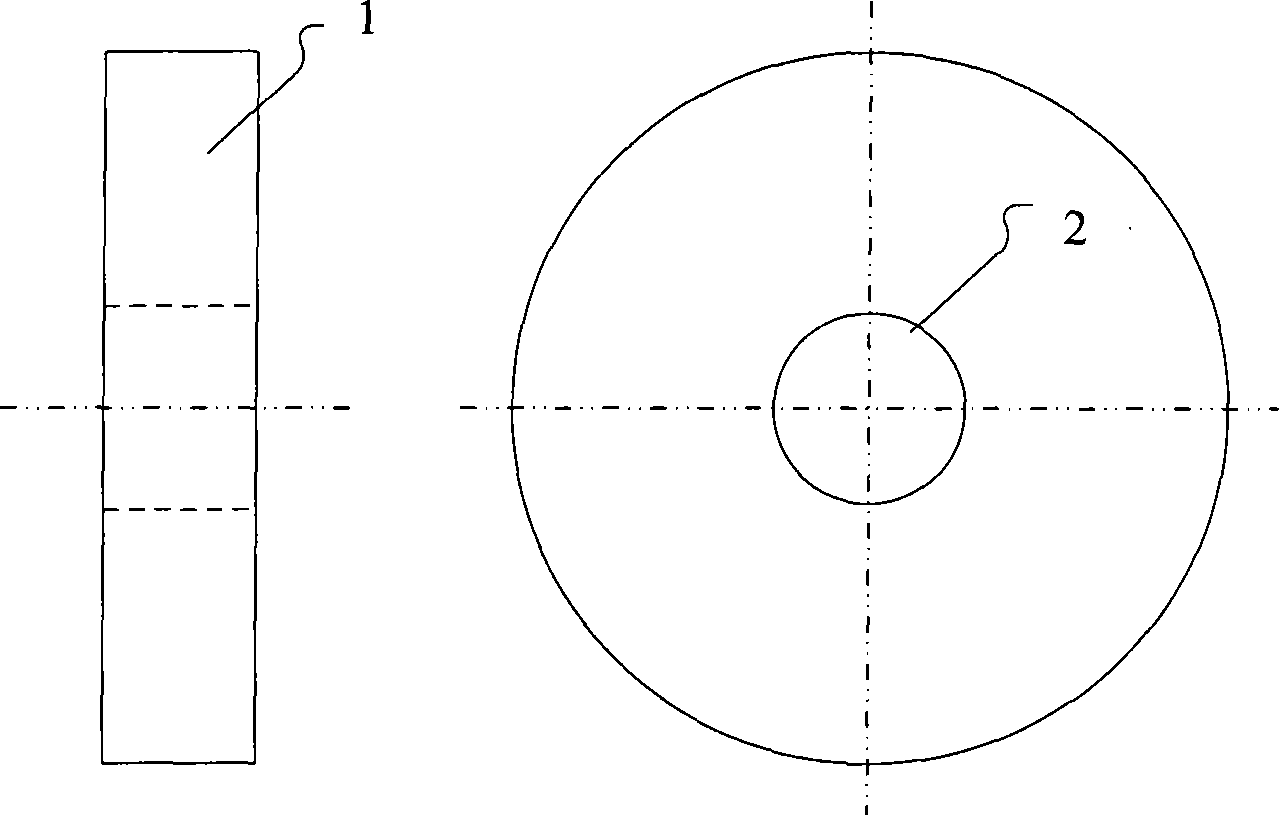

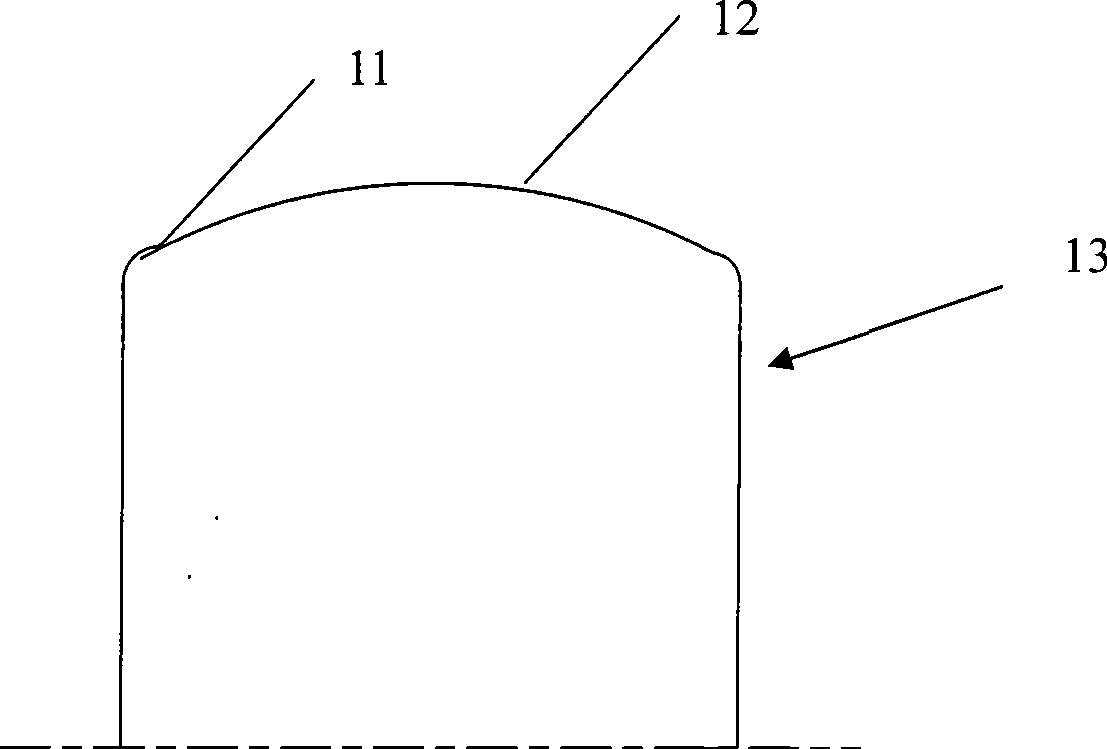

Blade for a helicopter Anti-torque device

ActiveUS20120195767A1Reduce monopole noiseIncrease thickness noisePropellersRotary propellersLeading edgeEngineering

A blade (1) for a tail anti-torque device of a helicopter, said device comprising a ducted rotor (13). The blade (1) has an assembly of sections, a leading edge (2) and a trailing edge (3); a stacking line (4) of the profiles extending at a distance lying in the range 25% to 50% of the chord (C). The stacking line (4) presents a shape that is curved having successively from the root (5) to the end (6) of the blade a back sweep, a forward sweep, and a last back sweep; and a chord (C) that becomes larger going towards the end (6) of the blade (1) over at least the end profile (1a).

Owner:EUROCOPTER

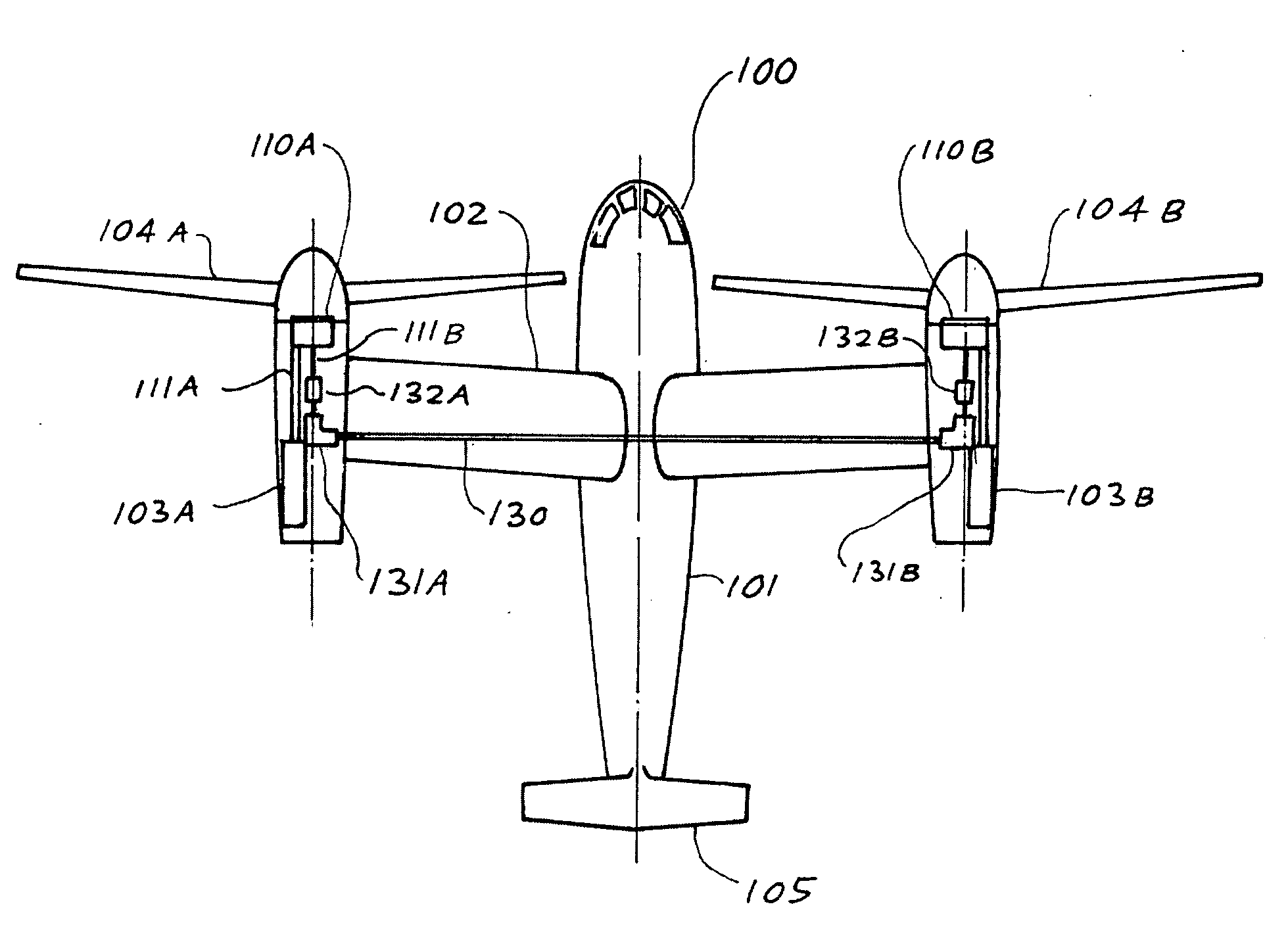

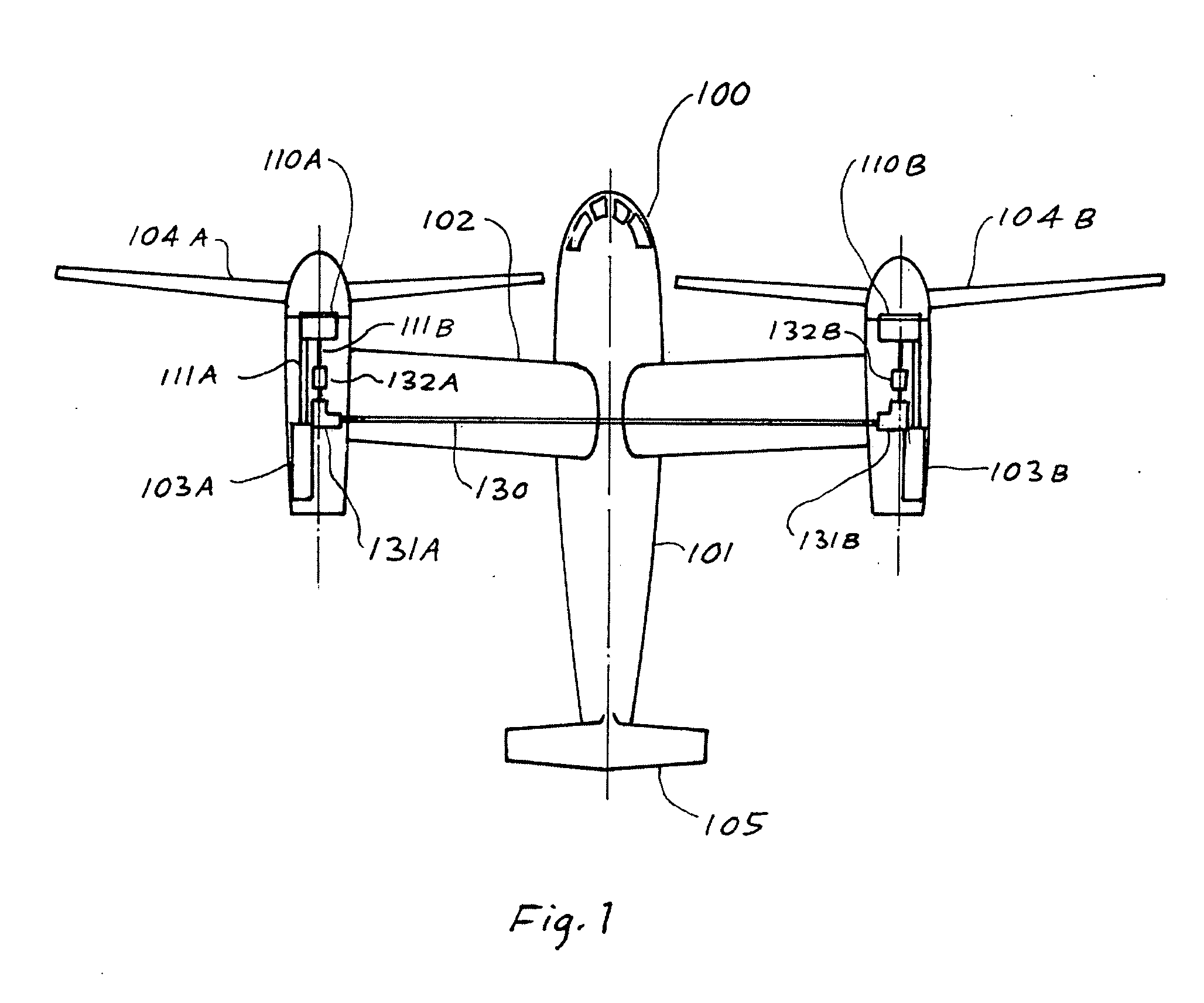

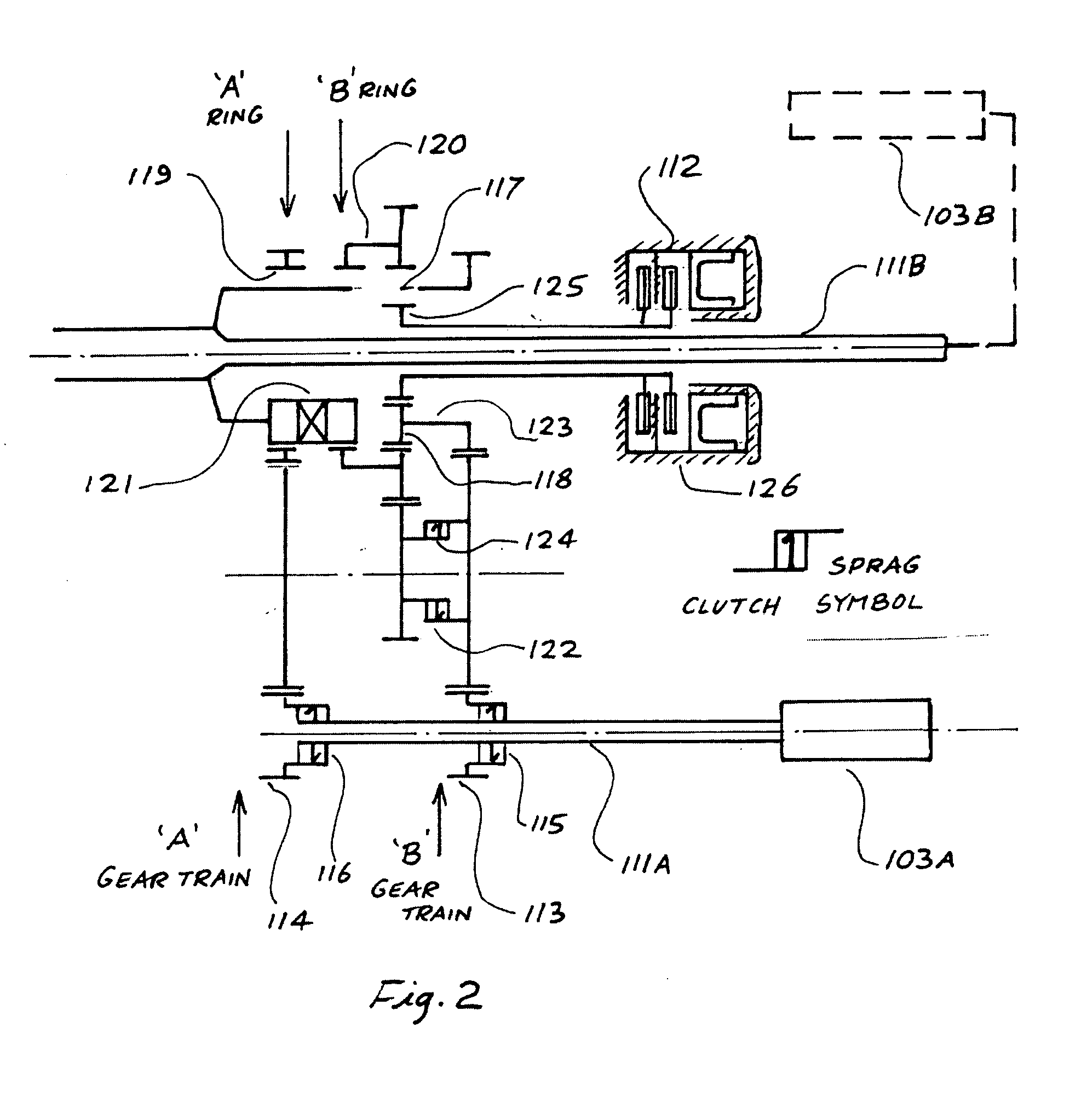

Speed changing gearbox with dual path input

InactiveUS20070205321A1Large weightReduce peripheral speedGearingDepending on number of propellersGear wheelTransmitted power

Contemplated gearboxes provide first and second power-balanced paths in which a speed changer is configured to operate with only one path. Most preferably, the gearbox includes a friction clutch and a sprag clutch arranged such that, together with a layshaft and spur-gear differential, gear shifting can be done while transmitting power.

Owner:KAREM AIRCRAFT INC

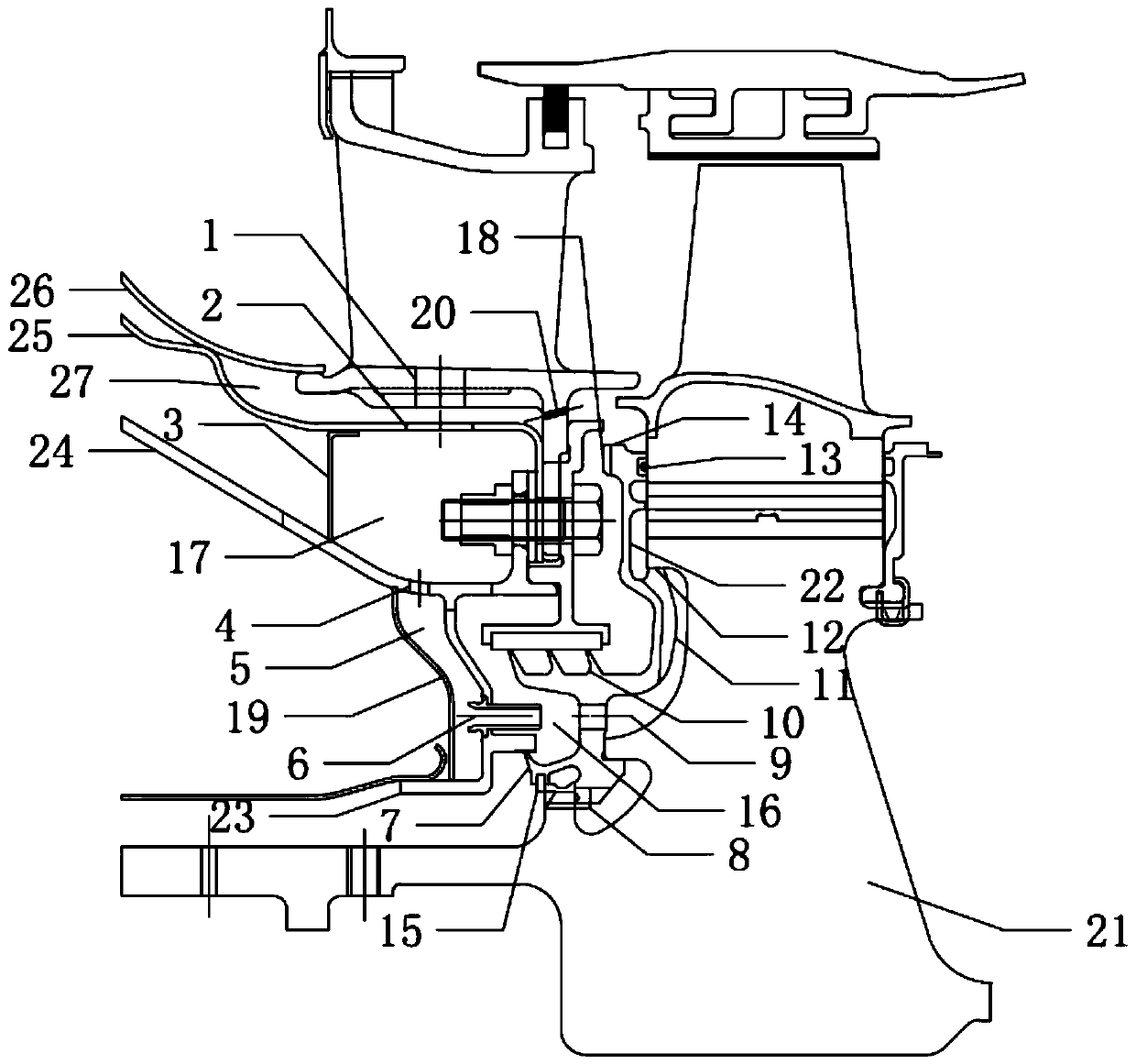

Engine turbine disc cavity structure with pre-rotation nozzle and flow guiding disc

ActiveCN111441828AShorten speedLower the total temperatureBlade accessoriesLeakage preventionEngineeringConvection heat

The invention discloses an engine turbine disc cavity structure with a pre-rotation nozzle and a flow guiding disc. The engine turbine disc cavity structure comprises a turbine disc and further comprises the flow guiding disc and a pre-rotation nozzle ring which are arranged in front of the turbine disc. High-pressure low-temperature two-strand airflow is divided into two strands after entering apre-rotation airflow cavity through the pre-rotation nozzle ring. One strand of airflow passes through pre-rotation cool air receiving holes evenly distributed in the circumferential direction of theflow guiding disc and enters an axial ventilation hole in the bottom of a turbine disc mortise along a radial flow guiding plate on the rear side of the flow guiding disc. The other strand of airflowpasses through a sealed grid tooth ring on the flow guiding disc, and after the other strand of airflow is pre-rotated and pressurized through an inclined flow guiding plate above the front side of the flow guiding disc and is converged with cool air from cool air impact holes evenly distributed in the circumferential direction of the installing edge of a guiding device, the other strand of airflow enters a main runner through a turbine rotor and stator gap. By means of the engine turbine disc cavity structure, the relative total temperature of cool air can be reduced, convection heat exchangeof cool air and the turbine disc is enhanced, pre-rotation pressurizing is conducted on the wheel edge seal gas, the seal effect is improved, and seal gas and main flow mixing losses are reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

