Handheld electrical tool with a suction module for a dust separation device

A technology of hand-held power tools and power tools, which is applied in the field of drilling rigs, impact drills or hammer drills, and can solve the problems of the operability of hand-held power tools and achieve the effect of completely maintaining the operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

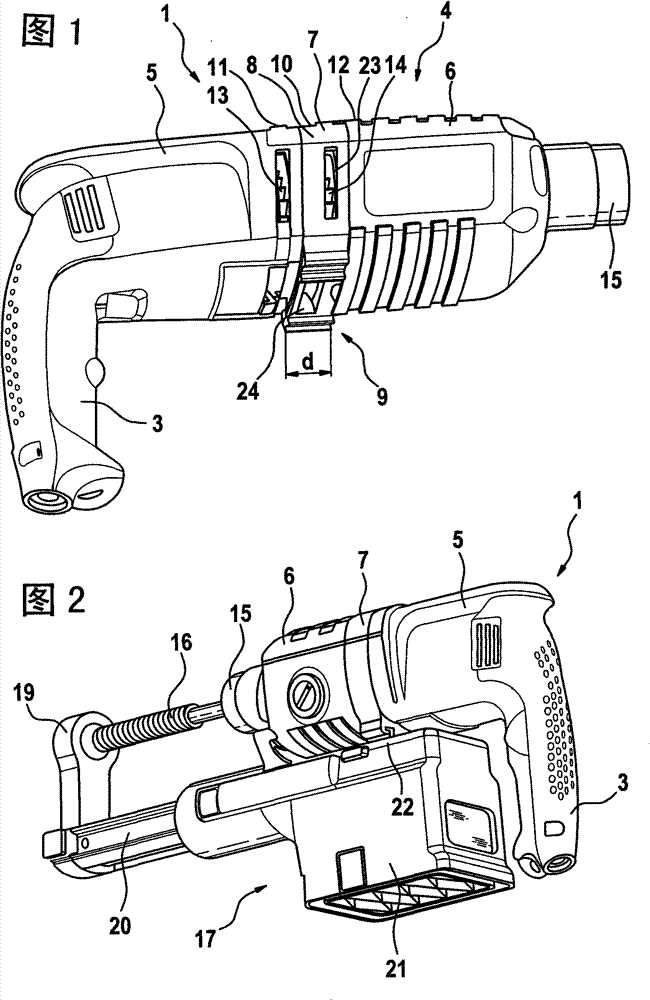

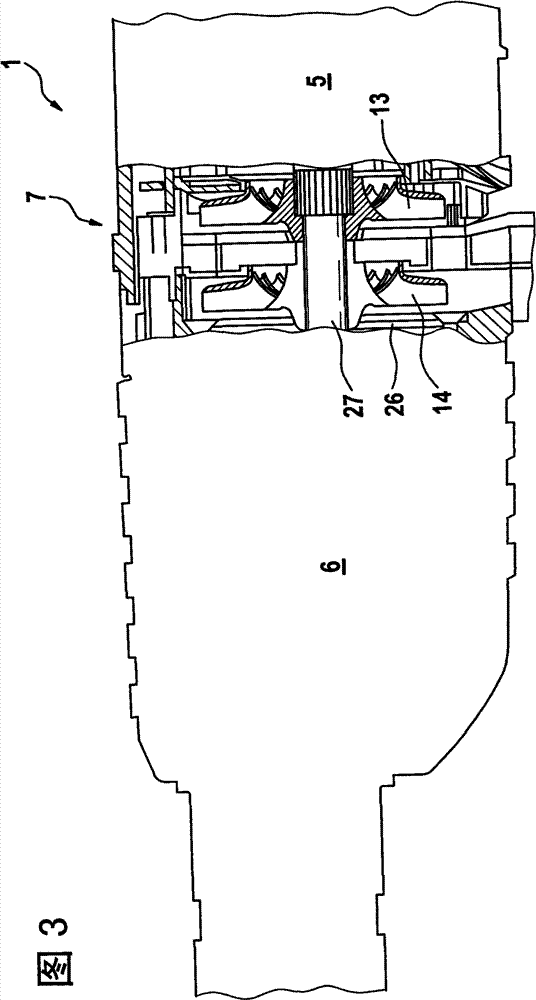

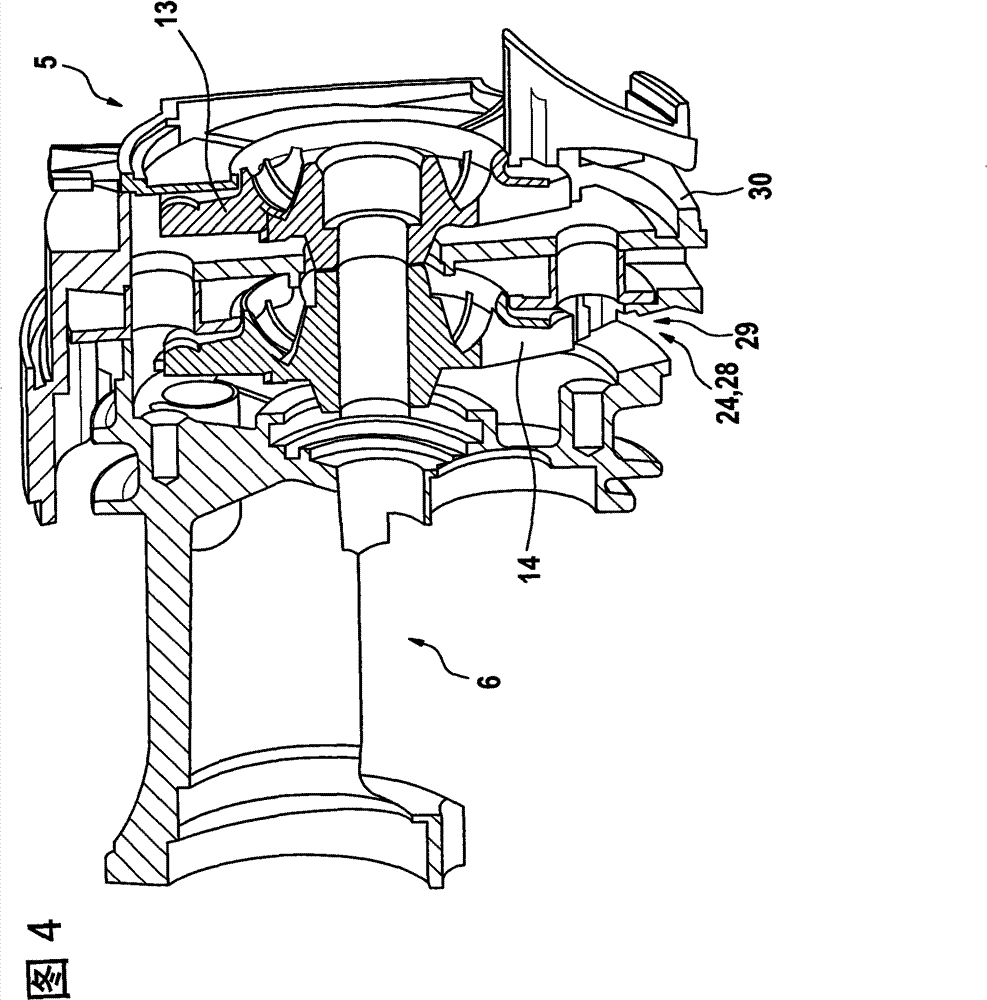

[0022] FIG. 1 shows a hand-held electric power tool 1 designed as a hammer drill 2 or hammer drill 2 . It has the design of a pistol due to the handle part 3 and a main part 4 extending at an angle to the handle part 3 and having a motor part and a transmission part. The transmission part includes an impact mechanism. The motor part forms a first functional part 5 and the transmission part forms a second functional part 6 , wherein a suction module 7 is arranged between the two functional parts 5 and 6 . The suction module 7 is designed as a disk element 8 with a thickness d. In the region adjoining the suction module 7 , the cross-sectional profile of the first functional part 5 is substantially identical to the cross-sectional profile of the disk element 8 . Furthermore, the cross-sectional profile of the region of the second functional component 6 adjoining the suction module 7 substantially corresponds to the cross-sectional profile of the suction module 7 , that is to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com