Supercharged ventilator

A ventilator and diffuser technology, which is applied in the direction of non-displacement pumps, non-variable pumps, machines/engines, etc., which can solve the problems of large lubricating oil consumption, large flow resistance of the centrifugal ventilator structure, and insufficient sealing pressure difference etc. to achieve the effect of reducing oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

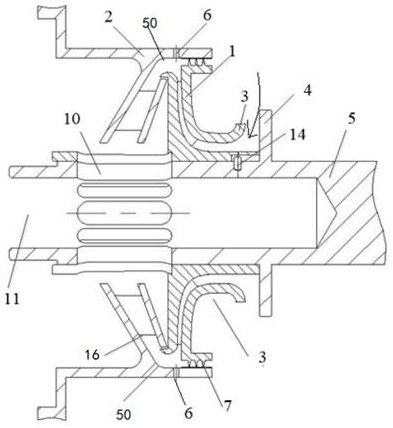

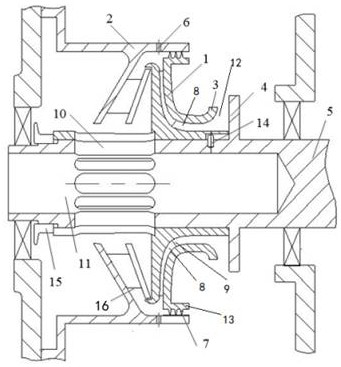

[0044] Such as figure 1 As shown, the pressurized ventilator is installed inside the gearbox, including a centrifugal compressor 1 and a diffuser 2. The centrifugal compressor 1 includes rotor blades 9, and an arc portion 3 is installed on the rotor blade 9. The arc portion 3 is "Trumpet" shape, arc radius 8mm. The gear oil pan 4 provided on the power transmission shaft 5, the distance between the oil gear pan 4 and one end of the adjacent arc portion 3 is 15mm, that is, the gap 12 is 15mm. The arc-shaped part 3 is installed on the rotor blade 9, and forms a narrow air flow channel (gradual structure setting, with figure 2 The placement direction is for reference, and the increase gradually changes from left to right), the purpose is to avoid a large number of lubricating oil particles from being inhaled. The air flow forms a vortex area on the arc portion 3 at the entrance of the centrifugal compressor 1, and after colliding with the oil retaining pan 4, a large number of ...

Embodiment 2

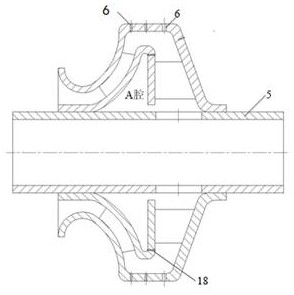

[0048] Such as image 3 As shown, the difference lies in that the centrifugal compressor 1 and the diffuser 2 are arranged in an integrated structure, installed on the transmission shaft 5, and can rotate together. A plurality of oil outlets 6 are provided in the transition area 50 to recycle the lubricating oil particles in the separated air for the second time, and there are a plurality of axial holes 18 on the housing, the diameter of which is Φ1mm, so as to avoid the A formed by the housing and the transmission shaft 5. Oil accumulation in cavity.

[0049] For the setting form of the rotor blades 9 on the above-mentioned center centrifugal compressor 1, see Figure 4 and 5 , can be composed entirely of long blades, or can be composed of long and short blades. In order to reduce the loss of the blades to lubricating oil particles, the number of blades should not be too many. When the blades are all long blades, the number can be up to 18. When the short blades are combin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com