Novel in-line pump dedicated motor

A technology for special motors and pipeline pumps, applied in electromechanical devices, electrical components, electric components, etc., can solve problems such as the weight of the rotor should not be too large, the heat dissipation effect of the bearing pad is poor, and the oil film cannot be formed, so as to achieve improved operation stability and noise reduction Effect improvement, heat reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

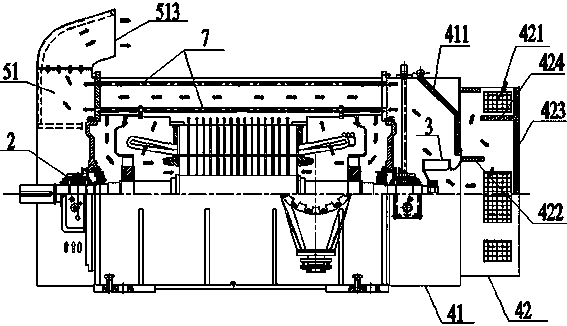

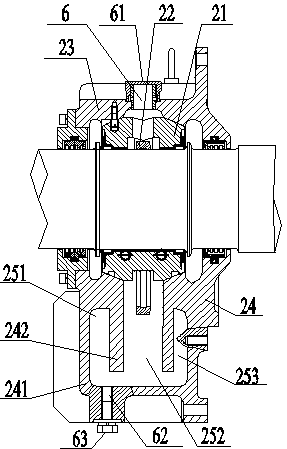

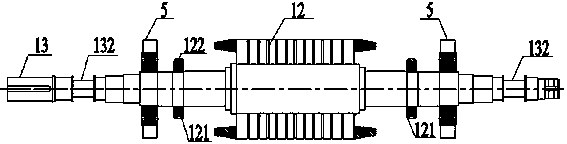

[0031] The invention provides a new type of special motor for pipeline pumps, such as Figure 1 to Figure 6 shown. The special motor for the new pipeline pump includes a machine base 1, an inner fan 5, a stator 11 installed in the machine base 1, and a rotor 12 installed in clearance with the stator 11. The rotor 12 is fixedly installed on the rotating shaft 13, and the outer circumference of the stator iron core is on the The machine base is fixed with a plurality of cooling pipes 7 arranged axially through, and the cooling pipes 7 communicate with the air outlet cover 51 arranged at the shaft extension end; the front and rear ends of the machine base 1 are respectively provided with end covers , a bearing device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com