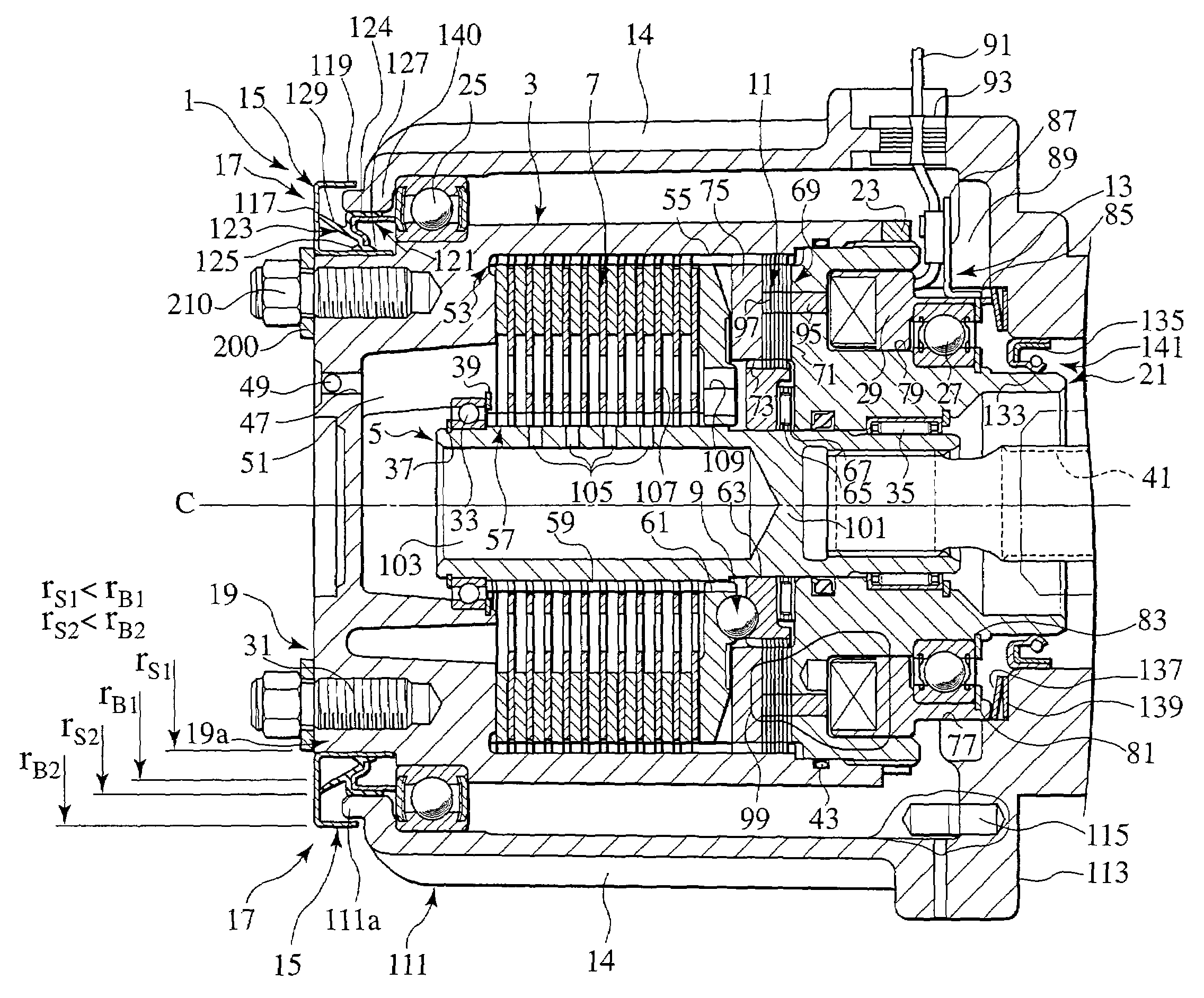

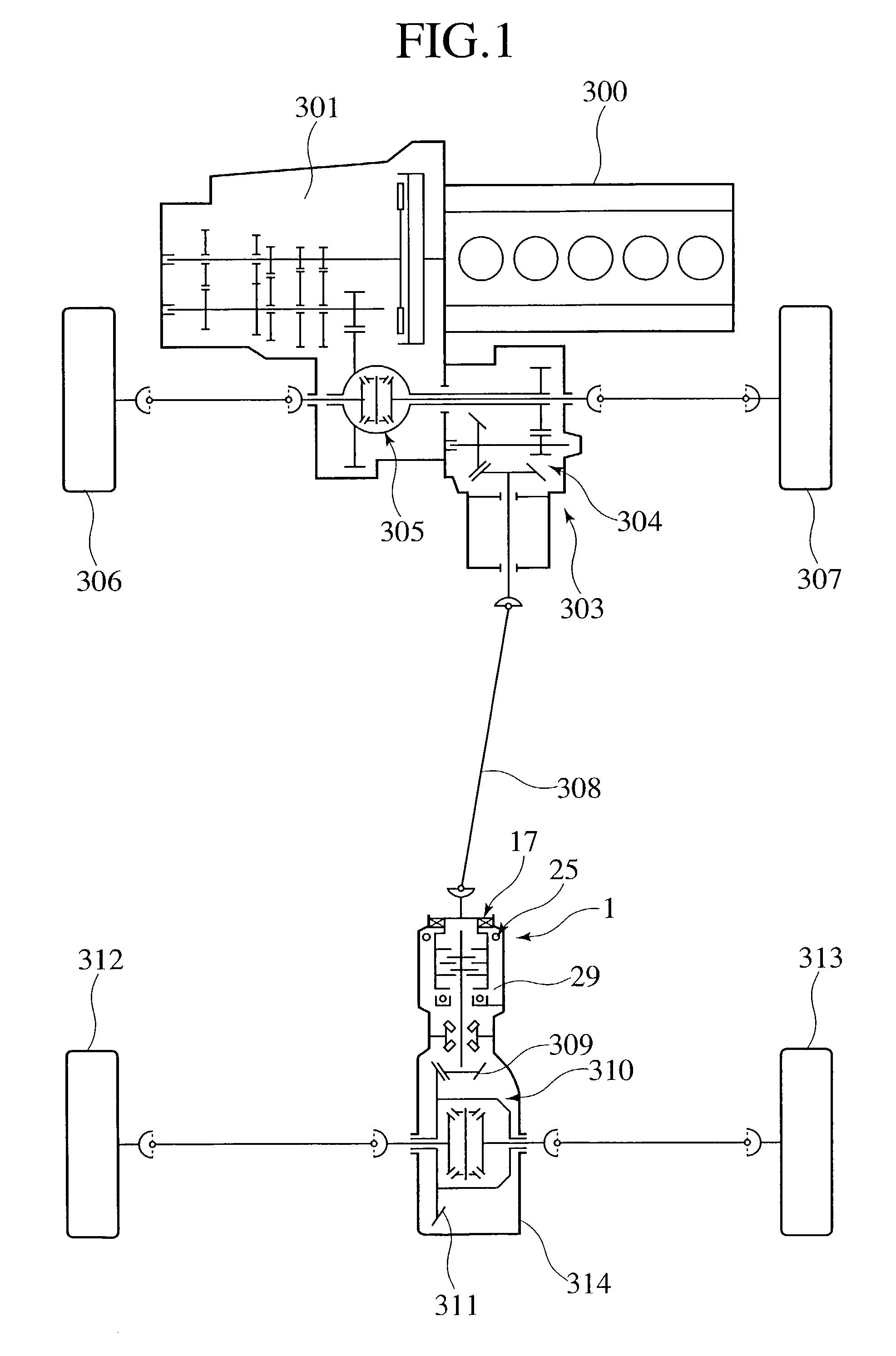

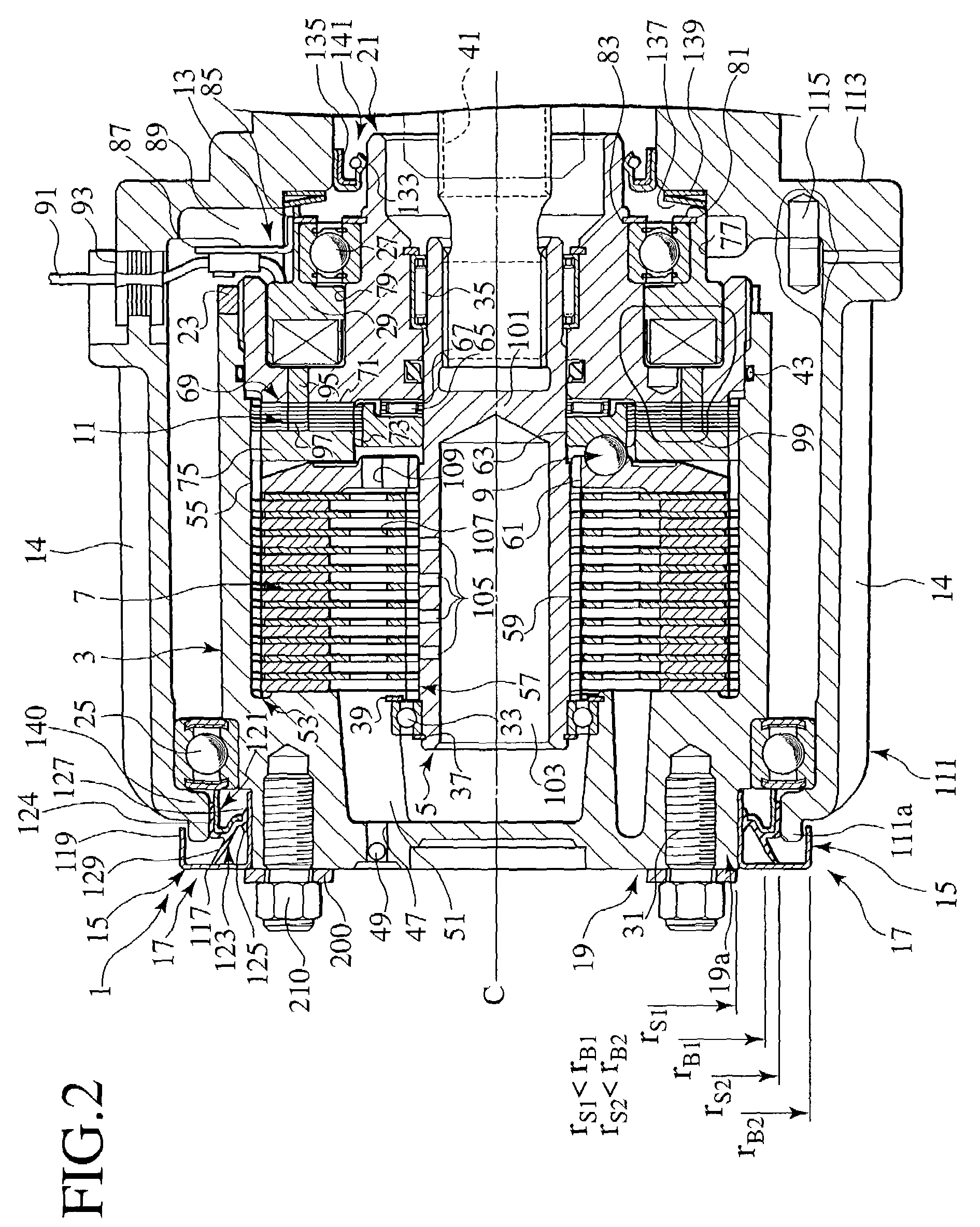

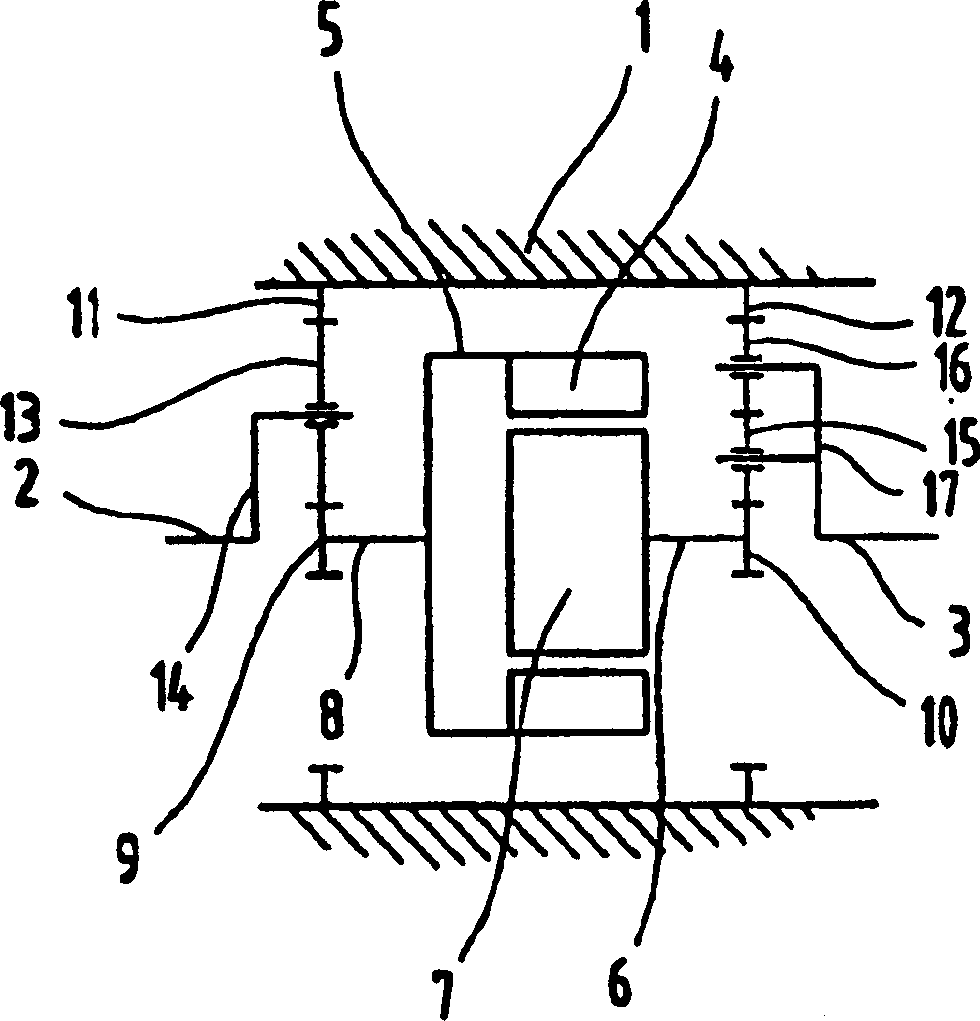

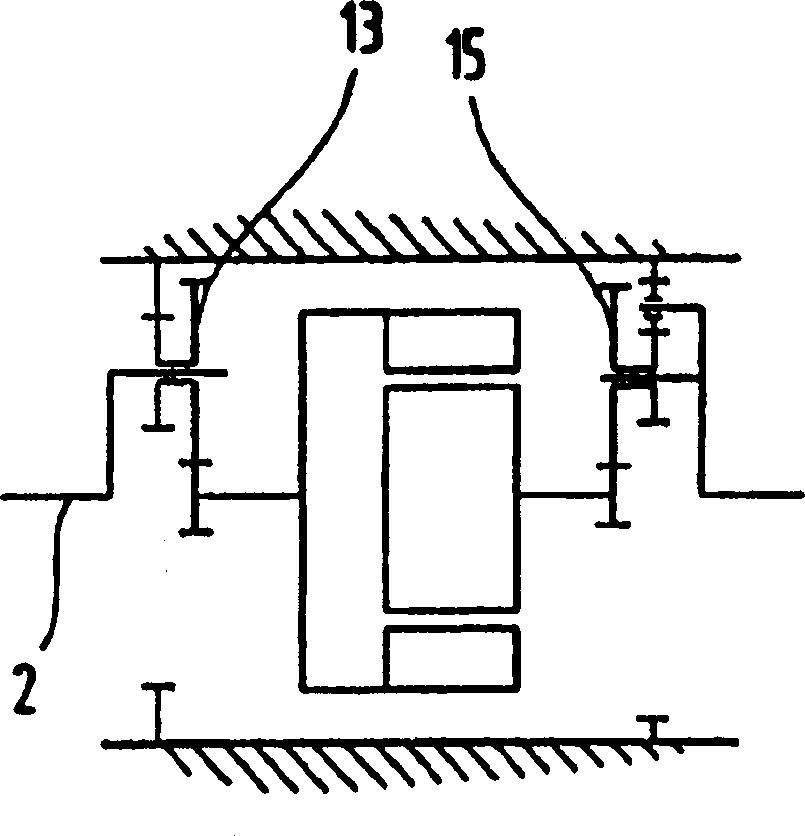

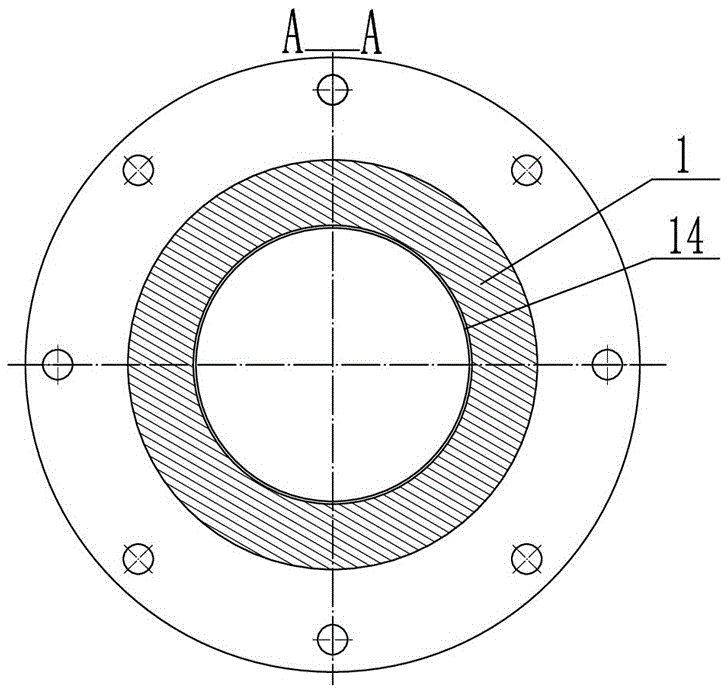

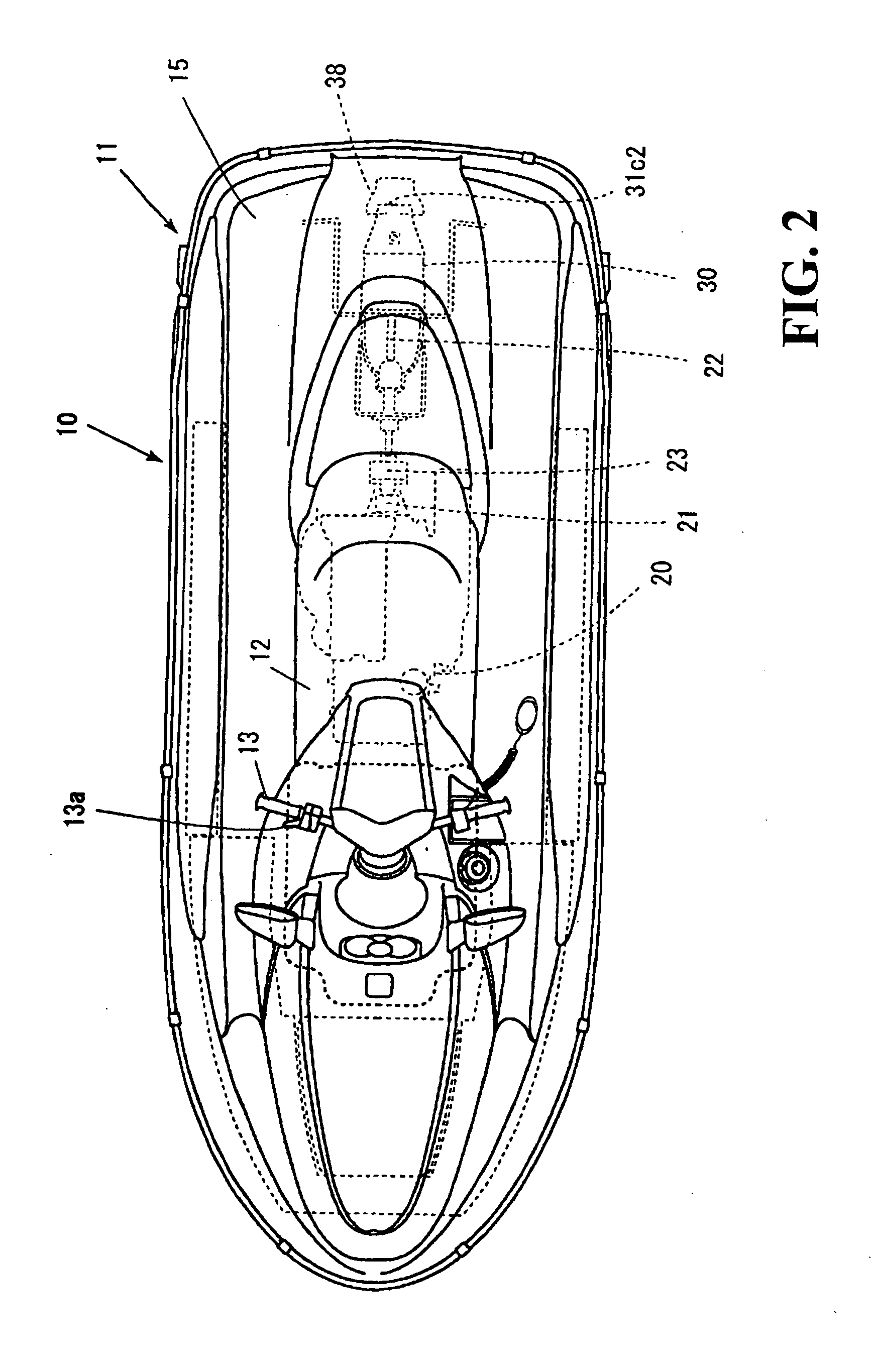

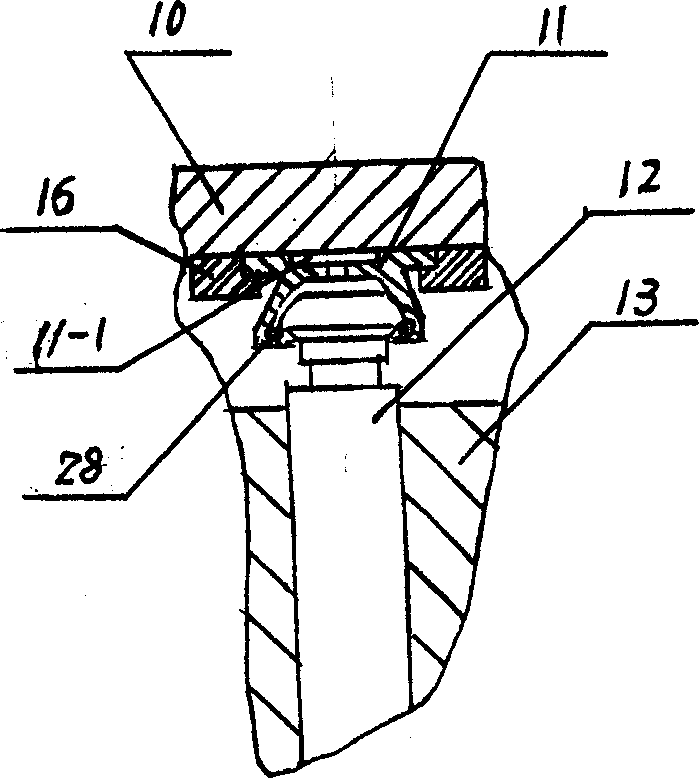

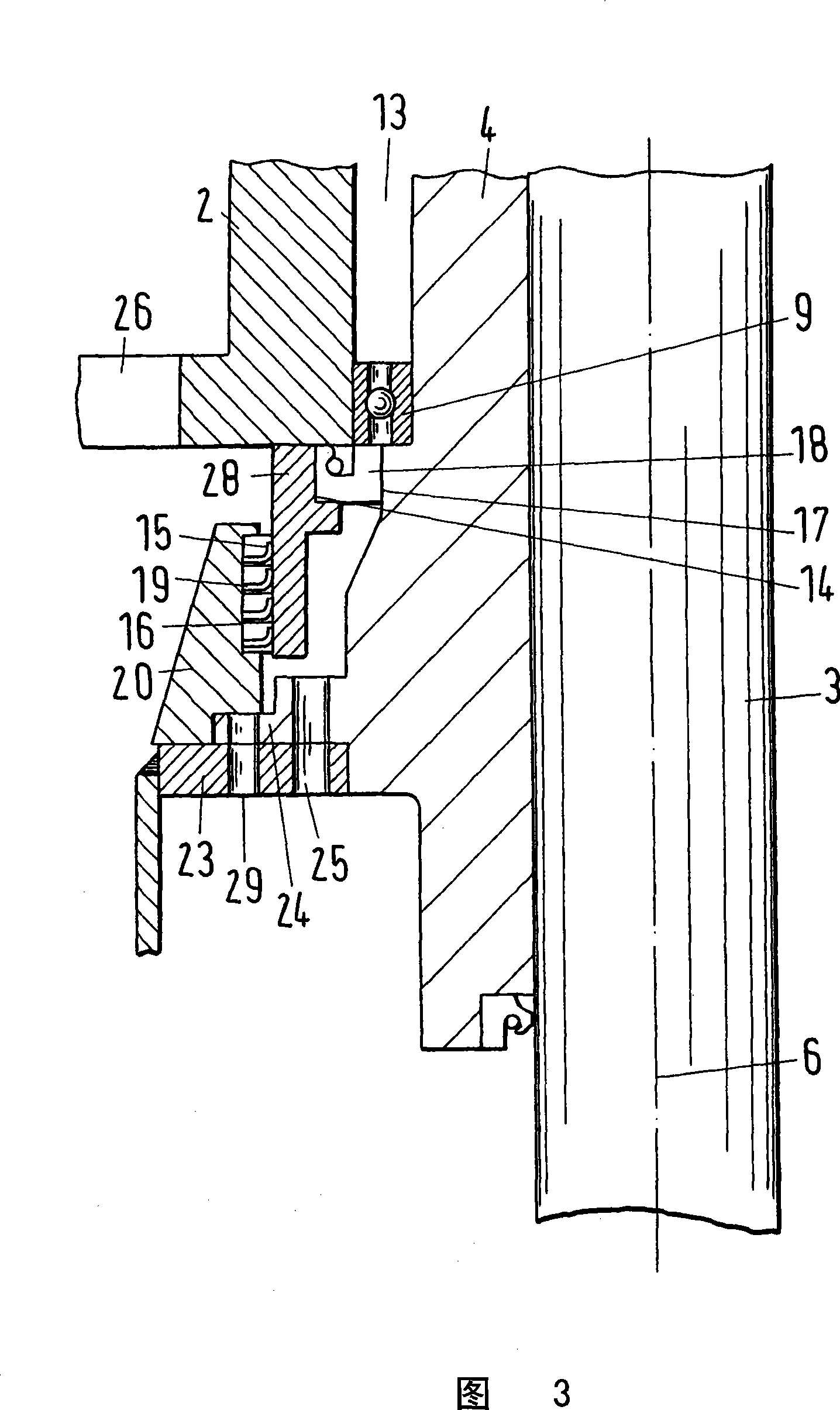

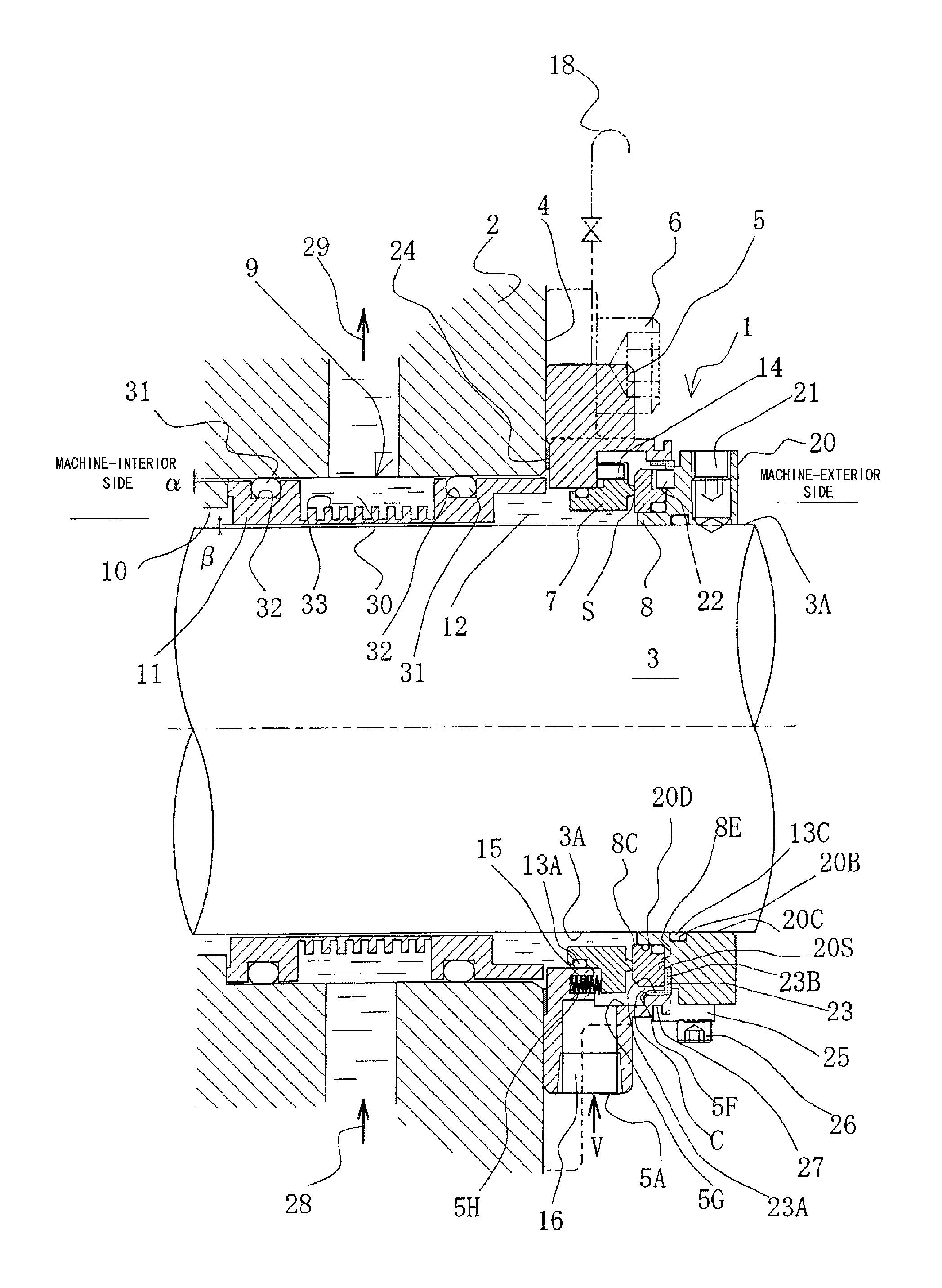

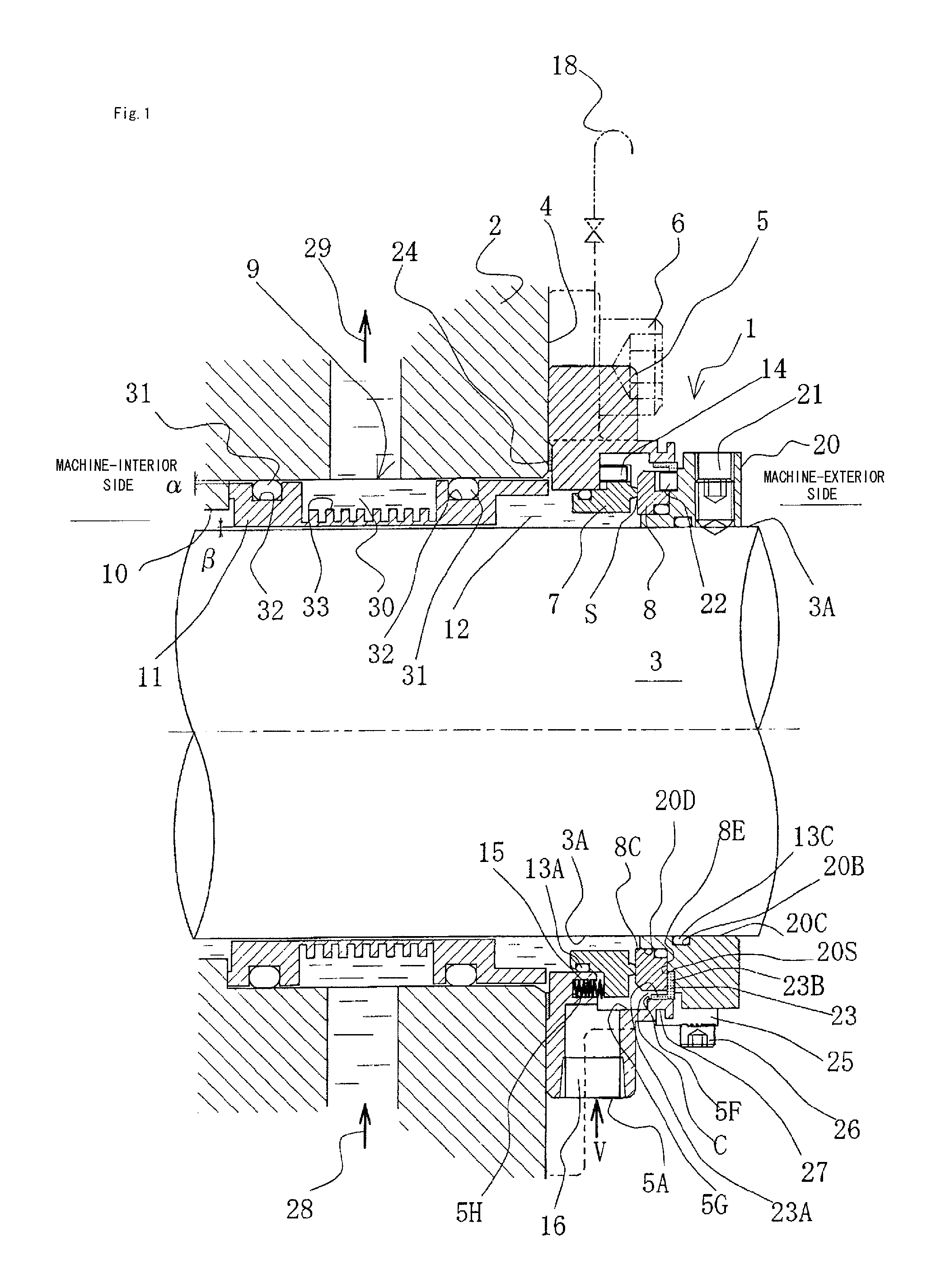

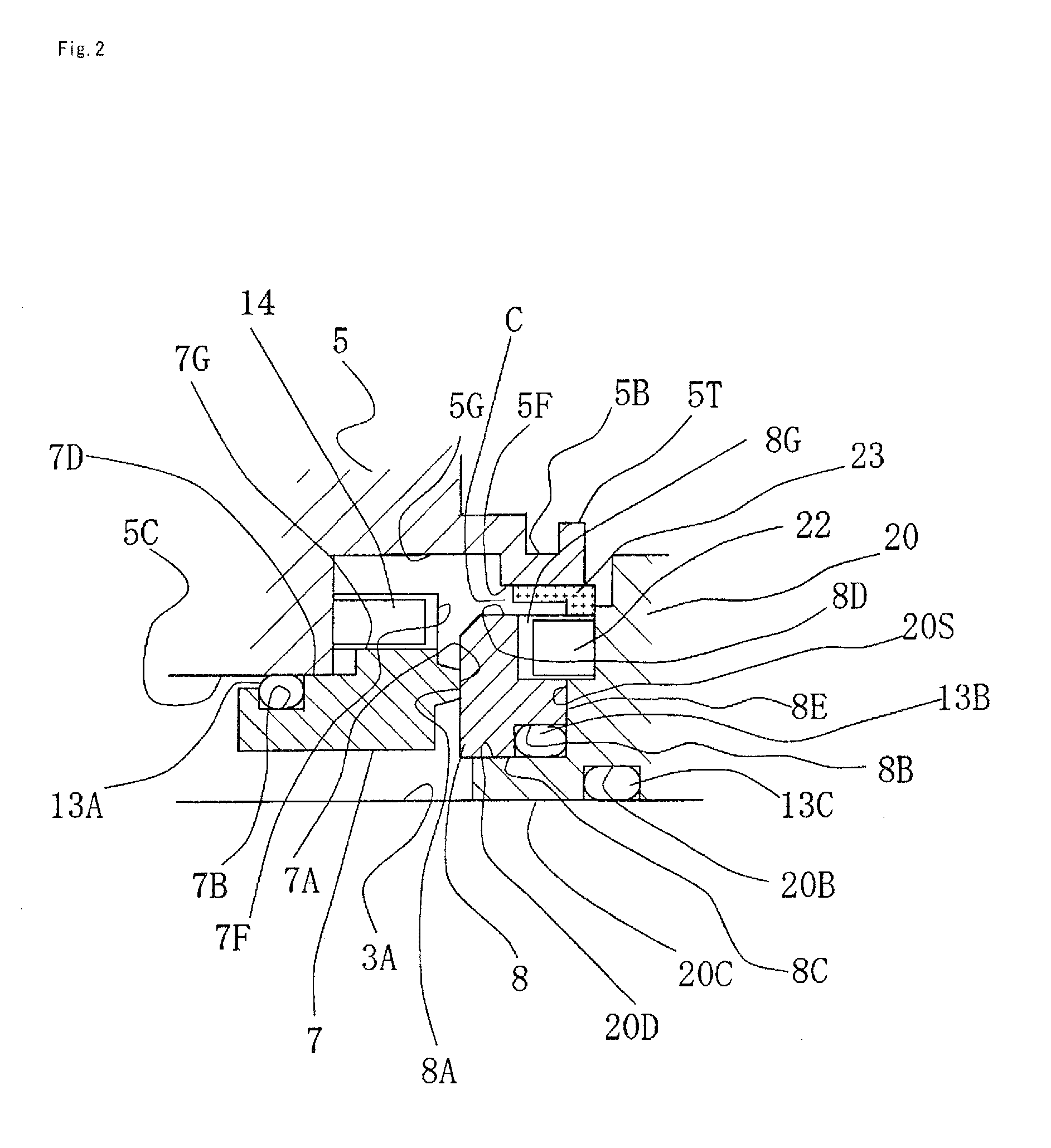

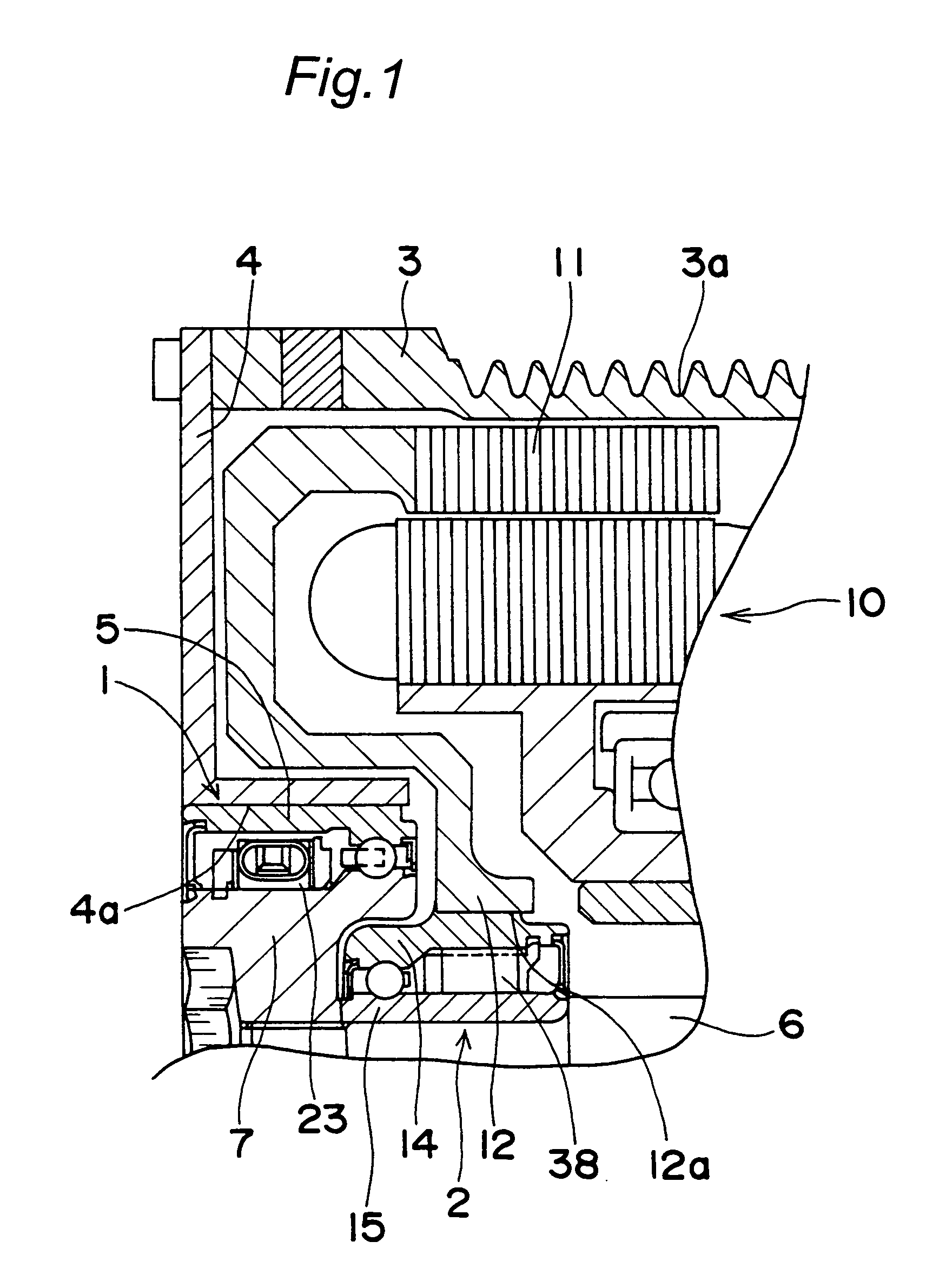

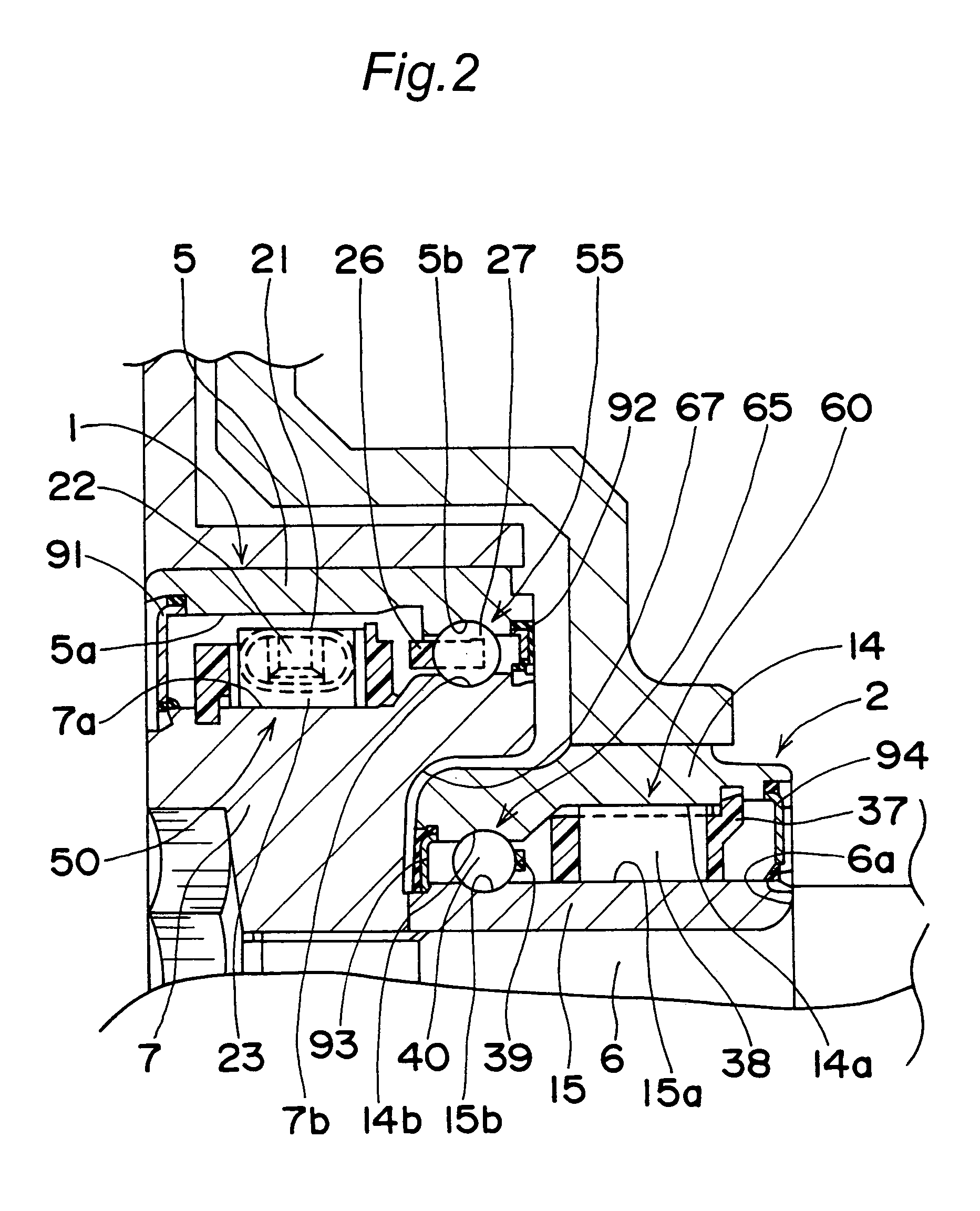

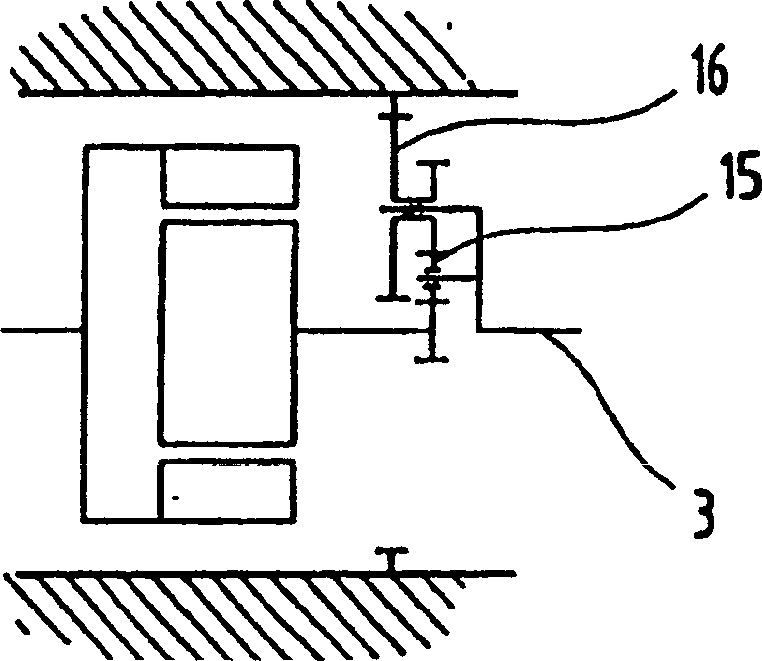

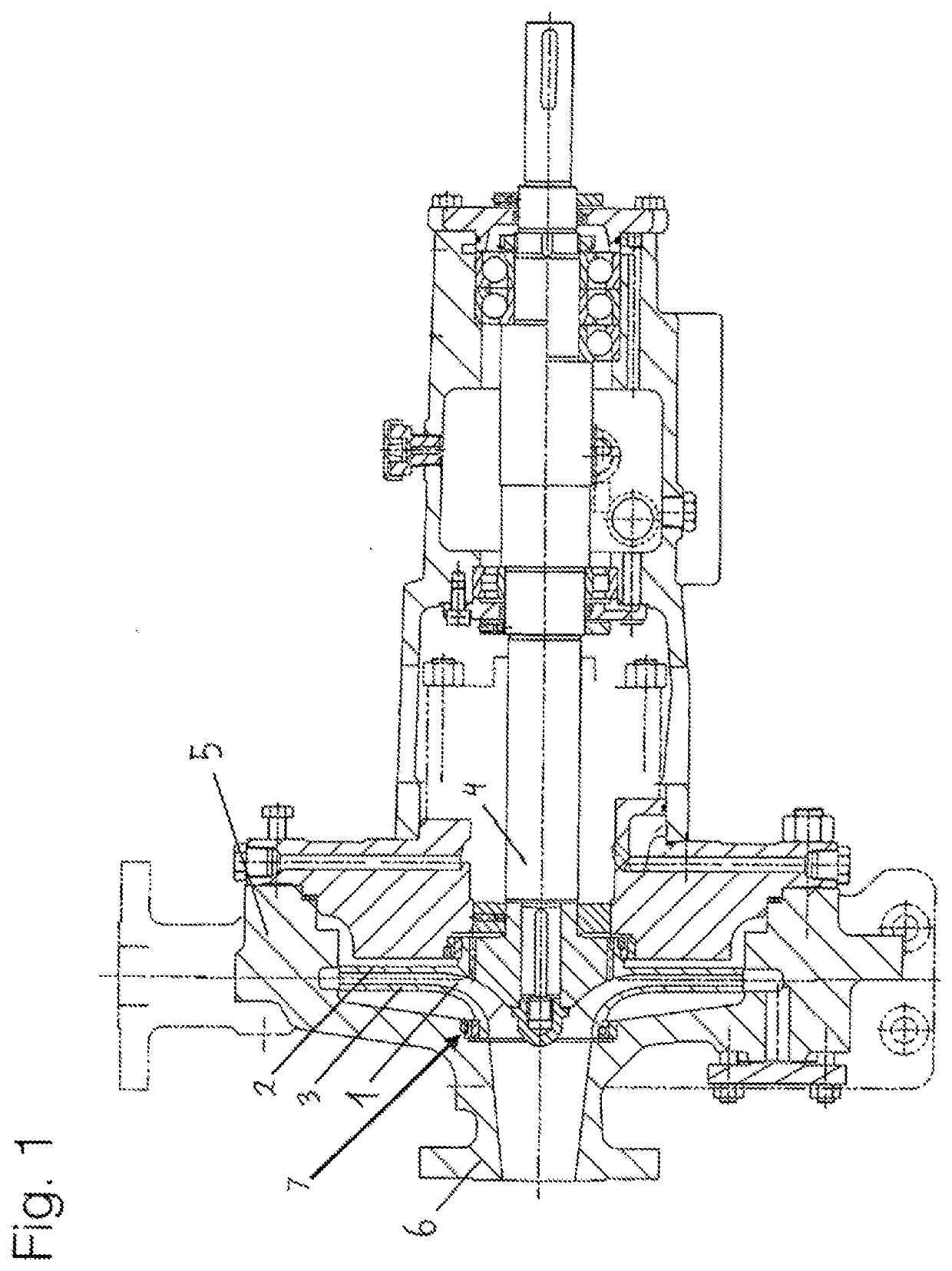

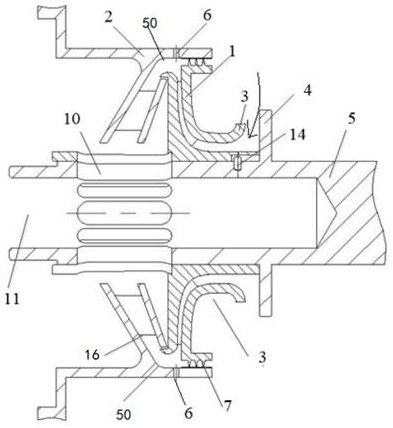

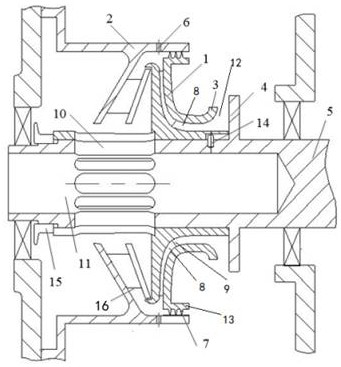

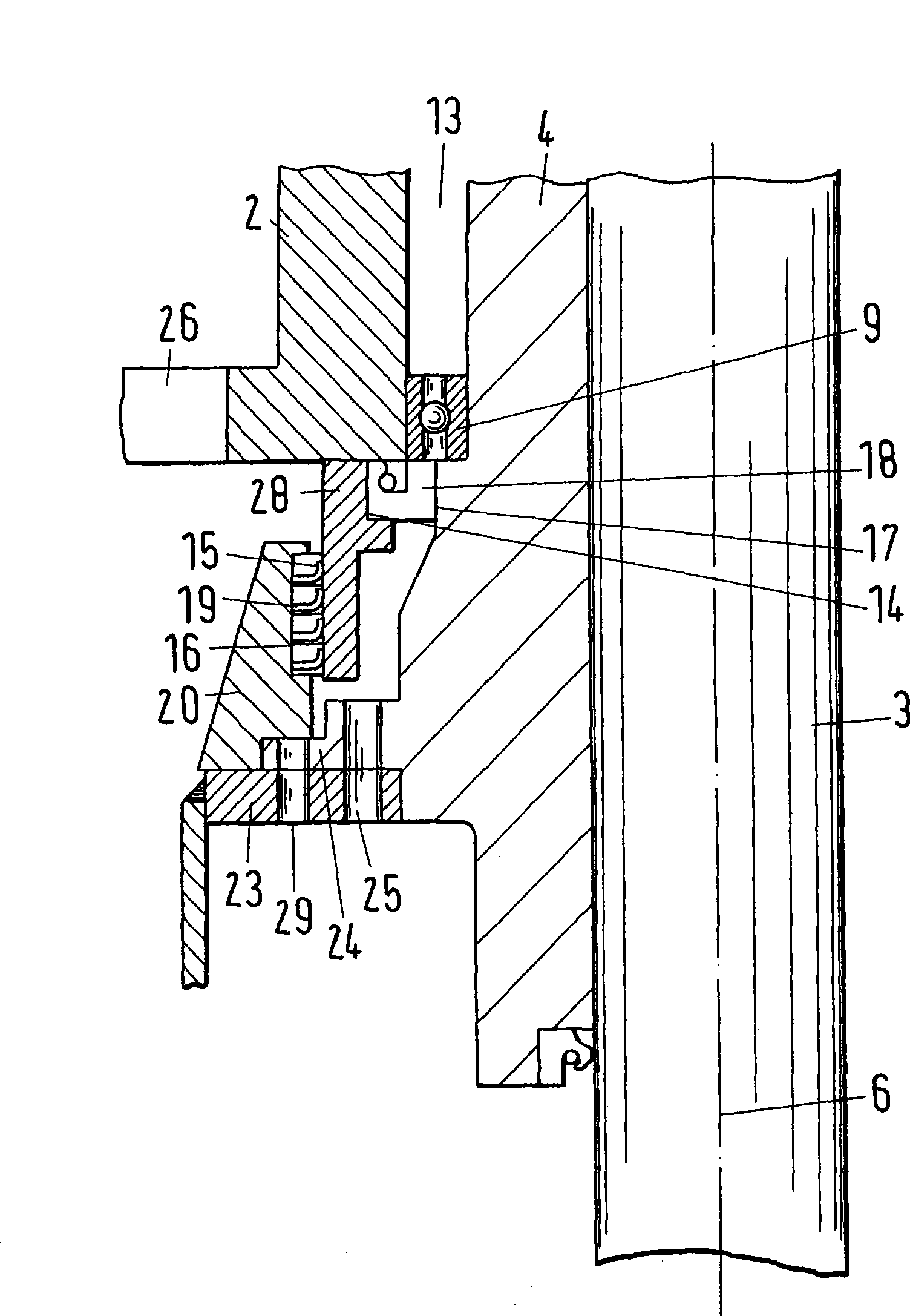

Seal structure for relatively rotational members

InactiveUS7063193B2Improve sealingReduce peripheral speedEngine sealsRoad transportForeign matterEngineering

A seal structure is disclosed as mounted in a coupling 1, exposed in the vicinity of a stationary member 14, with a dust cover 15 being mounted to a cylindrical member 19 for preventing foreign material from entering a gap between the coupling 1 and the stationary member 14, and a seal member 17 is disposed at a position opposed to the dust cover on the stationary member 14, with a seal portion 123 of the seal 17 being held in sliding contact with the dust cover 15.

Owner:TOCHIGI FUJI IND CO LTD

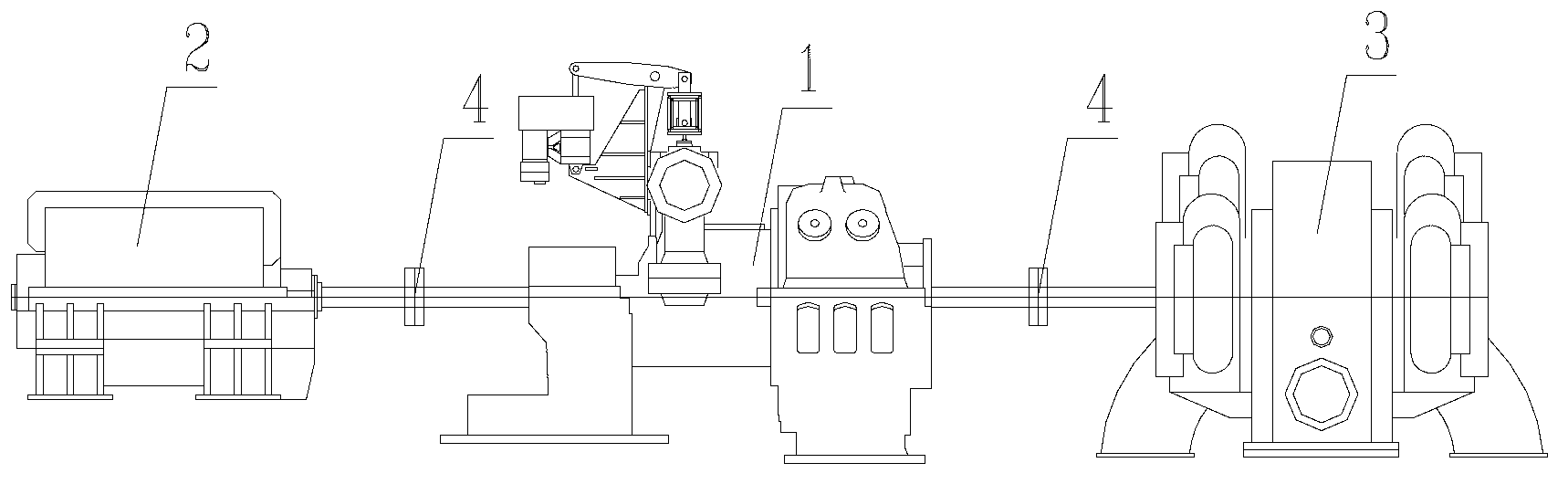

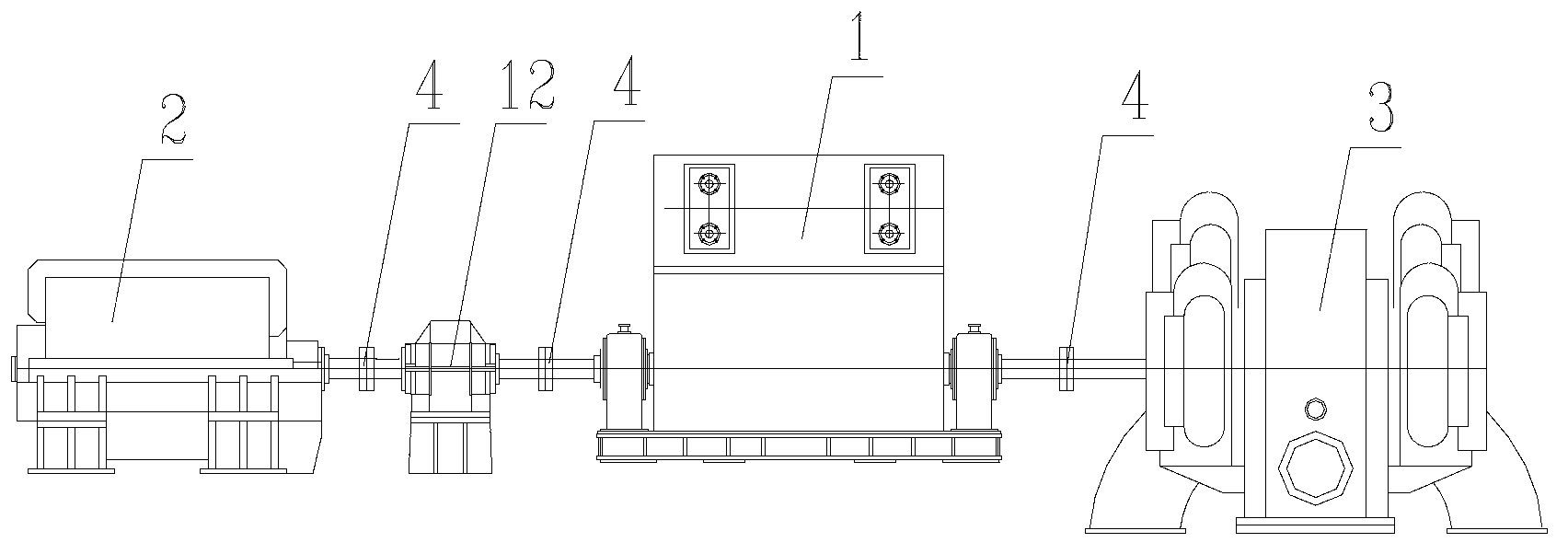

Single-shaft plusing multiple-shaft type carbon dioxide gas centrifugal compressor unit

ActiveCN102979751ADetermine the numberSingle stage pressure ratio highPump installationsNon-positive displacement fluid enginesProcess systemsCoupling

A single-shaft plusing multiple-shaft type carbon dioxide gas centrifugal compressor unit comprises a double extended shafts type driving device. A diaphragm coupling which is used for a left extended shaft of the double extended shafts type driving device is directly connected with a single-shaft type low pressure cylinder. The diaphragm coupling which is used for a right extended shaft of the double extended shafts type driving device is connected with a multiple-shaft type high pressure cylinder. Carbon dioxide gas enters into a first stage impeller of the single-shaft type