Patents

Literature

53results about How to "No undercut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photosensitive resin composition for black matrix

InactiveUS20080220372A1No undercutNo white dot defectPhotosensitive materialsPhotosensitive materials for photomechanical apparatusArylHalogen

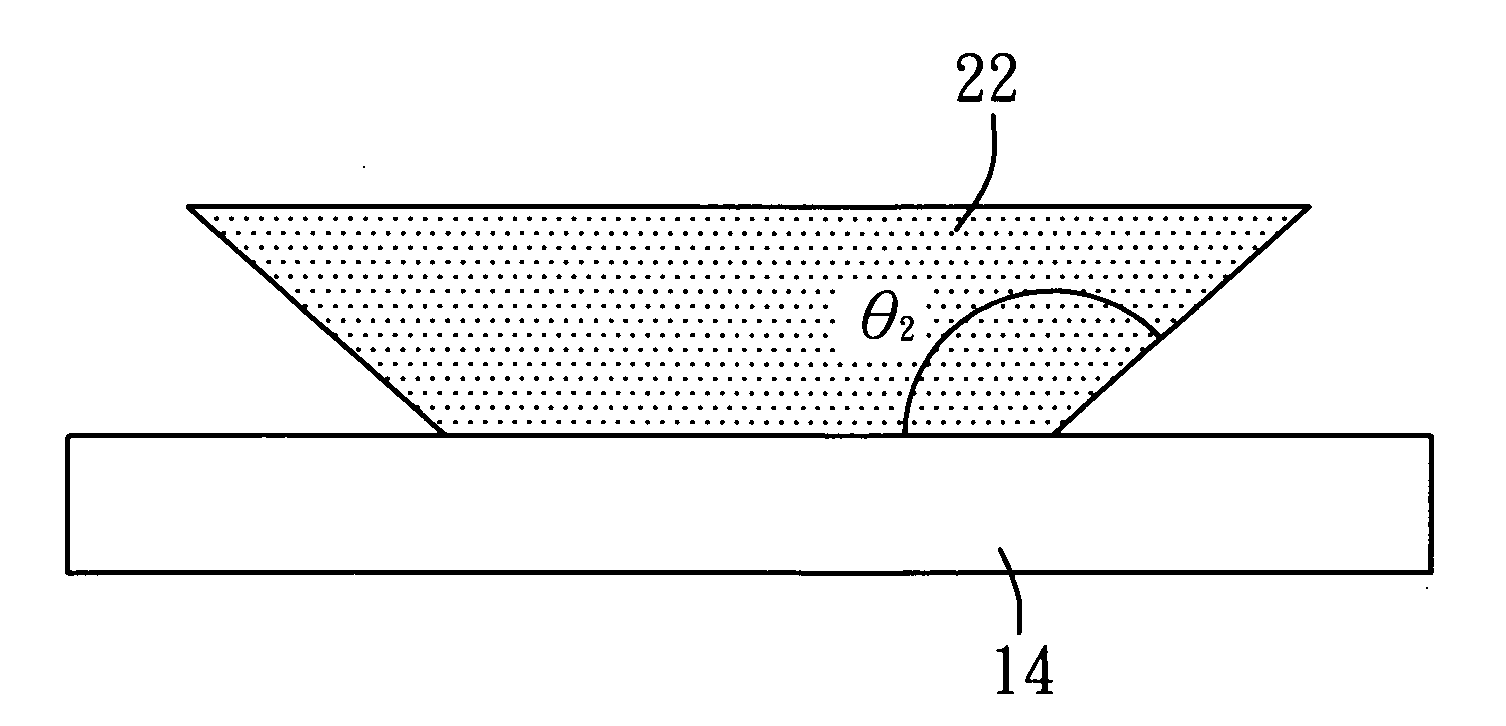

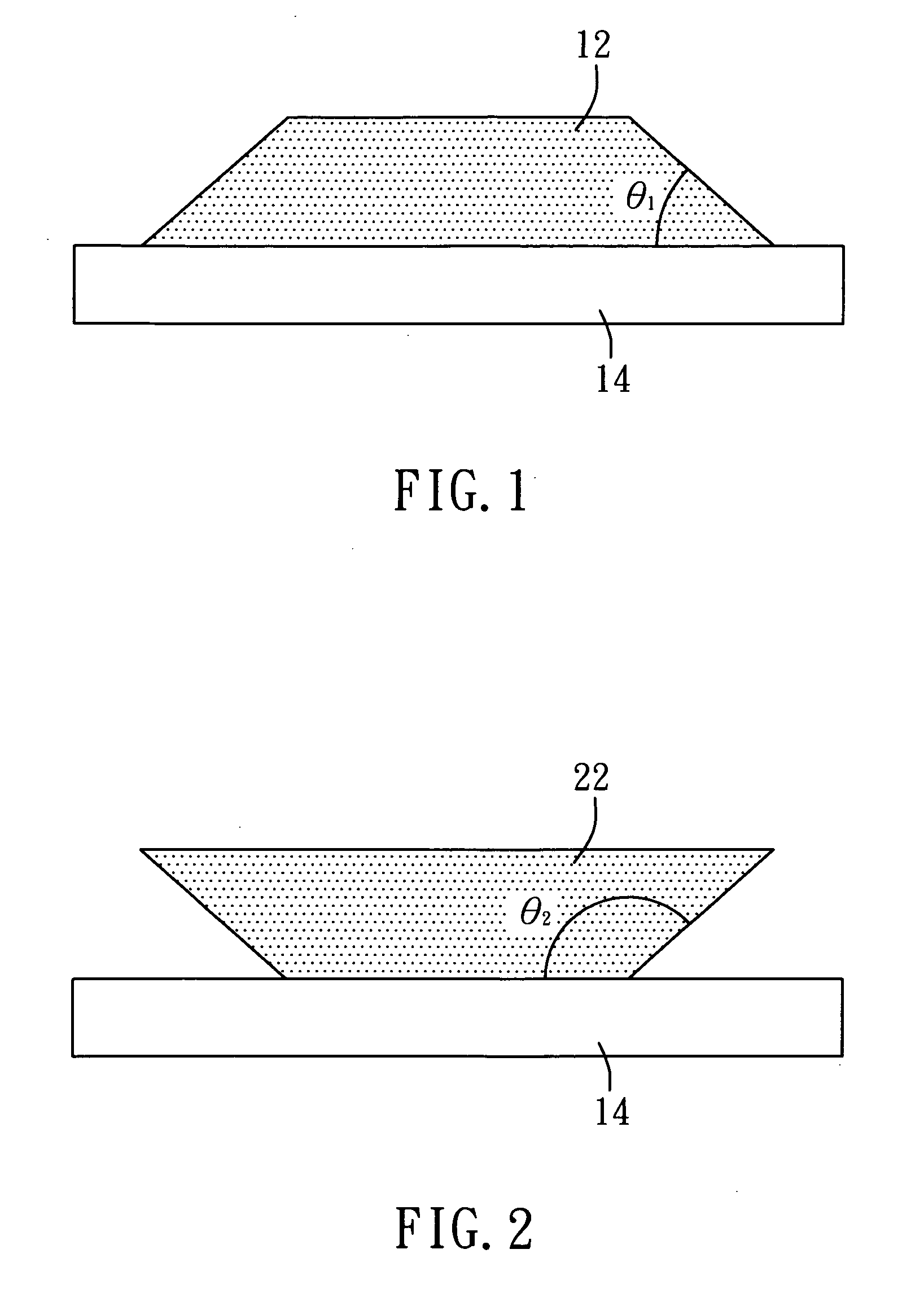

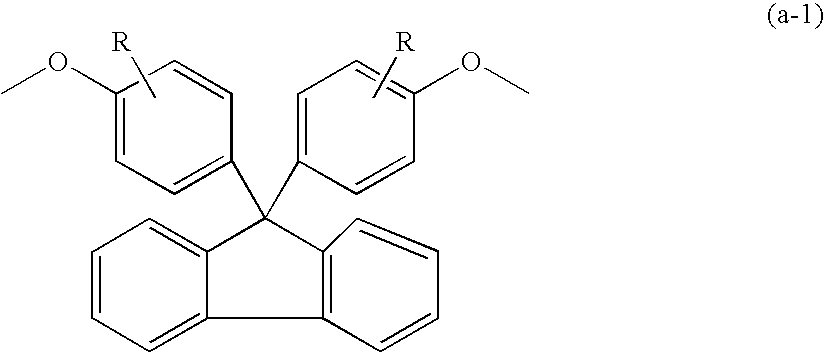

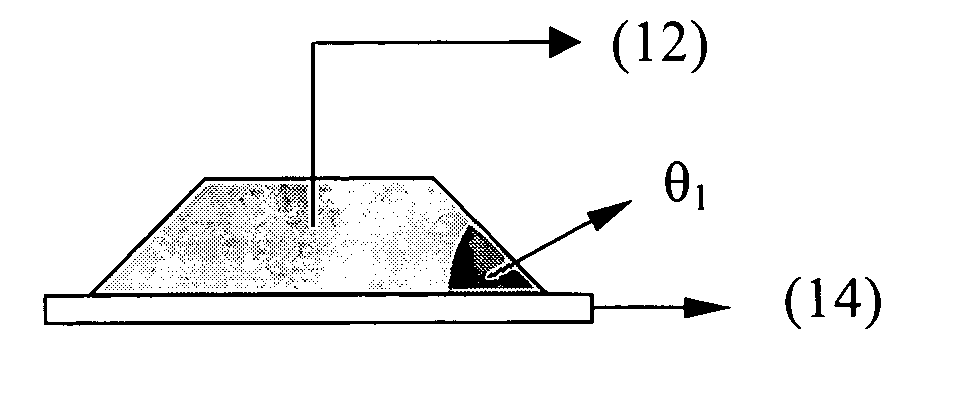

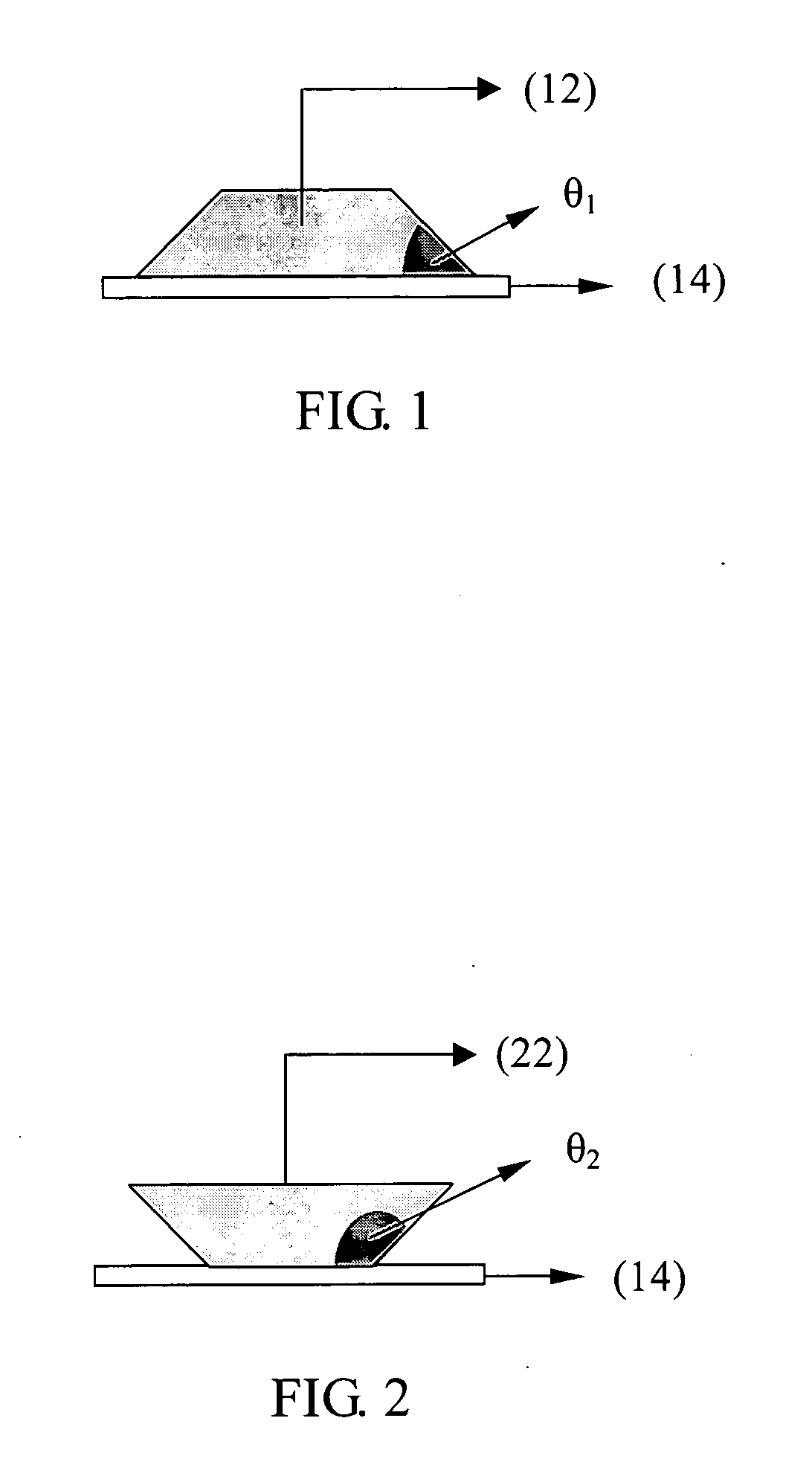

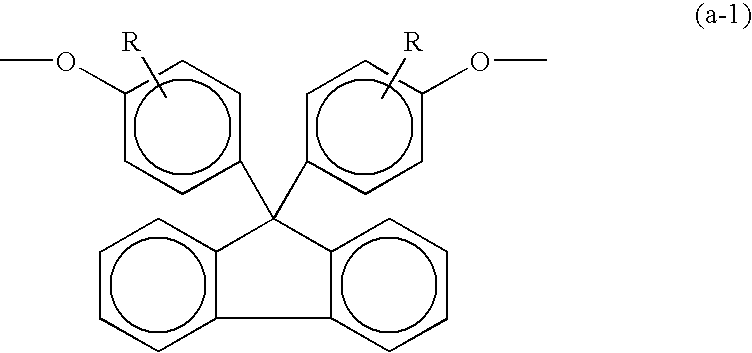

The present invention discloses a photosensitive resin composition for black matrix, which shows no undercut after development. The photosensitive resin composition comprises (A) an alkali-soluble resin, (B) a photopolymerizable monomer, (C) a photoinitiator, (D) a solvent, and (E) a black pigment; wherein the alkali-soluble resin (A) comprises a functional