Self-driven outer duct contrarotating annular fan blade compressing device

A technology of compression devices and external ducts, which is applied to jet propulsion devices, machines/engines, etc., can solve the problems of limiting the advantages of multi-ducted engine variable cycles, expanding the working range of engines, and limiting the choice of blade tangential speed, etc., to achieve increased The effect of design difficulty, structural layout optimization, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

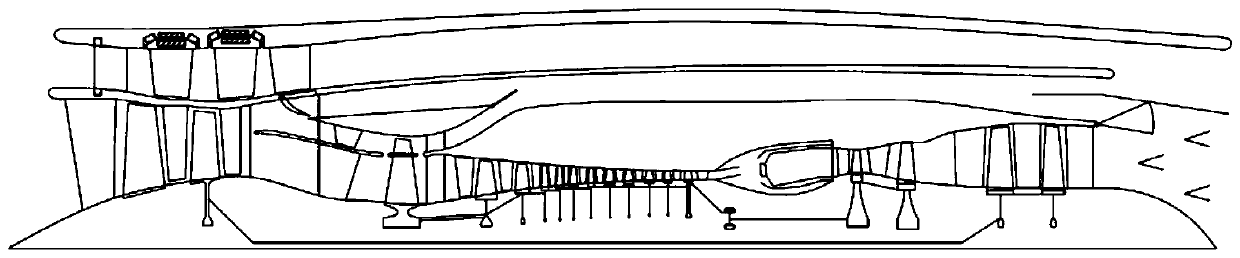

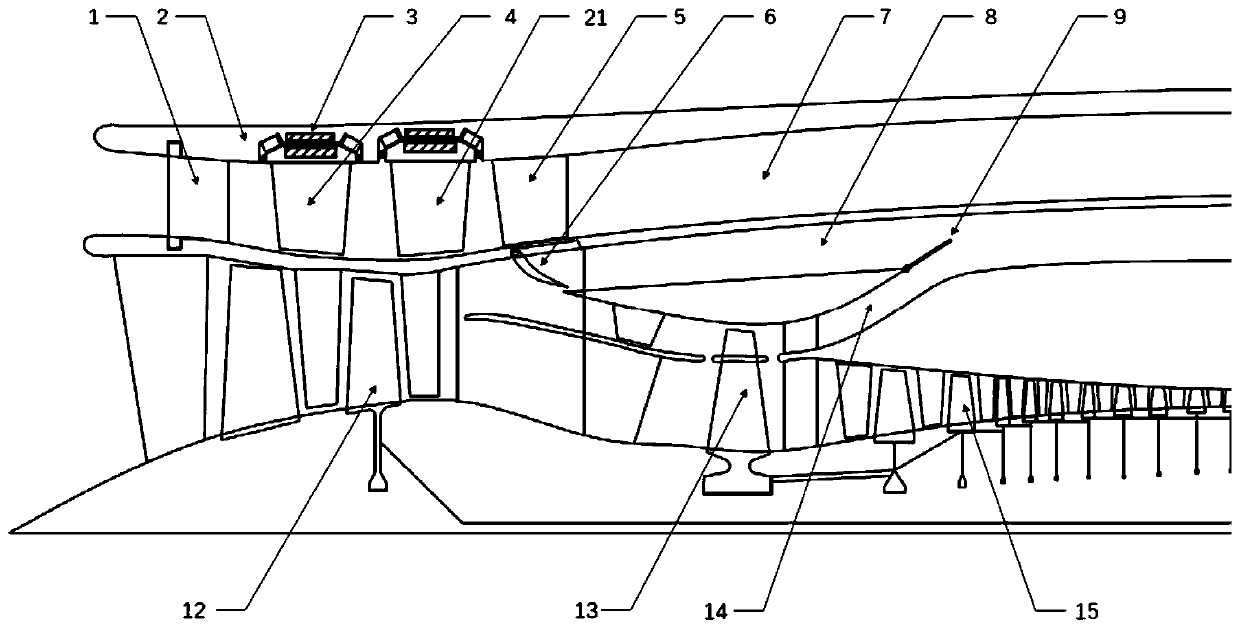

[0029] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a self-driven external duct annular counter-rotating fan blade compression device is provided with three flow channels inside, middle and outside at the rear of the traditional fan 12. The inside flow channel is connected with the core machine driving fan 13, and the middle flow The channel is connected with the entrance of the second outer duct 14, the outer flow channel is communicated with the entrance of the first outer duct 8, and the outlet of the second outer duct 14 is connected with the first duct ejector 9 through the front variable area. The outer duct 8 is connected, and a mode selection valve 6 is also provided at the entrance of the first