low pressure cylinder, after four stage compression, the carbon dioxide gas flows out through a back outlet pipeline of a fourth stage of the low pressure cylinder and then enters into a first stage impeller of the multiple-shaft type high pressure cylinder. After another four stage compression, the carbon dioxide gas is discharged from a fourth stage impeller of the multiple-shaft type high pressure cylinder 3 and enters into subsequent process system. The single-shaft plusing multiple-shaft type carbon dioxide gas centrifugal compressor unit can save energy by over 10 % compared with the existing single-shaft plusing multiple-shaft type device and is high in security and stability compared with the multiple-shaft type carbon dioxide gas compressor in foreign.

Owner:西安赛尔机泵成套设备有限责任公司

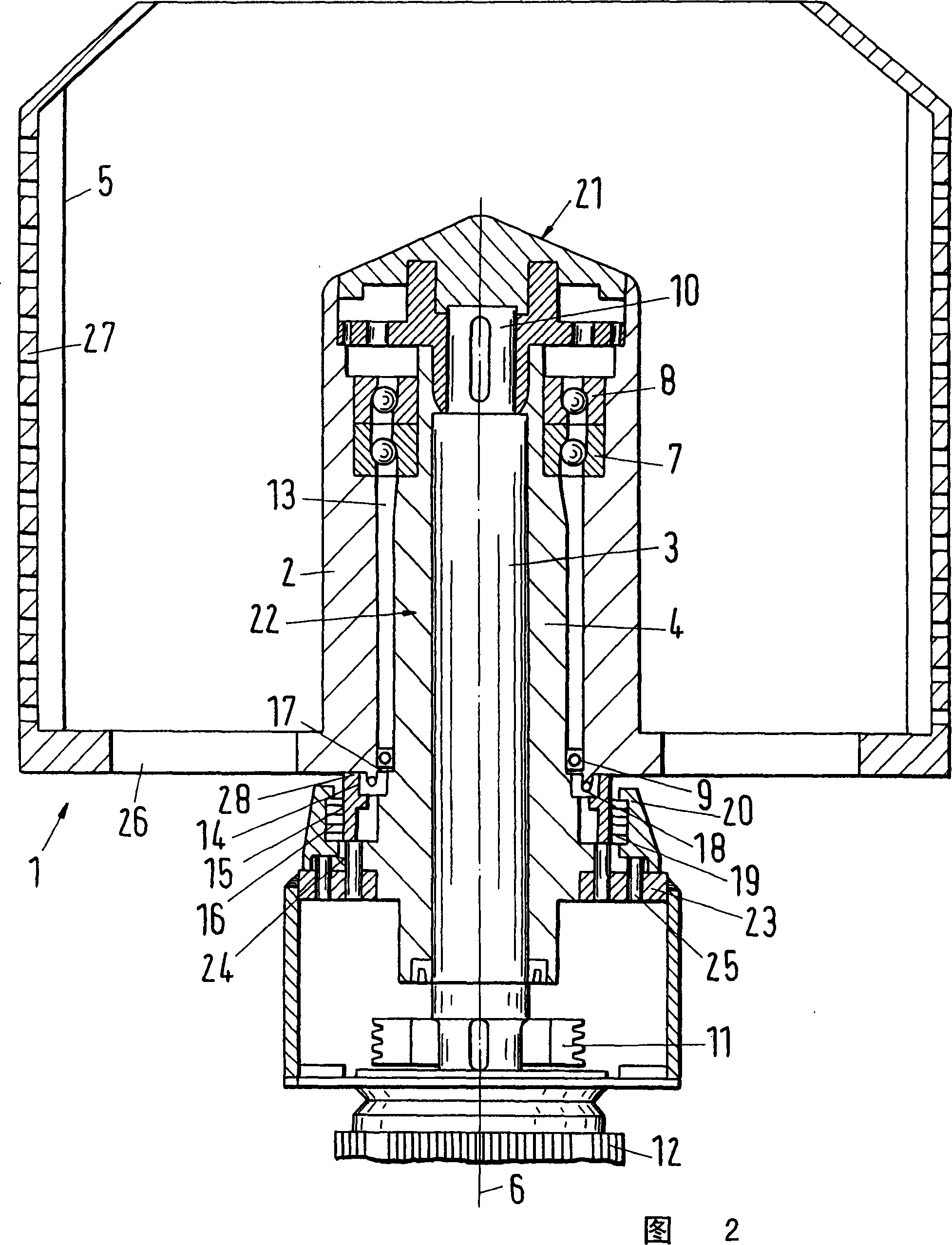

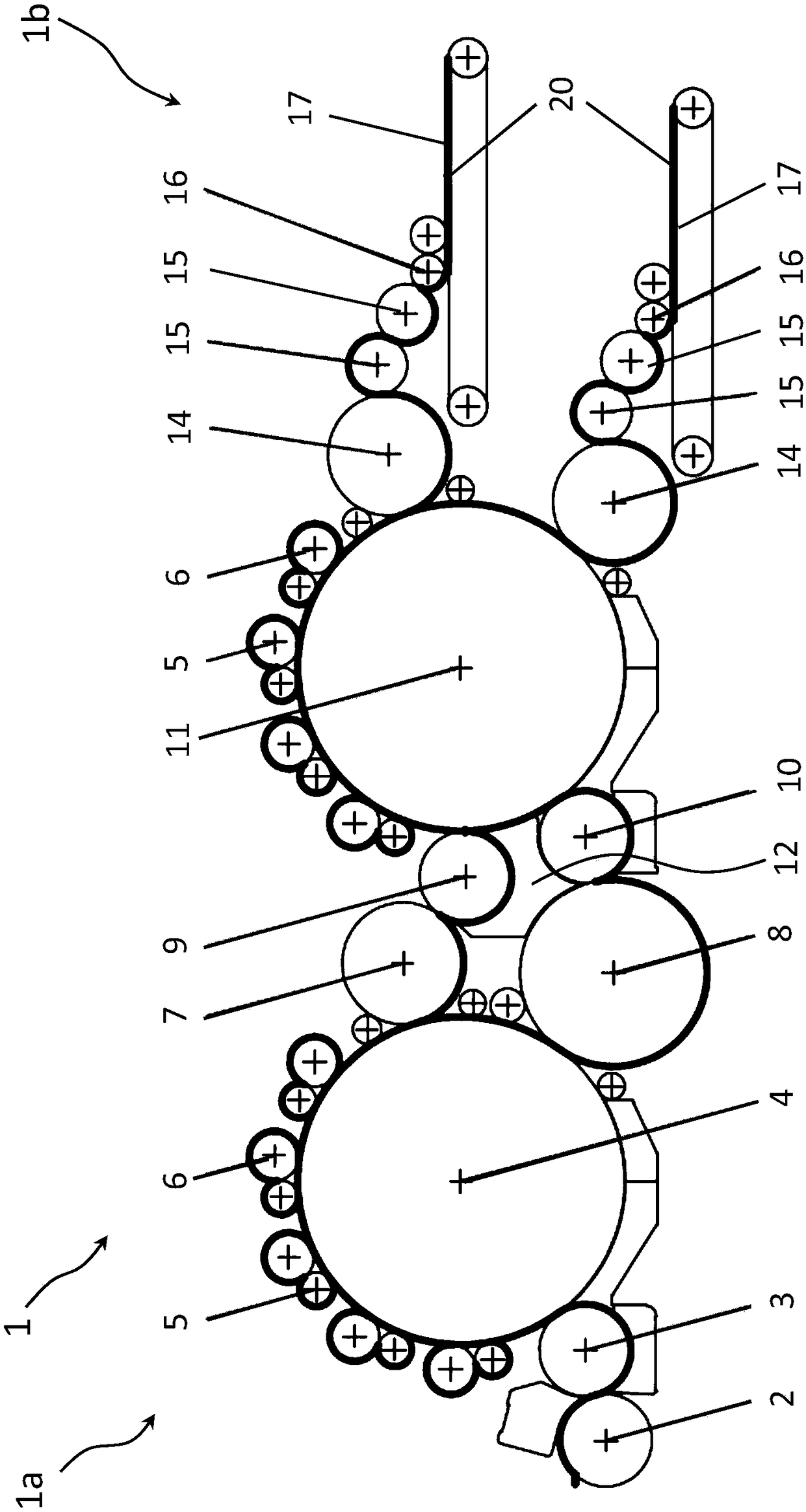

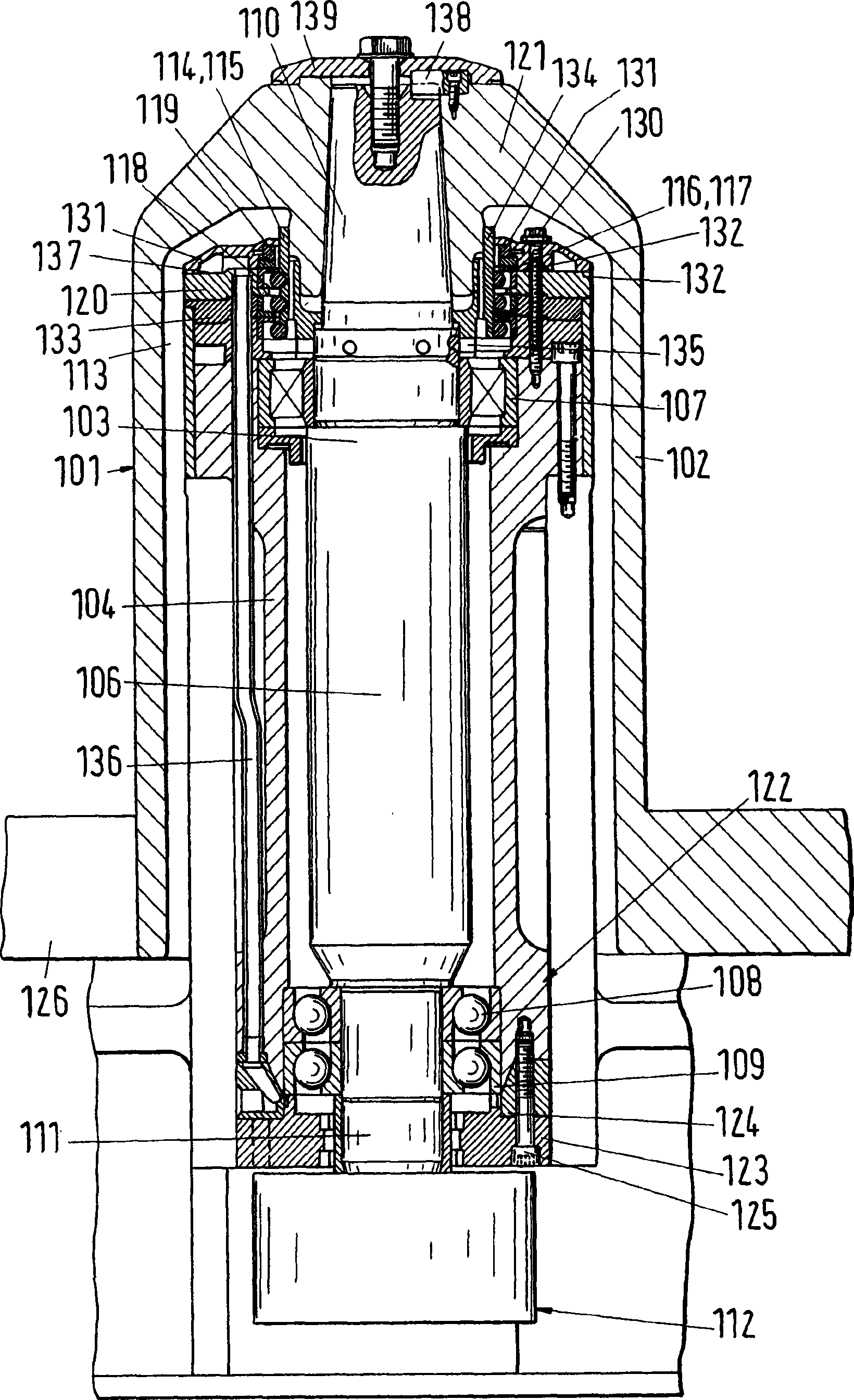

Electric device for vehicle

InactiveCN1397103ACompact structureIncrease gear ratioSpeed controllerElectric propulsion mountingGear driveVehicle frame

The invention relates to an electric drive for a vehicle. A housing (1) that is stationary in relation to the vehicle frame is provided. A motor housing (5) having a stator (4) and a rotor (7) being provided in said motor housing (5) are rotationally mounted in said housing. The motor housing and the rotor perform opposite rotational movements. A drive train (2) is connected to the motor housing and the rotational movement of the motor housing is carried out by means of a transmission device with the same drive and output direction of rotation. The remaining drive train is connected to the rotor and the rotational movement of the rotor is carried out by means of a transmission device with opposite drive and output direction of rotation. The transmission devices are planetary gears. The rotor engages with the planet wheels (13 or 16) of the allocated planetary gear by means of a spur pinion (10) that is arranged on the shaft or the motor housing engages with the planet wheels of the allocated planetary gear by means of a spur pinion that is connected to the motor housing and is arranged on the axis of the motor housing. A web (14 or 17) is provided. Said web is connected to the axles of the planet wheels of each planetary gear and drives the wheel shaft assigned thereto.

