Swing angle type radial plunger variable pump

A radial column, variable pump technology, used in piston pumps, pumps, multi-cylinder pumps, etc., can solve the problems of the balance of axial force cannot be effectively controlled, the sliding shoes and the two side plates are easy to wear, etc. Noise reduction effect

Inactive Publication Date: 2005-11-23

顾智刚

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a static and dynamic pressure balanced swing angle radial plunger variable pump to solve the problems of the existing radial plunger pumps, such as easy wear of the sliding shoes and two side plates, and the radial displacement between the rotor and the plunger. The problem that the balance of force and axial force cannot be effectively controlled

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

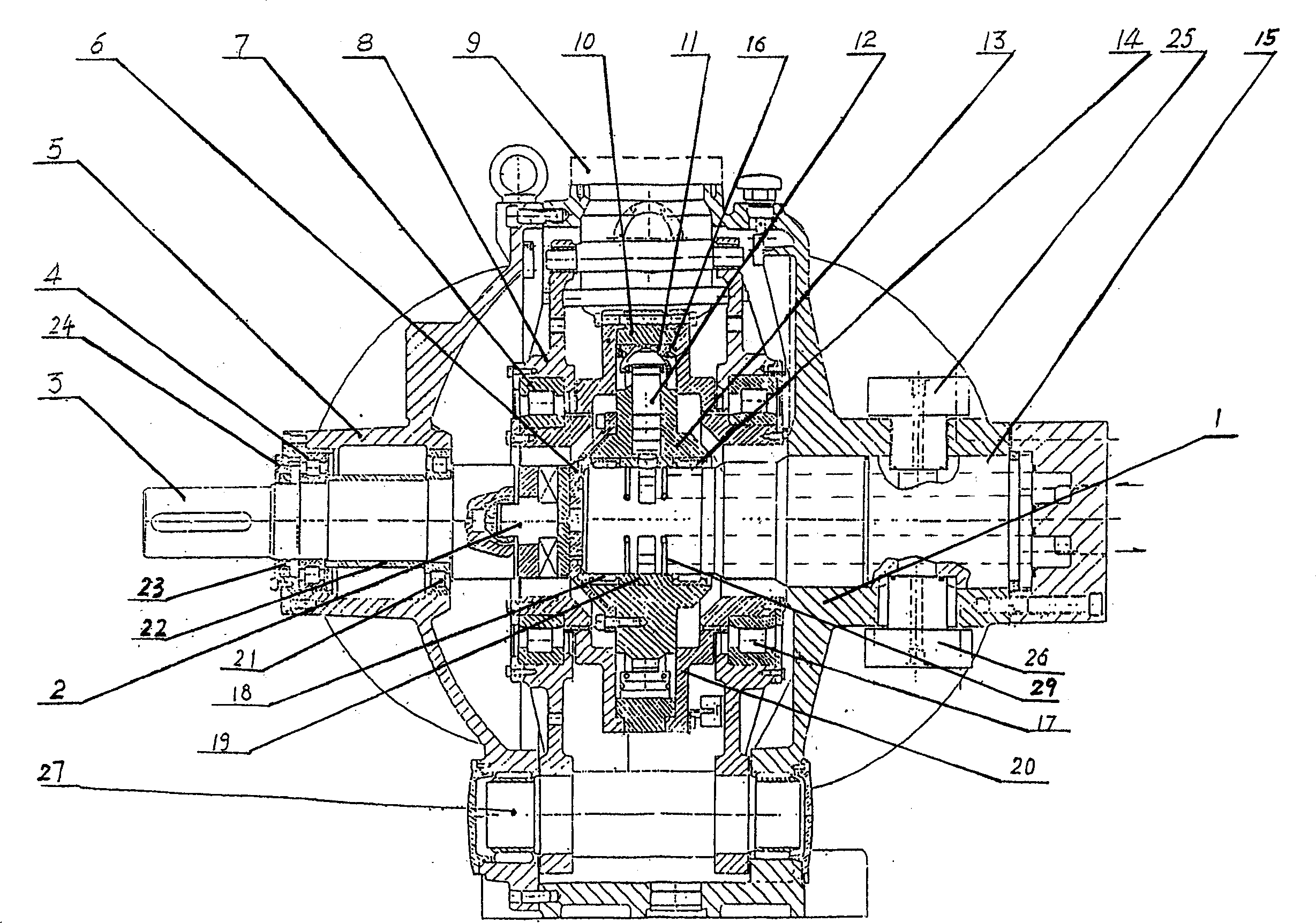

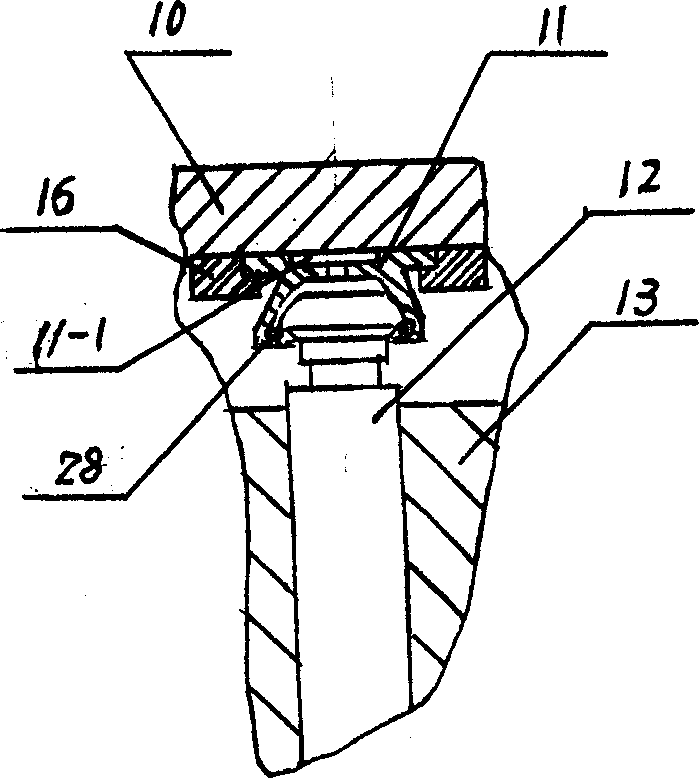

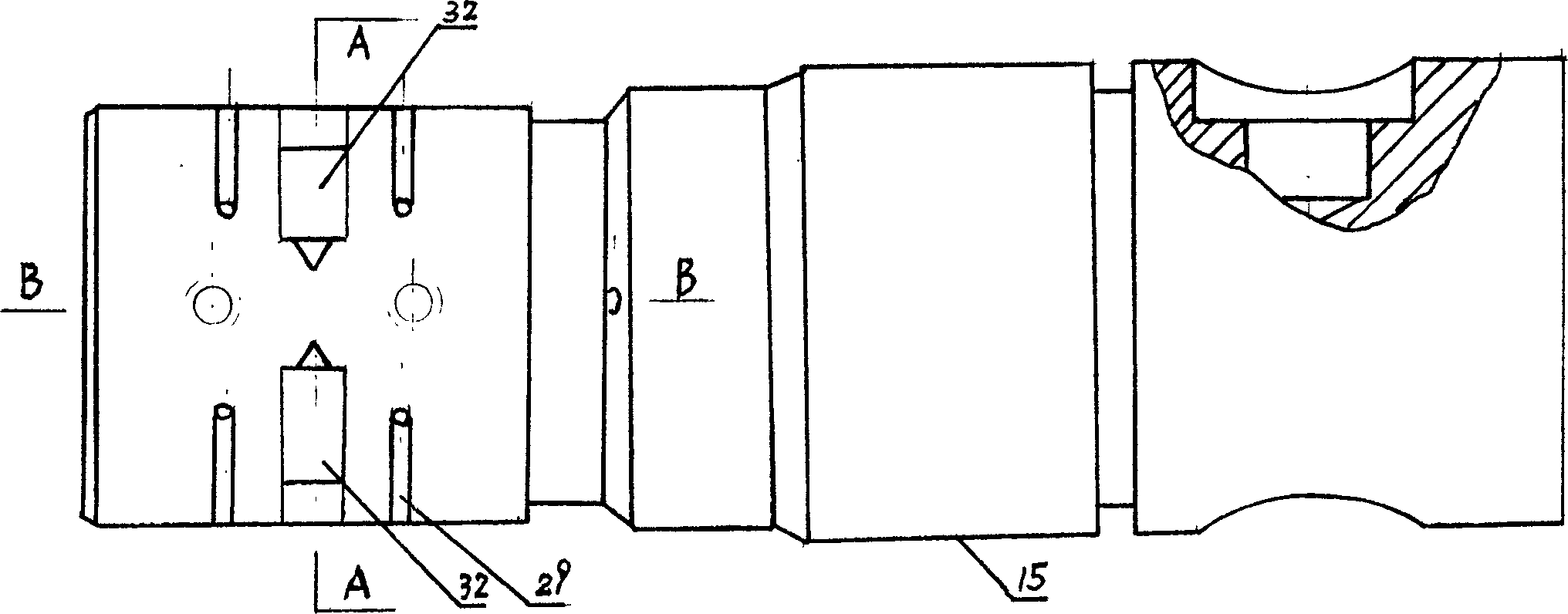

The invention discloses a swing radial piston variable-capacity pump with static and dynamic pressure balance; it solves the problem of keeping axial under the transient load mode. In the pump body installed a stator swing span and a swing span rotation shaft, the swing roller bearing on the stator swing span connects with an end of the stator mount, the other end of the stator mount connects with the stator; on the plunger connecting rod sliding boot installed a static pressure balance chamber, the holding rings are arranged on the two sides of the plunger connecting rod sliding boot which has a fit clearance with the holding rings; the rotor rotates the stator simultaneously via the plunger piston; the needle roller bearings are arranged on the two inner circles and fit with the port axle. In the invented device, the rotor and stator rotate simultaneously, the plunger connecting rod sliding boot slices on the inside surface of the stator, the linear speed is 0 or very low (0-40r / min).

Description

Technical field: [0001] The invention relates to a swing-angle radial plunger variable pump, in particular to a radial plunger variable pump suitable for displacements above 500mL / r. Background technique: [0002] Since the 1950s, most of the axial and radial piston variable pumps above 500mL / r are imported from abroad. Several domestic hydraulic parts manufacturers have just researched and developed high-pressure and large-displacement hydraulic pumps, but the performance technology The index is low, far from meeting the requirements of industrial production development. According to preliminary research, my country needs to import more than 1,500 high-pressure and large-displacement hydraulic pumps above 500mL / r from abroad every year, especially forging machinery and ship machinery. The import price of each 500mL / r high-pressure and large-displacement hydraulic pump is in the (20-40) million yuan, and the import cycle is long. [0003] The 500mL / r radial piston variable ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F04B1/30

Inventor 卢堃

Owner 顾智刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com