outer duct 8; the rear part of the core machine driving fan 13 is the inner side and the outer side two annular flow channels, and the inner side The annular flow passage communicates with the high-pressure compressor 15, and the middle...

Embodiment 2

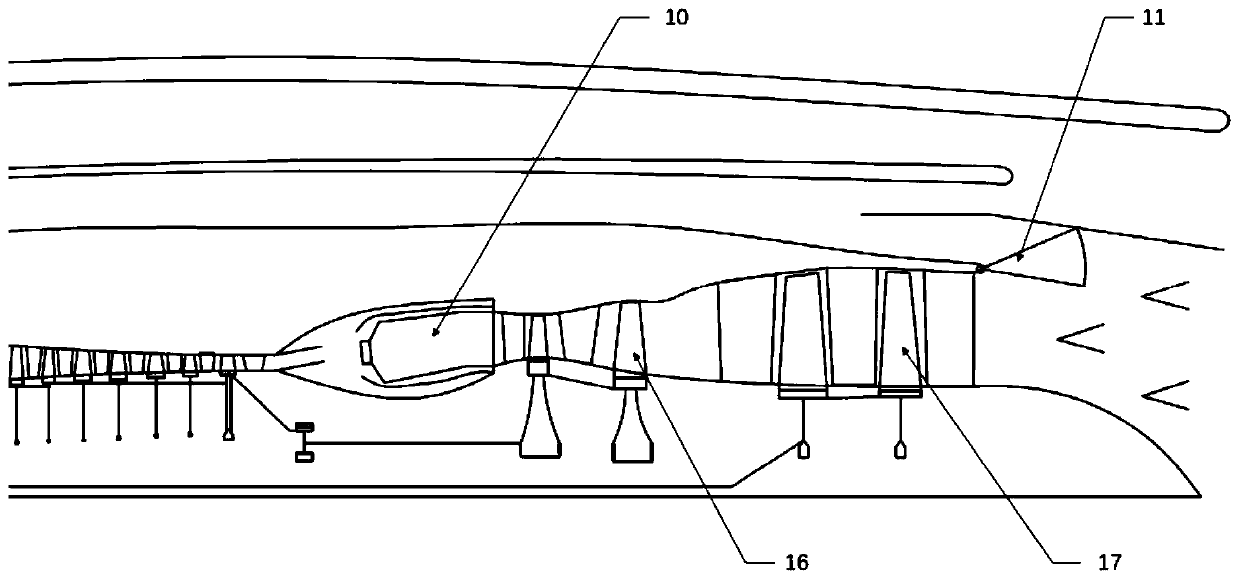

[0032] Embodiment 2: as Image 6 , Figure 7 As shown, it is the same as in Embodiment 1, except that the two rows of counter-rotating components include an upstream fan blade 4 and a downstream fan blade 21, and the upstream fan blade 4 and the downstream fan blade 21 are respectively arranged on two annular support frames. 18 on the outer wall, the annular support frame 18 has inner and outer walls, and an electromagnetic device 19 is arranged on the inner wall of the annular support frame 18; On the casing, the inner casing corresponding to the electromagnetic device is also provided with a motor stator 3, the magnetic poles of the electromagnetic device 19 and the motor stator 3 are arranged in a circumferential array, and the polarity of the electromagnetic device 19 and the motor stator 3 on the contrary. The bearing clearance of the slewing bearing is smaller than the blade tip clearance, and the blade tip clearance refers to the outer casing clearance between the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com