group having a general formula (a-1);(each R is independently H, linear or branch alkyl of C1-C5, phenyl, or halogen.) wherein a photoinitiator having a general formula (c-1)(Z1 is selected from the group consisting of Ra, Rb—S, Rc-O, wherein each of Ra, Rb, Rc is independently H, alkyl or aryl; Z2 is H, alkyl of C1-C4, or halide.), wherein the moisture content of said photosensitive resin composition is less than 3,000 ppm, and the optical density value of said black matrixis is greater than 4.0.

Owner:CHI MEI CORP

Photosensitive resin composition for black matrix

InactiveUS20050175930A1High formIncrease photosensitivityOptical filtersPhotosensitive material auxillary/base layersArylPolymer science

The present invention discloses a photosensitive resin composition for black matrix, which shows high photosensitivity and forms a pattern with good smoothness of edge, high resolution, no undercut and free of peeling after development. The photosensitive resin composition comprises (A) an alkali-soluble resin, (B) a photopolymerizable monomer, (C) a photoinitiator having a general formula (c-1), (D) a solvent, and (E) a black pigment; wherein the alkali-soluble resin (A) comprises a functional group having a general formula (a-1); (Each R is independently H, linear or branch alkyl of C1-C5, phenyl, or halogen.) (Z1 is selected from the group consisting of Ra, Rb-S, Rc-O, wherein each of Ra, Rb, Rc is independently H, alkyl or aryl; Z2 is H, alkyl of C1-C4, or halide.)

Owner:CHI MEI CORP

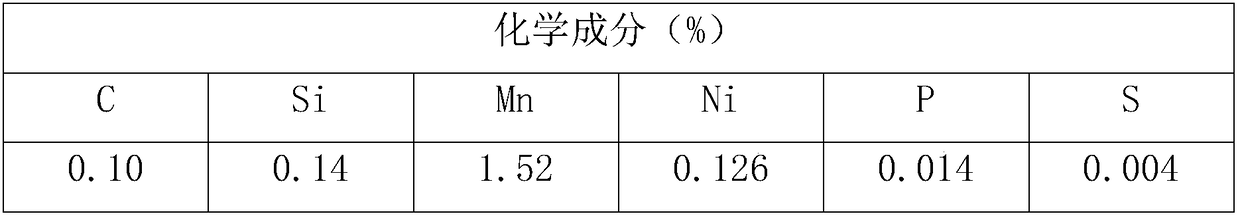

Submerged arc welding wire of high tensile pipeline steel

ActiveCN101905391AHigh yield strengthQuality improvementArc welding apparatusPipeline systemsCrack resistanceSheet steel

The invention discloses a submerged arc welding wire of a high tensile pipeline steel. The welding wire material comprises the following chemical components in percentage by weight: not more than 0.10 of C, not more than 0.6 of Si, 1.3-1.8 of Mn, 1.4-2.5 of Ni, 0.25-0.55 of Mo, not more than 0.12 of Ti, not more than 0.05 of V, not more than 0.35 of Cr, 0.0005-0.005 of B, not more than 0.015 of S, not more than 0.015 of P, and the balance of Fe and other inevitable impurities. The submerged arc welding wire of the high tensile pipeline steel provided by the invention has the yield strength of deposited metals of more than 690MPa and the tensile strength of more than 785Mpa, has attractive welding formation, high intensity, high flexibility and high crack resistance without defects of cracking, undercut and the like, and has favorable matching effect with X100 level pipeline steel plates, and meets the requirement on the welding of oil-gas transmission pipelines under the condition of higher pressure.

