Self-elevating drilling platform and automatic uniform-load planet differential lifting device thereof

An automatic load equalization and drilling platform technology, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as equipment damage, poor load equalization capacity and operation stability, troublesome installation, manufacturing and maintenance, and facilitate installation and maintenance and maintenance, strong automatic load balancing capacity, and good running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

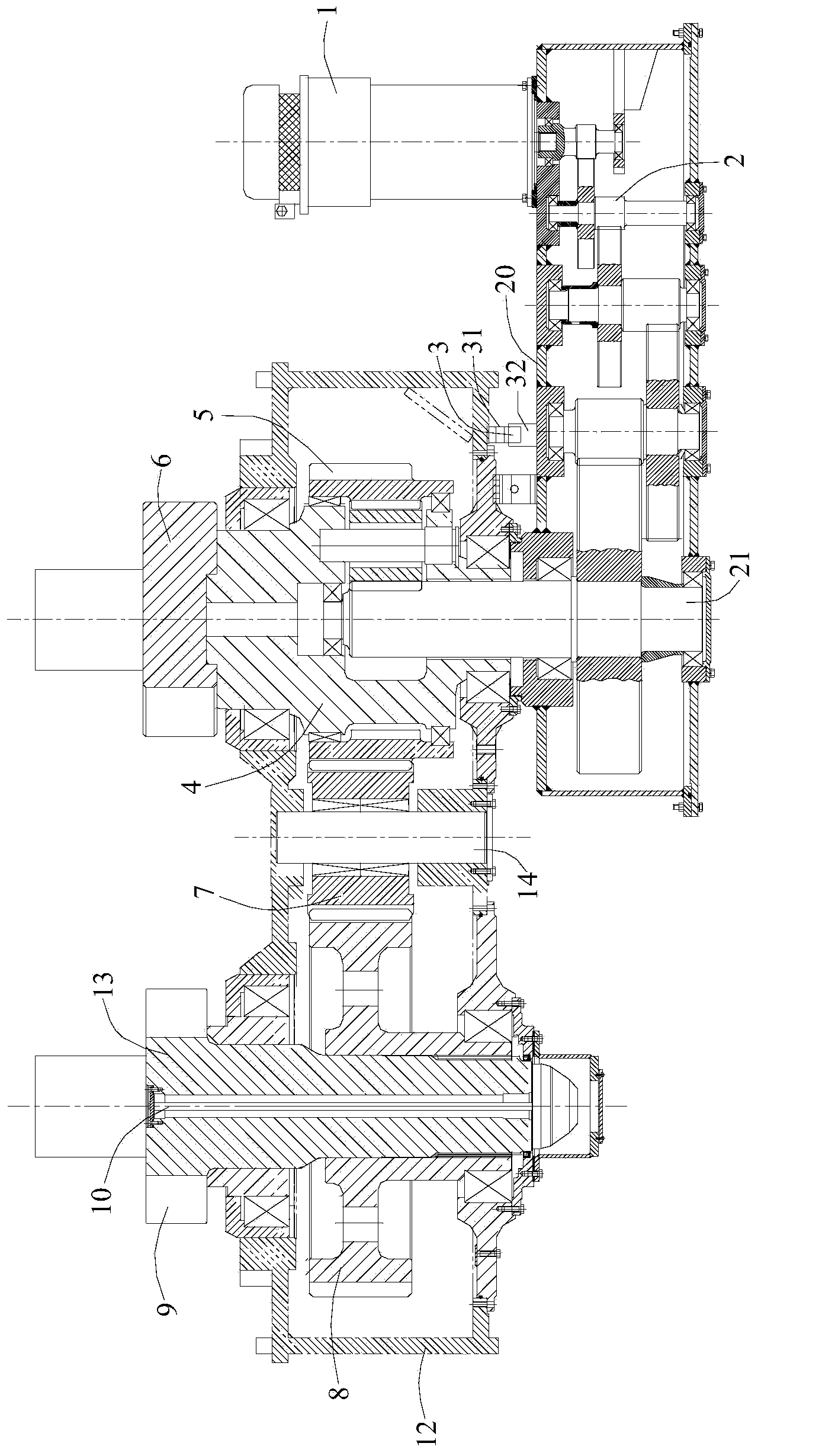

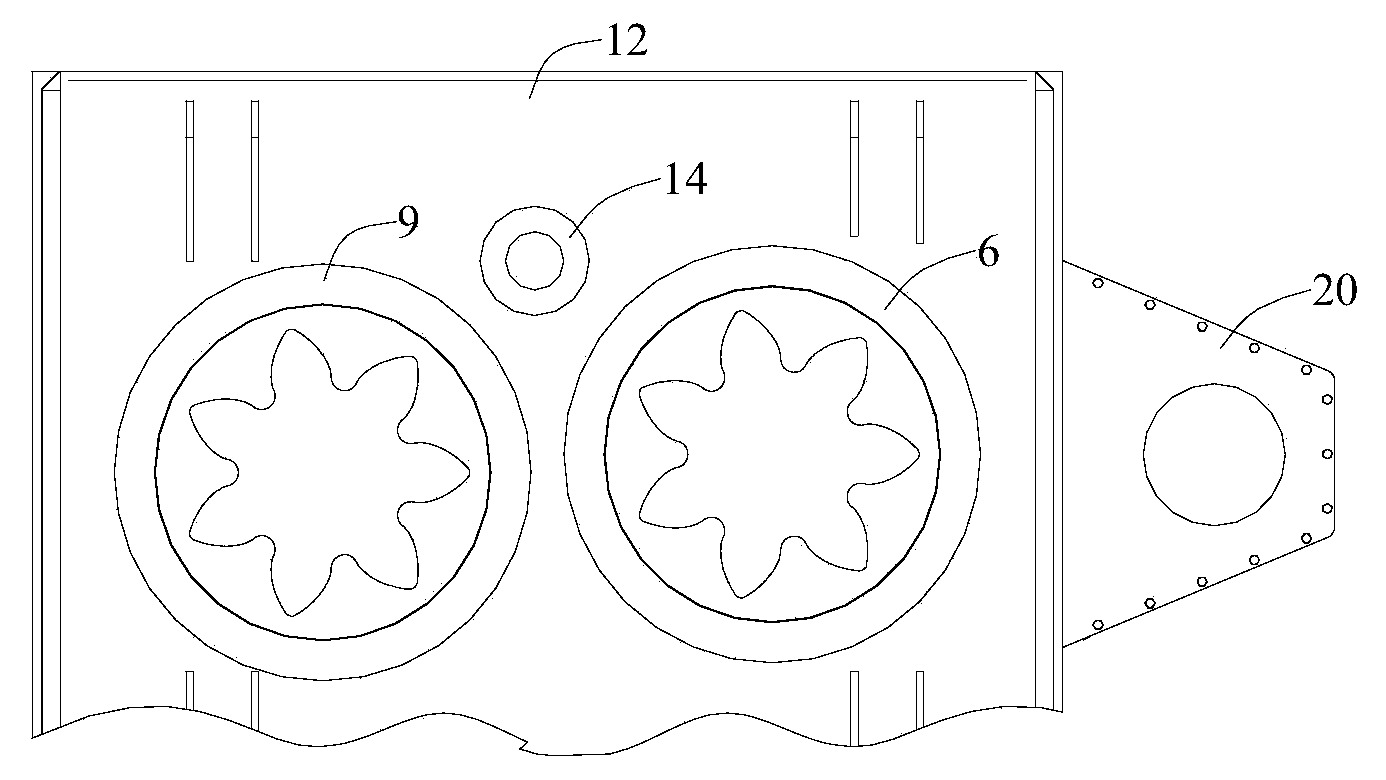

[0023] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not intended to limit the present invention .

