Totally enclosed main motor

A traction motor, closed-type technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of large-scale traction motors, increased noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

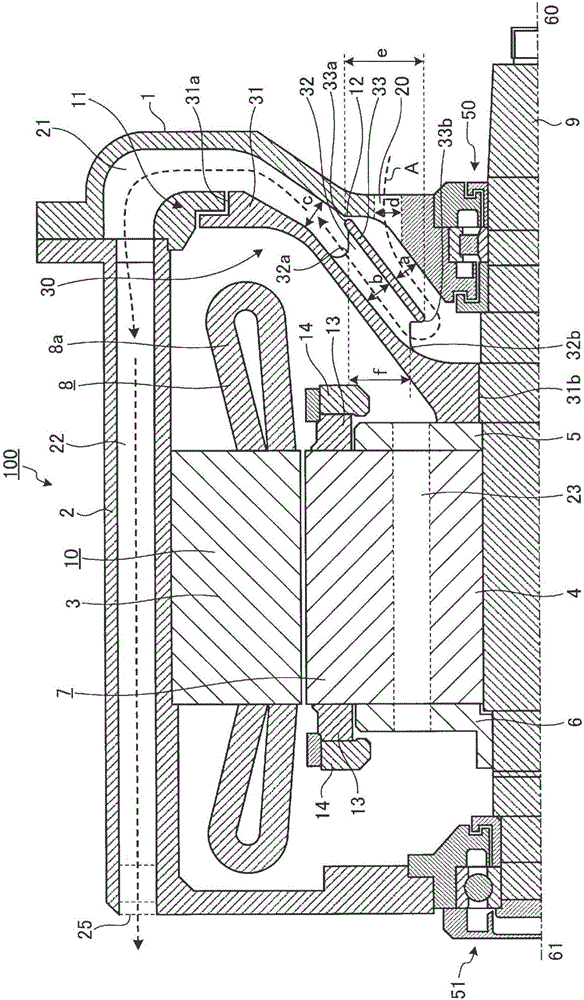

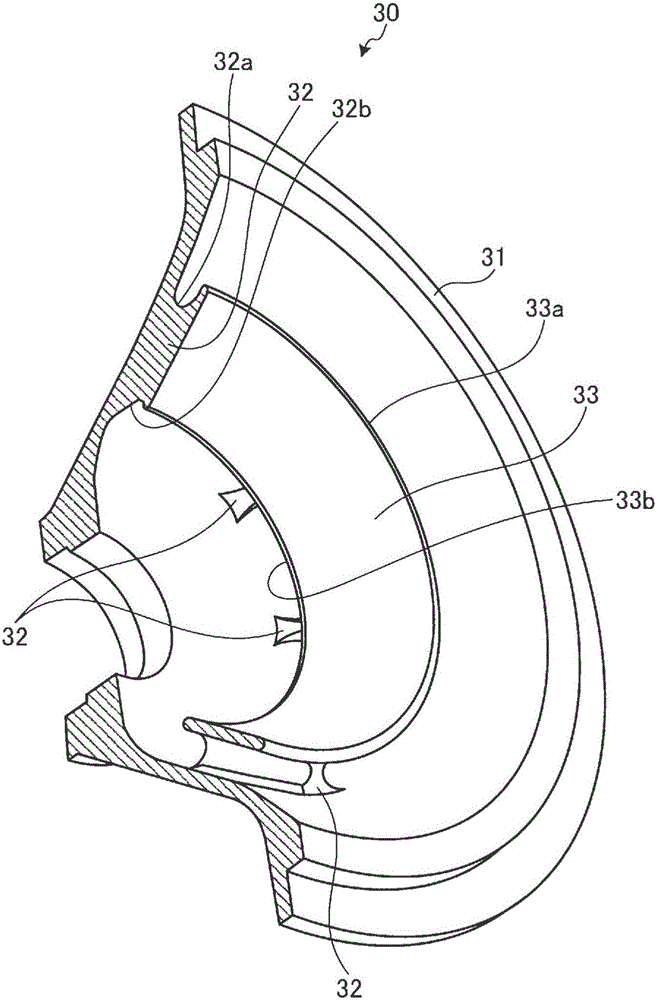

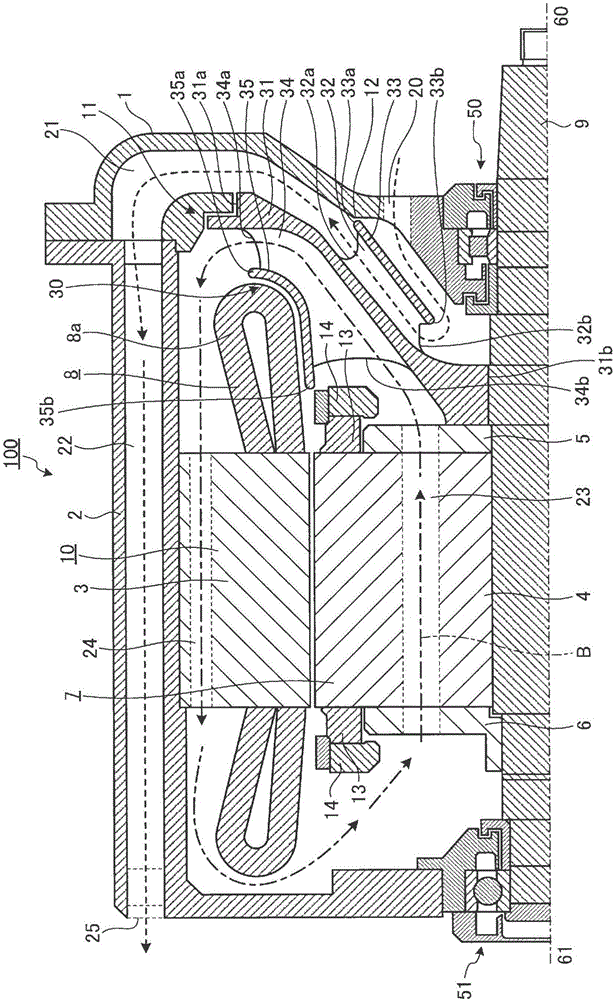

[0024] figure 1 It is a longitudinal sectional view of a fully enclosed traction motor according to an embodiment of the present invention. figure 2 yes figure 1 A perspective cutaway view of the cooling fan shown.

[0025] A fully enclosed traction motor (hereinafter referred to as "traction motor") 100 is configured to include: a stator 10 composed of a stator core 3 and a stator coil 8; a rotor 7 disposed inside the stator 10; a frame 2, The frame 2 surrounds the stator 10 and the rotor 7 ; the bracket 1 is arranged on the driving side 60 of the frame 2 ;

[0026] An air duct 21 and an air inlet 20 communicating with an air duct 22 of the frame 2 are formed in the bracket 1 . The suction port 20 is provided along the circumferential direction. In addition, the suction port 20 is provided in a region where the guide 33 is projected toward the bracket 1 .

[0027] An air passage 22 located on the outer peripheral side of the stator core 3 is formed in the frame 2 . A p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com