Owner:YICHANG MONKEY KING WELDING WIRE

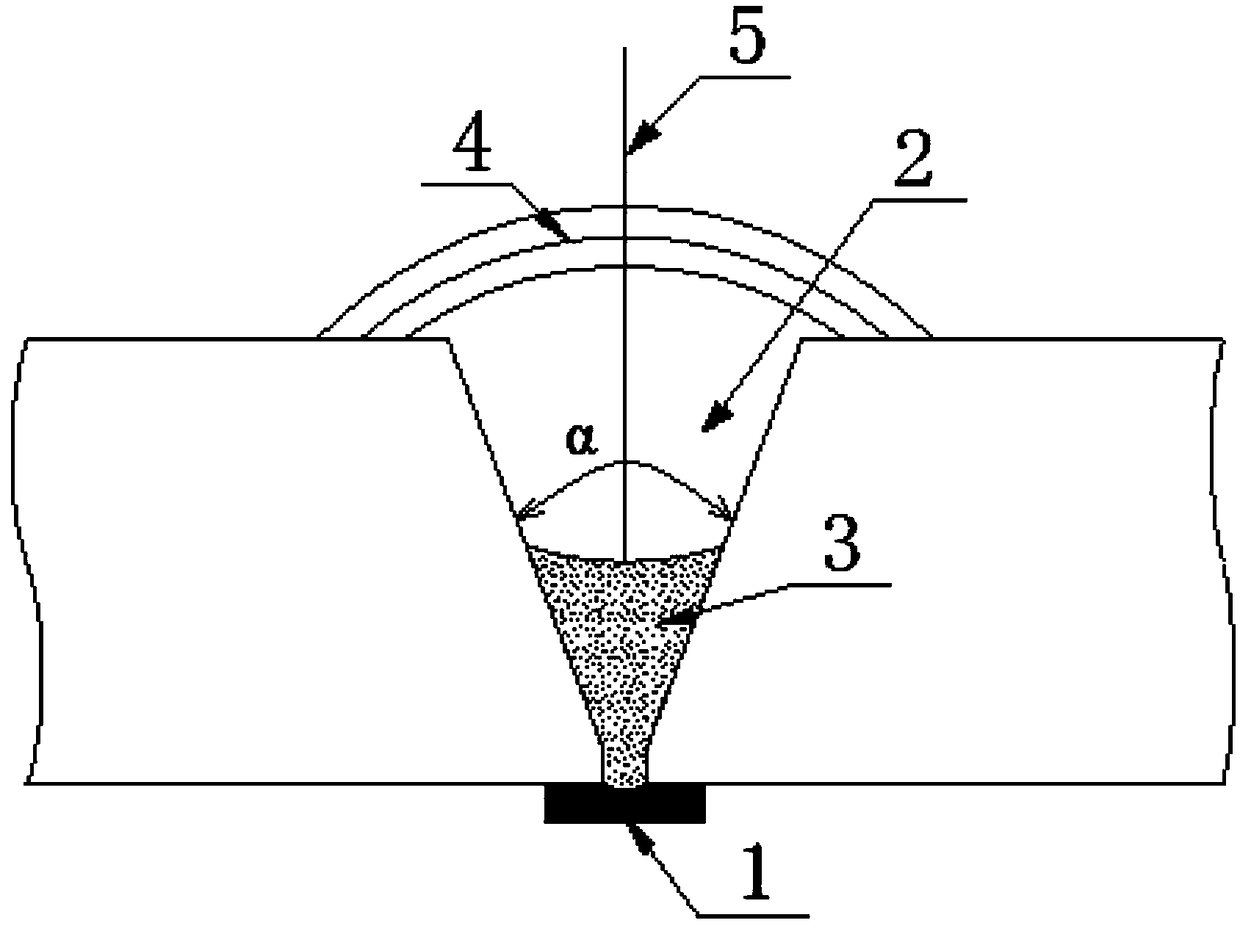

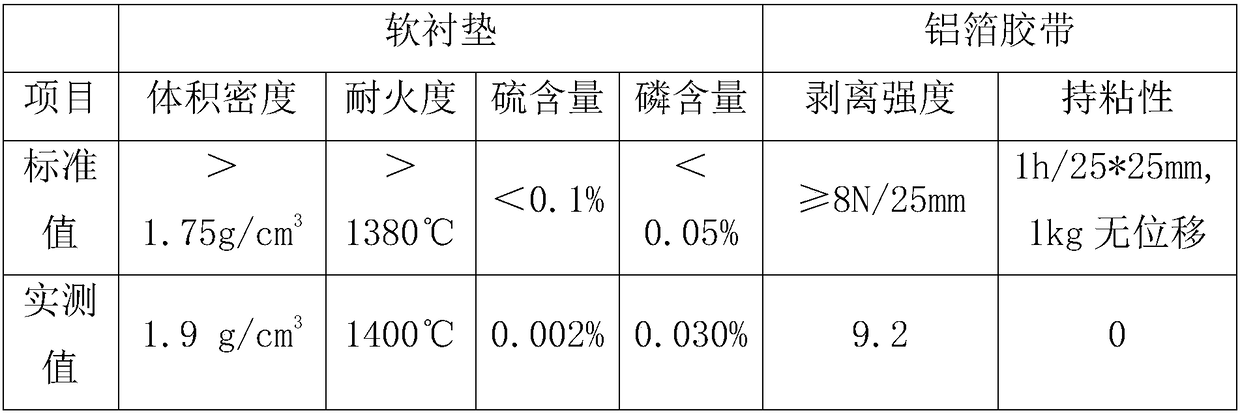

Sintered flux utilized in automatic submerged arc welding with multiple wires in high speed

InactiveCN1415454AGood composition uniformityImprove low temperature toughnessWelding/cutting media/materialsSoldering mediaWeld seamSoldering process

A sintering welding wire for the multi-wire high-speed autoamtic hidden arc welding contains MgO (19-28 mass%), CaF2 (12-18%), ZrO2 (8-15%), Al2O3 (18-24%), SiO2 (17-25%), CaO (7-13%), RE (0-7%), MnO (0-5%), TiO2 (0-5%), Na2O+K2O (2-5%), S (0-0.05%), and P (0-0.06%). Its advantages are stable arc, beautiful welded seam, and high welding speed (1.5-2 m / m).

