Gravity type titable metal mold casting machine

A technology for casting machinery and metal molds, applied in the field of gravity-type tiltable metal mold casting machinery, can solve the problems of high metal lower mold height and difficult operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

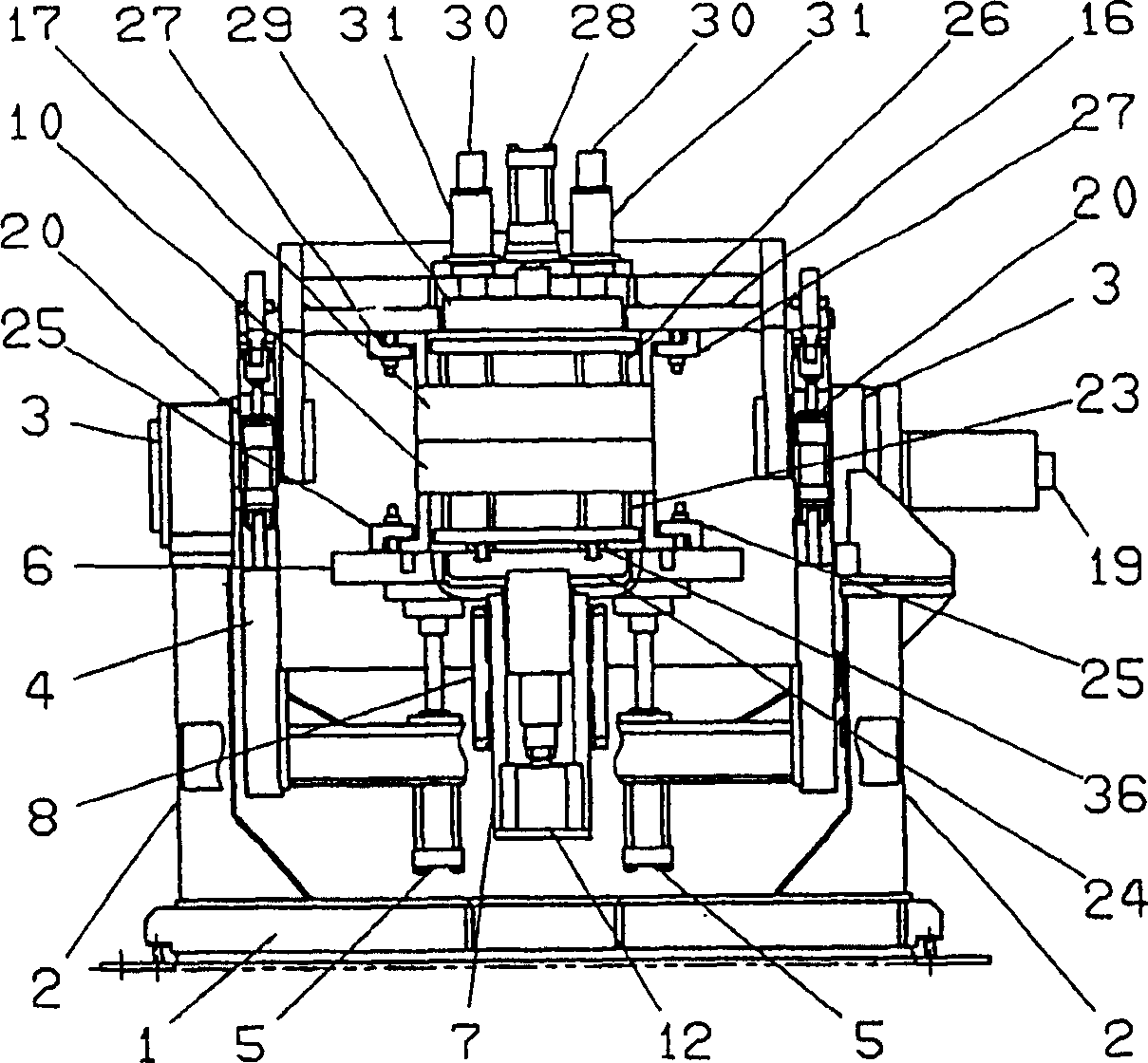

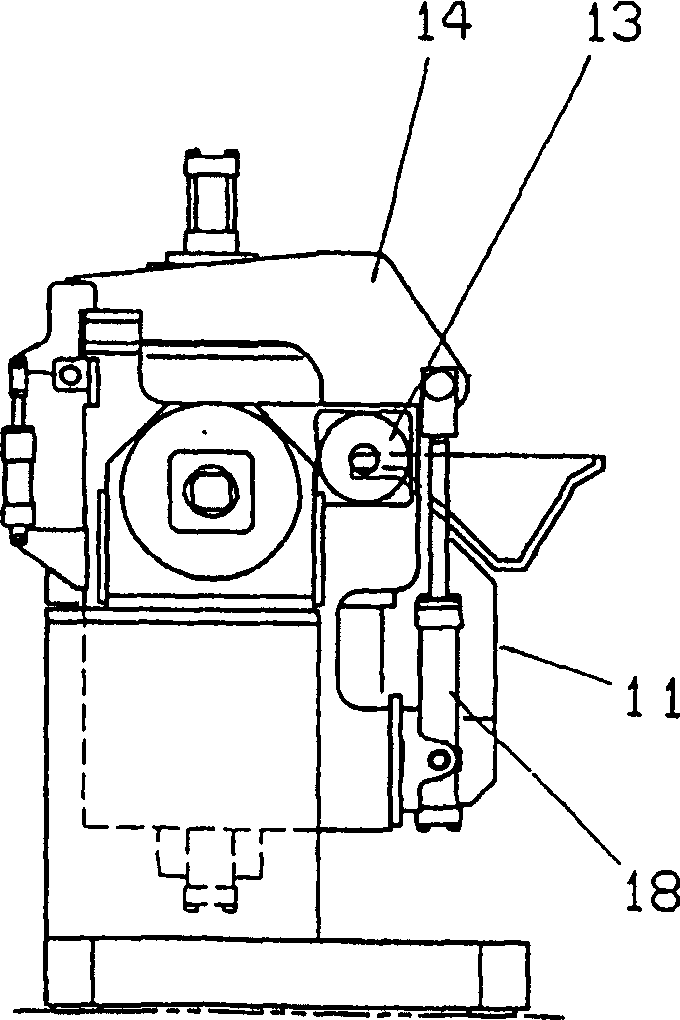

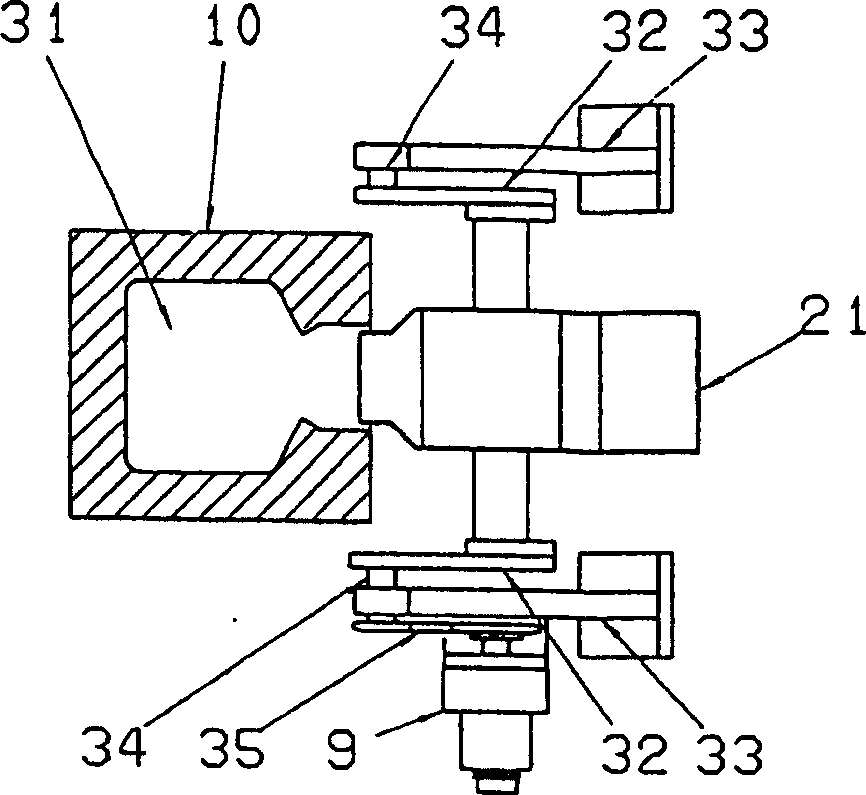

[0022] The embodiments of the present invention are described in detail below with reference to the accompanying drawings. in figure 1 with 2 A pair of relatively upright frames 2 and 2 are installed on the base 1. A pair of opposed main rotating shafts 3, 3 are arranged on the axis and rotatably mounted on the upper ends of the upright frames 2, 2. The main frame 4 is fixedly mounted on the main rotating shafts 3, 3 in such a way that the main frame hangs down from the main rotating shaft and is suspended between them. In order to reversibly rotate the main frame 4A, a main motor 19, such as a servo motor, is mounted on one of the supporting frames. A main motor 19 for reversibly rotating the main frame 4 is connected to one end of one of the main rotating shafts 3 and 3.

[0023] In order to fasten the mold, a number of upward facing cylinders 5 and 5 are installed in the lower part of the main frame 4. A lower template 6 is fixed to the ends of the piston rods of the mold clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com