Owner:奥斯卡・瓦绍尔

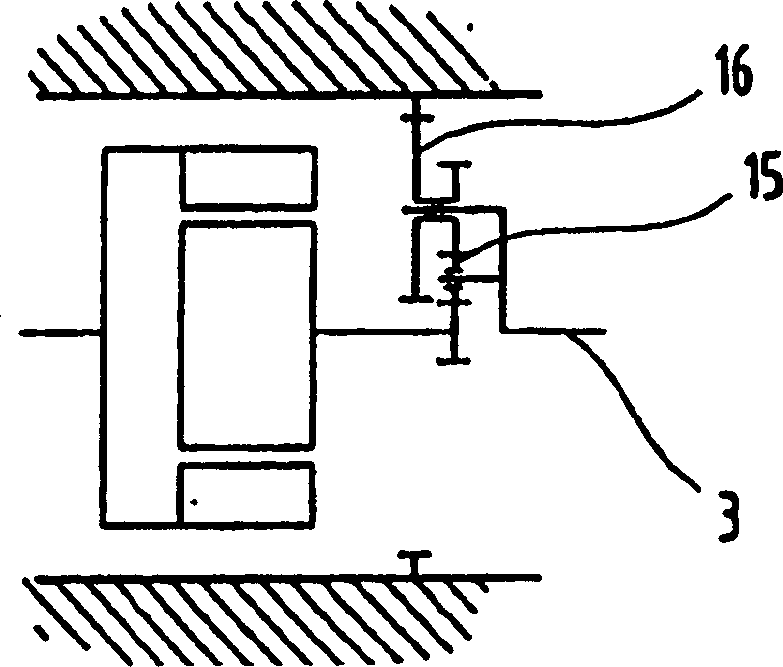

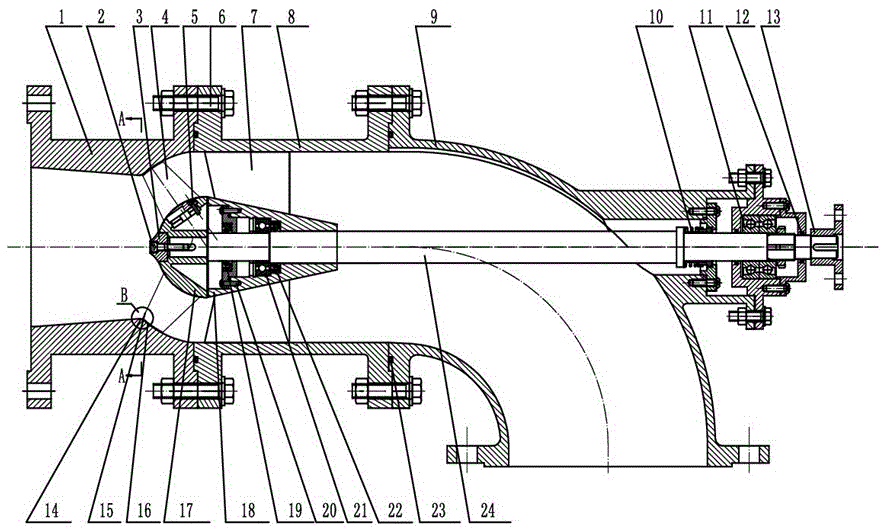

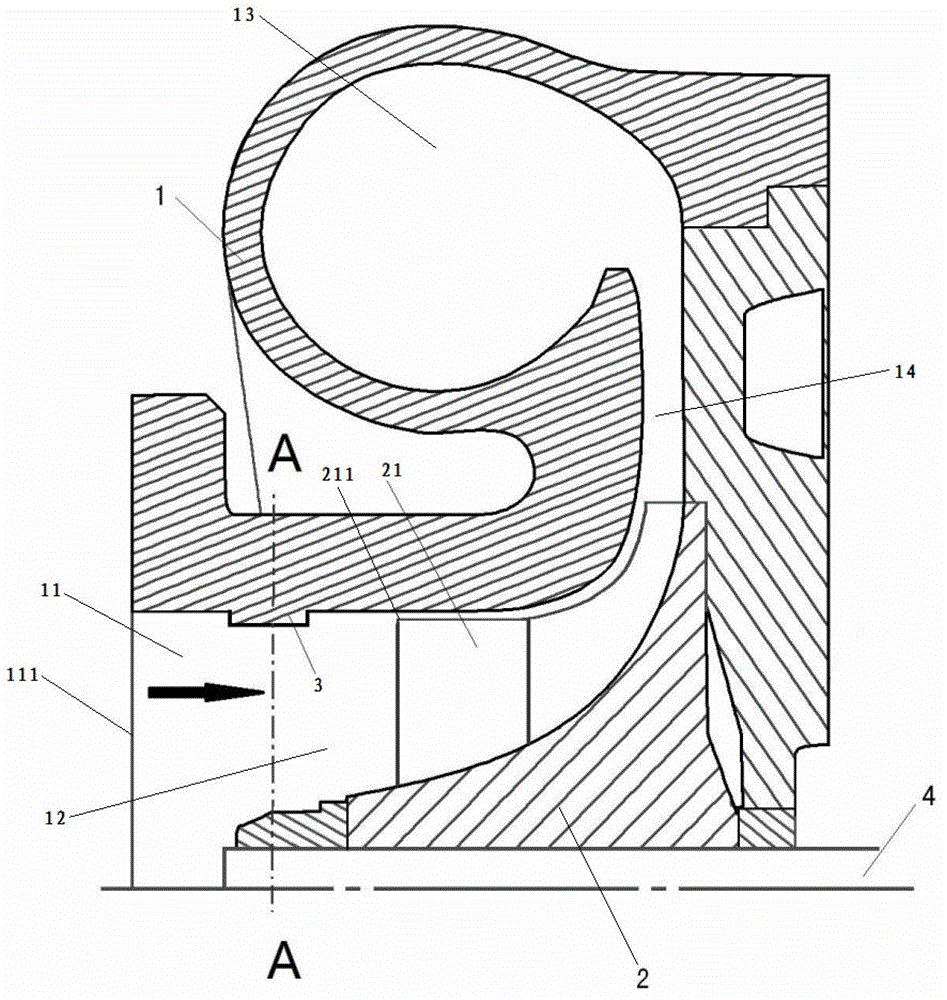

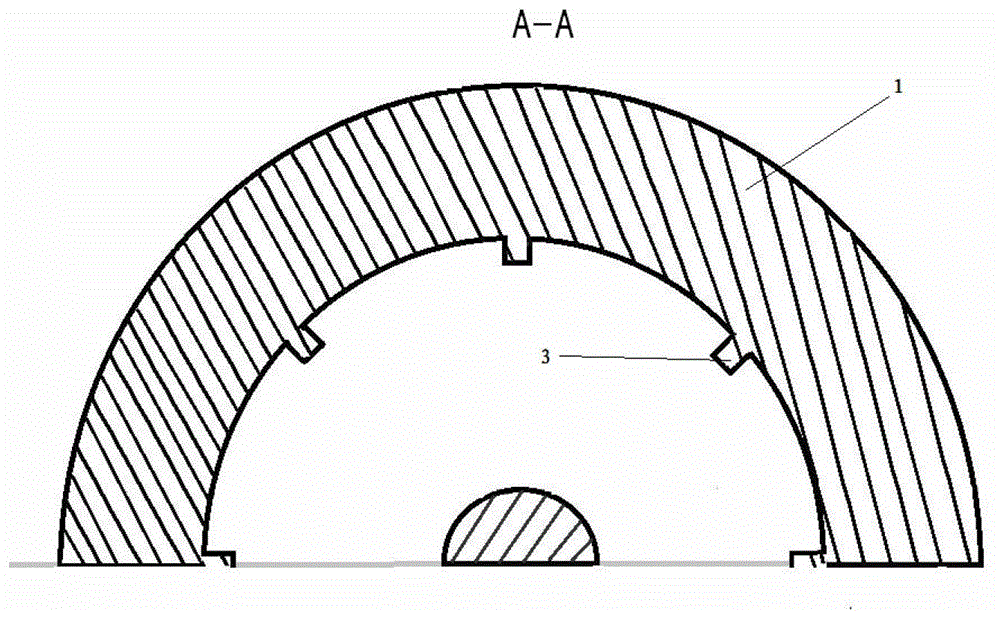

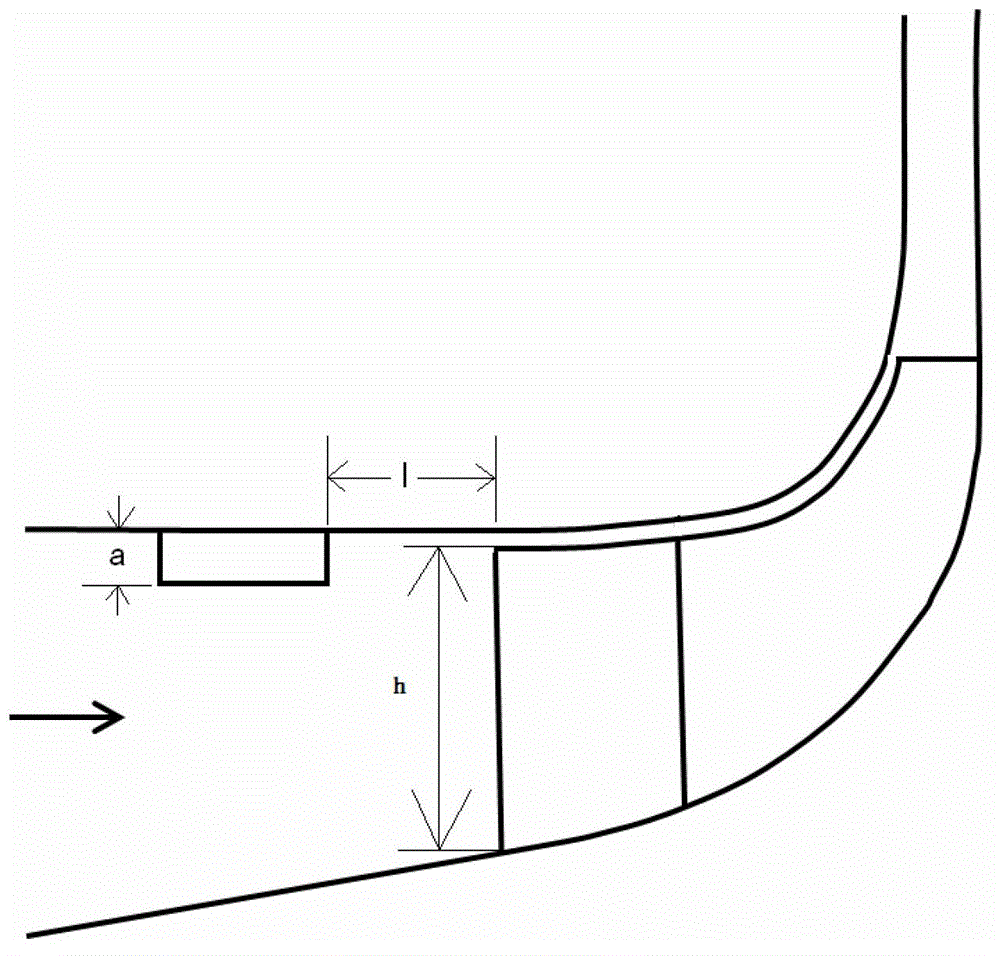

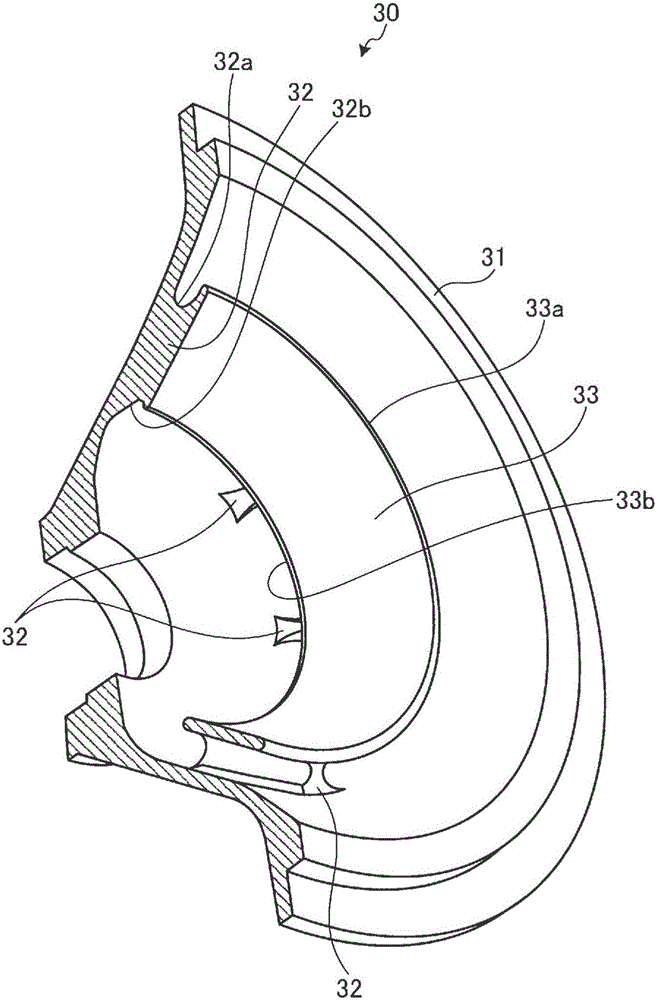

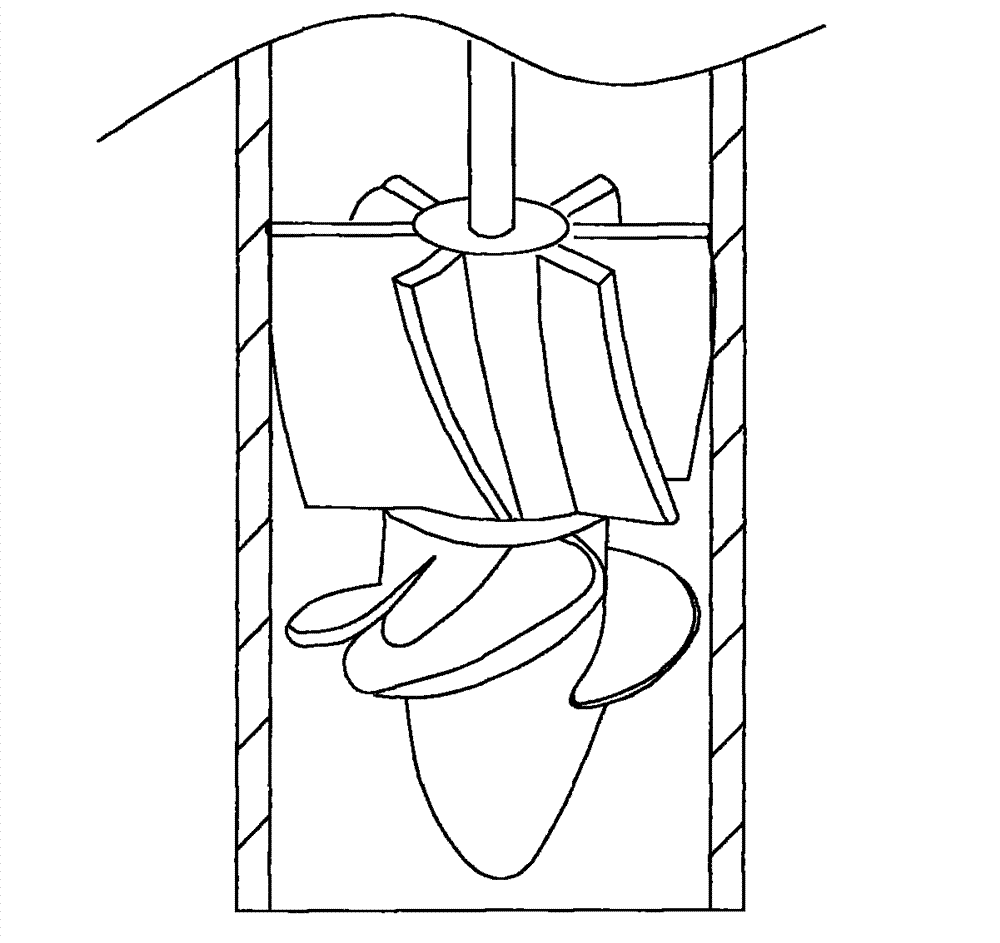

Diagonal flow pump

The invention provides a diagonal flow pump. The diagonal flow pump comprises a pump shaft, an inlet section, a cylindrical outer barrel and a bent pipe section, wherein the pump shaft penetrates through the cylindrical outer barrel and the bent pipe section, blades are mounted on the pump shaft, an inner cavity wall surface of the inlet section comprises an inlet chamber wall surface and a rotating wheel chamber wall surface, the inlet chamber wall surface is a conical surface, the rotating wheel chamber wall surface is an arc surface, the rotating wheel chamber wall surface is tangential with the inner wall surface of the cylindrical outer barrel, the blades are located in a rotating wheel chamber of the inlet section, and an annular groove is formed in the junction position of the inlet chamber wall surface and the rotating wheel chamber wall surface. The diagonal flow pump can weaken the strength of the blade-tip leakage flow at an inlet and reduce the influence of the blade-tip leakage flow to flowing inside an impeller, the performance of the diagonal flow pump is improved, appearance of hump zones is effectively inhibited, and the running stability of the diagonal flow pump is improved.

Owner:JIANGSU UNIV

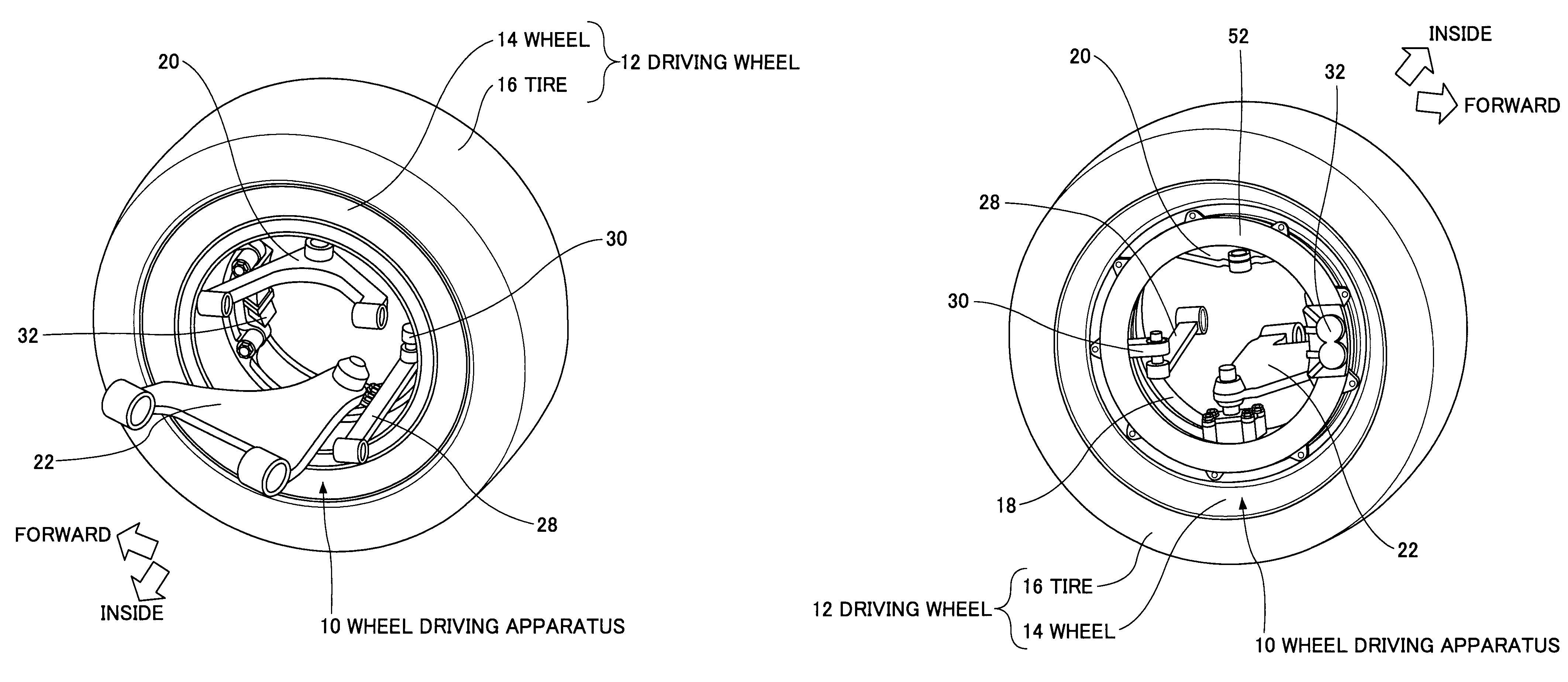

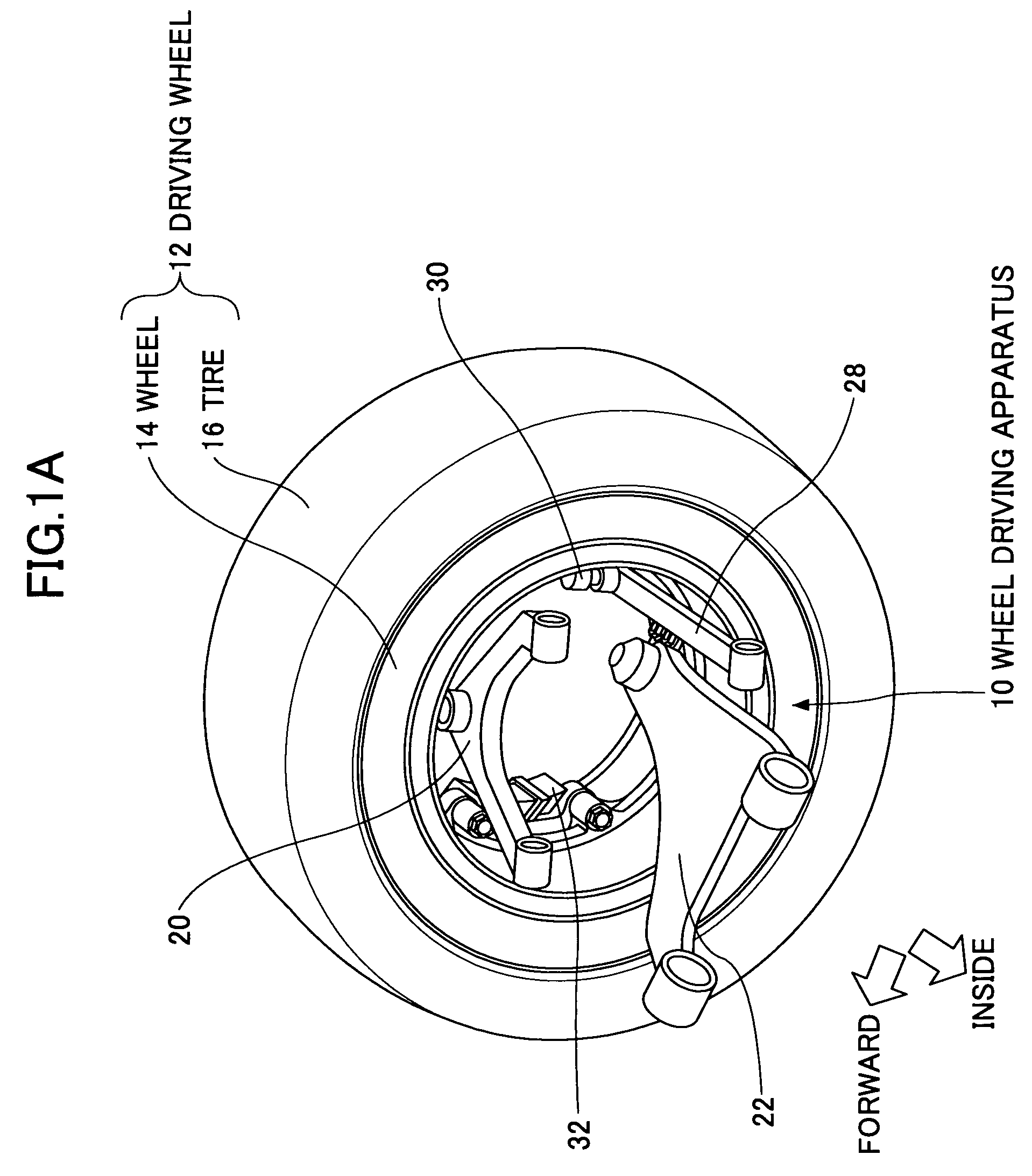

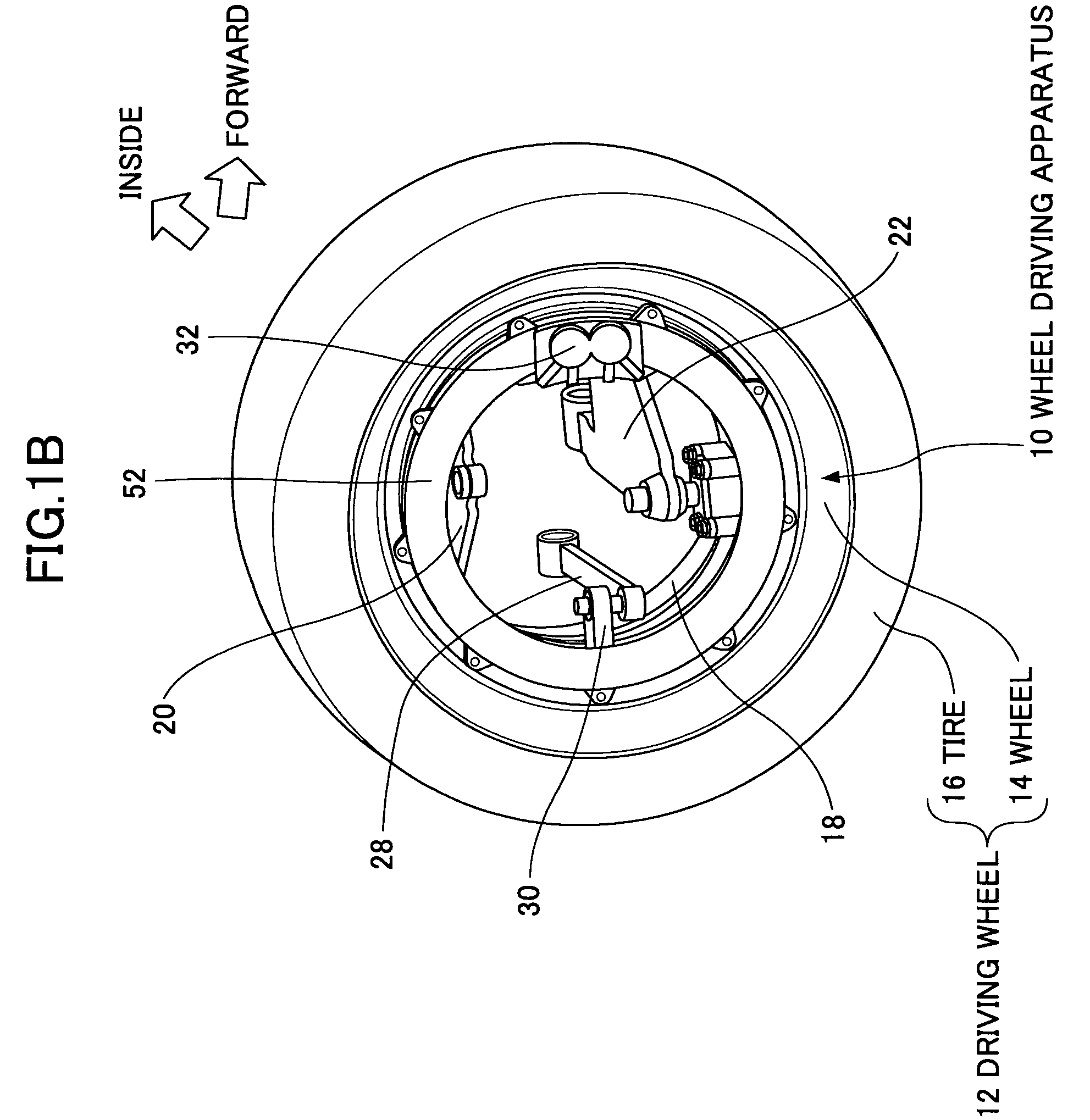

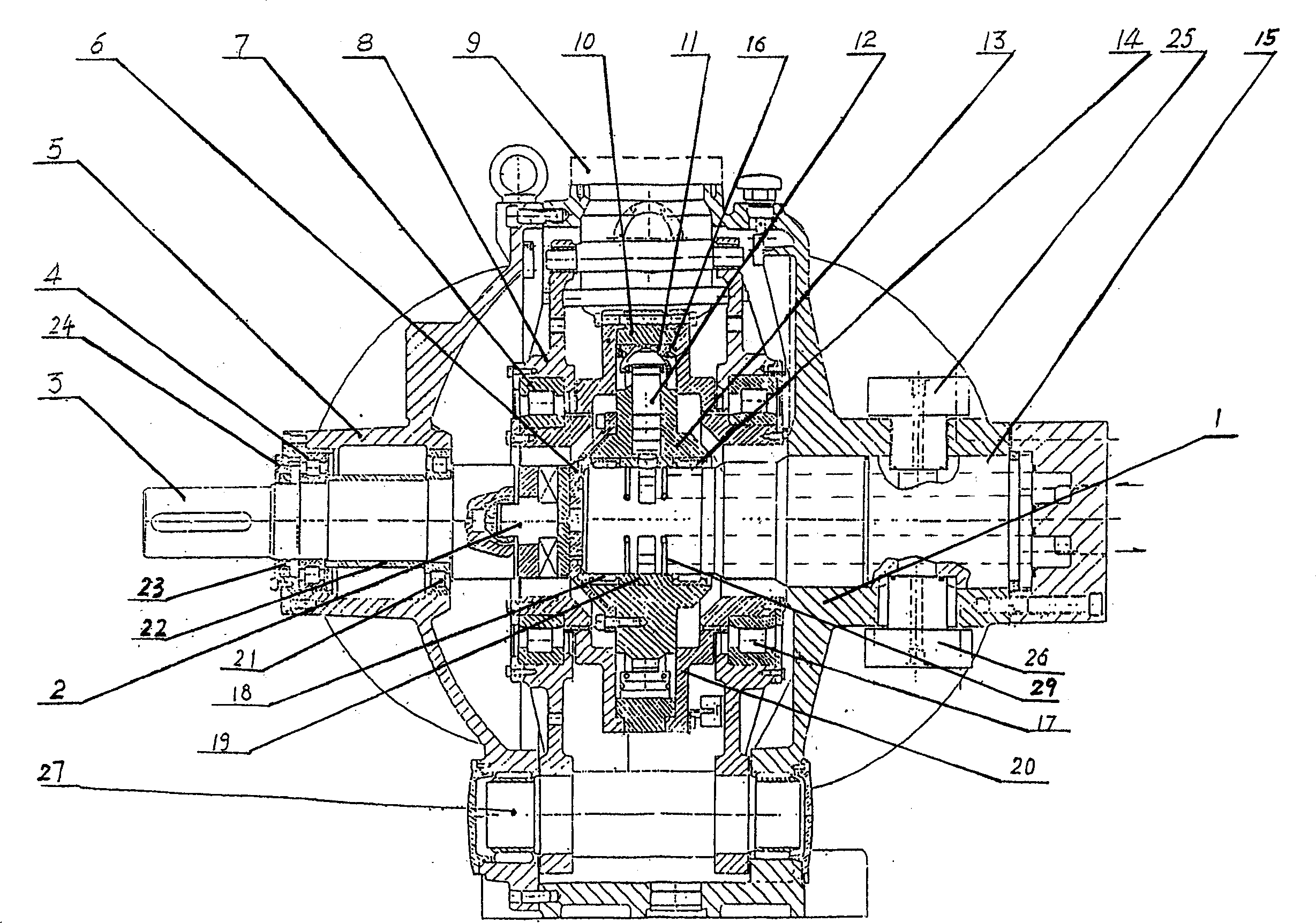

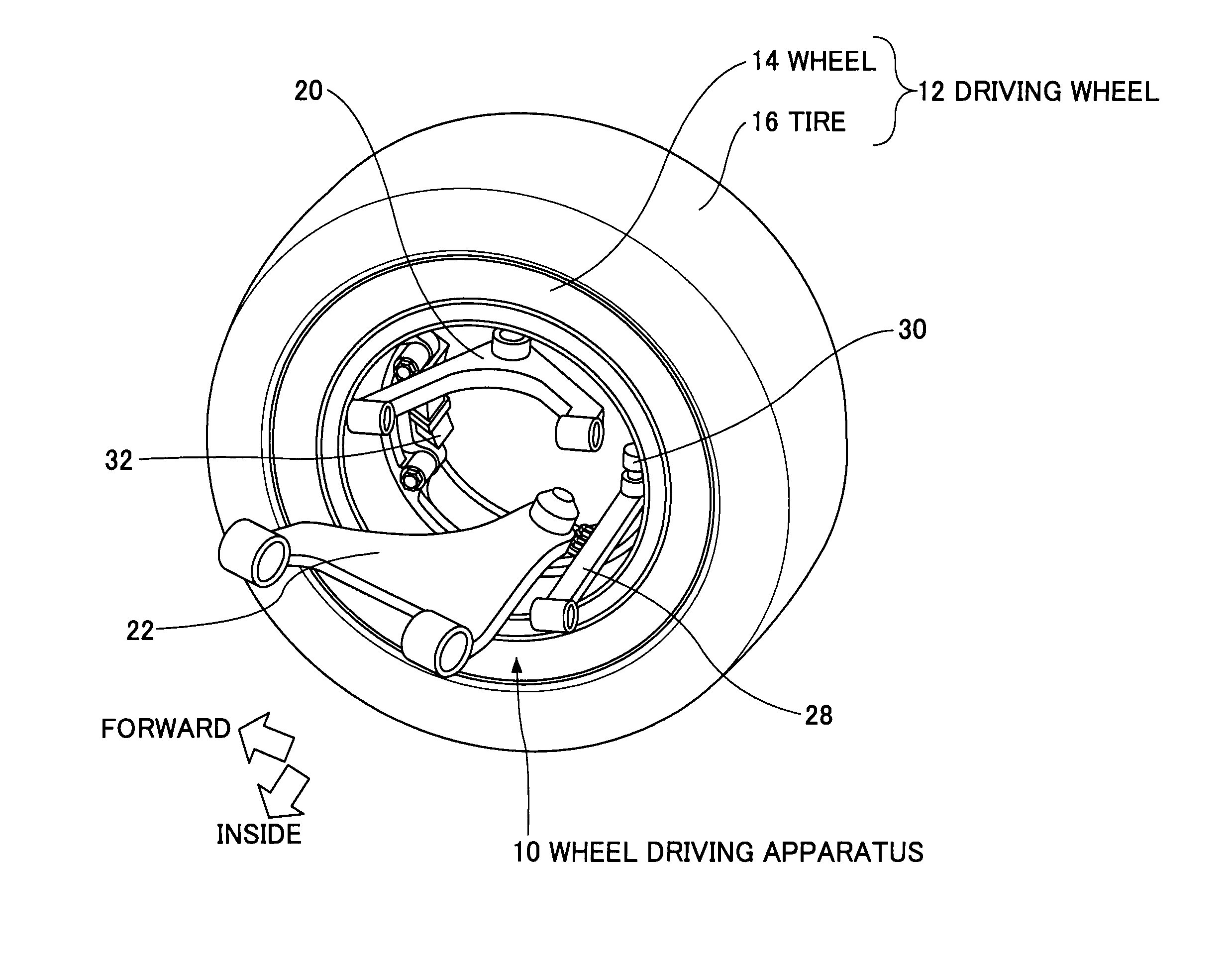

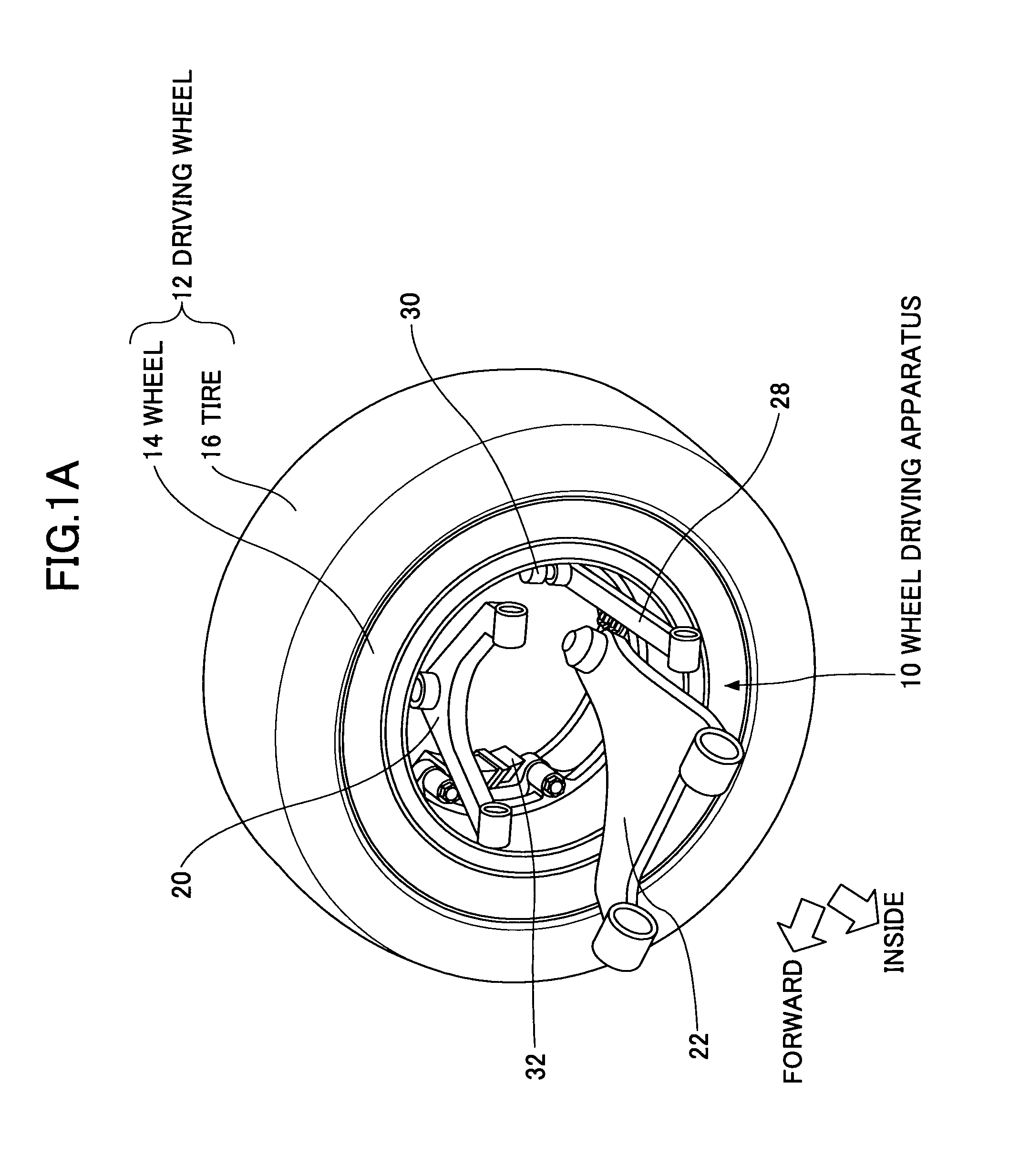

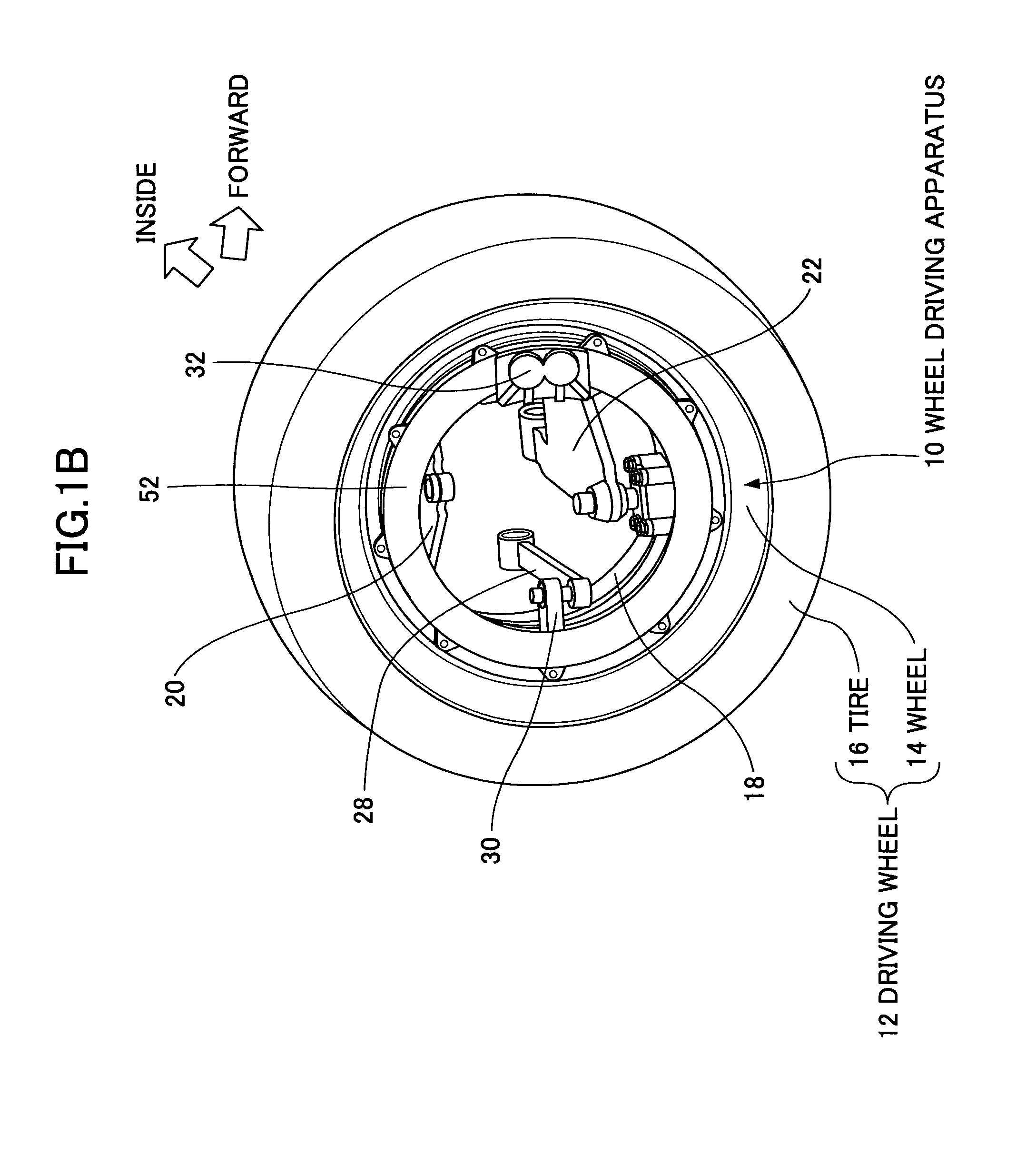

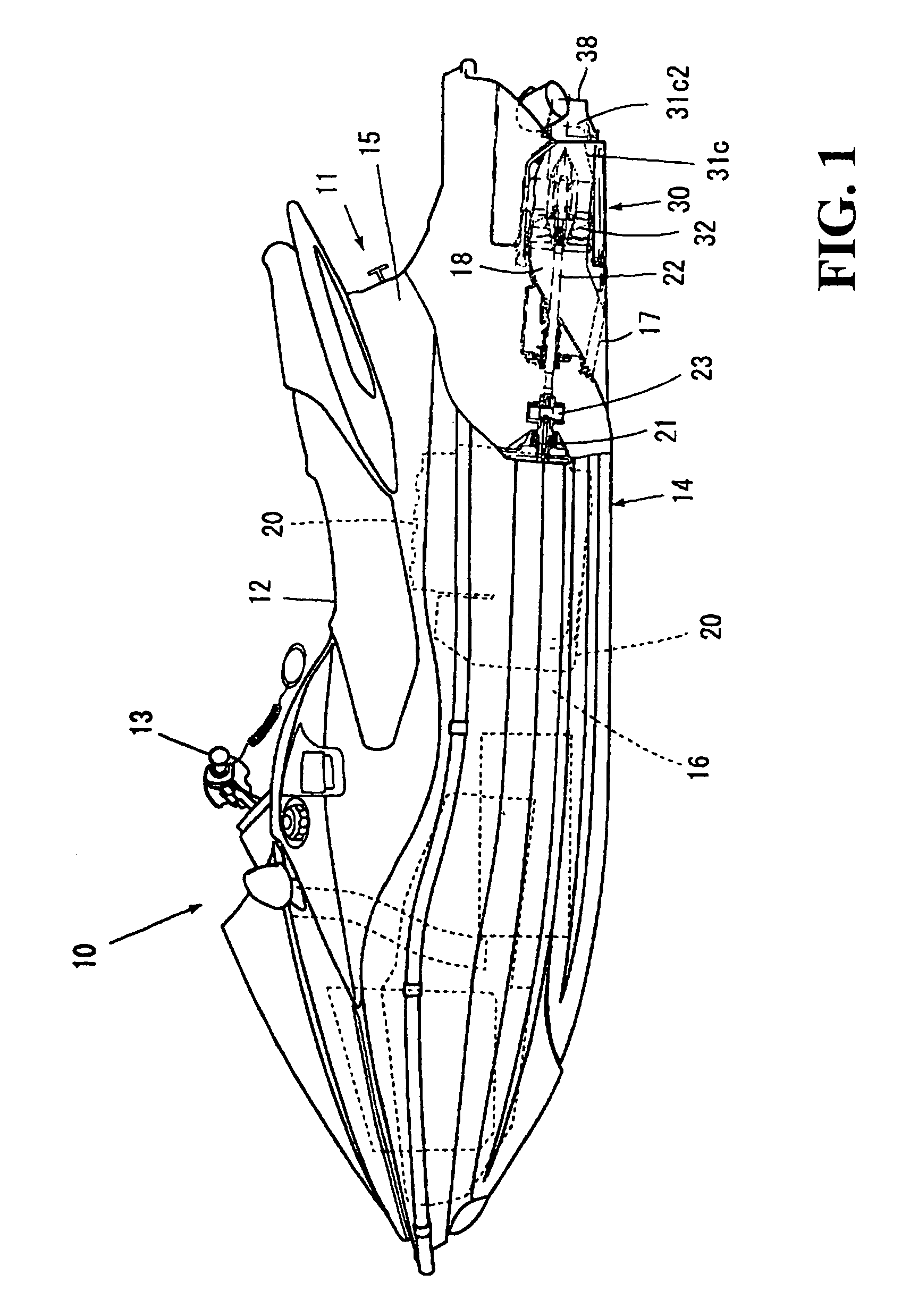

Wheel driving apparatus

ActiveUS8616314B2Improve workabilityHigh hardnessRimsElectric propulsion mountingEngineeringWheel drive

