Bearing assembly for a centrifuge

A bearing device, centrifuge technology, applied in centrifuges, engine seals, mechanical equipment and other directions, can solve problems such as cost waste, and achieve the effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

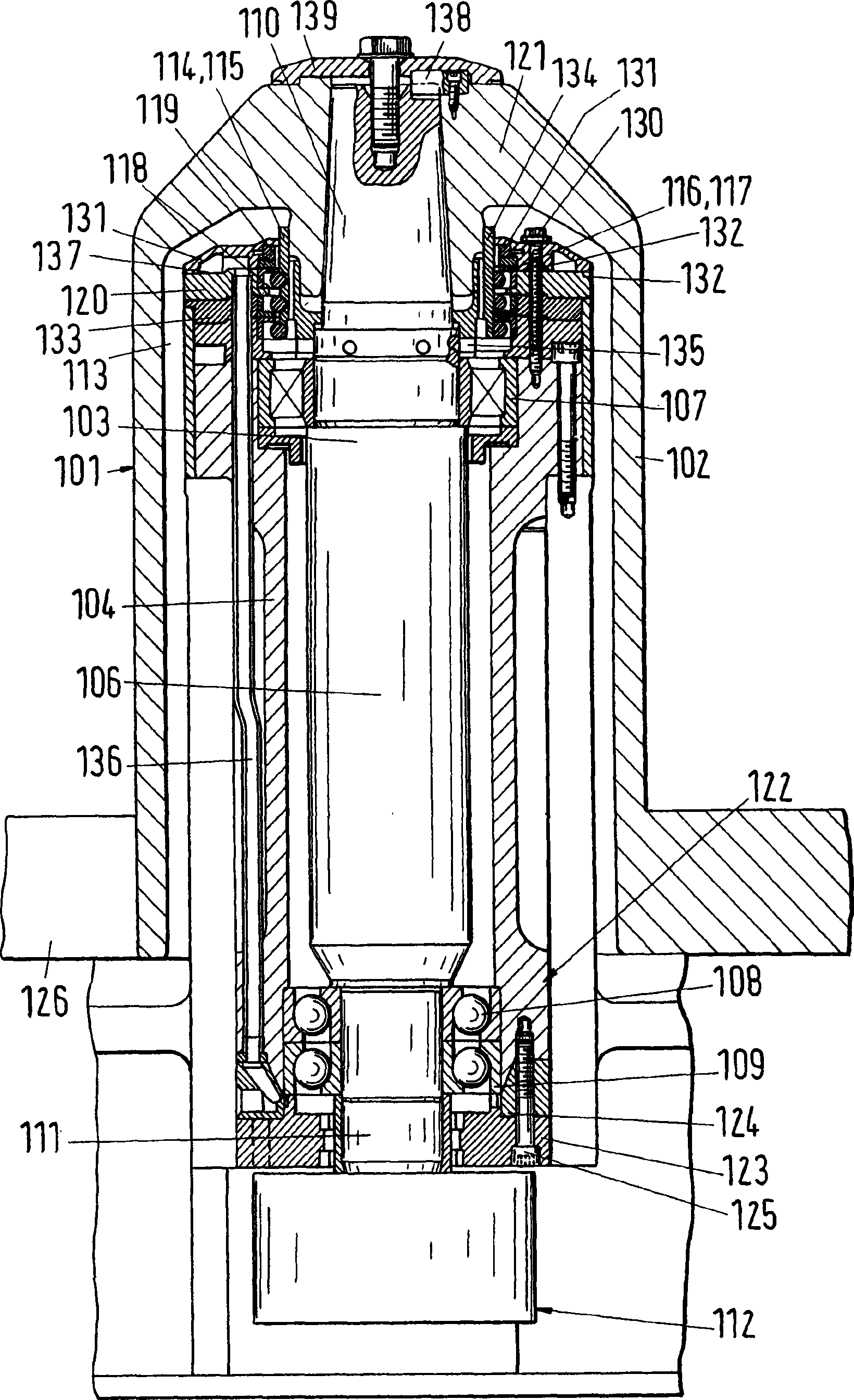

[0043] exist figure 1 In the preferred prior art embodiment shown, the bearing arrangement comprises a drum 101 rotationally fixedly connected to a drive shaft 103 via a suspension 121 . A suspension 121 is located at the first end 110 of the drive shaft, said first end being conical in this embodiment. The conical shape is chosen in order to minimize the weakening of the drive shaft 103 by the notch effect. Each direct diameter transition of the drive shaft 103 is referred to as a weakening phenomenon under load leading to local load peaks, and these load peaks correspond to the notch effect. The drive shaft must bear not only the total load and torsional force of the drum 101, but also the power generated by the rotating motion of the drum and / or the drive shaft 103 itself. These dynamics introduce cyclically fluctuating alternating bending stresses into the shaft that can lead to fatigue failure, and it is known that fatigue failures of this type usually start from struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com