Electronic fuel oil activator

An activator and fuel technology, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problems of insignificant effect, shortened life, and interference with the normal operation of the vehicle computer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

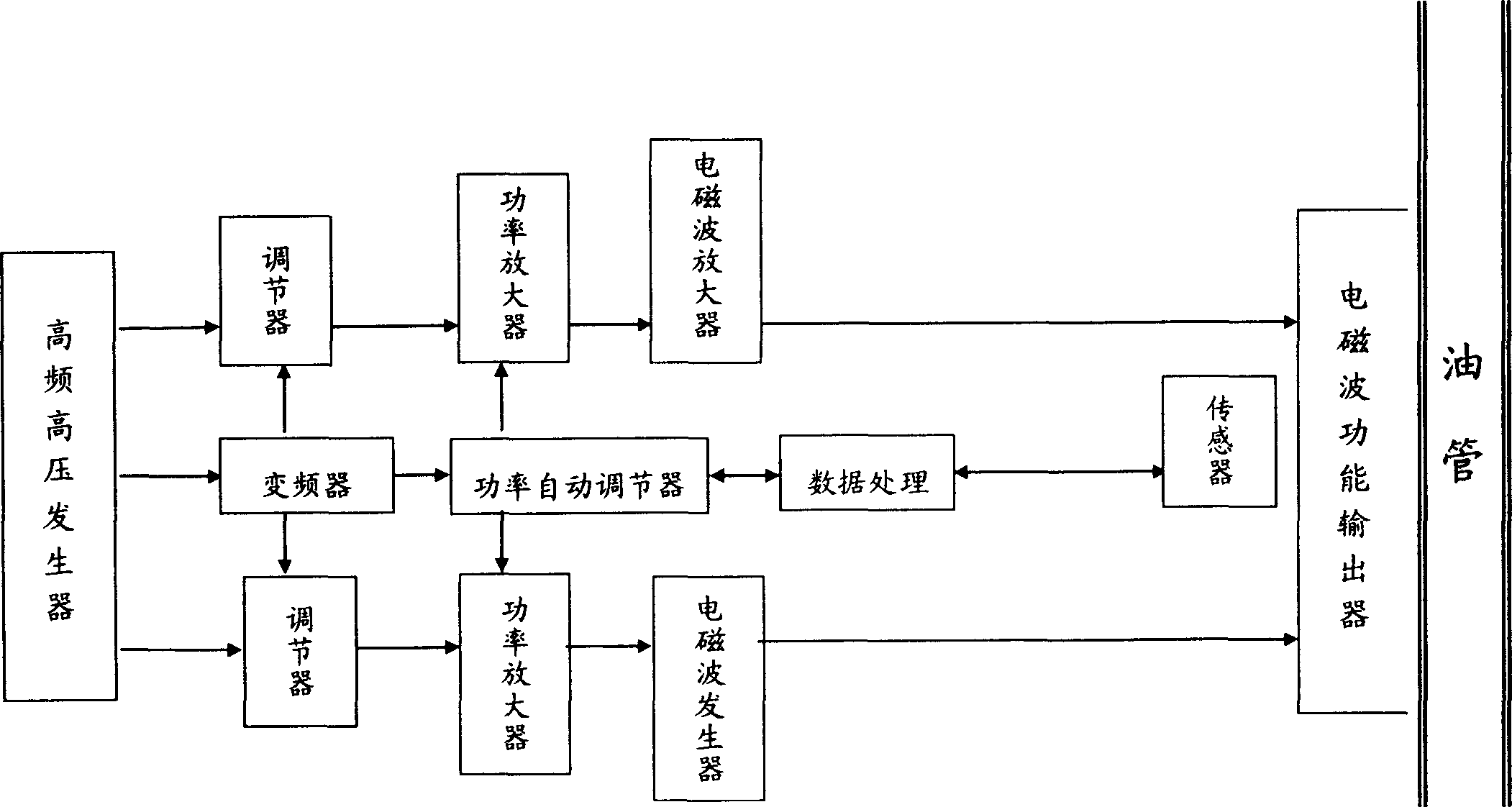

Image

Examples

Embodiment Construction

[0012] The appearance design of the electronic fuel activator of this embodiment can be designed and manufactured into any shape, any color and any connection and installation method according to the installation requirements, and is used for any fuel engine. Its connection and use only need to fix the device near the oil inlet pipe of the gasoline engine near the carburetor or the oil inlet pipe of the EFI chamber, and near the oil inlet pipe of the high-pressure oil pump for the diesel engine. On the oil path of the above-mentioned oil inlet pipe, one end is connected and fixed with the oil inlet pipe with an oil-resistant and pressure-resistant oil pipe, and the other end is connected and fixed with the oil inlet hose of the original machine. The negative wires of the two power cables are connected to any iron wires and screws in the engine room of the engine casing, or directly connected to the negative pole of the battery. The positive line can be connected to the positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com