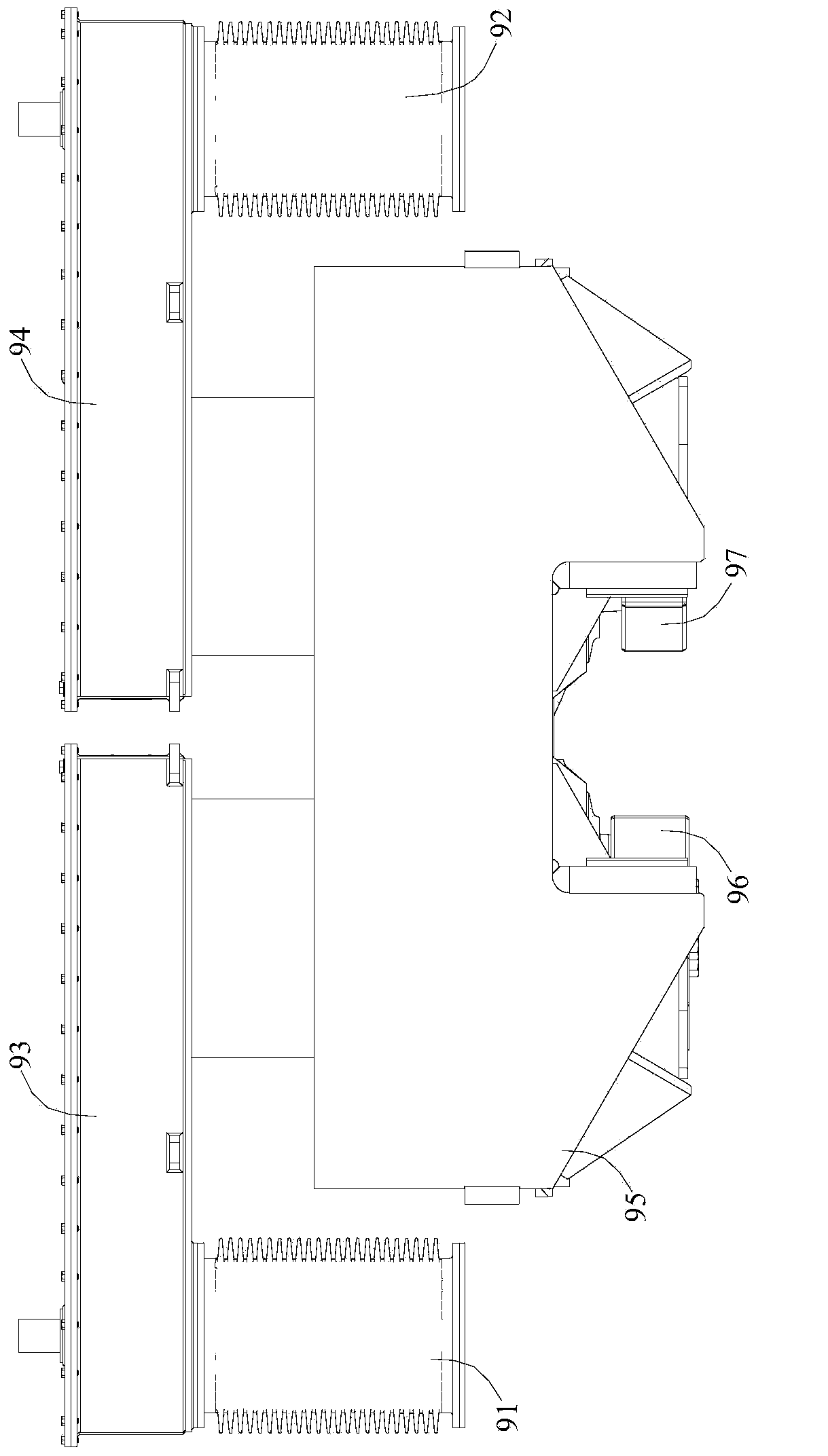

[0024] The automatic equalizing planetary differential lifting device of the embodiment of the present invention can be used in the jack-up drilling platform of the embodiment of the present invention. The jack-up drilling platform of the embodiment of the present invention has the automatic equalizing planetary differential of the embodiment of the present invention Lifting device.

[0025] The following describes in detail the automatic equal load planetary differential lifting device of the embodiment of the present invention.

[0026] see figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com