Owner:YANSHAN UNIV

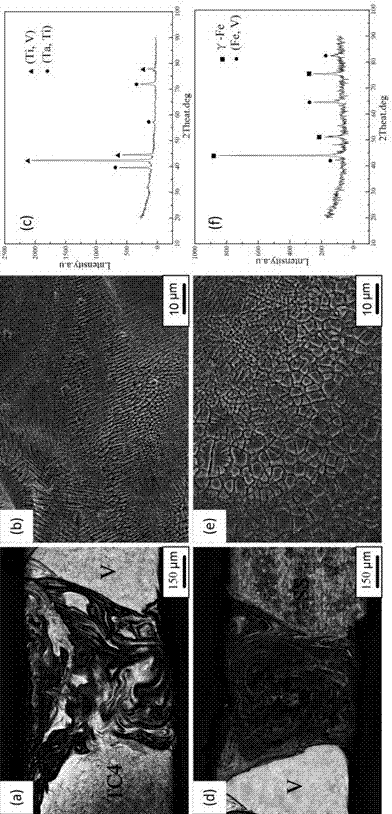

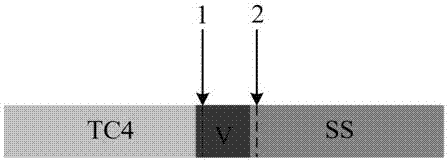

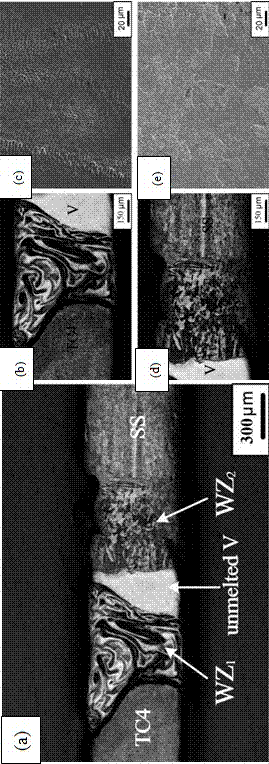

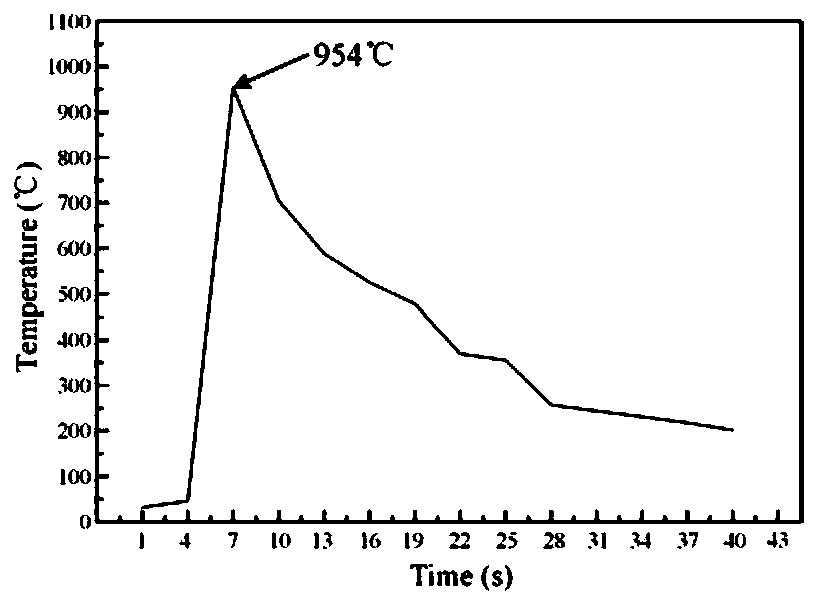

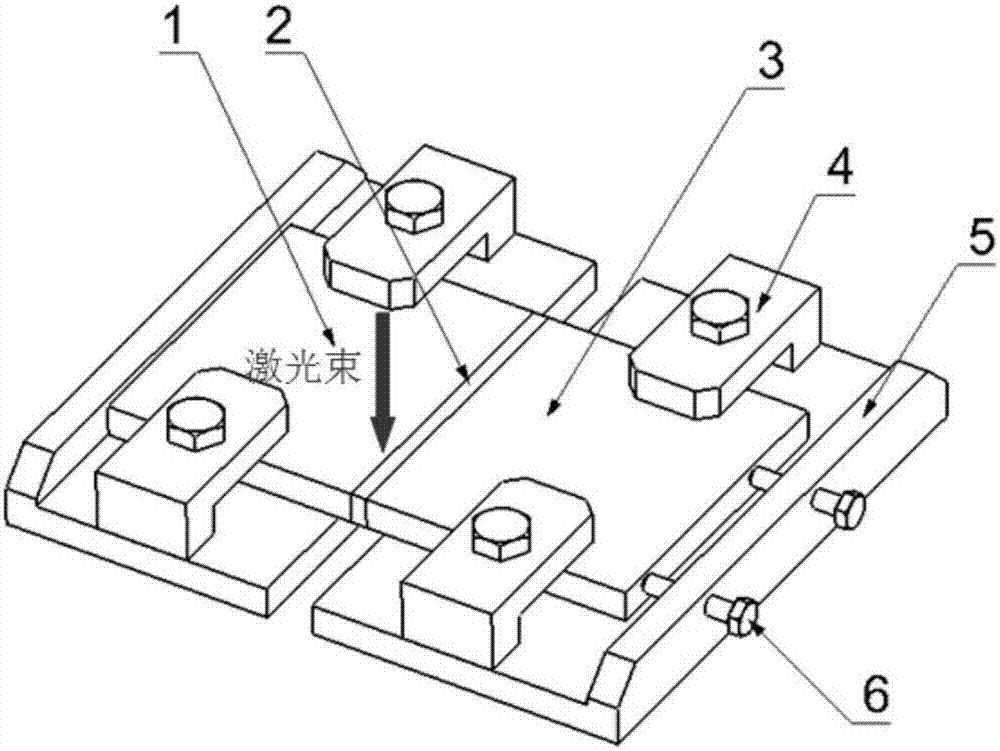

Laser welding method of titanium alloy-stainless steel dissimilar metal by adopting composite intermediate layer

ActiveCN107127454AEasy to shapeAvoid unfusedWelding/soldering/cutting articlesLaser beam welding apparatusOmegaTitanium alloy