Owner:TOYOTA JIDOSHA KK

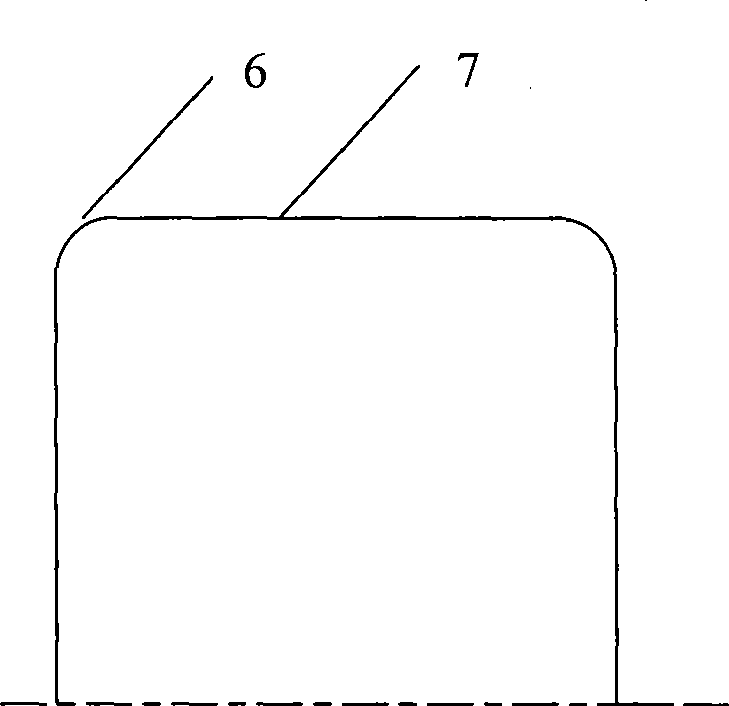

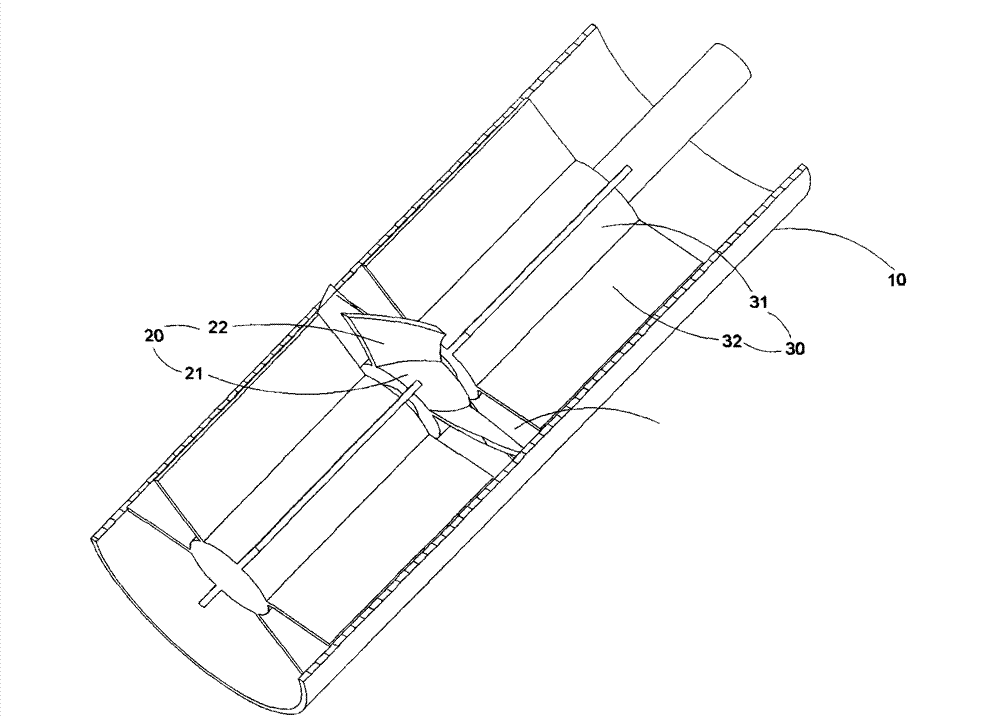

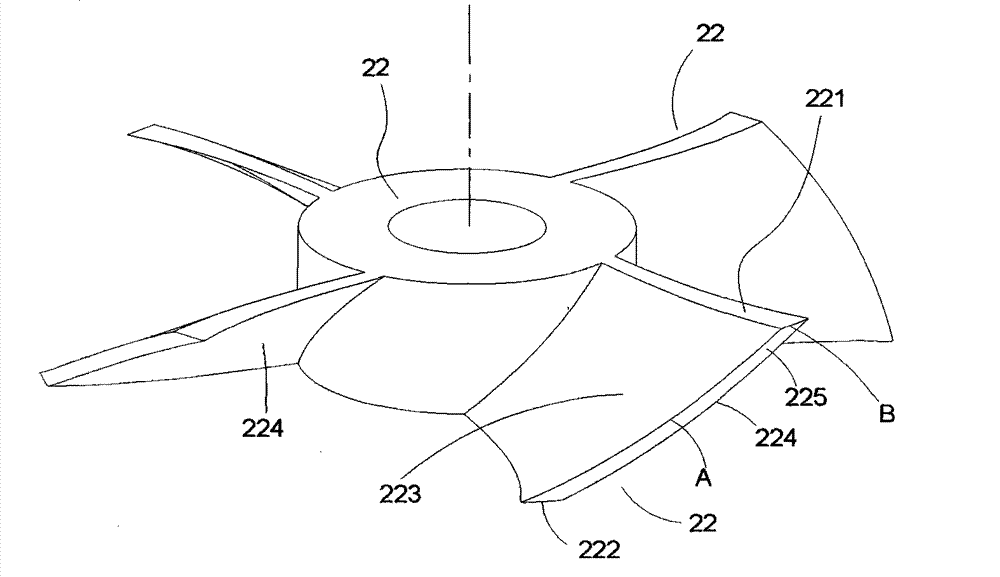

Centrifugal compressor with inlet guide blades and turbocharger

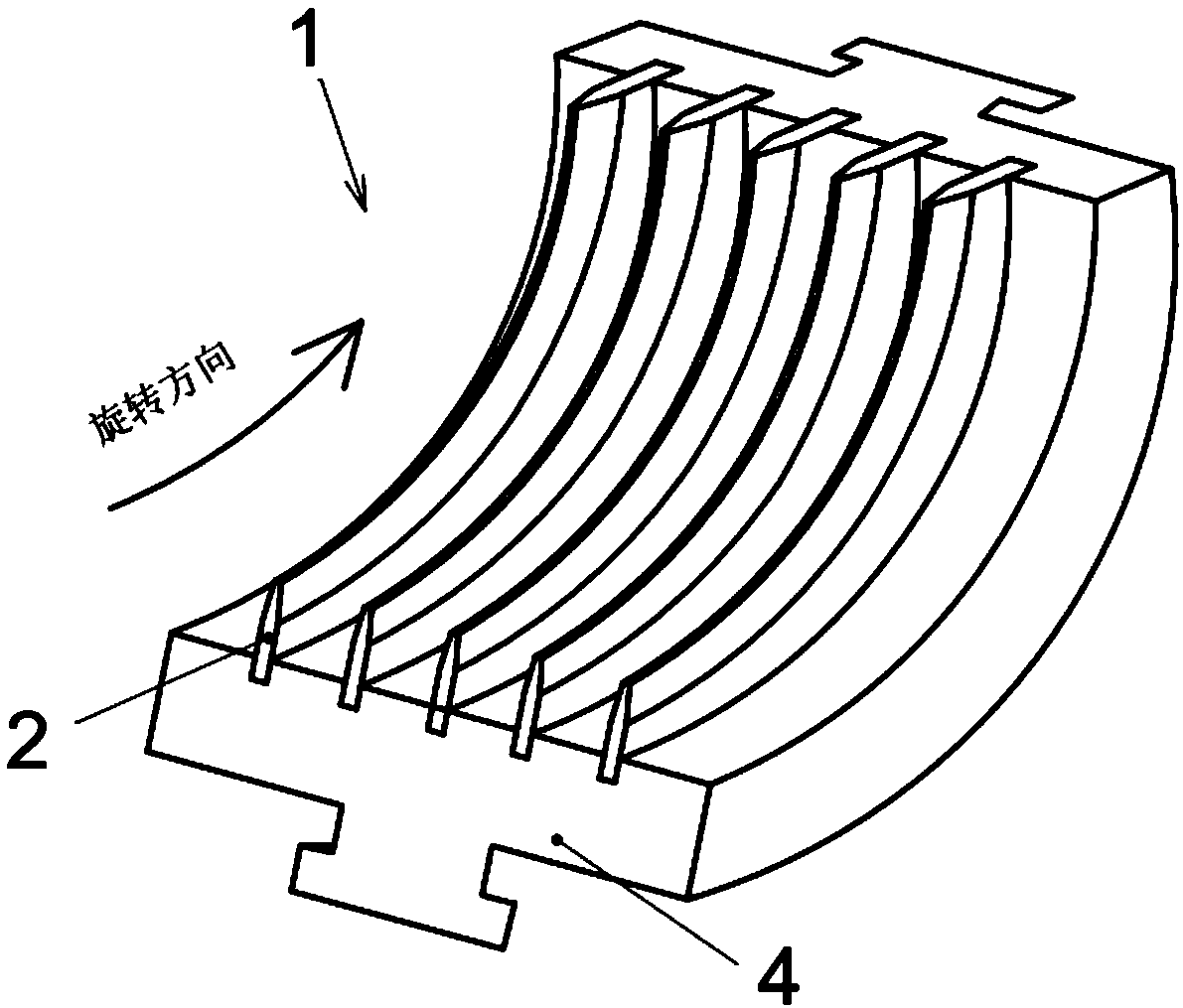

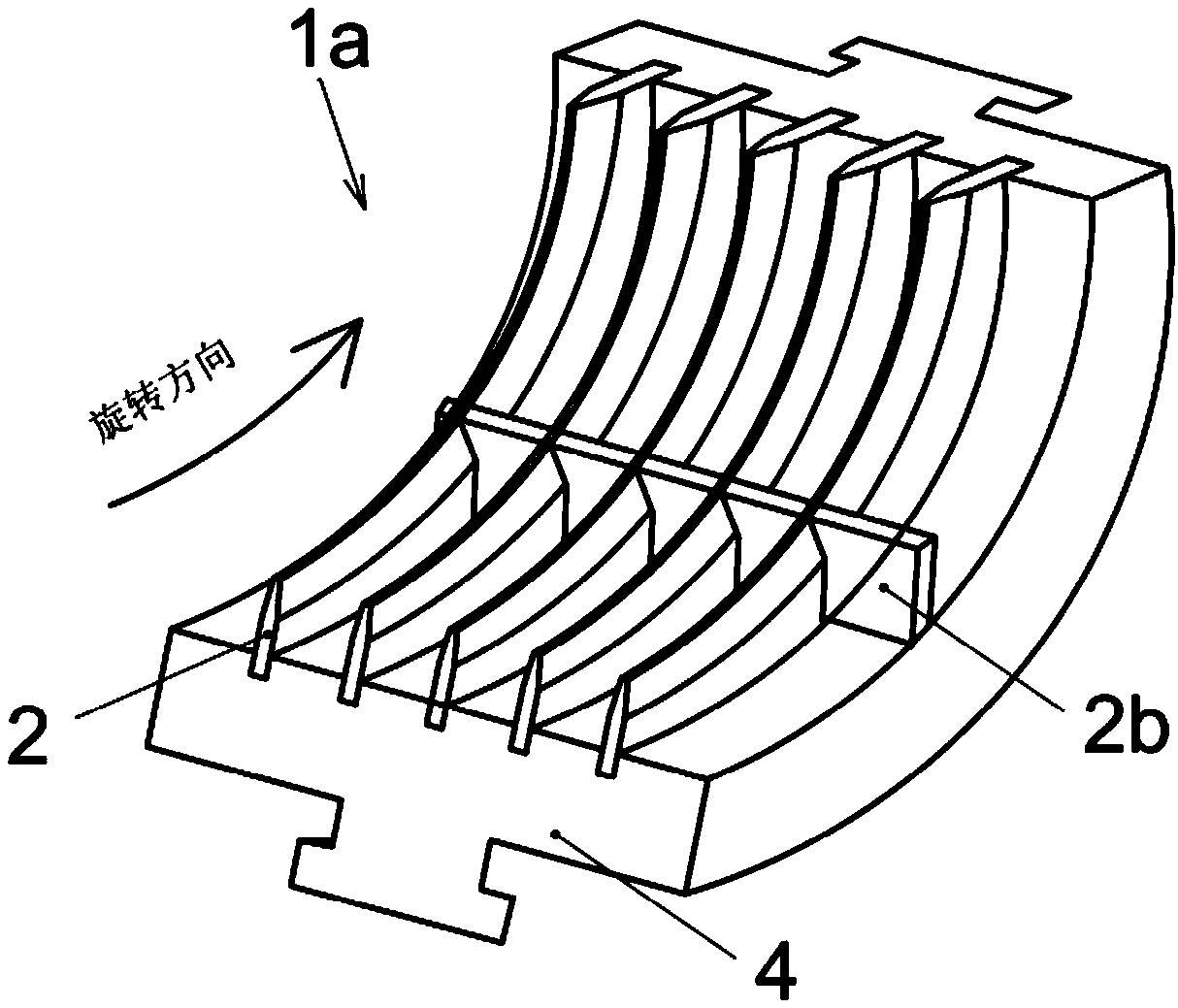

ActiveCN103148021AImprove performanceReduce peripheral speedEngine manufacturePump componentsInlet channelTurbocharger

The invention discloses a centrifugal compressor with inlet guide blades and a turbocharger. The centrifugal compressor comprises a volute, an impeller and guide blades, wherein an air inlet channel, an impeller mounting space and an air outlet channel are defined in the volute, the impeller mounting space is respectively communicated with the air inlet channel and the air outlet channel, and the air inlet channel is provided with an air inlet and the air outlet channel is provided with an air outlet; the impeller can be rotationally arranged in the impeller mounting space by surrounding around a revolving shaft and is provided with a plurality of blades; and guide blades are arranged on a peripheral wall of the air inlet channel. According to the centrifugal compressor provided by the invention, the peripheral speed of fluid such as air in the air inlet channel is reduced by the fact that the guide blades are mounted, so that air inflows at the tips of the blades can be more uniform; and moreover, and the sudden change of the peripheral speed can be reduced, so that the increasing ranges of thermal charges at the tips of the blades can be reduced, the property of the centrifugal compressor can be further improved, especially, the property can be remarkably improved under the small flow working condition.

Owner:TSINGHUA UNIV

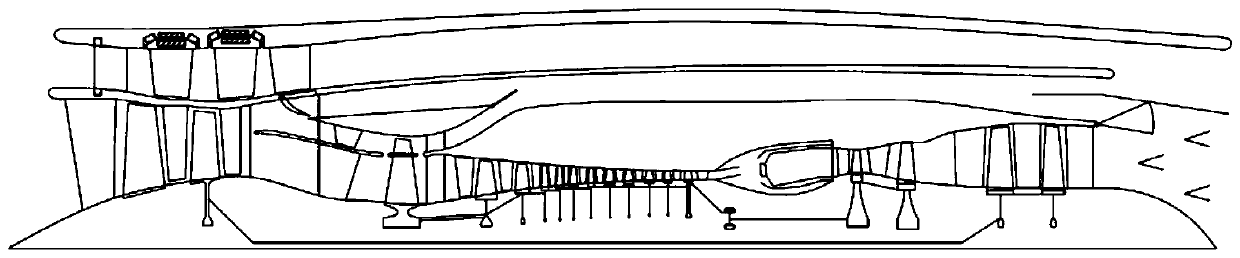

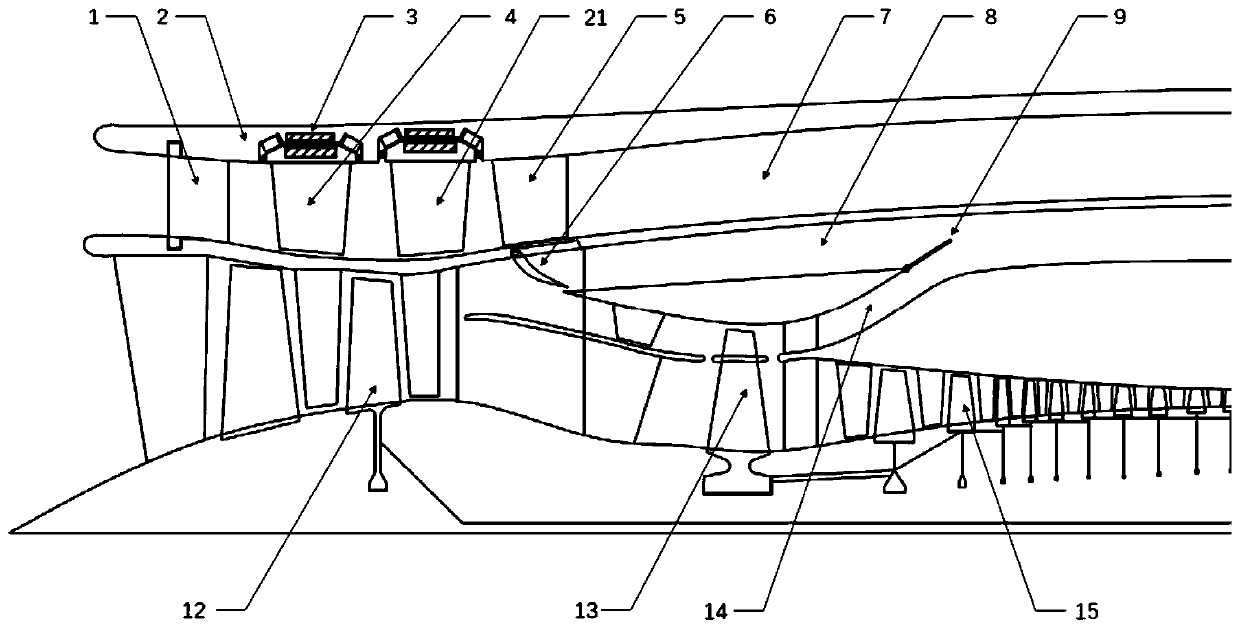

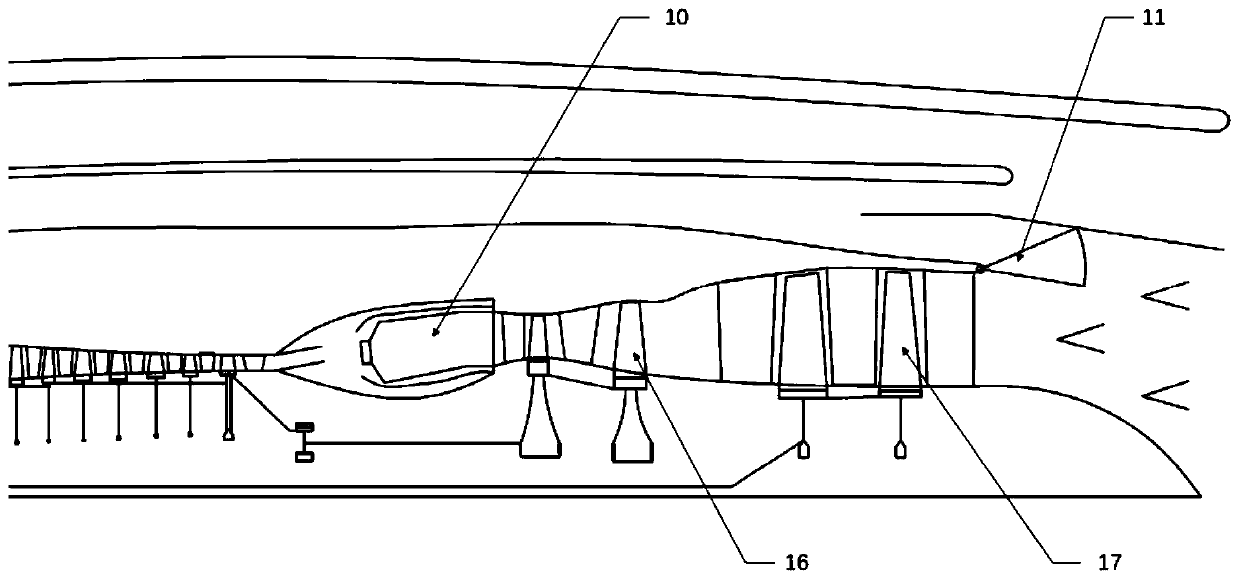

Self-driven outer duct contrarotating annular fan blade compressing device

The invention relates to a device of adjusting bypass ratio of a turbofan engine continuously, in particular to a self-driven outer duct contrarotating annular fan blade compressing device. The self-driven outer duct contrarotating annular fan blade compressing device comprises an inner duct of the engine. A duct arranged on the outer side of the inner duct is a third outer duct, two rows of contrarotating members are arranged between an inlet guide vane and a stator vane in the third outer duct, the two rows of contrarotating members are separately upstream rotating members and downstream rotating members, and the upstream rotating members and downstream rotating members are arranged on a duct cartridge receiver of the third outer duct through a turntable bearing, separately. By adoptingthe two rows of contrarotating annular fan structures, the rotating speed of a rotor structure is reduced effectively and the dimension of the third outer duct is decreased effectively on the condition that the pressure ratio and the flow of the third outer duct are the same, so that the noise, the electric power consumption and the design difficulty are reduced, the working range of the turbofanengine is expanded greatly, and a variable cycle advantage of the engine is exerted to a greater extent.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

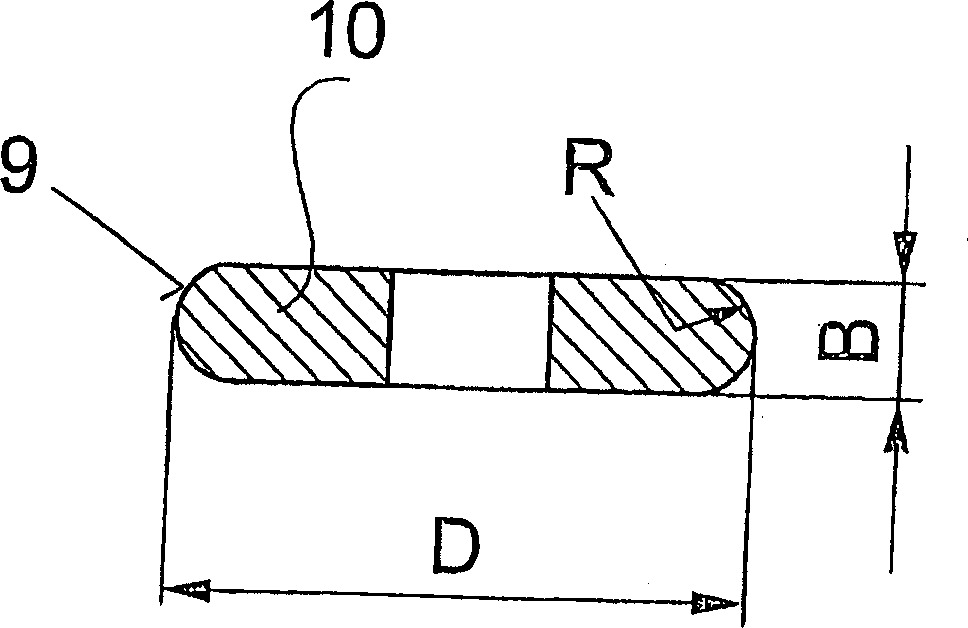

Grinding wheel and use thereof for grinding hard-face roller

InactiveCN101481596AGood heightReduce peripheral speedOther chemical processesBonded abrasive wheelsEngineeringSingle crystal

The invention relates to a grinding wheel which is characterized in that the grinding wheel has the following components: 30-35% of alumina, 30-35% of single alundum and 30-40% of carborundum, and the ratio between the alumina and the single alundum is 1:1. After being trimmed, the grinding wheel has two symmetric sections of width outer margins formed by a first sine curve and a second sine curve smoothly connected with the first sine curve. When the grinding wheel is used for grinding a high-speed steel roller, the rotation speed and the Z-axis speed of the grinding wheel can be reduced, however, the amount of feed is increased, and the grinding time is reduced. The grinding wheel has prolonged service life and reduces the time for the grinding wheel replacement and the labor intensity of grinder workers. The amount of sand and mud is reduced during the grinding so that the environment around a grinder can be improved; and the cost performance of the grinding wheel is remarkably improved.

