Labyrinth seal structure with brush type seal strips

A brush seal, labyrinth seal technology, applied in non-variable-capacity pumps, components of pumping devices for elastic fluids, preventing leakage, etc. Large radial clearance, etc., to reduce the hysteresis effect, maintain the circumferential resistance, and achieve the effect of small leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The present invention will be described in further detail below in conjunction with the accompanying drawings. The following implementations are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

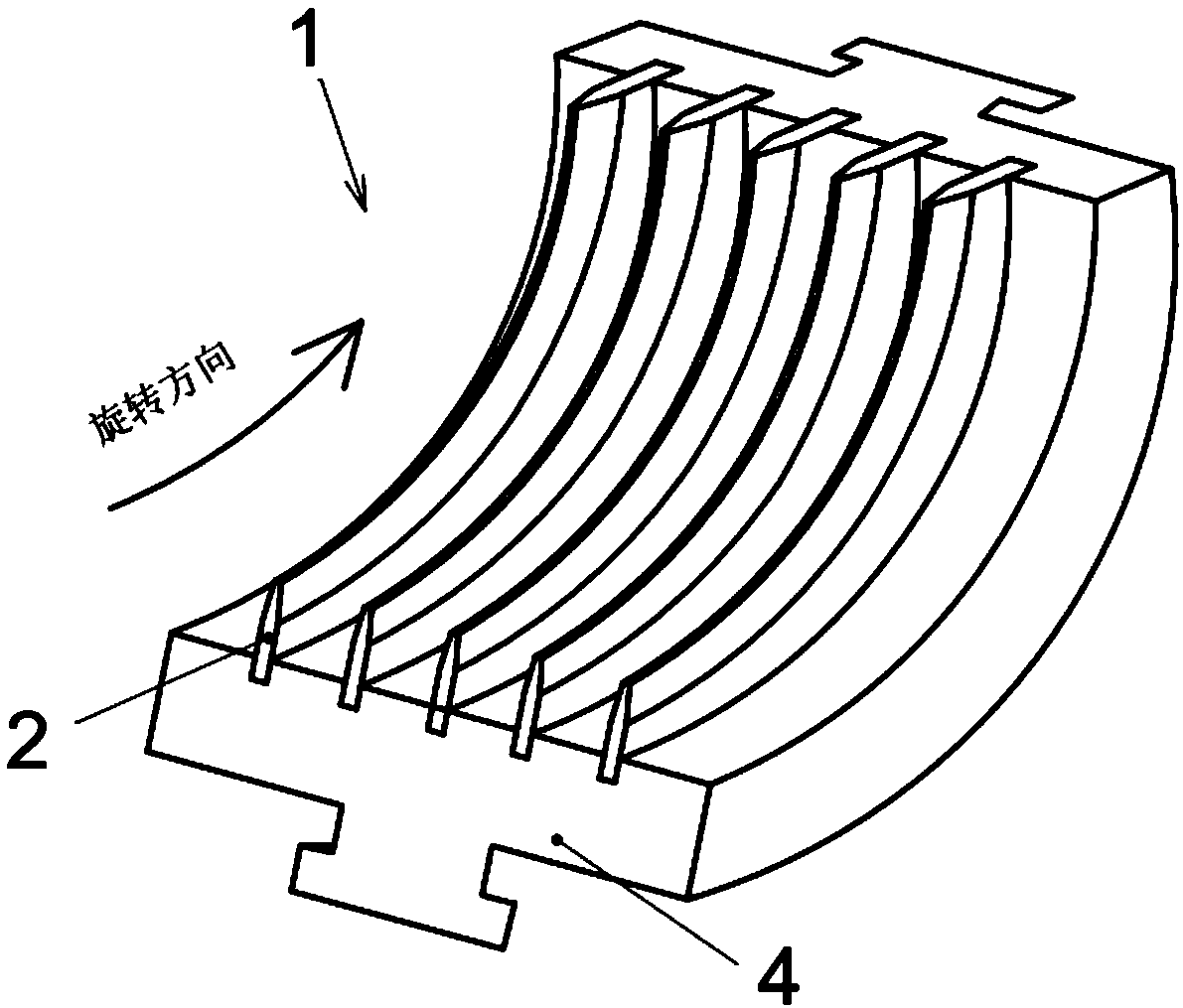

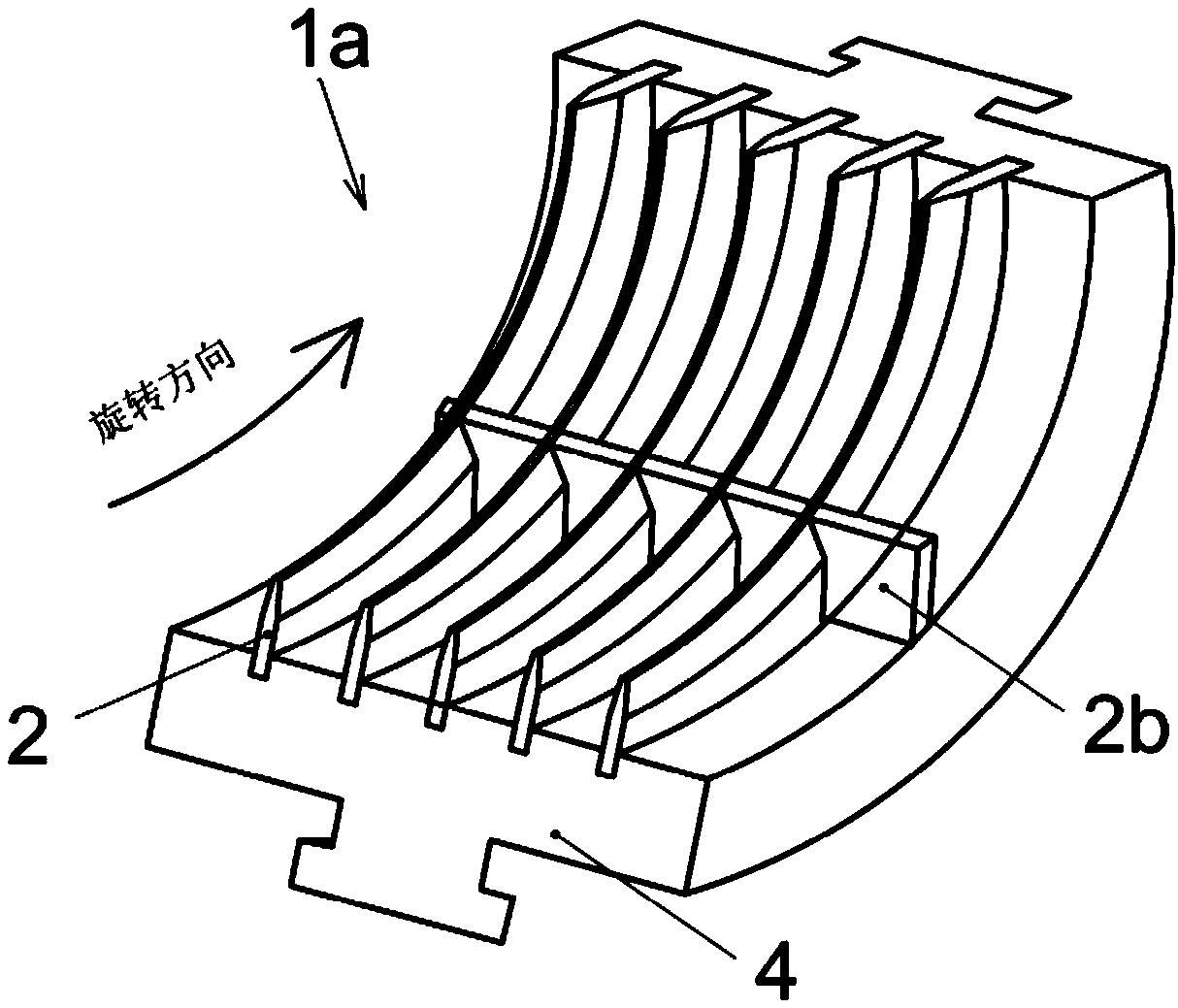

[0041] Concrete structure of the present invention sees appendix Figure 2-10 :

