Novel extraction process for aromatic hydrocarbons

A technology of aromatics extraction and new technology, which is applied in the chemical industry, hydrocarbon purification/separation, sustainable manufacturing/processing, etc., can solve the problems of equipment maintenance cost and difficulty increase, product quality decline, pipeline blockage, etc., and achieve good Energy-saving effect and economic benefits, less solvent decomposition, and lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the devices and implementation cases of the accompanying drawings, but does not impose any limitation on the present invention.

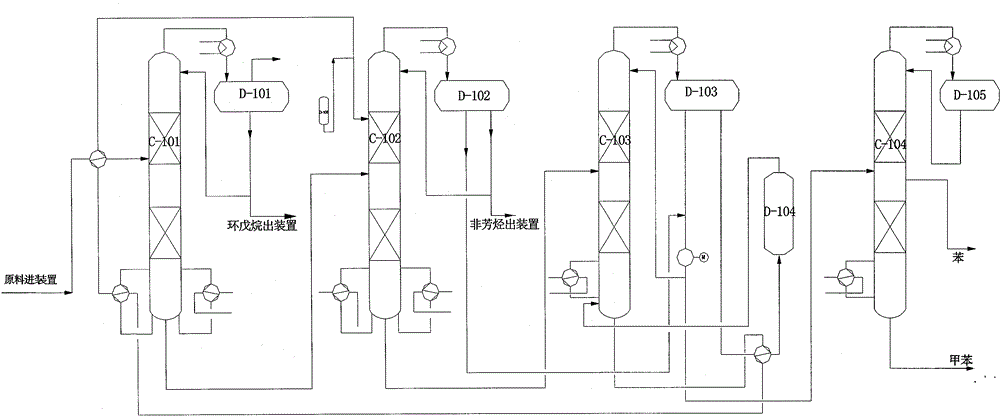

[0015] The energy-saving production process for extracting aromatics is composed of a depentanizer, an extractive distillation tower, a solvent recovery tower, a benzene tower four-tower system and other auxiliary devices. The raw material enters the depentanizer C-101 after being preheated, and cyclopentane is removed at the top of the depentanizer, and the bottom material enters the extractive distillation tower C-102 and the solvent fed from the side line of C-102 for mixed extraction , the top of the extractive distillation tower removes non-aromatic hydrocarbons, and the liquid at the bottom of the tower enters the solvent recovery tower C-103. The solvent recovery tower strips the aromatic components from the rich solvent through the bottom reboiler, and the lean ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com