Owner:BAOSHAN IRON & STEEL CO LTD

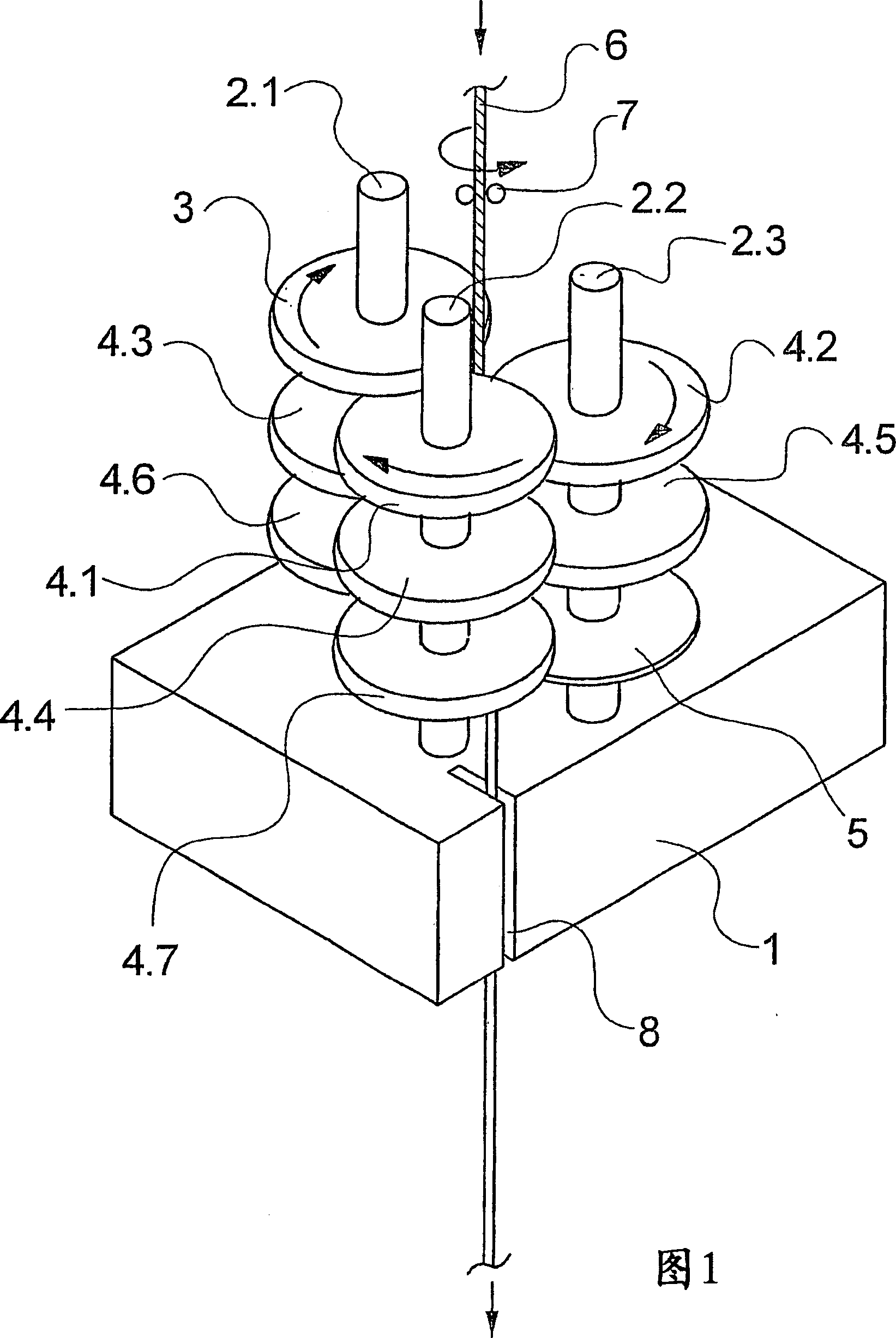

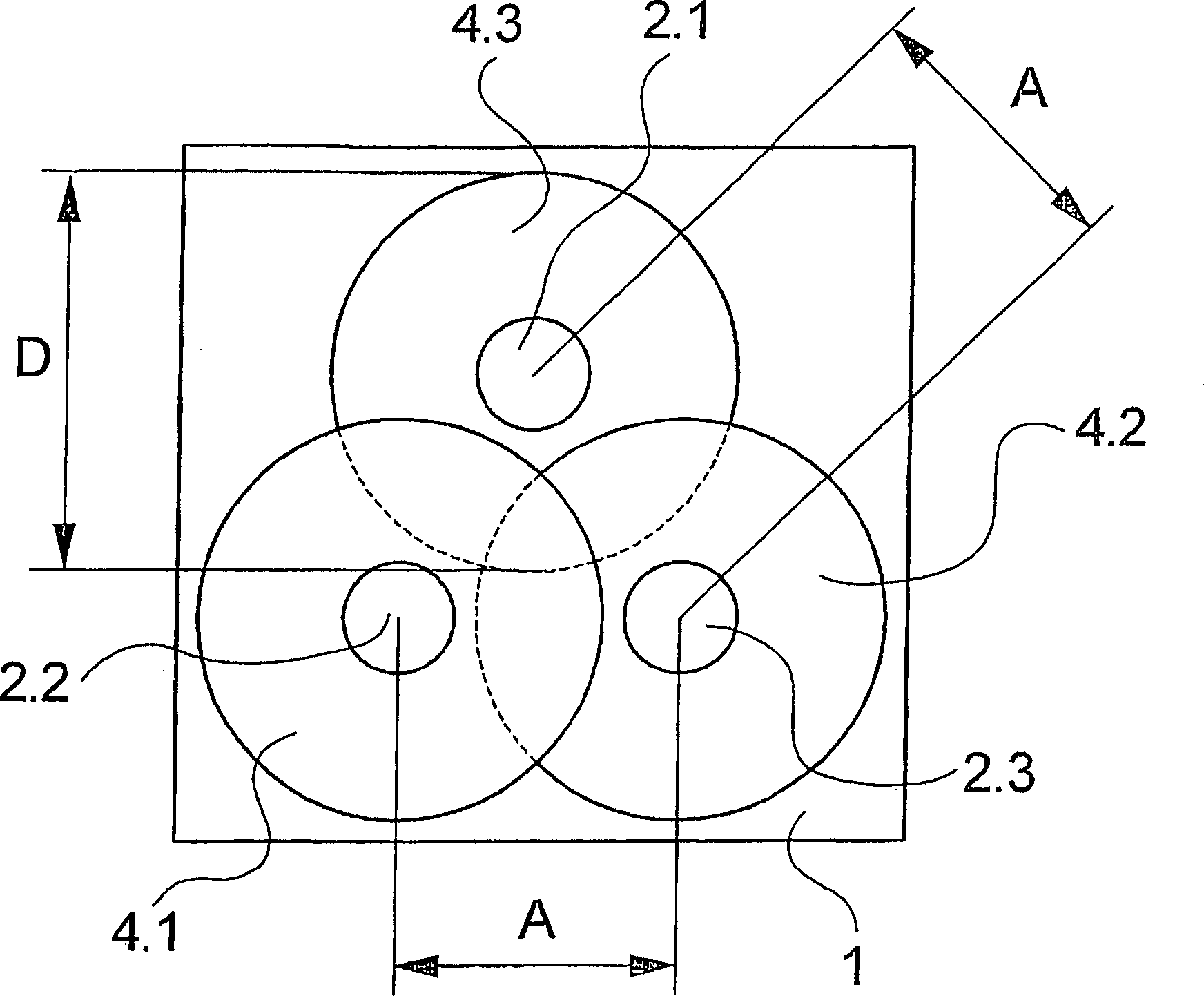

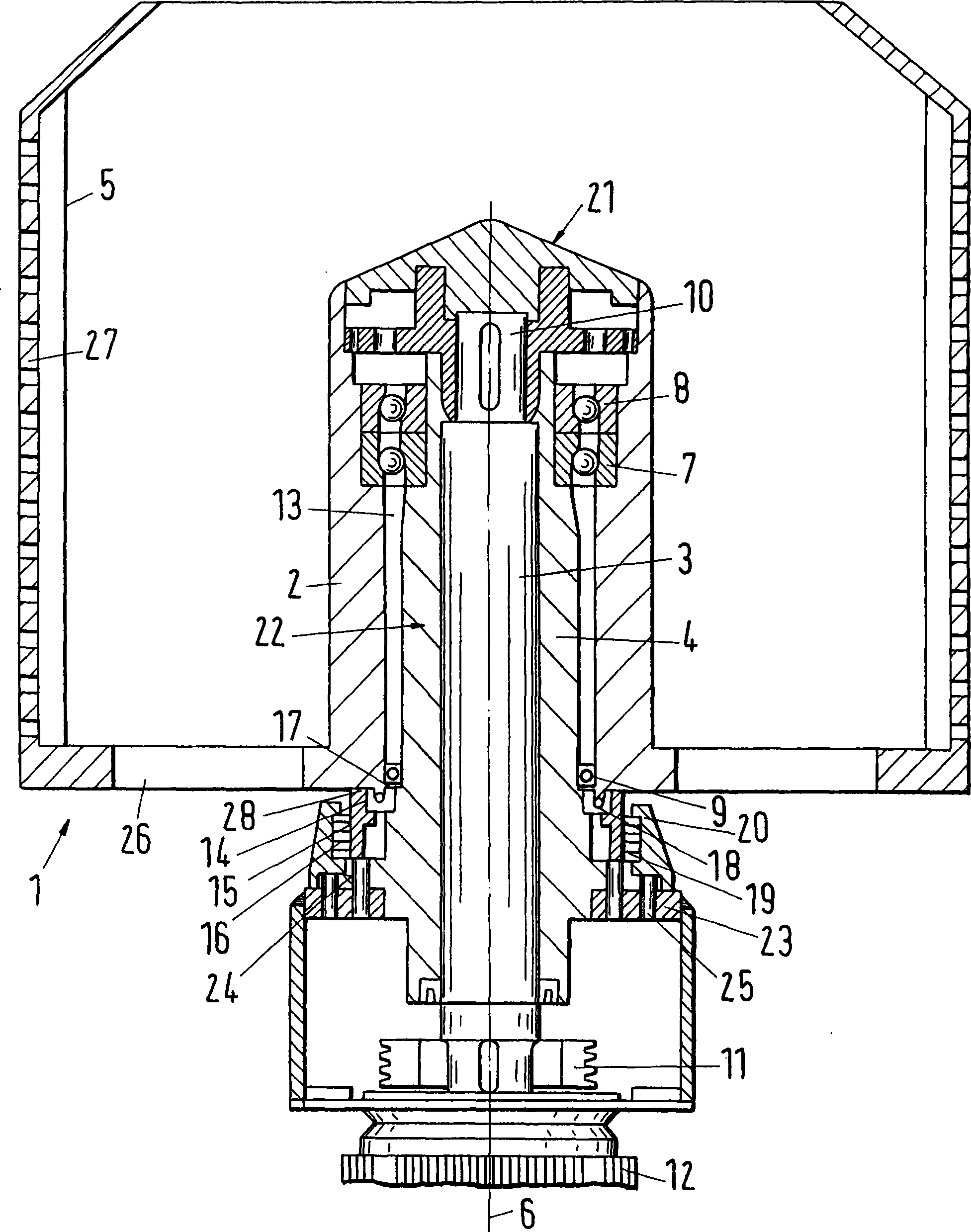

False-twisting device

InactiveCN1856602AReduce peripheral speedImprove delivery capacityTextiles and paperSpinningEngineering

Disclosed is a device for false-twisting a synthetic thread, comprising several shafts that are rotatably mounted on a bearing block. Said shafts are arranged at a respective axial distance from each other so as to form a triangle. Several friction disks are mounted on the shafts so as to be offset relative to each other. The friction disks have a diameter that is large enough for the friction disks to overlap in the center of the triangle while the circumferential surfaces thereof form a wound thread course. In order to lower the thread tension at high production speeds while obtaining a great twisting effect, the degree of overlapping of the friction disks is determined by a ratio between the disk diameter and the axial distance, which is >1.45, the friction disks having a width ranging between 9.5 mm and 11.5 mm.

Owner:SAURER GMBH & CO KG

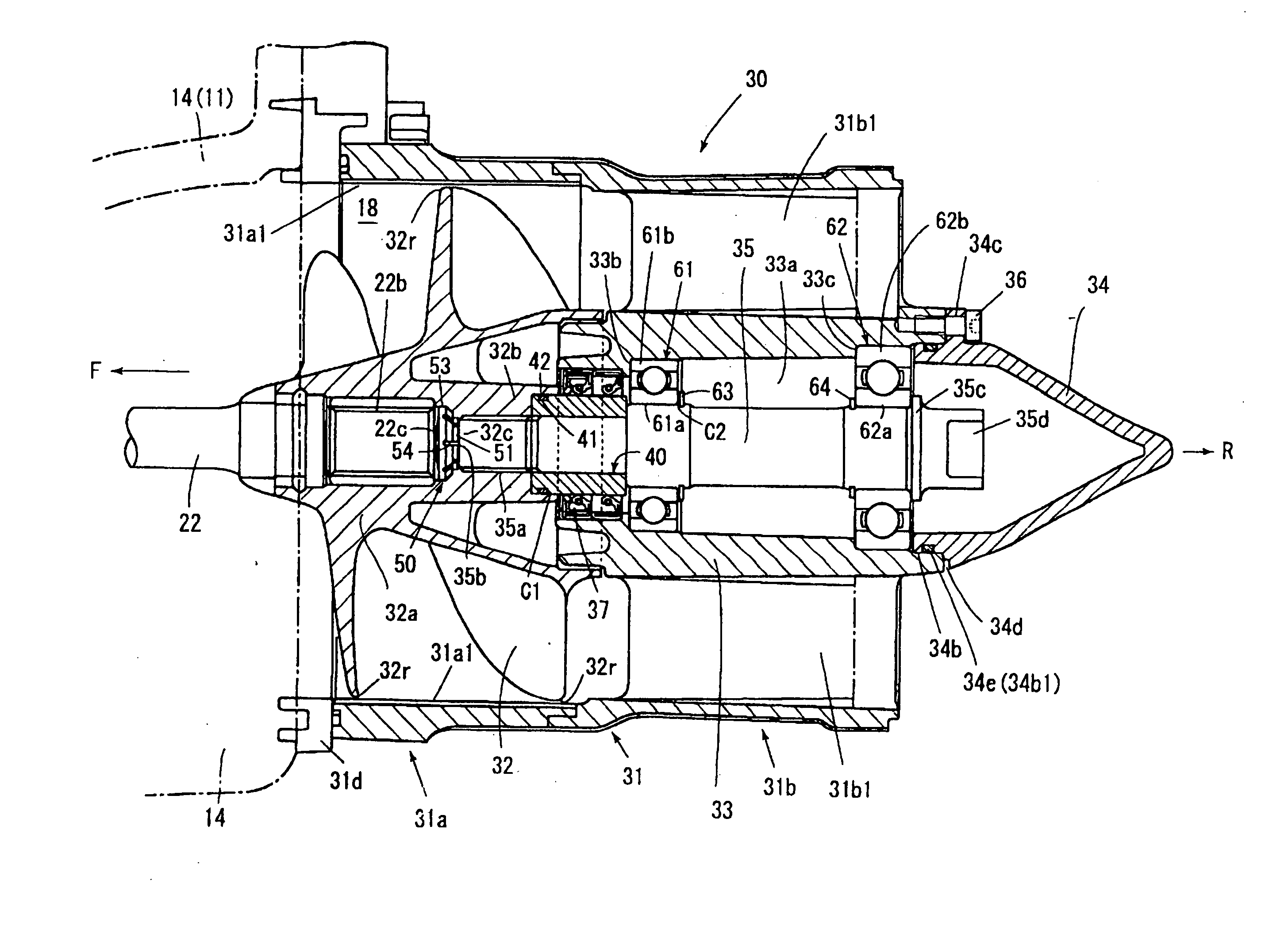

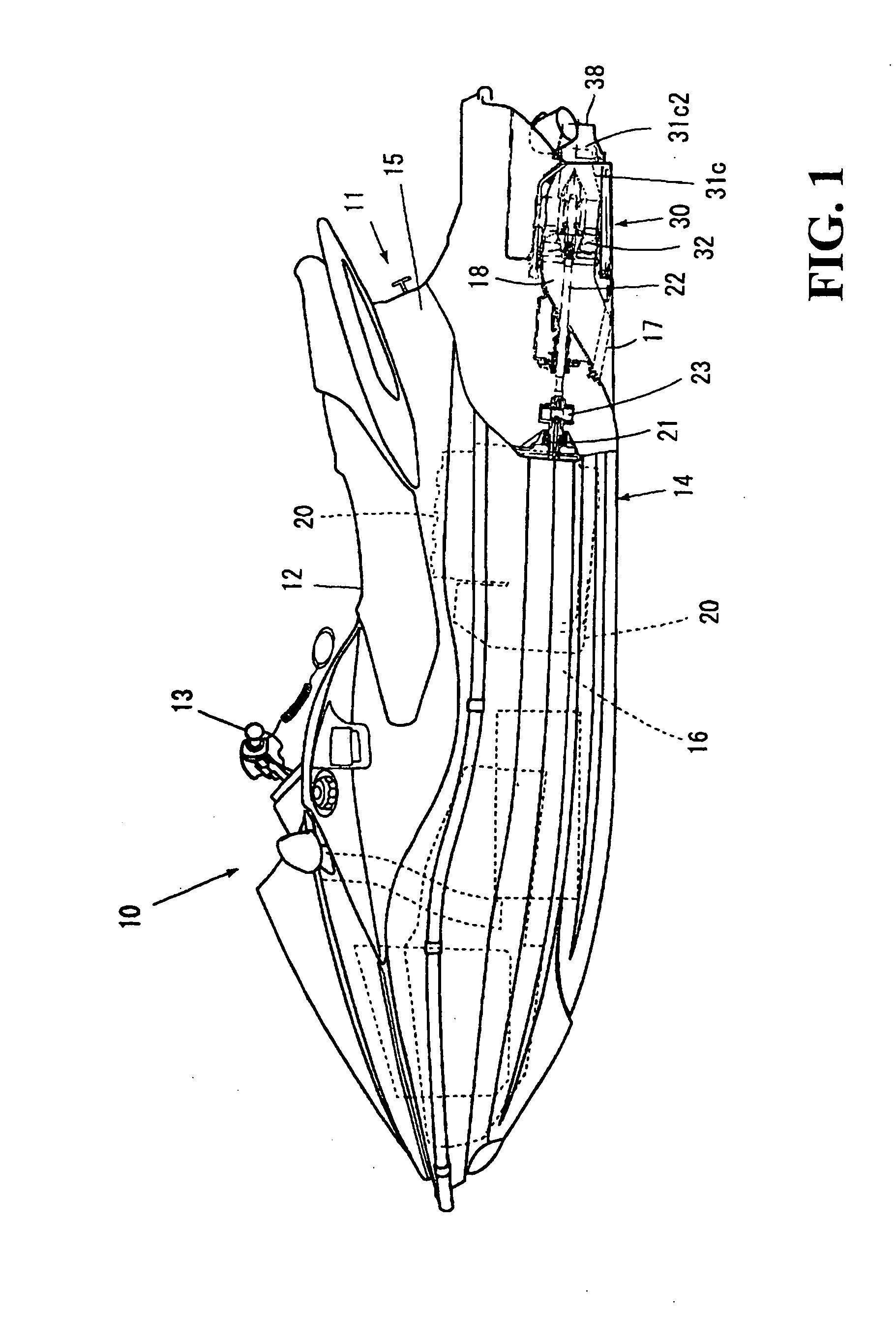

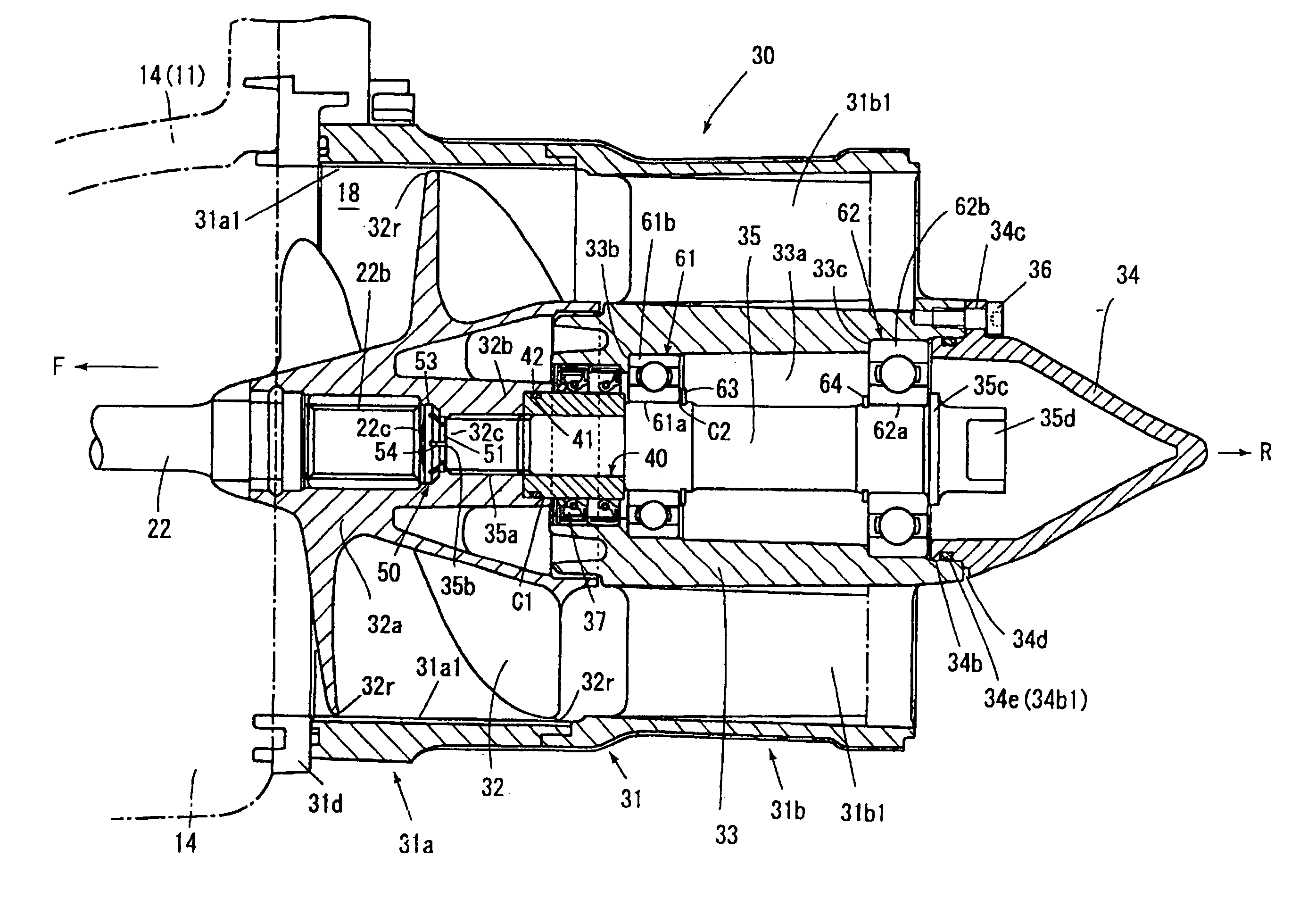

Water jet pump

InactiveUS20050048852A1Reduce cavitationImprove pumping efficiencyPump componentsPropulsive elementsImpellerCavitation

A water jet pump is provided which reduces cavitation and thereby allows an improvement in pump efficiency. In a water jet pump in which an impeller driven for rotation and is provided in a cylindrical housing, an edge portion of the outer circumferential surface of the impeller that opposes the inner surface of the housing is formed with a radius of curvature. This structure reduces a variation in the pressure of a water stream passing between the outer circumferential surface of the impeller and the inner surface of the housing toward the impeller front surface side, thereby reducing the occurrence of cavitation and improving the pump efficiency.

Owner:HONDA MOTOR CO LTD

Swing angle type radial plunger variable pump

InactiveCN1699749AAvoid noiseReduce noisePiston pumpsPositive-displacement liquid enginesNeedle roller bearingRadial piston pump

The invention discloses a swing radial piston variable-capacity pump with static and dynamic pressure balance; it solves the problem of keeping axial under the transient load mode. In the pump body installed a stator swing span and a swing span rotation shaft, the swing roller bearing on the stator swing span connects with an end of the stator mount, the other end of the stator mount connects with the stator; on the plunger connecting rod sliding boot installed a static pressure balance chamber, the holding rings are arranged on the two sides of the plunger connecting rod sliding boot which has a fit clearance with the holding rings; the rotor rotates the stator simultaneously via the plunger piston; the needle roller bearings are arranged on the two inner circles and fit with the port axle. In the invented device, the rotor and stator rotate simultaneously, the plunger connecting rod sliding boot slices on the inside surface of the stator, the linear speed is 0 or very low (0-40r / min).

Owner:顾智刚

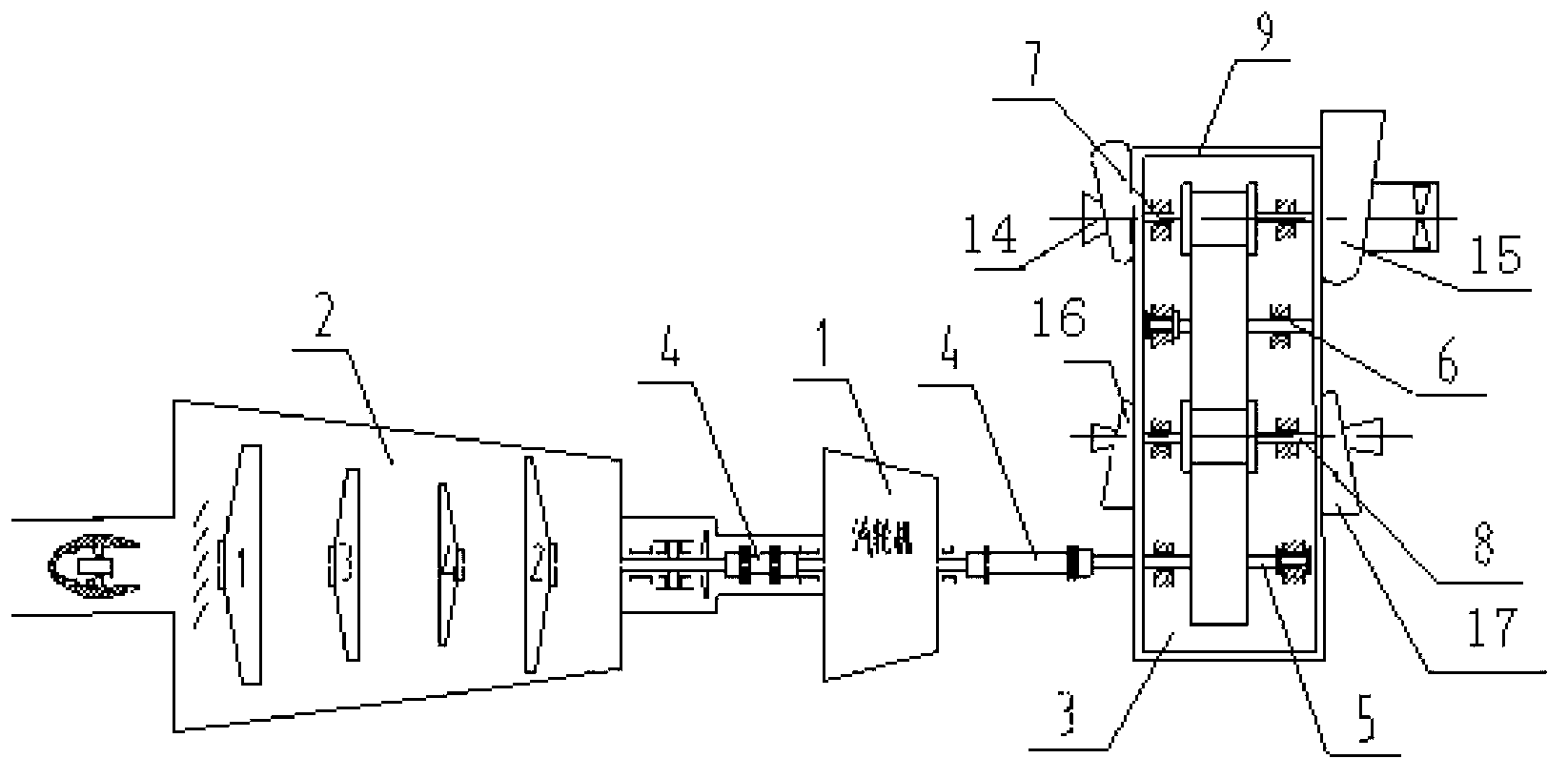

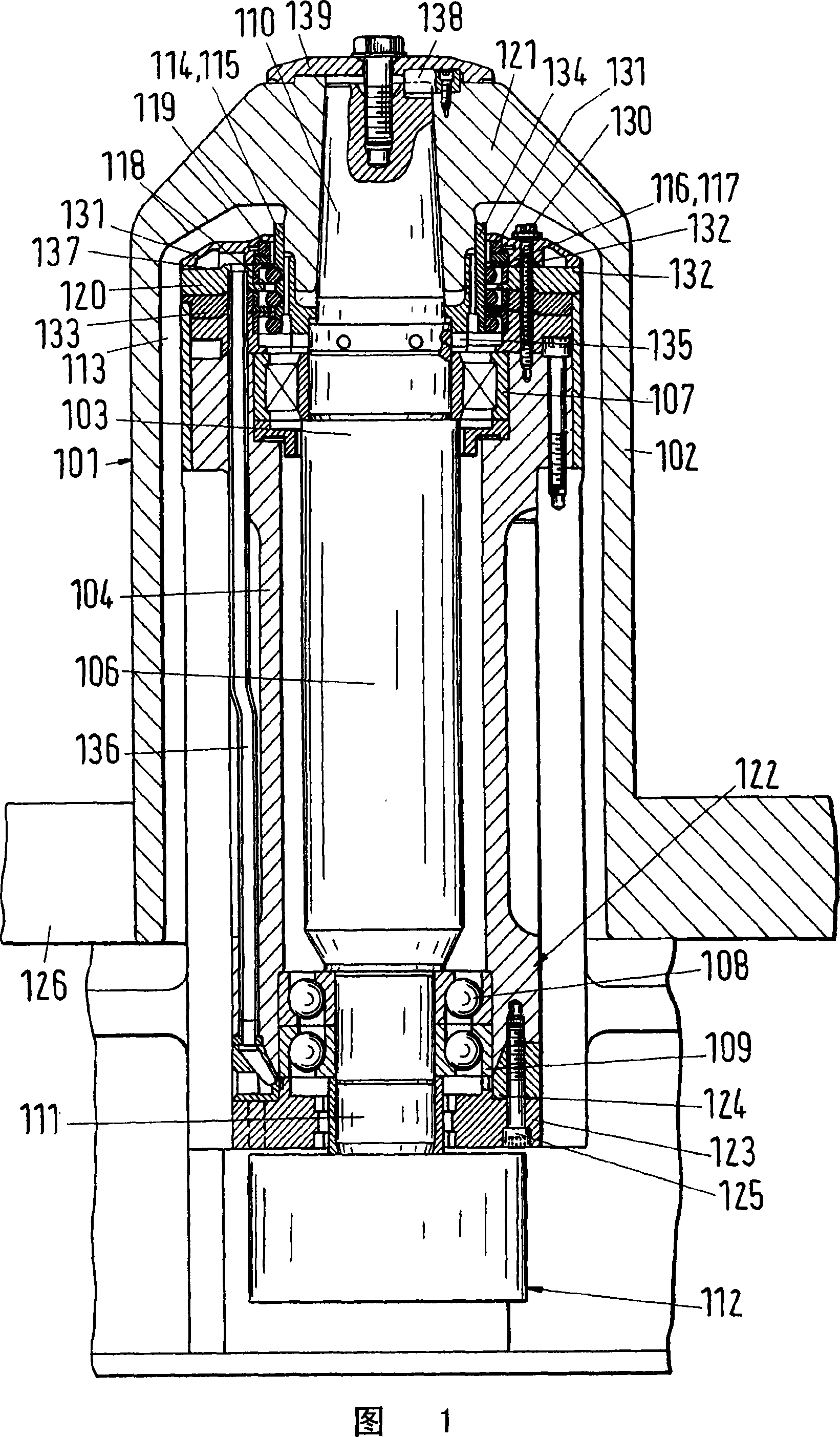

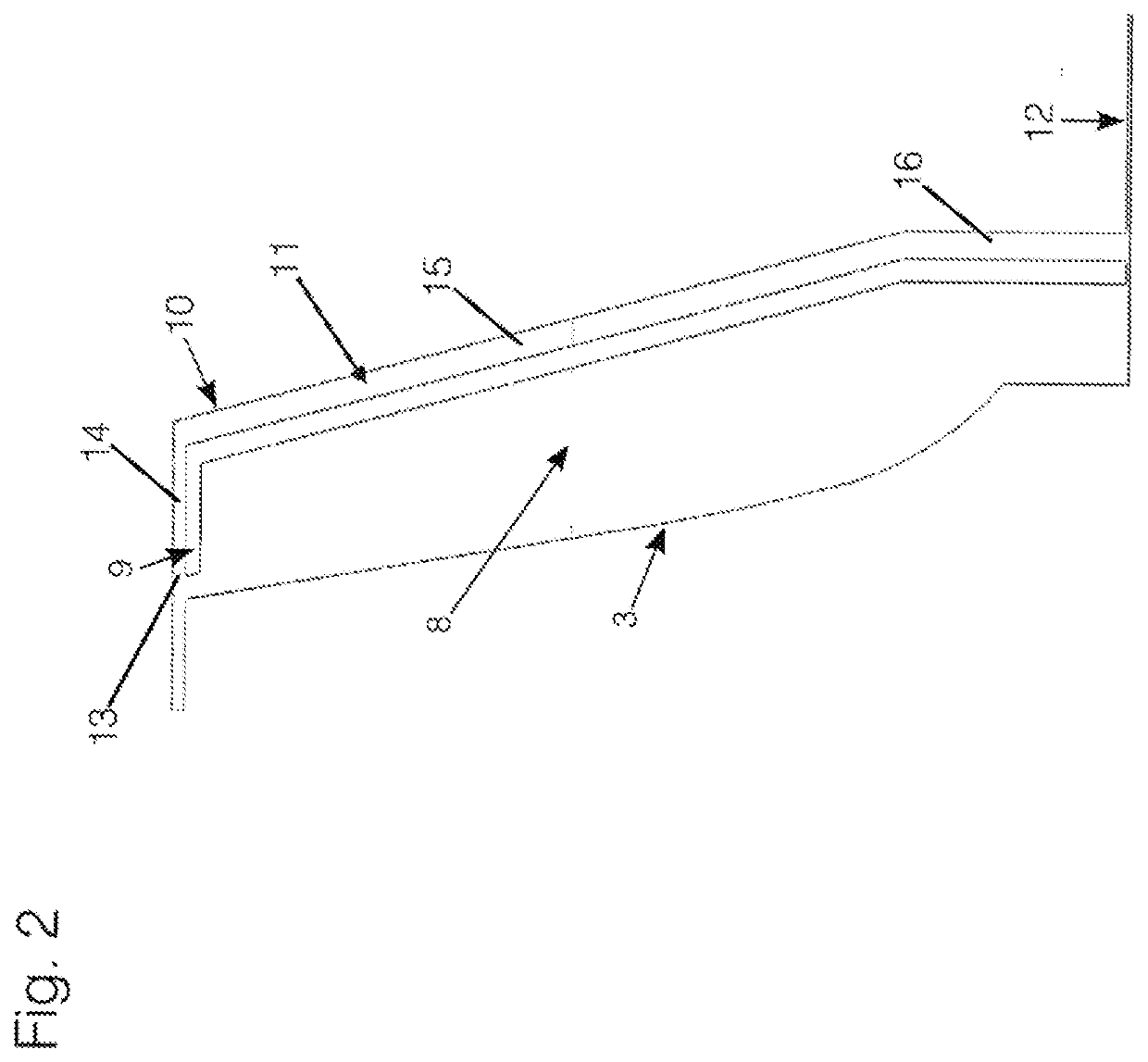

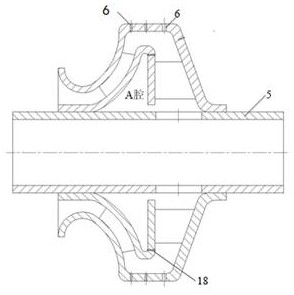

Bearing assembly for a centrifuge

InactiveCN101062489AReduce peripheral speedExtended service lifeEngine sealsCentrifugesDrive shaftEngineering

In a bearing assembly of a centrifugal revolving drum (1) around a spin axis (6), the revolving drum (1) is fixed by rotation through a drum hub (2) and a hanger bracket (21) of the revolving drum (1) and connected with a drive shaft (3). The drive shaft is connected with a drive set (12) and extends along the spin axis (6) in the bearing block (4, 7, 8, 9, 20, 24). The revolving drum (1) is supported on the bearing block (4, 7, 8, 9, 20, 24), thereby basically separating supporting force generated by power from the drive shaft (3).

Owner:FERRUM

Wheel driving apparatus

ActiveUS20110247887A1Improve workabilityHigh hardnessRimsElectric propulsion mountingEngineeringWheel drive

A wheel driving apparatus including a cylindrical inner housing (18) supported by a vehicle body via a suspension, a wheel (14) supported by the cylindrical inner housing (18) so that the wheel (14) is rotatable relative to the cylindrical inner housing (18), a motor (40) having a stator (44) attached to the cylindrical inner housing (18) and a rotor (42) attached to the wheel (14), wherein the wheel includes: a main body portion (60); and an outside portion (64) positioned on an outer side of the vehicle body, and the rotor (42) is attached to the main body portion (60).

