Quartz glass slicer

A quartz glass and slicing machine technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of restricting the development of the quartz glass processing industry, poor straightness of the saw edge, and high labor intensity, saving raw materials, The effect of reducing waste and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

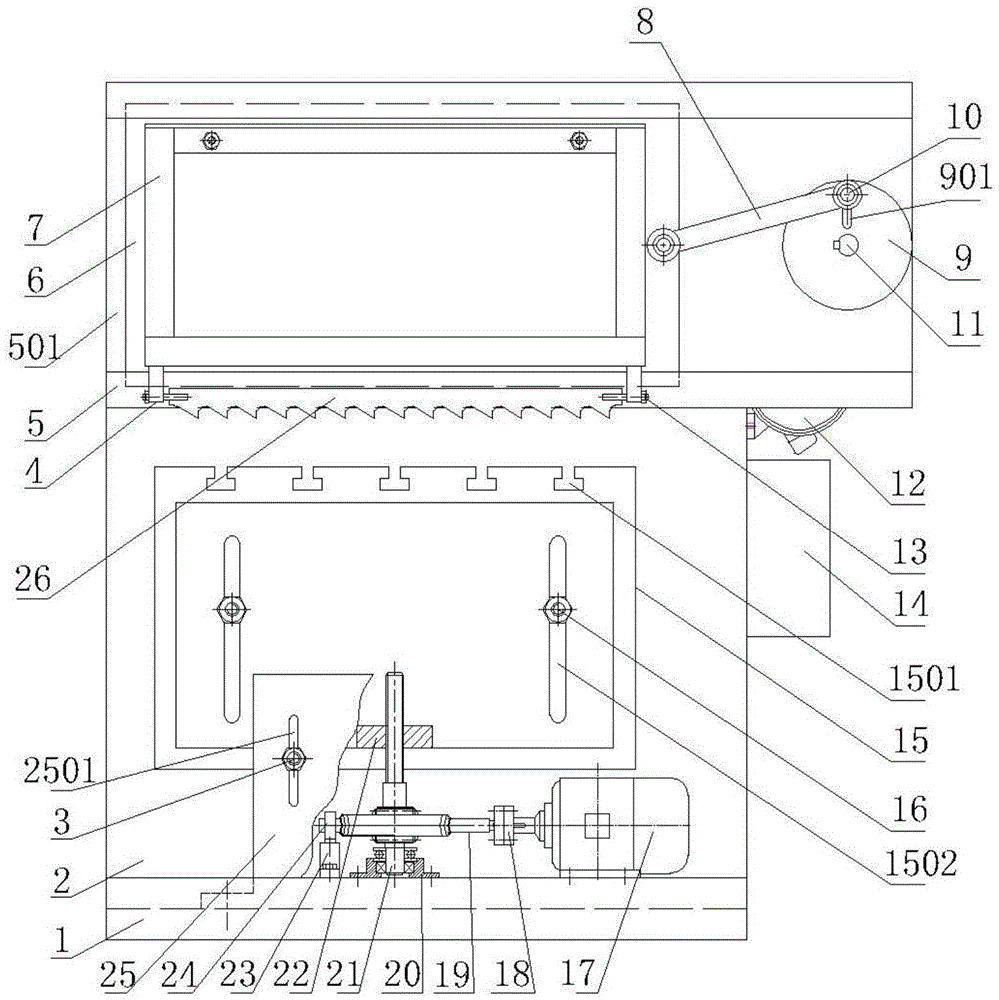

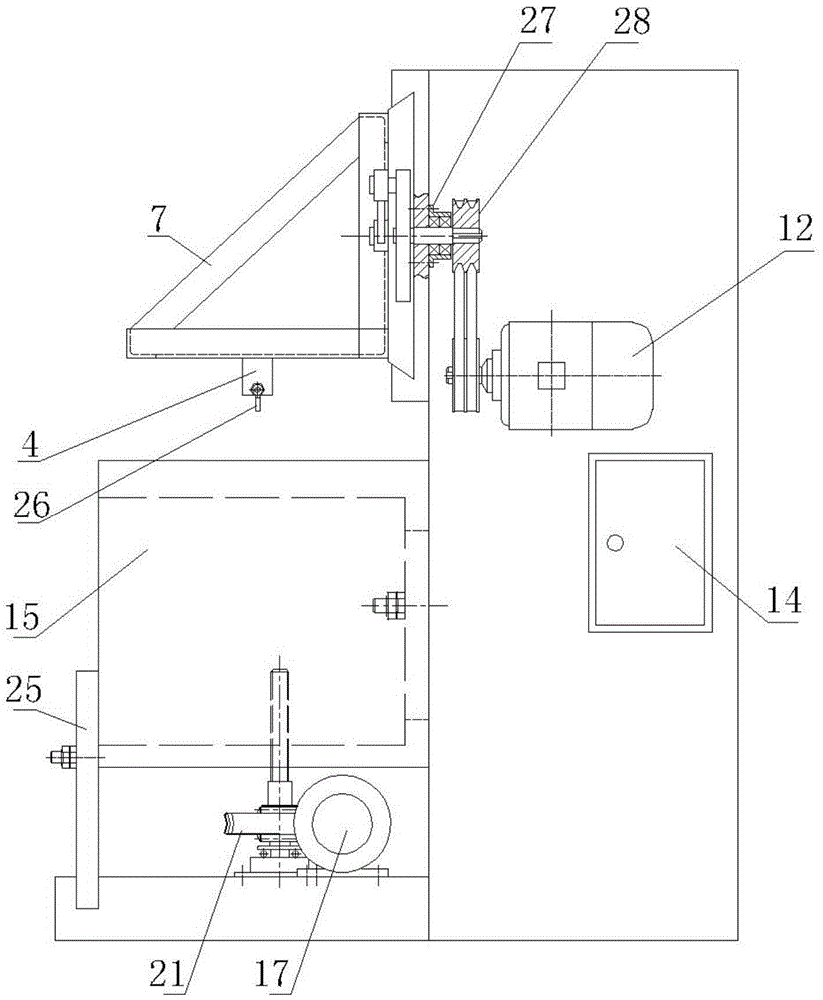

[0018] Such as figure 1 with figure 2 As shown, a quartz glass slicer according to the present invention includes a body 2, which is a casting and hollow structure, and a base 1 is fixedly connected to the lower end of the front of the body 2. The upper part of the front of the body 2 is fixed with a slideway seat 5 with a slideway 501 inside, the slideway 501 is a dovetail groove, and a slide plate 6 is arranged in the slideway 501 of the slideway seat 5. 6. The section is trapezoidal and fits with the sliding clearance of the slideway 501. One end of the slideway seat 5 is provided with a crank linkage mechanism, and a drive motor 12 is fixed on one side of the crank linkage mechanism on the body 2 top, and the crankshaft 11 of the crank linkage mechanism passes through the slideway seat 5 and is connected to the drive motor. 12 transmission connections, the free end of the connecting rod 8 of the crank linkage mechanism is hinged at the middle part of one end of the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com