Carding machine

A technology of carding machine and pressure roller, which is applied in the field of carding machines, can solve the problems of increasing the size of carding machines, and achieve the effects of shortening the structure length, reducing random flying of fibers, and simplifying control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

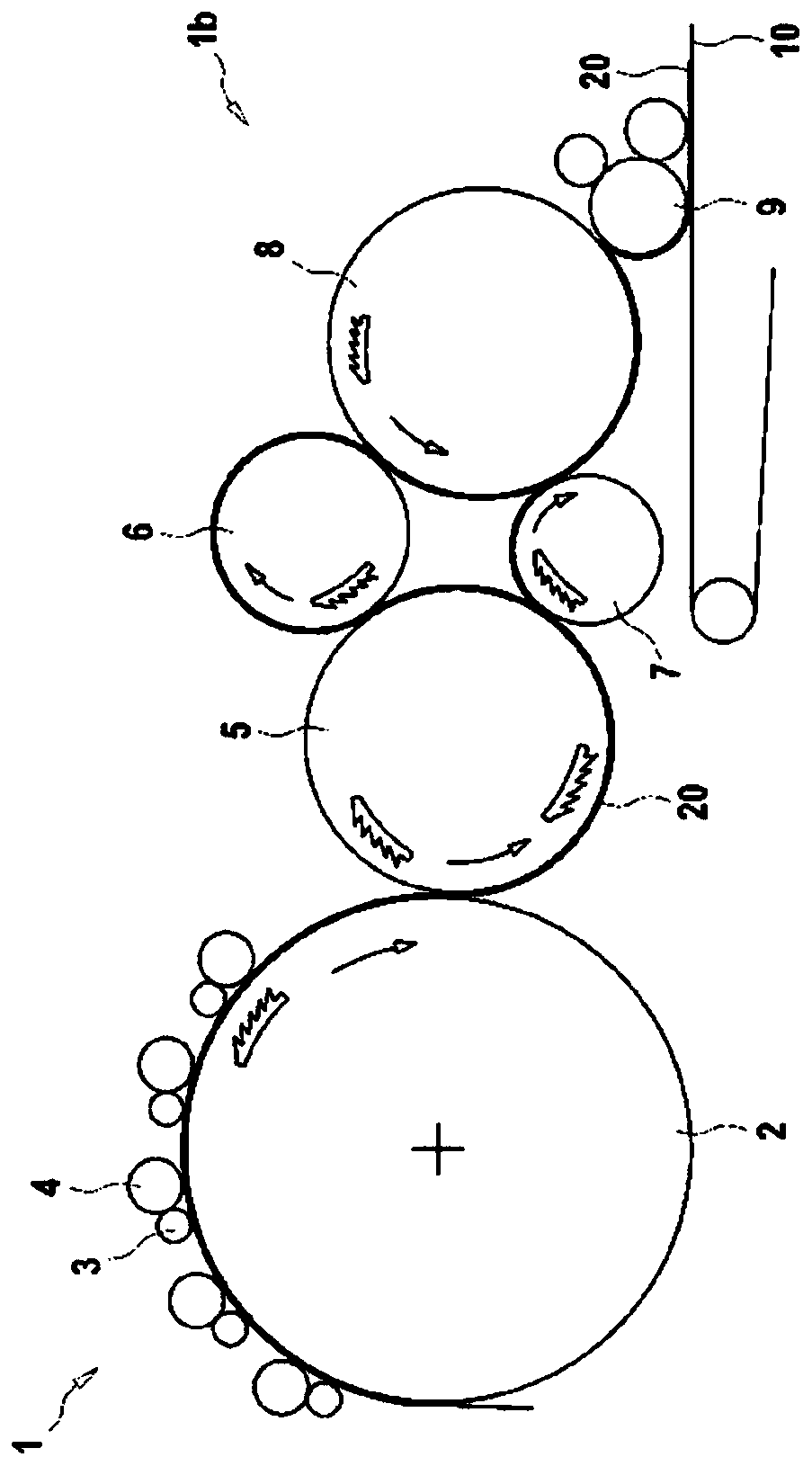

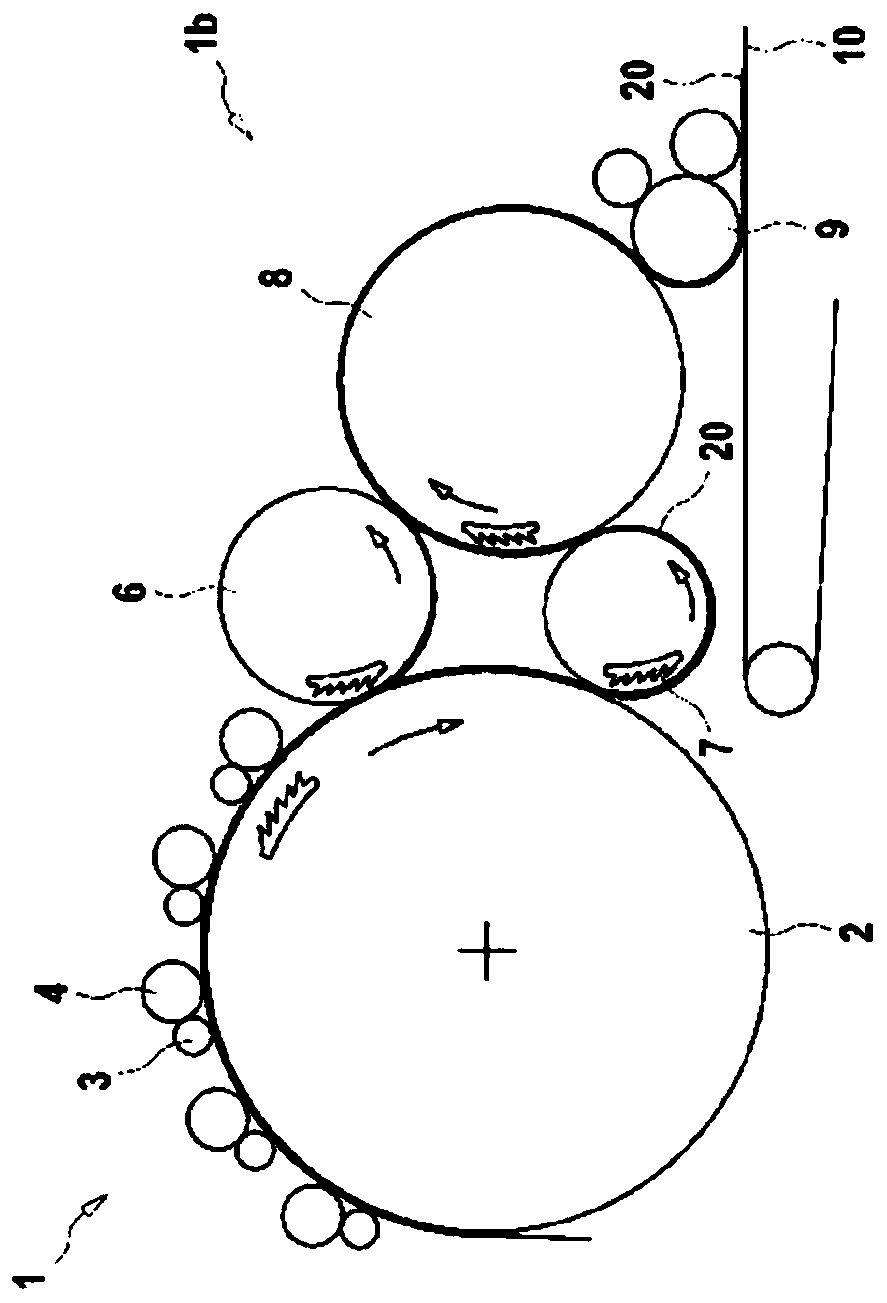

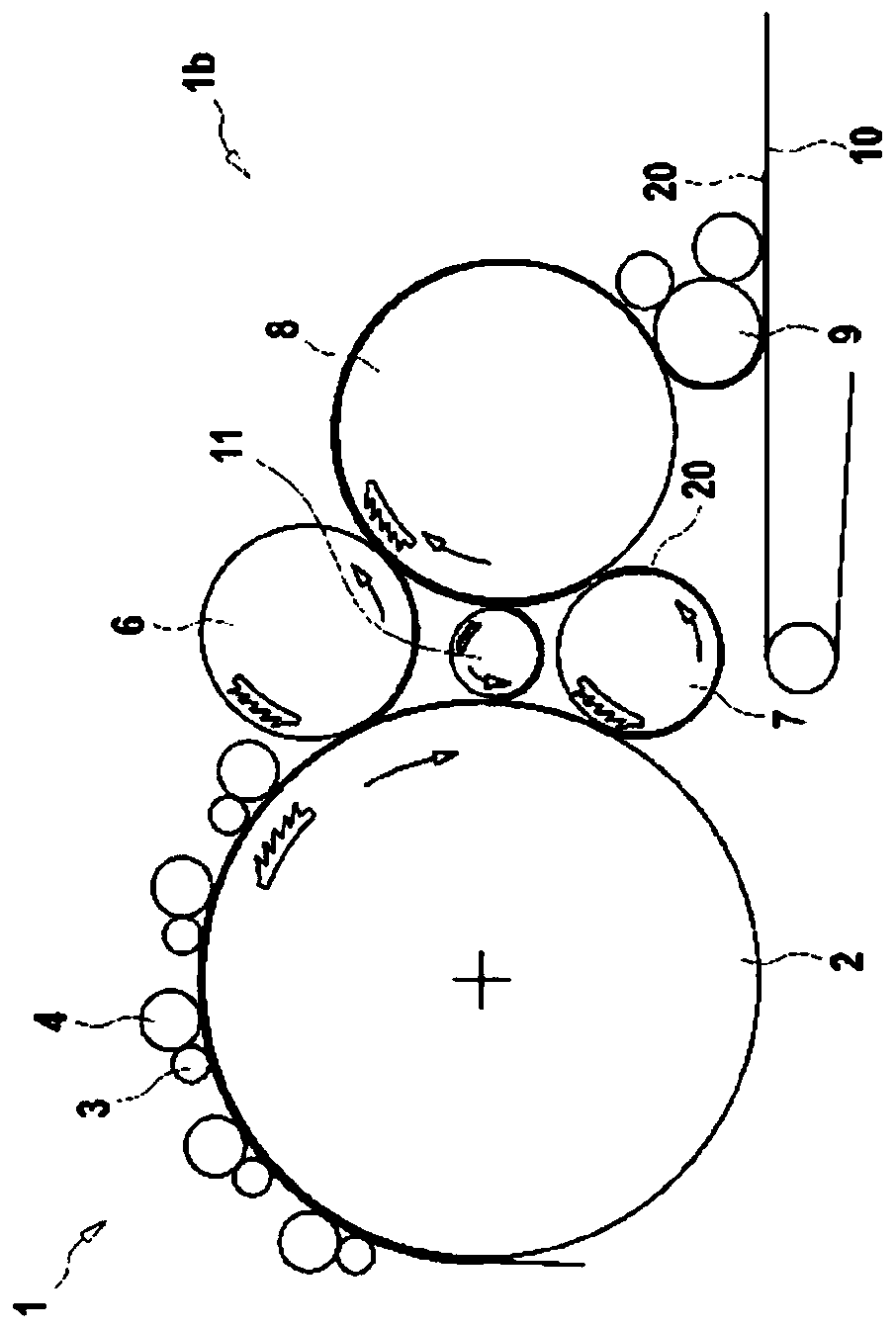

[0025] figure 1 A card 1 according to the invention is shown in , which has a feed side (not shown) for fiber bundles and a discharge side 1 b for loose fibers 20 .

[0026] In the card 1, the fiber bundle is introduced at the infeed side of the device and is introduced into the cylinder 2 via rollers (not shown here) of the front drum, or directly into the cylinder 2, at which rollers in the first stage The fiber bundles are unraveled into individual fibers and aligned. During the transport of the fiber bundle on the cylinder 2 , the stripping rollers and work rolls 3 , 4 fix the fibers on the cylinder 2 so that the first bulk fibers 20 are formed. Loose fibers can be extracted from the cylinder 2 by transfer rollers 5 . In this case, the cylinder 2 rotates in a clockwise direction and its clothing or teeth are likewise inclined in a clockwise direction or in the direction of rotation. The transfer roller 5 rotates counterclockwise, wherein the clothing or teeth of the tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com