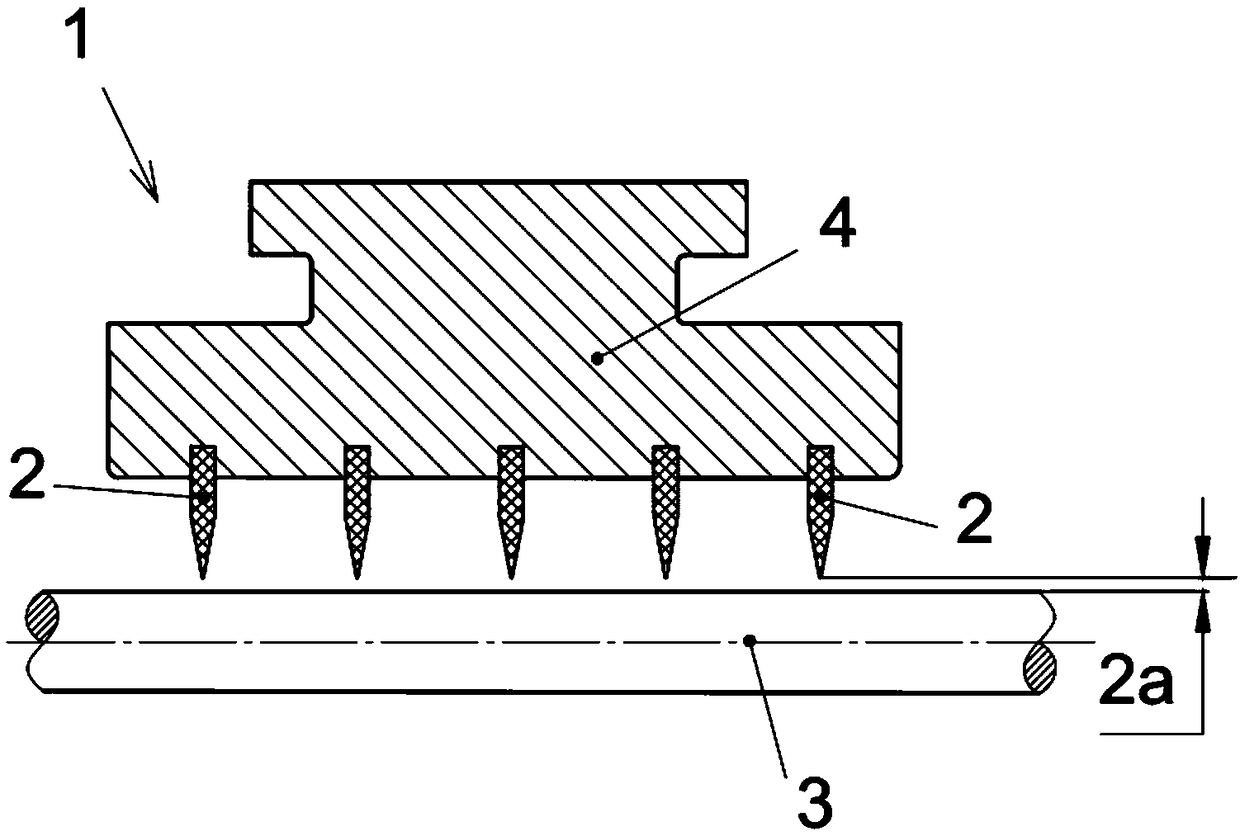

[0042] see figure 2 , a labyrinth seal structure with a brush seal provided by the present invention, the labyrinth seal structure includes a labyrinth seal 8 and a brush seal 6 after the brush seal is removed, and the labyrinth seal 8 after the brush seal is removed is used Set on the circumferential direction of the rotor 3, and leave a gap 2a with the rotor 3 bracket, the labyrinth seal 8 after removing the brush seal strip includes the seal body 4 and the labyrinth teeth 2 arranged inside the seal body 4, the present invention uses the brush seal The sealing strip 6 is axially installed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com