False-twisting device

A technology of false twisting and friction discs, which is applied in the direction of textiles and papermaking, and can solve problems such as increased tension, small engagement angle, and reduced twisting component force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

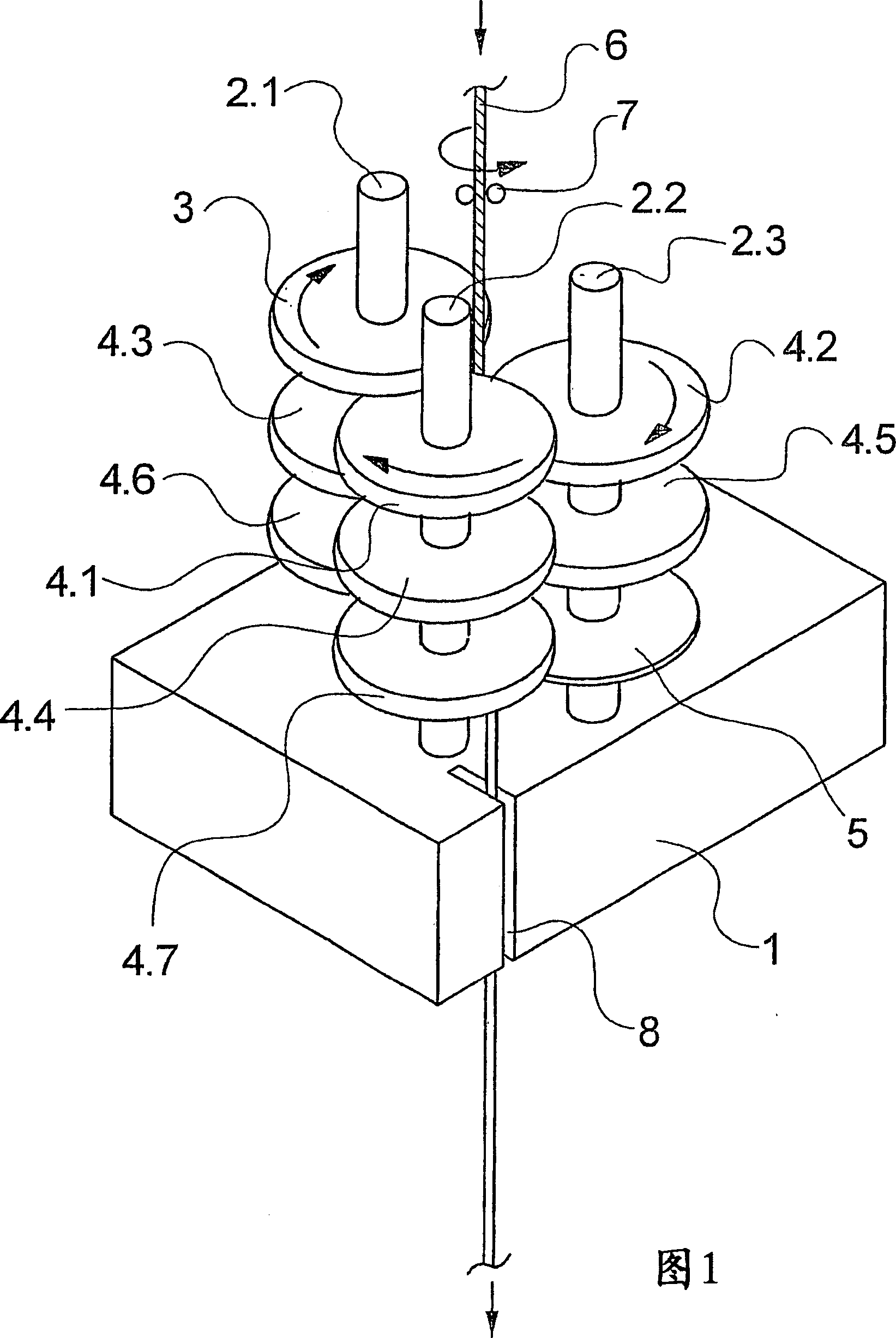

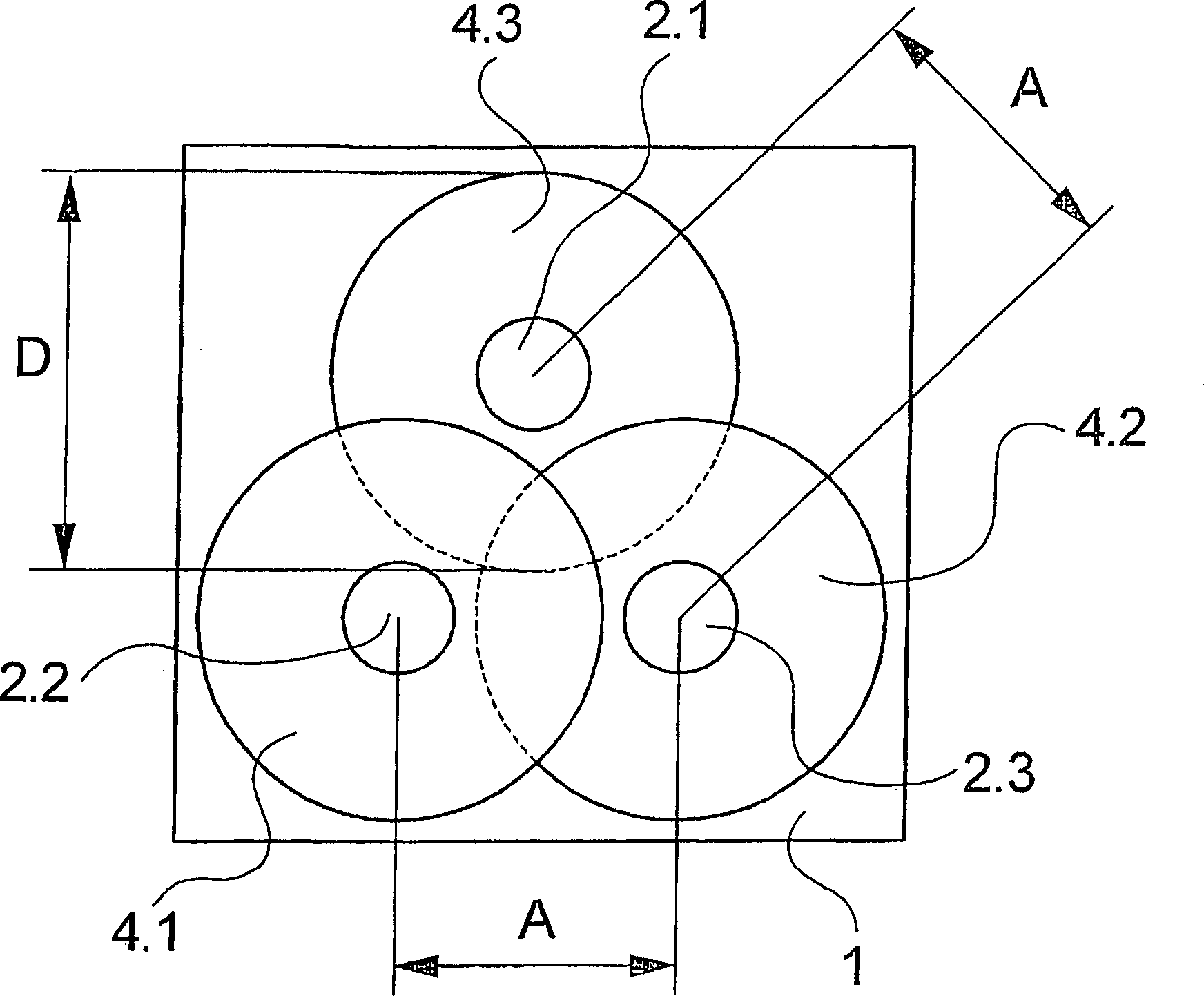

[0022] In Figure 1 and figure 2 A first embodiment of the false twisting device of the present invention is schematically shown in . Fig. 1 is the perspective view of false twist device, figure 2 It is a top view of the false twisting device. The following description applies to both figures, unless one of them is explicitly referenced.

