Electric power driven hydrostatic test block valve for thermal power generation

A hydrostatic test and valve blocking technology, which is applied to sliding valves, engine components, valve devices, etc., can solve the problems of labor-intensive pipeline blocking, high labor intensity, and expensive valve blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

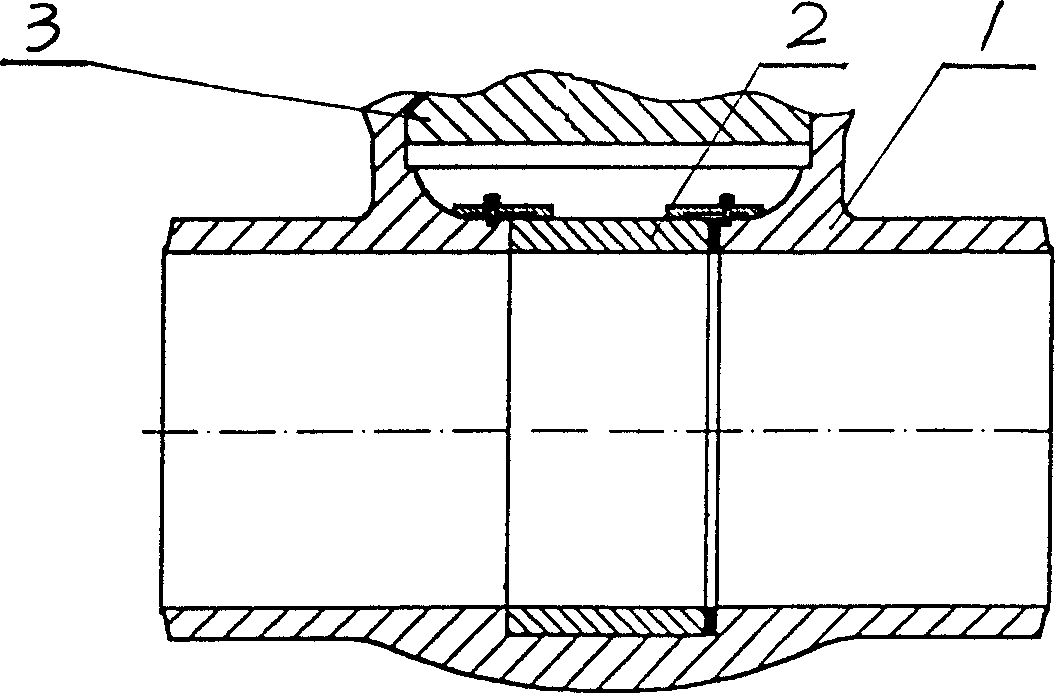

[0017] figure 1 When the pipeline in the prior art is in normal operation, a diversion sleeve 2 is fixedly installed in the pipe groove of the valve body 1, and a sealing member and a sealing cover 3 are installed at the opening of the upper part.

