Welding equipment of plastics acidic bath and welding process thereof

A technology of welding equipment and plastic acid, which is applied in the field of welding equipment for plastic pickling tanks and its welding process, can solve the problems of affecting the service life of pickling tanks, poor welding quality, and inability to guarantee welding quality, etc., and achieves equipment installation. , long service life, beautiful shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

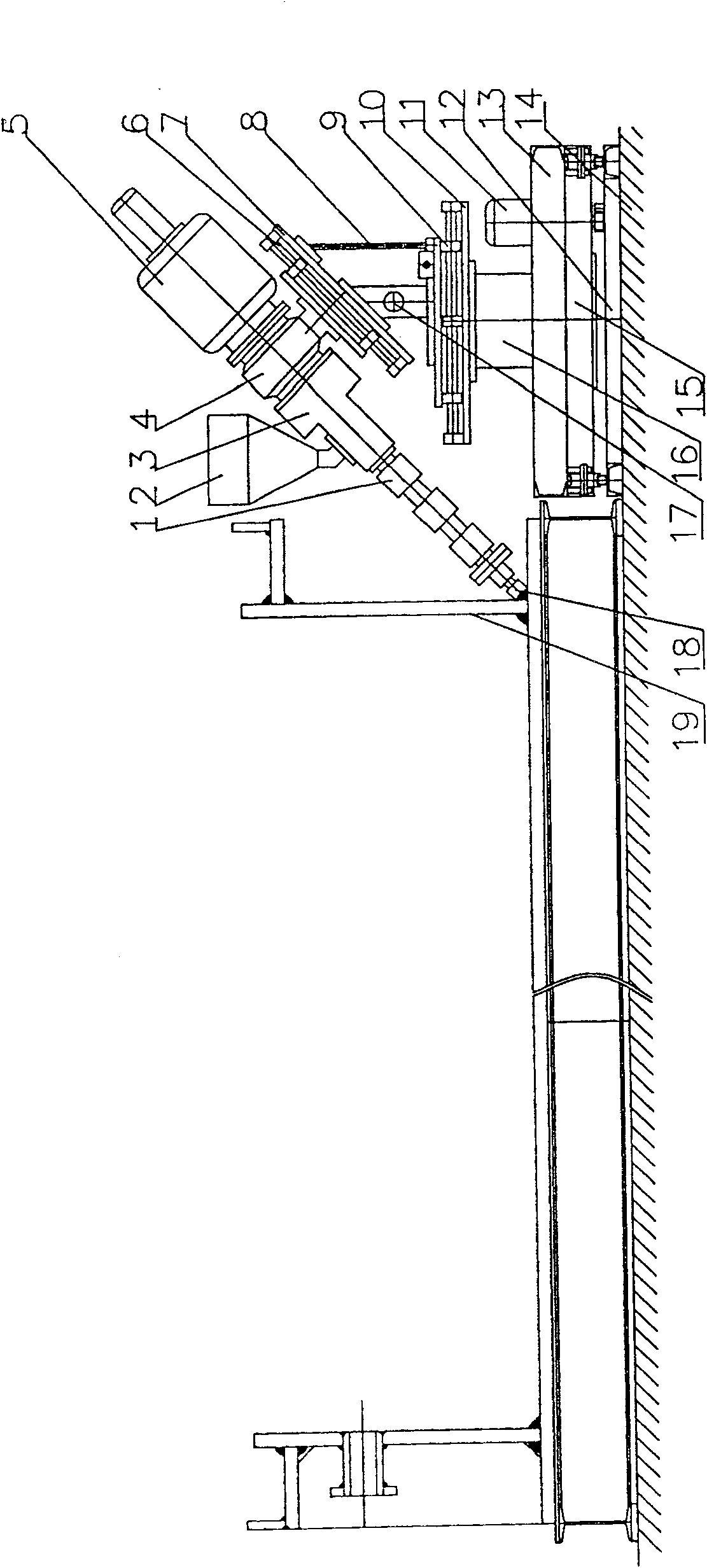

[0024] The specific implementation manner of the present invention will be further described below in conjunction with the examples given in the accompanying drawings.

[0025] Such as figure 1 As shown, according to the welding equipment of the plastic pickling tank of the present invention, it is characterized in that by the workbench 14, the track 12 that is located on this workbench 14, and the walking trolley that rolls or slides with this track 12 is located at this The support 13 on the walking trolley, the horizontal sliding mechanism that is located on this support 13, the inclined sliding mechanism that is connected with the horizontal sliding mechanism on this support 13 by adjusting screw rod 8, the welding that is located on this inclined sliding mechanism device consists of.

[0026] Described horizontal sliding mechanism is made up of the support 16 that is connected with described support 13, the plane bottom plate 10 that is arranged on this support 16, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com