Owner:TOYOTA JIDOSHA KK

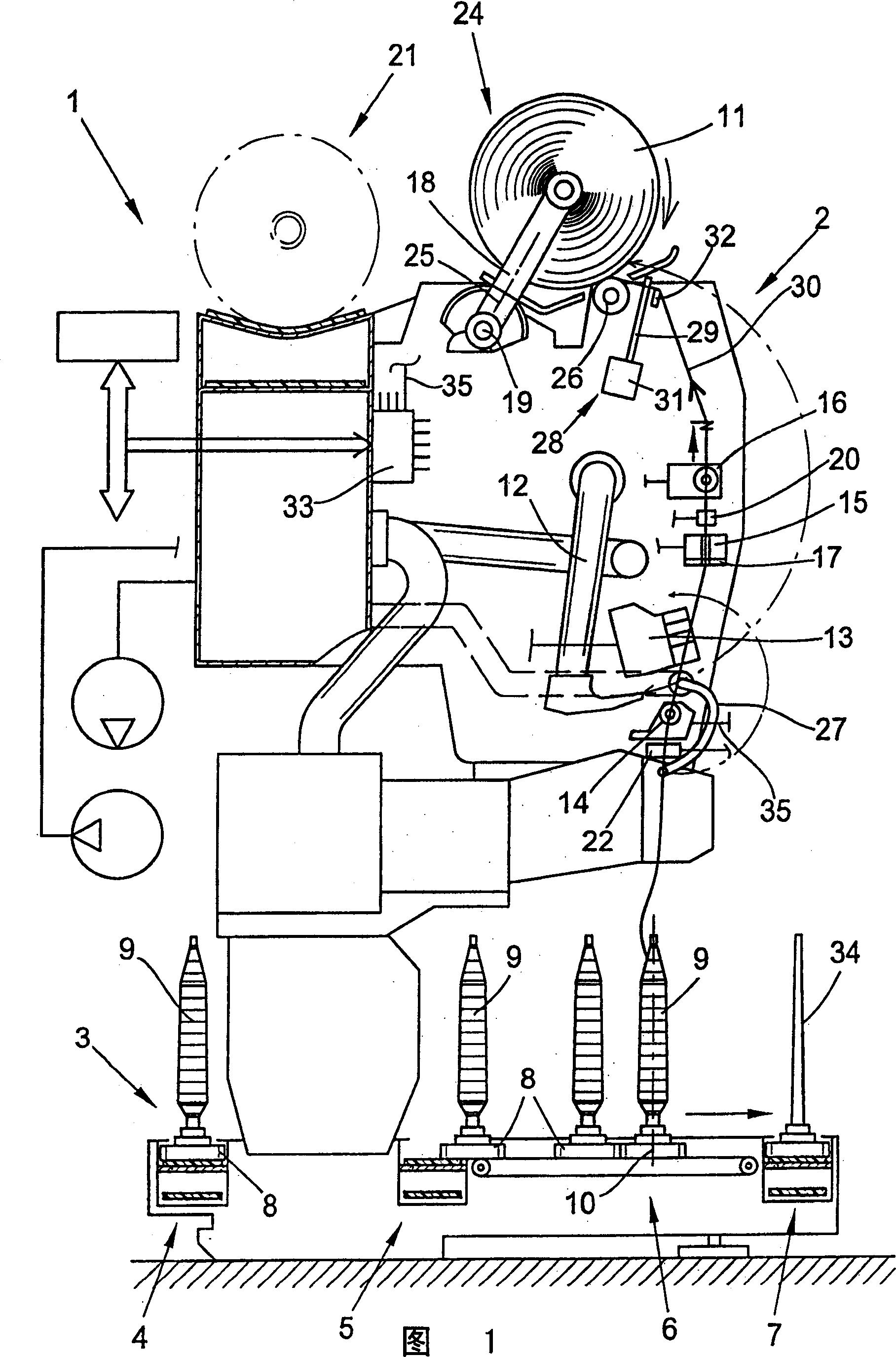

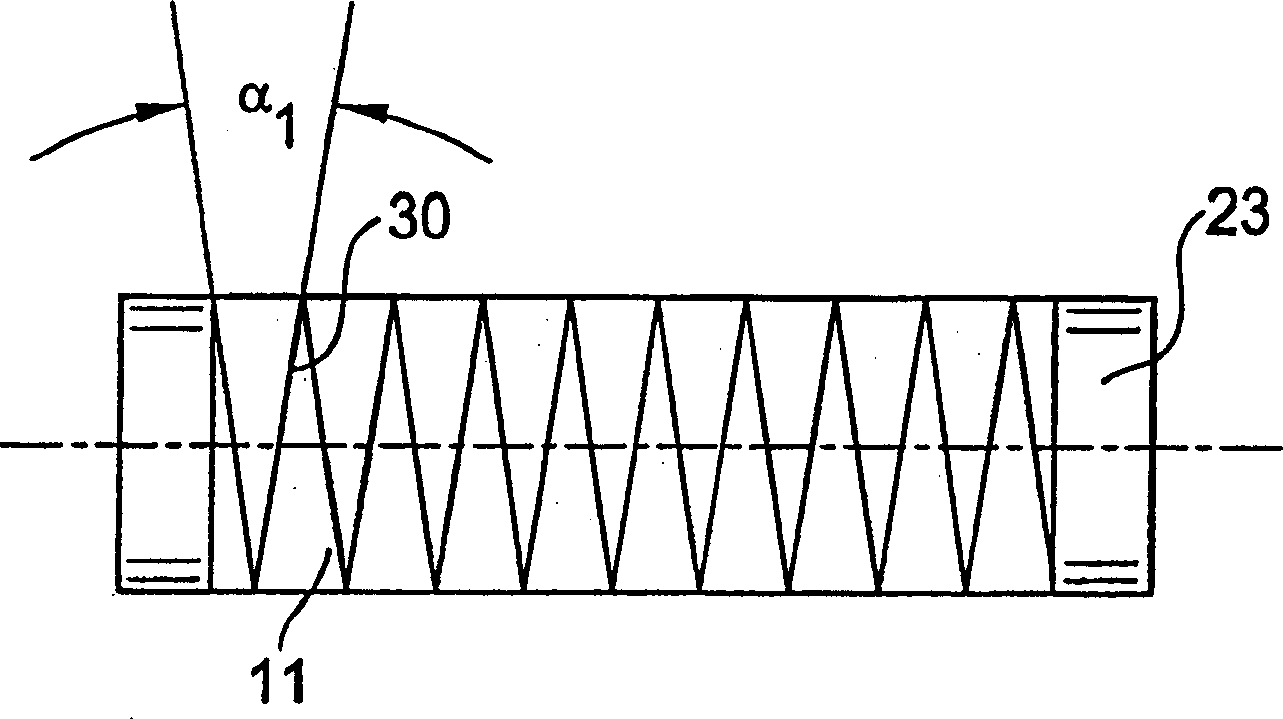

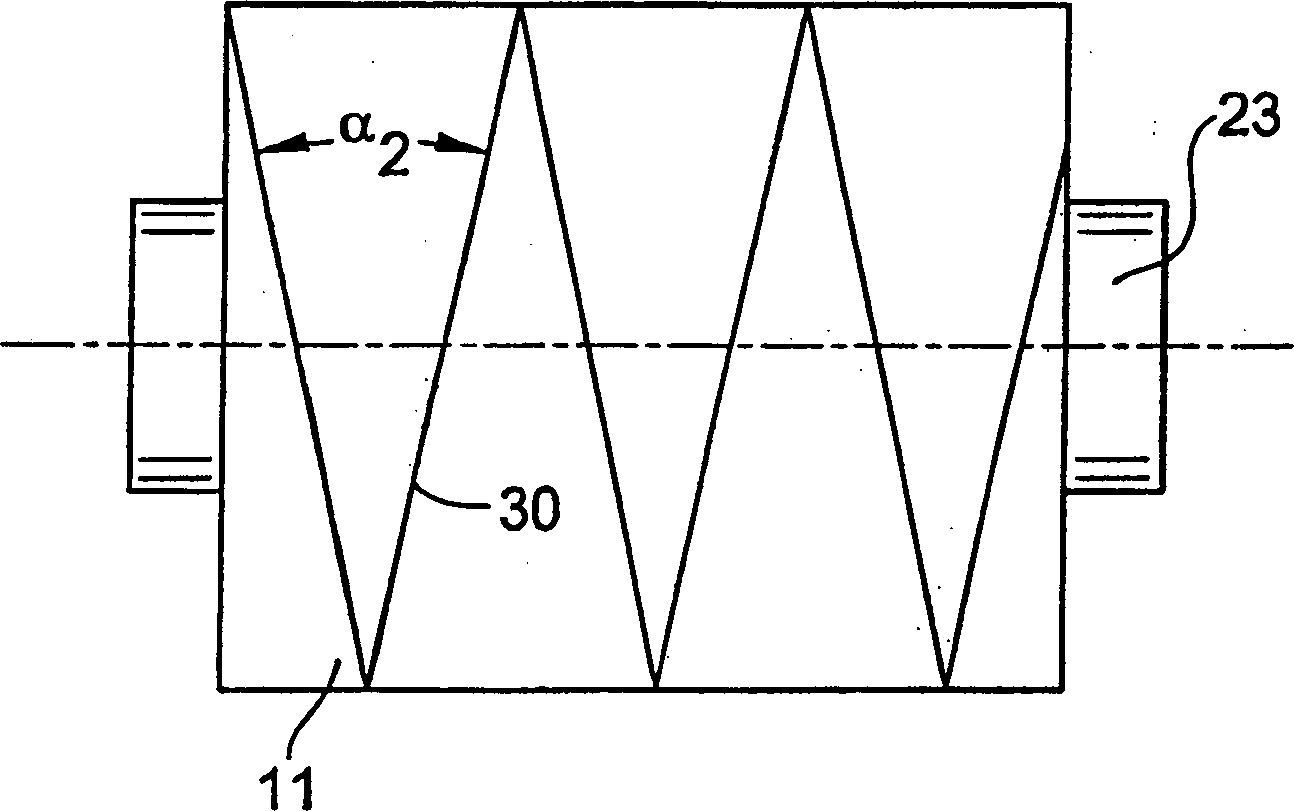

Method for manufacturing cross winding bobbin

To produce a cross wound bobbin (11), at the workstation (2) of a bobbin winder (1), the yarn (30) is wound at the start of a winding cycle at a crossing angle to increase the density of the bobbin core. The crossing angle is increased significantly during the winding cycle, so that the density of the wound bobbin is reduced progressively outwards. The increased crossing angle acts against the yarn laying width, and the stroke movement of the reciprocating yarn guide (29) has a defined increase.

Owner:SAURER GERMANY GMBH & CO KG

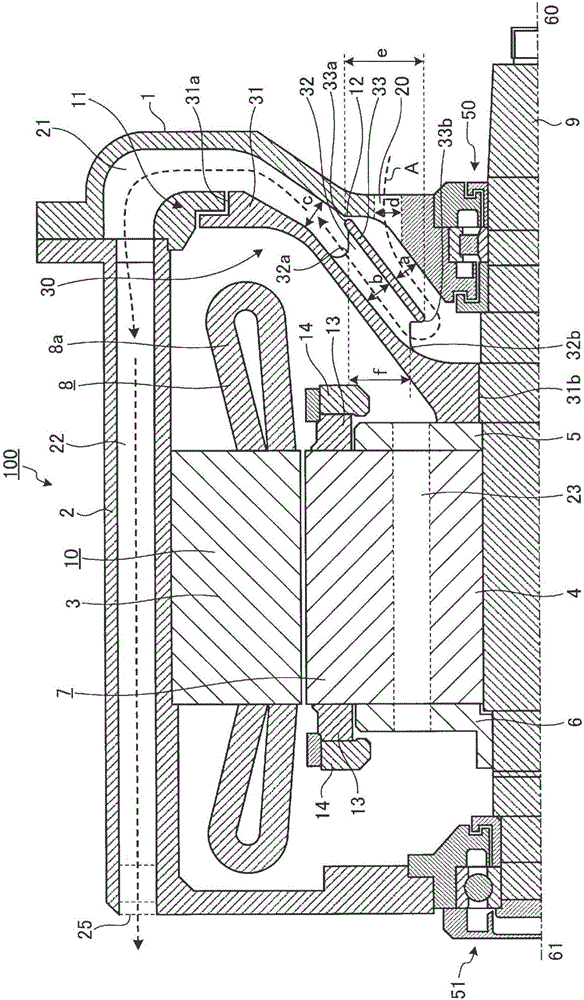

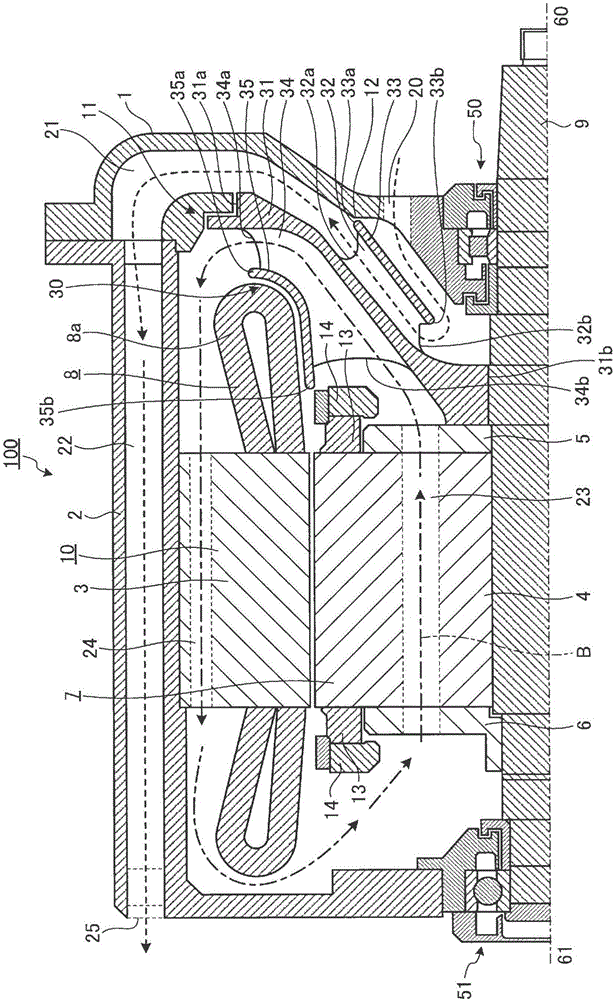

Totally enclosed main motor

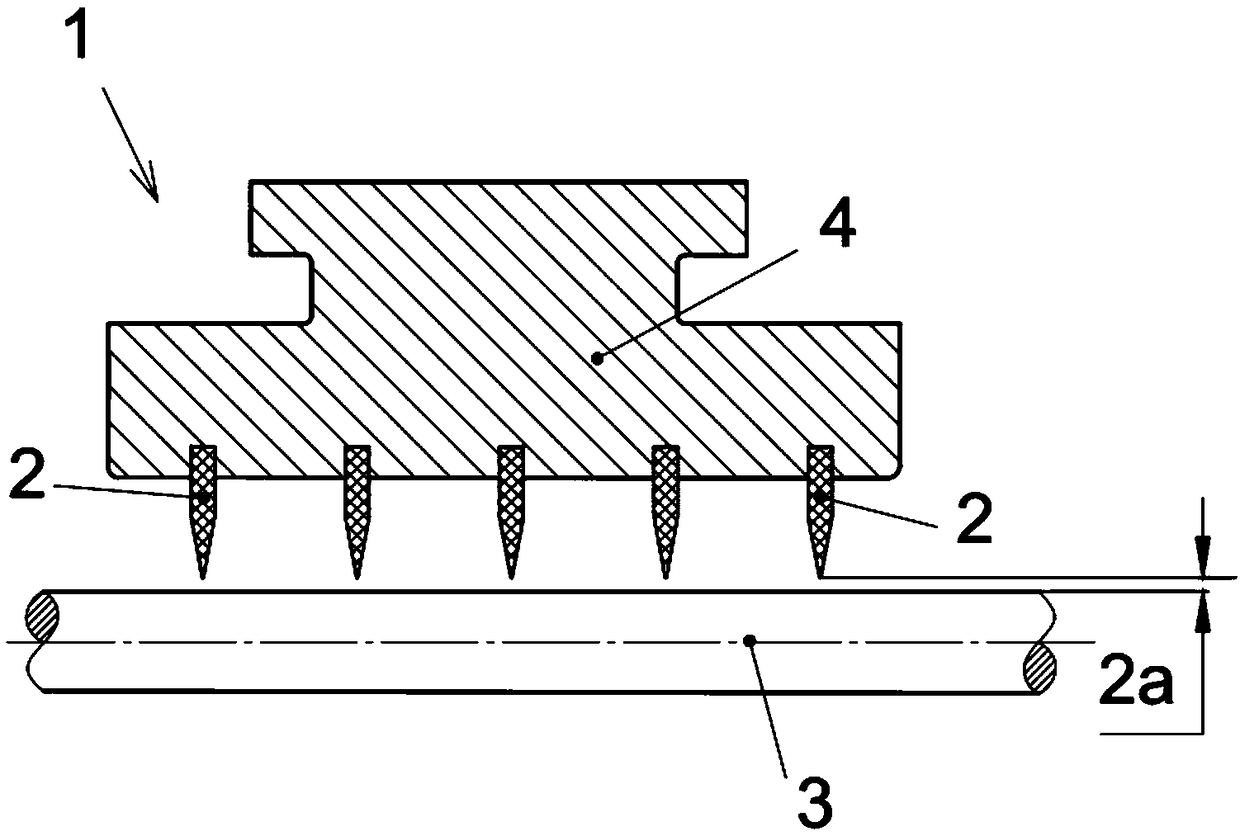

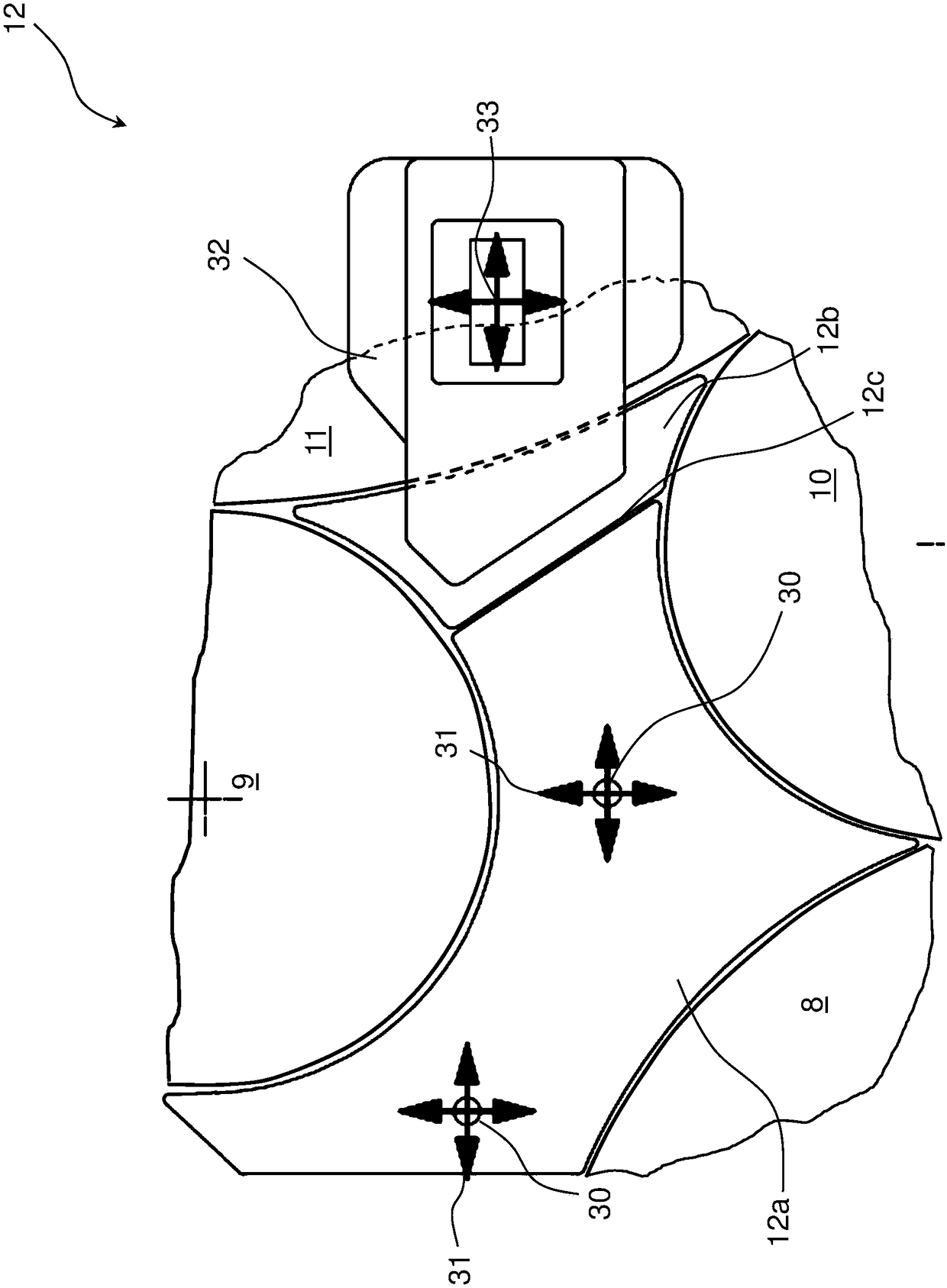

ActiveCN105981269AReduce peripheral speedEnsure cooling air volumeCooling/ventillation arrangementSupports/enclosures/casingsTraction motorStator

A main motor (100) comprises a stator (10), a rotor core (4), an iron core clamp (5), a cooling fan (30), a rotor (7), a frame (2), a bracket (1), and a bearing section (50). The cooling fan (30) comprises: a main plate (31) that partitions the inside and outside of the totally enclosed main motor (100); a plurality of blades (32) provided in the rotation direction of the rotor (7), on the bracket (1) side of the cooling fan (30); and a guide (33) provided on the bracket (1) side of the blades (32). An air intake port (20) is provided in the bracket (1), inside an area formed by projecting the guide (33) on to the bracket (1). The guide (33) is formed such that the air taken in from the air intake port (20) is guided to a rotor shaft (9).

Owner:MITSUBISHI ELECTRIC CORP

Mechanical seal

Owner:EAGLE INDS

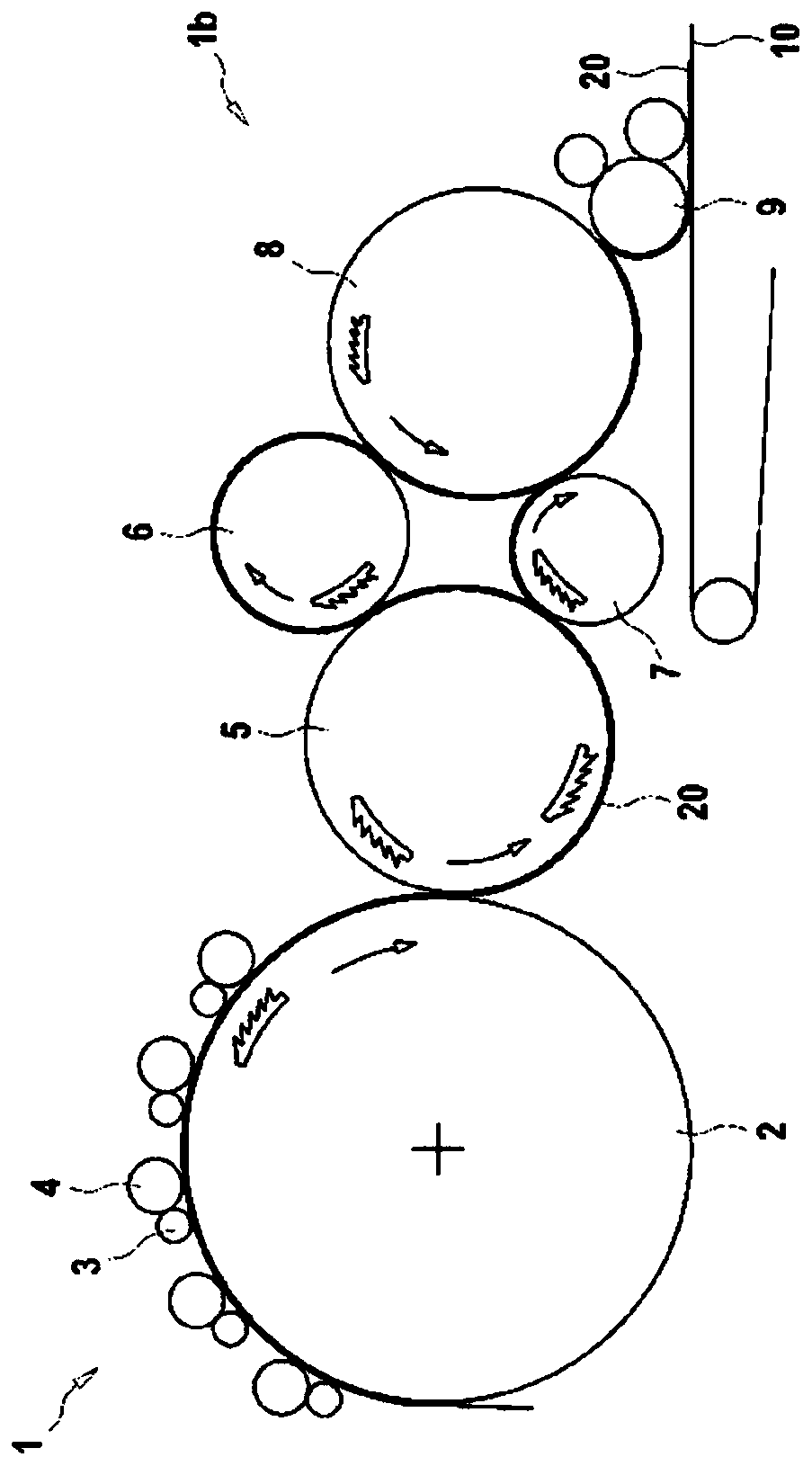

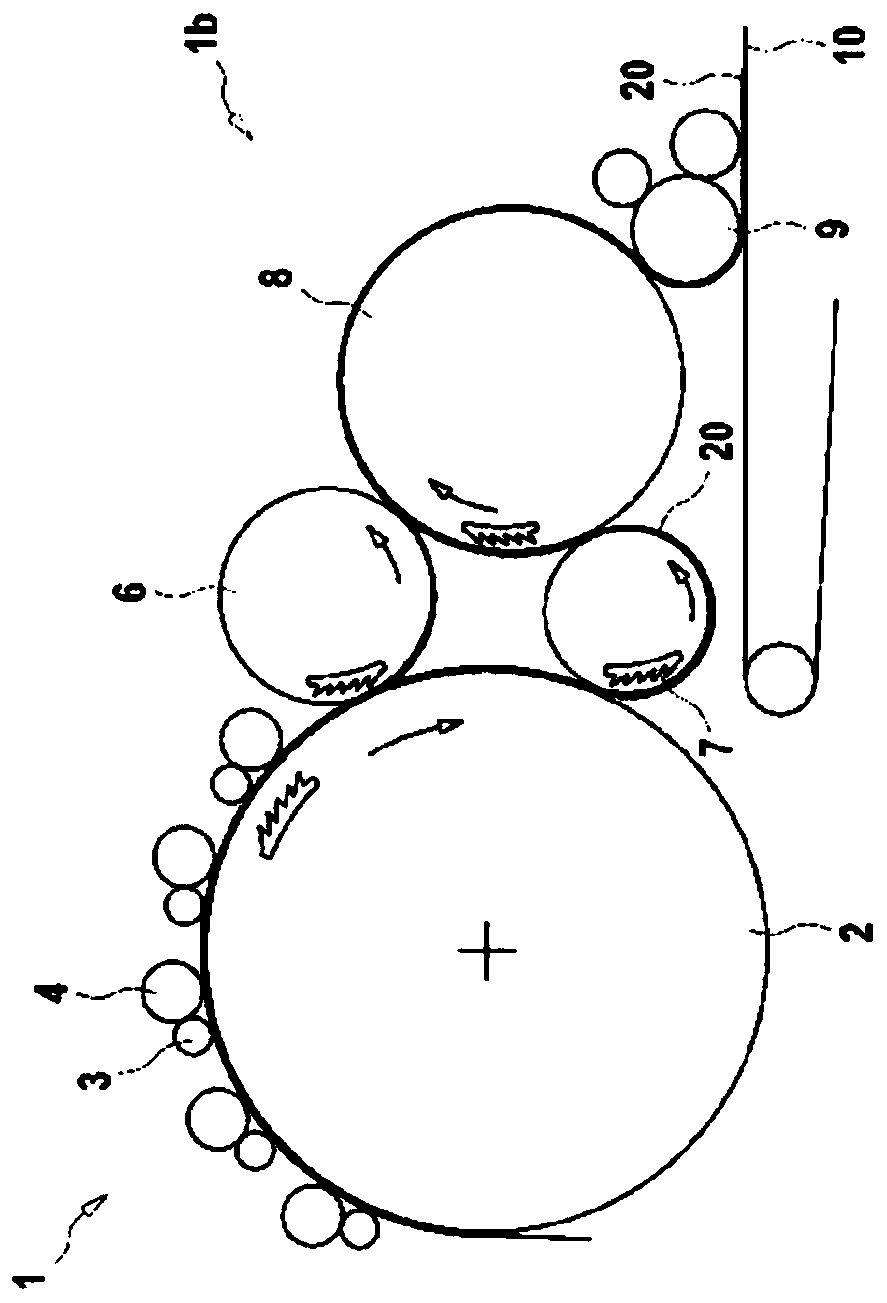

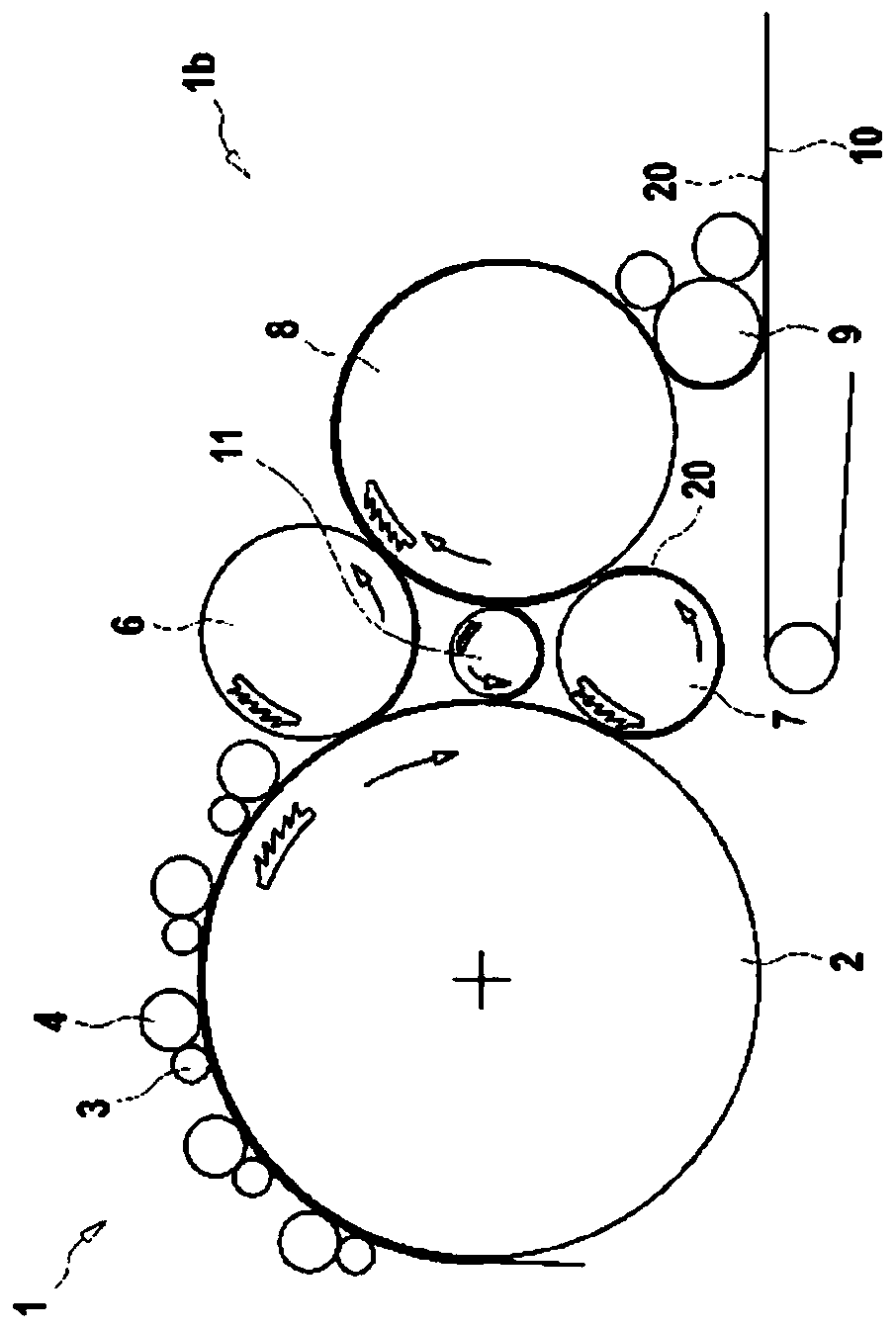

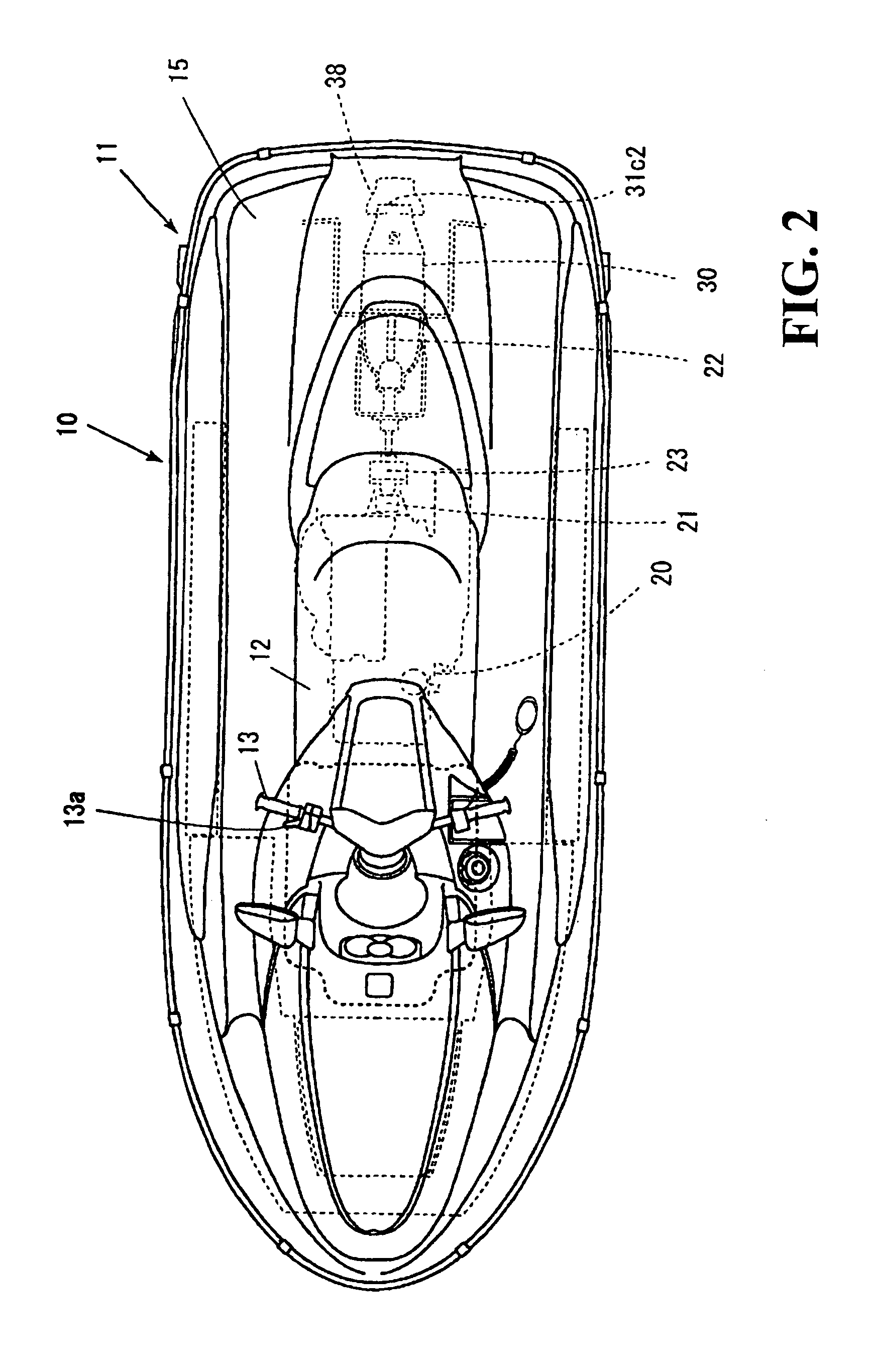

Carding machine

PendingCN110662859AIncrease the length of the structureShort structure lengthCarding machinesFiberEngineering

The invention relates to a carding machine for producing fleece from fiber material, comprising at least one tambour (2), having at least two doffing rollers arranged one after the other in the working direction and having a compressing roller (8), which is operatively connected to all doffing rollers downstream of the tambour (2), wherein the carding machine (1) is designed to transfer at least two layers of card web (20) by means of at least two doffing rollers to a compressing roller (8), wherein each of the at least two layers of card web are compressed separately by means of the compressing roller (8) and are joined on the compressing roller (8) into a single layer of card web (20) and said layer of card web (20) is removed, by means of a transfer roller (9), on an outlet side of thecarding machine for further processing. The invention is characterized in that the compressing roller (8) has a diameter of at least 600 mm.