[0023] The false twisting device has a support base 1 . A plurality of shafts 2.1, 2.2 and 2.3 are rotatably mounted on the bearing 1 in a protruding manner. The shafts 2.1, 2.2 and 2.3 are coupled at their bearing ends to a drive (not shown here). A drive of this type is known, for example, from EP 0 7444 80 A1. In this respect, the contents of the cited documents are all incorporated by reference.

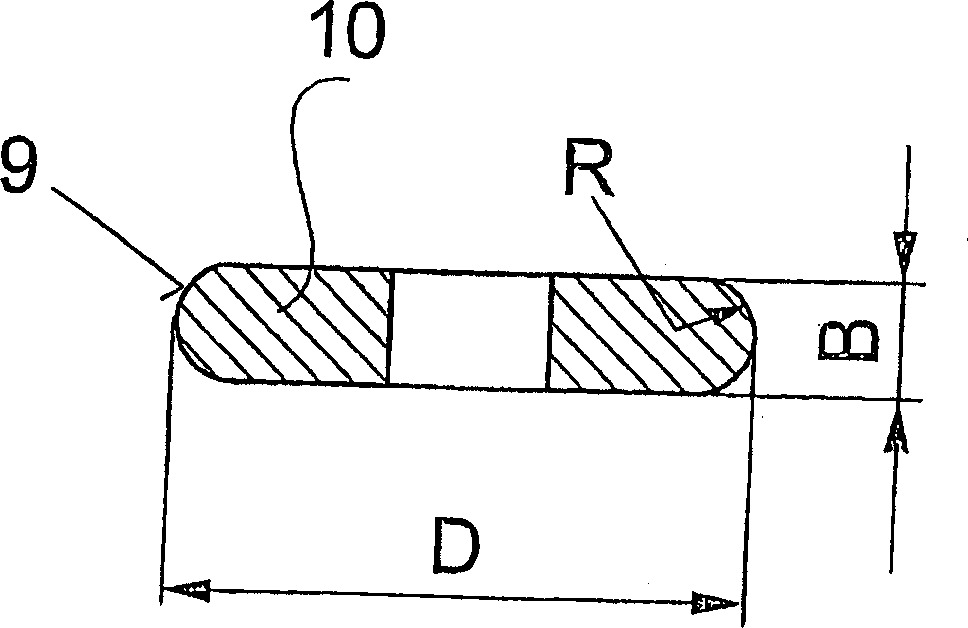

[0024] The axes 2.1, 2.2 and 2.3 are arranged in a triangle. A plurality of friction disks 4.1 to 4.7 offset from one another are arranged on the shafts 2.1, 2.2 and 2.3. Specifically, the shaft 2.1 has an input disc 3 and two friction d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com