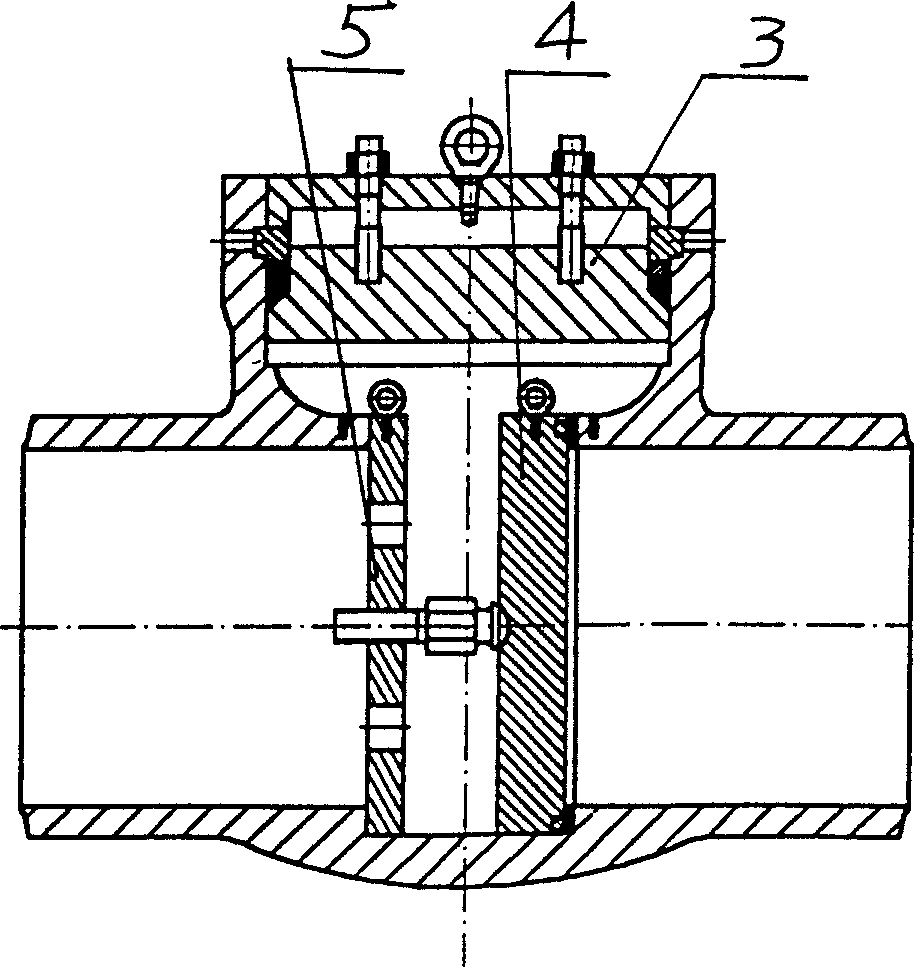

[0018] figure 2 It is the structural diagram of the pipeline in the prior art when the valve is blocked under the pressure test state. When the hydraulic test is required, the sealing cover 3 and the seal below it are opened, the diversion sleeve 2 is taken out, and the diversion sleeve 2 is installed. Install the blocking plate 4 and the support plate 5 on the two ends of the pipeline respectively, and then tighten the bolts so that the blocking plate 4 and the valve seat are pressed tightly, so that water can be passed through for the hydraulic test.

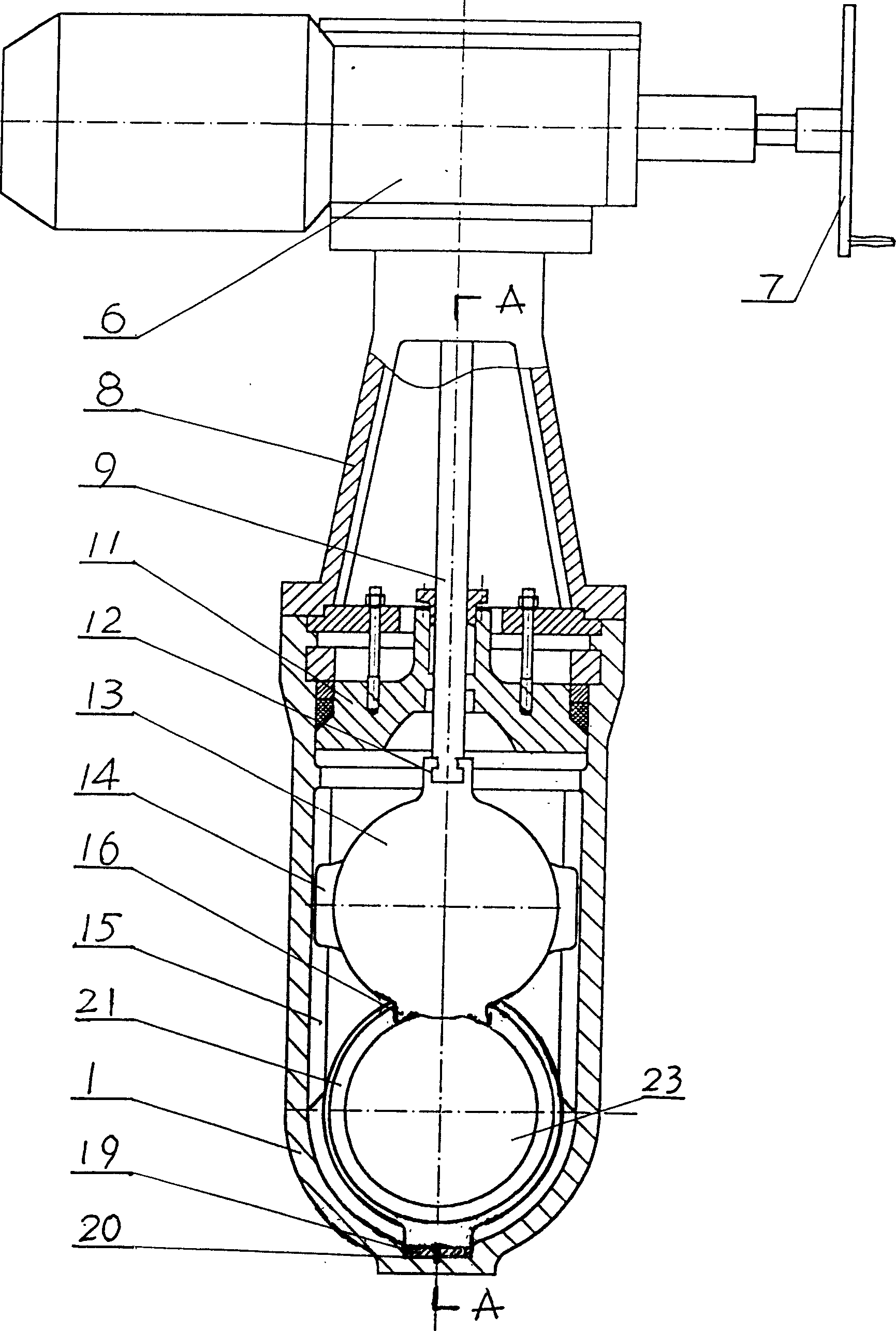

[0019] image 3 Among them, there is a horizontal pipe 23 (see Figure 4) that can connect the pipes at both ends at the lower part of the plugging valve body 1, and a bonnet 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com