Owner:TRUETZSCHLER GRP SE

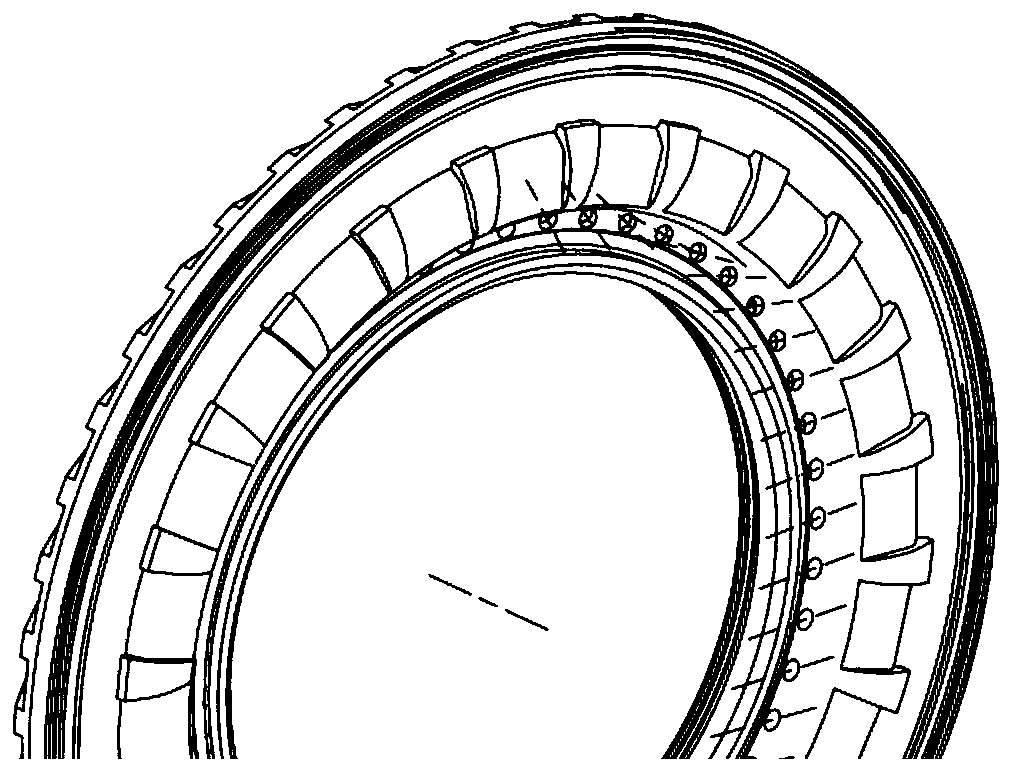

Labyrinth seal structure with brush type seal strips

ActiveCN108757055AReduce hysteresisMaintain circumferential resistancePump componentsLeakage preventionImpellerEngineering

The invention discloses a labyrinth seal structure with brush type seal strips. The labyrinth seal structure comprises a labyrinth seal and the brush type seal strips. The labyrinth seal is used for being mounted in the circumferential direction of a rotor in a sleeving manner, and a clearance is left between the labyrinth seal and a rotor. The labyrinth seal comprises a seal body and labyrinth teeth arranged on the inner side of the seal body. The brush type seal strips are assembled in an axial through groove in the axial direction, wherein the axial through groove is formed in the inner side of the labyrinth seal, the brush type seal strips penetrate the seal body in the axial direction, and the at least four brush type seal strips are arranged in the circumferential direction of the labyrinth seal. According to the labyrinth seal structure, according to a turbo machine rotor system, the labyrinth seal structure with the brush type seal strips is provided for the requirements for reducing forward rotational flow of a seal chamber, improving the seal rotor power characteristic, improving rotor stability and reducing the seal leakage amount; the forward rotational flow of the sealchamber can be effectively reduced, effective damping of a traditional labyrinth seal can be increased, and the seal leakage mount can be reduced; and therefore the problem of rotor vibration unstability is solved, and the stability and sealing performance of the rotor system are improved.

Owner:XI AN JIAOTONG UNIV

Power transmission device

InactiveUS7278938B2Simple structureSmall sizeYielding couplingMechanical actuated clutchesClutchRotational axis

A power transmission device includes a first one-way clutch that transmits a rotational power of a pulley to a rotating shaft, and a second one-way clutch that transmits a rotational power of a rotor of a motor to the rotating shaft. The first one-way clutch is of inner cam type in which an engagement cam-surface is formed in an outer periphery of a first inner ring, while the second one-way clutch is of outer cam type in which an engagement cam-surface is formed in an inner periphery of a second outer ring. This arrangement improves engagement performance of the first one-way clutch as well as reducing heat generation of the second one-way clutch, so that the lifetime of grease is prolonged.

Owner:JTEKT CORP +1

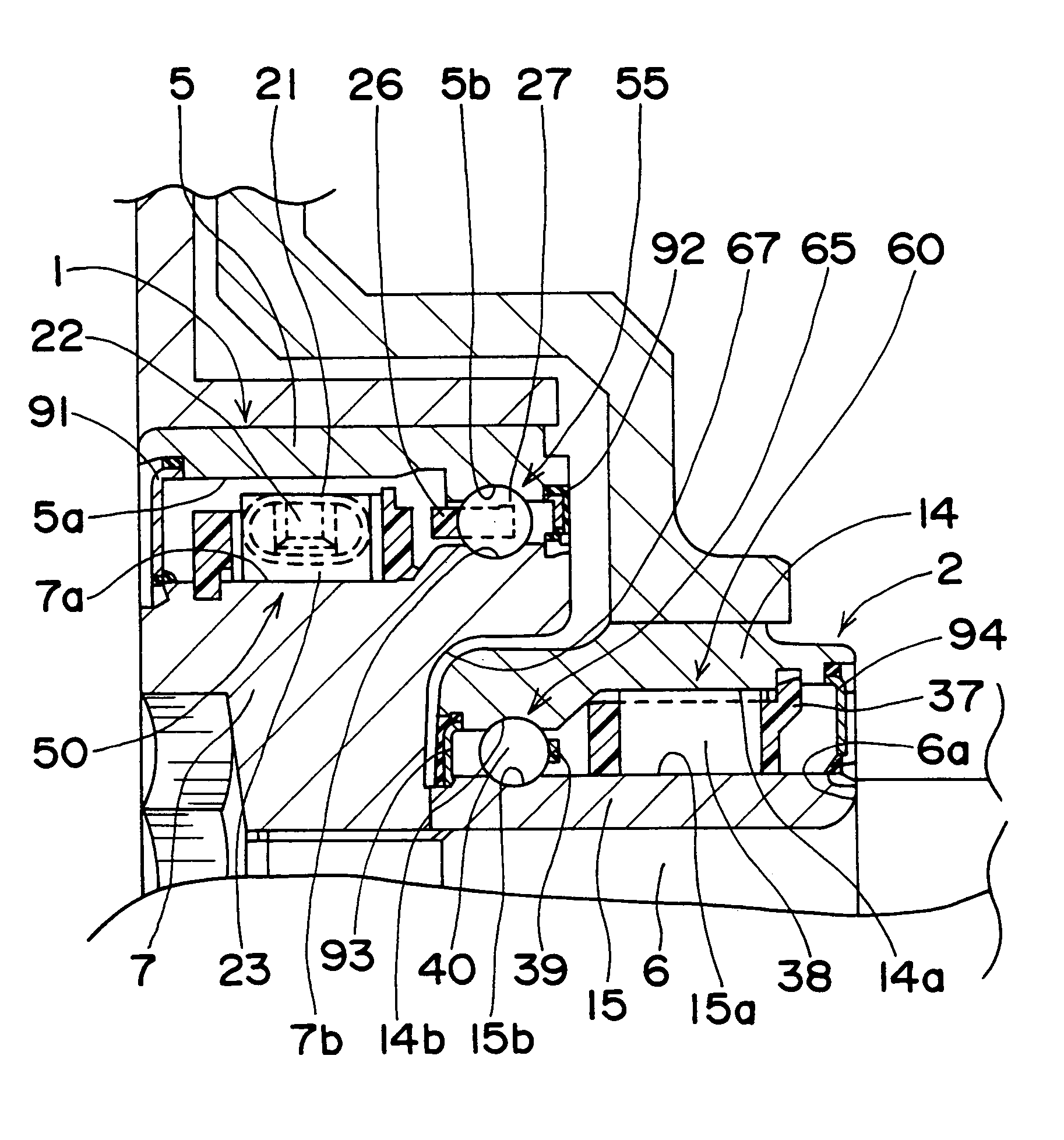

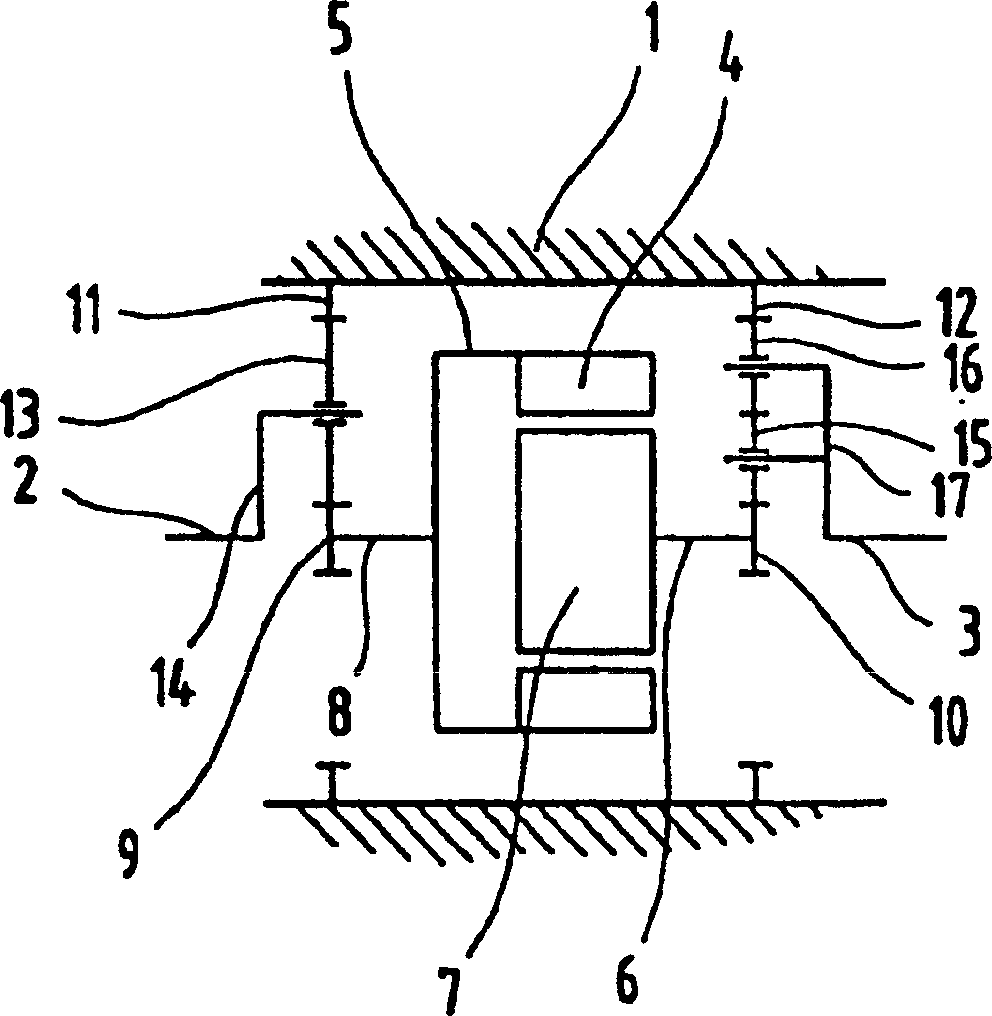

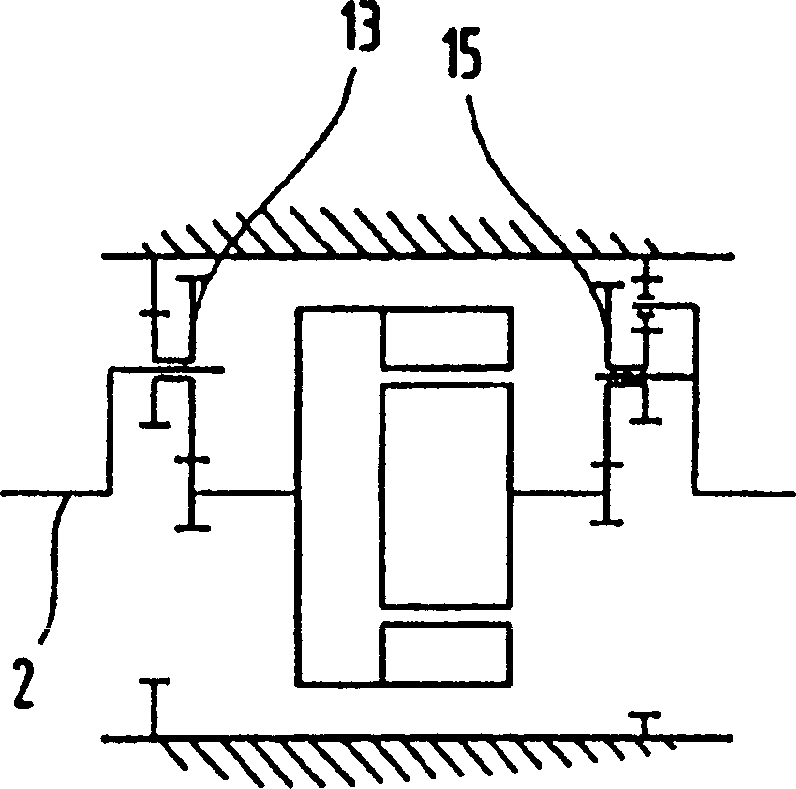

Electric transmission device for means of transportation

InactiveCN1272894CCompact structureReduce peripheral speedSpeed controllerElectric propulsion mountingVehicle frameGear wheel

The invention relates to an electric drive for a vehicle. A housing (1) that is stationary in relation to the vehicle frame is provided. A motor housing (5) having a stator (4) and a rotor (7) being provided in said motor housing (5) are rotationally mounted in said housing. The motor housing and the rotor perform opposite rotational movements. A drive train (2) is connected to the motor housing and the rotational movement of the motor housing is carried out by means of a transmission device with the same drive and output direction of rotation. The remaining drive train is connected to the rotor and the rotational movement of the rotor is carried out by means of a transmission device with opposite drive and output direction of rotation. The transmission devices are planetary gears. The rotor engages with the planet wheels (13 or 16) of the allocated planetary gear by means of a spur pinion (10) that is arranged on the shaft or the motor housing engages with the planet wheels of the allocated planetary gear by means of a spur pinion that is connected to the motor housing and is arranged on the axis of the motor housing. A web (14 or 17) is provided. Said web is connected to the axles of the planet wheels of each planetary gear and drives the wheel shaft assigned thereto.

Owner:奥斯卡・瓦绍尔

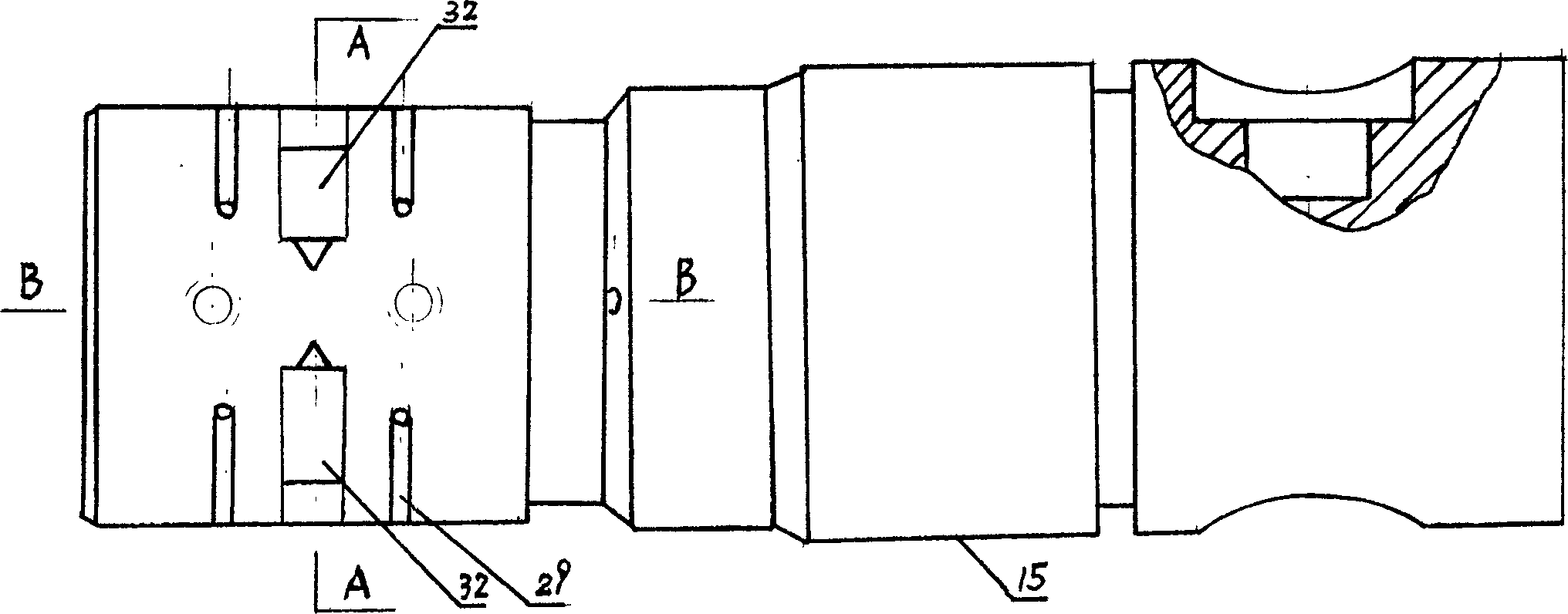

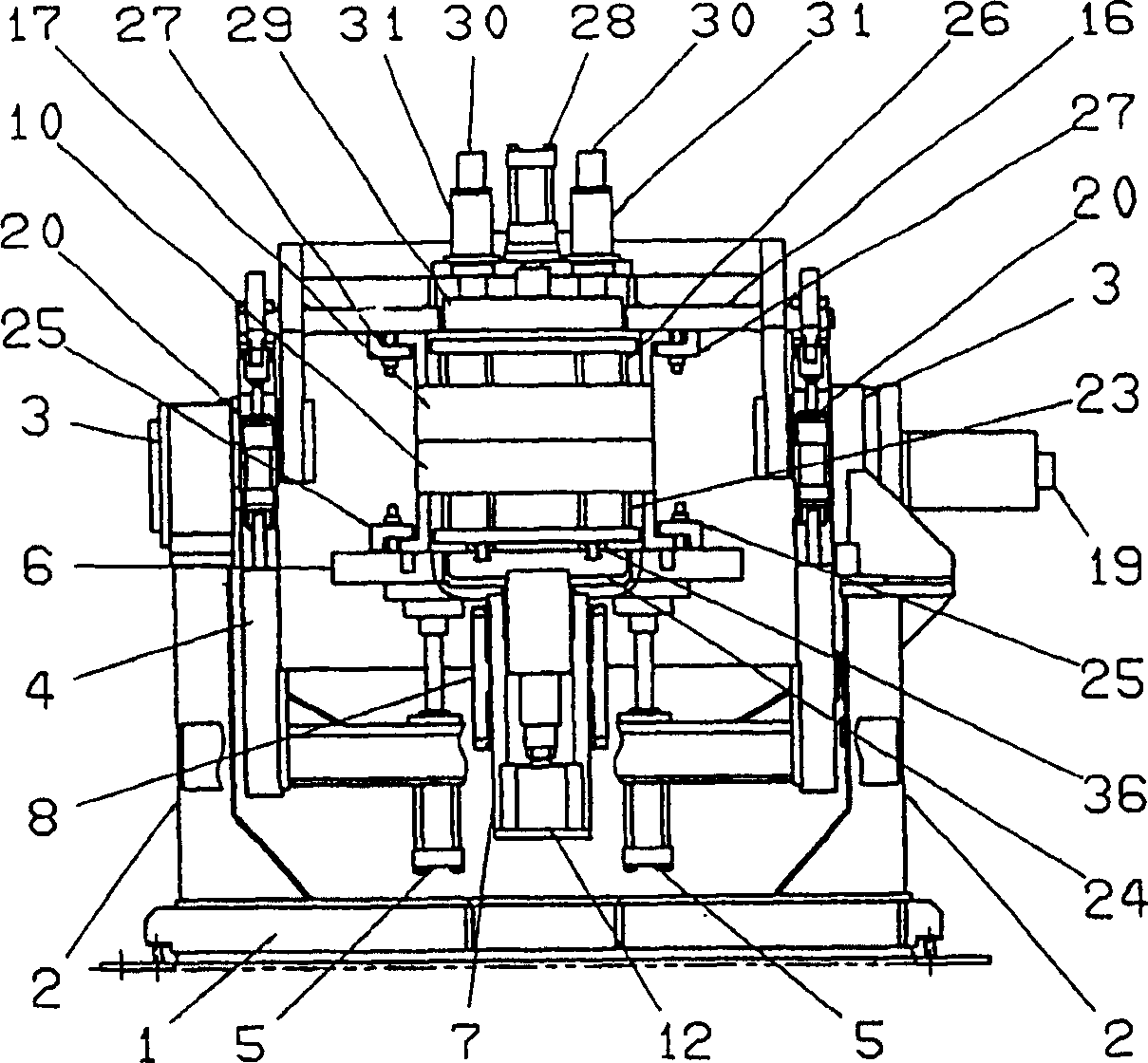

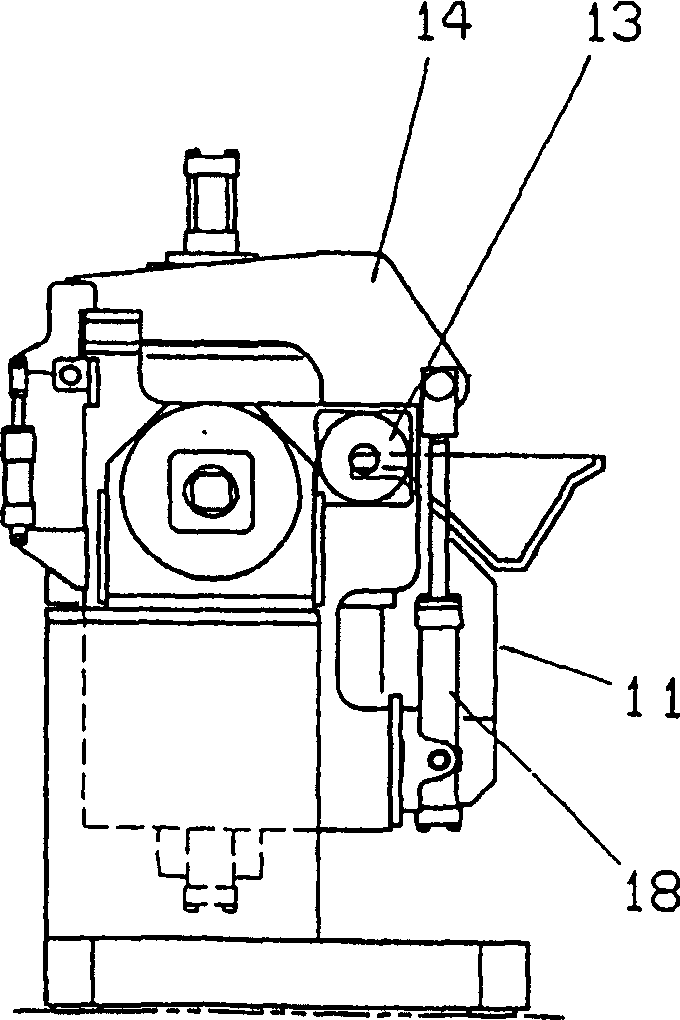

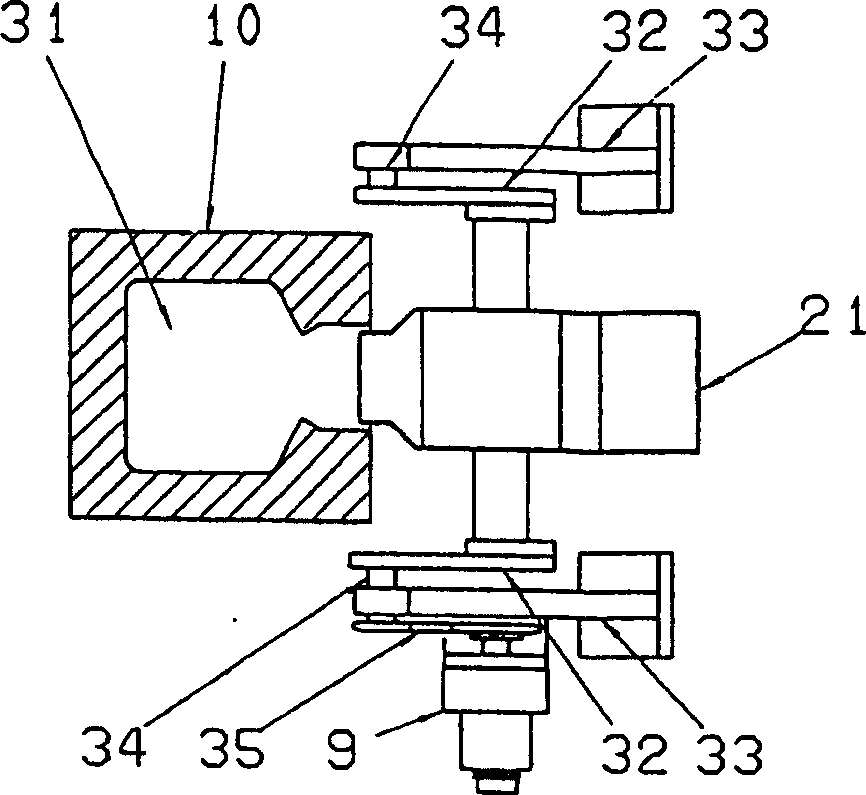

Gravity type titable metal mold casting machine

A gravity type tiltable metal mold casting machine, comprising: a pair of opposing upright supporting frames (2, 2); a pair of opposing main rotating shafts (3, 3) rotatably mounted on the upright supporting frames (2, 2); a main frame (4) suspended from and between the main rotating shafts (3, 3); an electric motor (19) attached to one of the main rotating shafts (3, 3) for reversibly rotating it and hence the frame (4); a drag die plate (6) vertically moved by mold-fastening cylinders (5, 5) mounted on a lower part of the main frame (4); a metal drag (10) secured to the drag die plate (6), the metal drag having a drag pushing-out mechanism (23) for pushing an as-cast product out of the metal drag; a pair of opposing horizontal cope tilting shafts (13, 13) secured to an upper end of the main frame at locations rearward of the main rotating shafts (3, 3); a cope-attaching frame (14) rotatably mounted at one end on the cope tilting shafts (13, 13); a cope die plate (16) secured to a lower surface of the cope-attaching frame (14); a metal cope (17) secured to the cope die plate (16), the metal cope having a cope pushing-out mechanism (26) for pushing an as-cast product out of the metal cope, a ladle (21) rotatably mounted about a horizontal axis of rotation, the horizontal axis of rotation being located rearward of the assembly of the metal cope and drag; and an electric motor (9) for reversibly rotating the ladle (21) about the horizontal axis of rotation, wherein the center of the assembly of the metal cope and drag is substantially on the axis of rotation of the main rotating shafts.

Owner:SINTOKOGIO LTD

Water jet pump

InactiveUS7001228B2Reduce cavitationImprove pumping efficiencyPump componentsPropulsive elementsImpellerCavitation

A water jet pump is provided which reduces cavitation and thereby allows an improvement in pump efficiency. In a water jet pump in which an impeller driven for rotation and is provided in a cylindrical housing, an edge portion of the outer circumferential surface of the impeller that opposes the inner surface of the housing is formed with a radius of curvature. This structure reduces a variation in the pressure of a water stream passing between the outer circumferential surface of the impeller and the inner surface of the housing toward the impeller front surface side, thereby reducing the occurrence of cavitation and improving the pump efficiency.

Owner:HONDA MOTOR CO LTD

Carding machine

PendingCN108691036AReduce centrifugal forceReduce flying catkinsCarding machinesSingle fiberMechanical engineering

The invention relates to a carding machine provided with an inlet side (1a) for fiber plush, the fiber plush is conveyed to a pre-carding machine drum (4) and loosened until becoming a single fiber and being oriented, a first layer of fiber web is conveyed to a conveying roller (9) through an upper doffer (7) and then conveyed to a cylinder (11), a second layer of fiber web is conveyed to a conveying roller (10) through a lower doffer (8) and then conveyed to the cylinder (11), and at least one layer of fiber web is taken down from an outlet side (1b) of the carding machine through at least adoffer (14) to realize further processing. The carding machine is characterized in that the conveying rollers (9, 10) comprise the same diameters. Besides, the invention comprises a grid used in the carding machine.

Owner:TRUETZSCHLER GRP SE

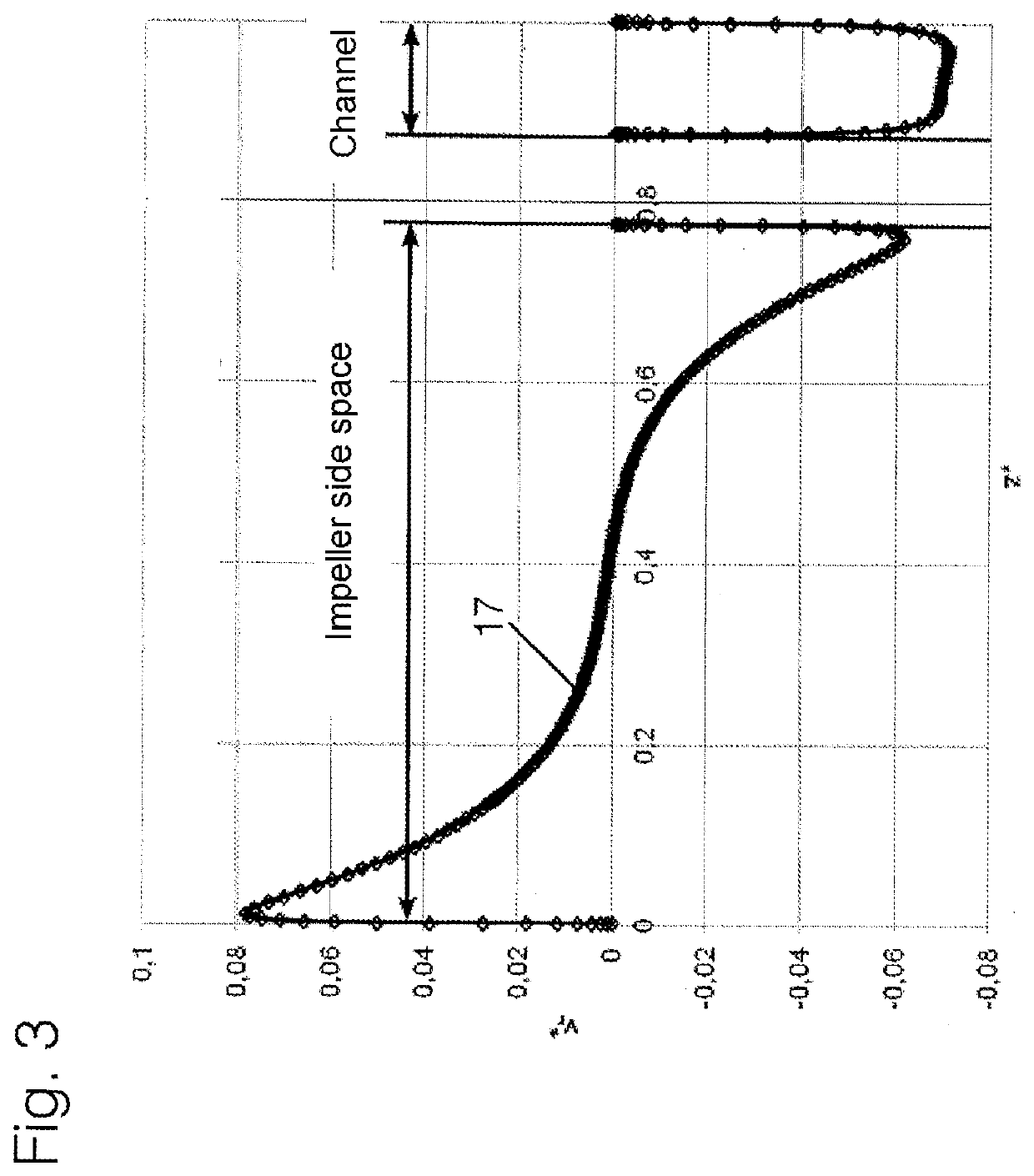

Centrifugal Pump Having a Radial Impeller

ActiveUS20190390686A1Increase dampingIncrease efficiencyPump componentsPumpsCentrifugal pumpAngular momentum

Owner:KSB AG

Matched improved structure for impeller and guide vane body bodies of axial flow pump

InactiveCN102966590AIncrease load pressureSolve the problem of not generating trafficPump componentsPumpsImpellerEngineering

The invention provides a matched improved structure for an impeller and a guide vane body bodies of an axial flow pump. The matched improved structure comprises a casing, an the impeller and two guide vane bodies, wherein the impeller comprises a hub and a plurality of vanes which are equidistantly distributed on the periphery of the hub; each vane is provided with an upper end surface, a lower end surface, a pressure surface, a rear end surface and a front end surface; and the axial displacement between any point on the each front end surface and the hub is equal to the axial distance between another point on the each front end surface and the hub. When the axial displacement between the each front end surface and the axis of the hub is R, an intersection line between the each pressure surface and the corresponding front end surface is a first intersection line; an intersection line between the each front end surface and the corresponding upper end surface is a second intersecting line; and an included angles between each points on the each first intersecting line and the each second intersecting line is are the same. According to the structure for improving the impeller and the guide vane bodies thereof, which is disclosed by the invention, the circumferential velocity component of fluid in the impeller is reduced, so that the circumferential velocity component of the fluid in the impeller approaches to the circumferential velocity of the impeller vane more difficultly and the effect of lifting a load pressure is achieved.

Owner:陈振明

Supercharged ventilator

InactiveCN113719354ASmall circulation resistanceReduce consumptionPump componentsDispersed particle separationDrive shaftControl theory

The invention discloses a supercharged ventilator, belongs to the technical field of aero-engine lubricating systems, and solves the technical problems of high structure circulation resistance of an existing centrifugal ventilator and / or insufficient sealing pressure difference and / or high lubricating oil consumption of an engine in a low-rotating-speed state. The supercharged ventilator is suitable for exhausting of an aero-engine; the aero-engine comprises a gear box; the gear box comprises a shell, and a transmission shaft arranged in the shell; a diffuser and a centrifugal compressor are adjacently mounted in the shell; the centrifugal compressor is mounted on the transmission shaft, and is provided with an oil-gas separation structure; the diffuser is fixedly mounted on the inner surface of the shell; the diffuser and the centrifugal compressor are connected in a sealing and communicating mode; an oil phase and a gas phase of an oil-gas mixture exhausted by the gear box are separated through the oil-gas separation structure; separated oil is recovered by an oil pumping device; and separated gas is exhausted through the diffuser. The supercharged ventilator is used for improving the fuel recovery efficiency.

Owner:AECC SICHUAN GAS TURBINE RES INST

Bearing assembly for a centrifuge

InactiveCN101062489BIncrease over timeReduce peripheral speedEngine sealsCentrifugesDrive shaftCentrifuge

In a bearing assembly of a centrifugal revolving drum (1) around a spin axis (6), the revolving drum (1) is fixed by rotation through a drum hub (2) and a hanger bracket (21) of the revolving drum (1) and connected with a drive shaft (3). The drive shaft is connected with a drive set (12) and extends along the spin axis (6) in the bearing block (4, 7, 8, 9, 20, 24). The revolving drum (1) is supported on the bearing block (4, 7, 8, 9, 20, 24), thereby basically separating supporting force generated by power from the drive shaft (3).

Owner:FERRUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com