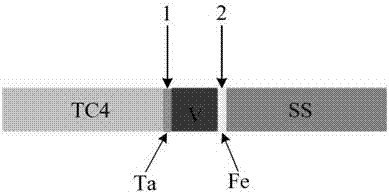

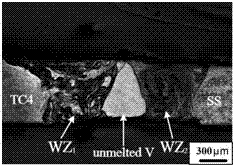

The invention relates to a laser welding method of a titanium alloy-stainless steel dissimilar metal by adopting a composite intermediate layer, and belongs to the technical field of material welding (connection). According to the method, laser is adopted as a welding heat source, and a Ta / V / Fe composite layer is used as an intermediate layer material, so that formation of an omega brittle phase in a titanium alloy-vanadium welding line and an alpha brittle phase in a vanadium-stainless steel welding line can be controlled, the joint brittleness can be reduced, and the joint performance can be improved; by adopting the two welding, a high-quality high-efficiency welding joint which is made of a dissimilar metal material and contains a titanium alloy-vanadium welding line, an unmolten vanadium layer and a vanadium-stainless steel welding line can be obtained. The process comprises the steps of plate assembling and clamping, preload adjustment of a titanium alloy-intermediate layer-stainless steel contact face, and laser welding along the center line of a Ta intermediate layer and the center line of a Fe intermediate layer, so that connection of the titanium alloy-stainless steel dissimilar metal can be realized. The method has the advantages of stable welding process, attracted welding line formation, no welding defects including crack, pore, undercutting, uncomplete welding, incomplete fusion and the like, and good welding process performance.

Owner:JILIN UNIV

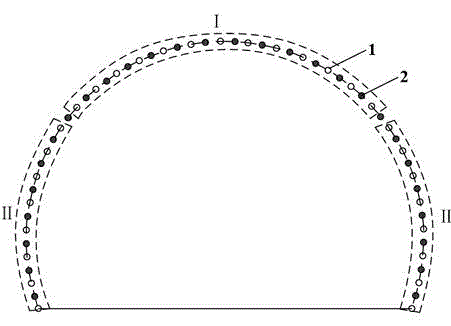

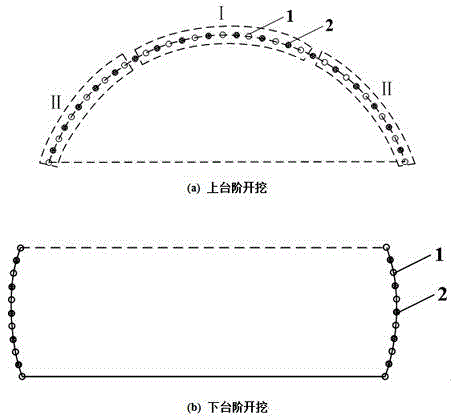

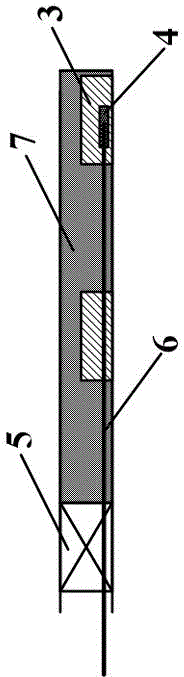

Permafrost region road tunnel peripheral hole blasting construction method

InactiveCN103983147APrevent thermal melt landslidesBlock free radical reactionBlastingDetonatorDynamite

The invention relates to the field of tunnel construction, in particular to a permafrost region road tunnel peripheral hole blasting construction method. The method comprises the following steps of step 1, according to the grade of a tunnel peripheral rock, determining a digging way and the single-circulation advanced depth; step 2, according to the position of the designed digging outline of a tunnel, drilling holes in the periphery at set intervals; step 3, after drilling the holes, cleaning the holes; step 4, filling dynamite into each blast hole, and connecting a percussion cap and a detonating cord; step 5, filling NaCl solution into each blast hole and each shock-absorbing hole, wherein each hole opening is blocked by stemming; step 6, using a blasting way to arrange a blasting network by using area-by-area blasting, blasting the peripheral holes in hole wall position areas, and then blasting the peripheral holes in the arch top. When the tunnel peripheral holes are designed, an un-coupled dynamite filling structure is adopted, and a section-to-section blasting way, a millisecond blasting way and a shock-absorbing design are adopted, so that the blasting heat is reduced, the blasting temperature of the peripheral rock is reduced, the stability of the permafrost is guaranteed, the construction cost is reduced, and construction is simply, conveniently and quickly performed.

Owner:TONGJI UNIV

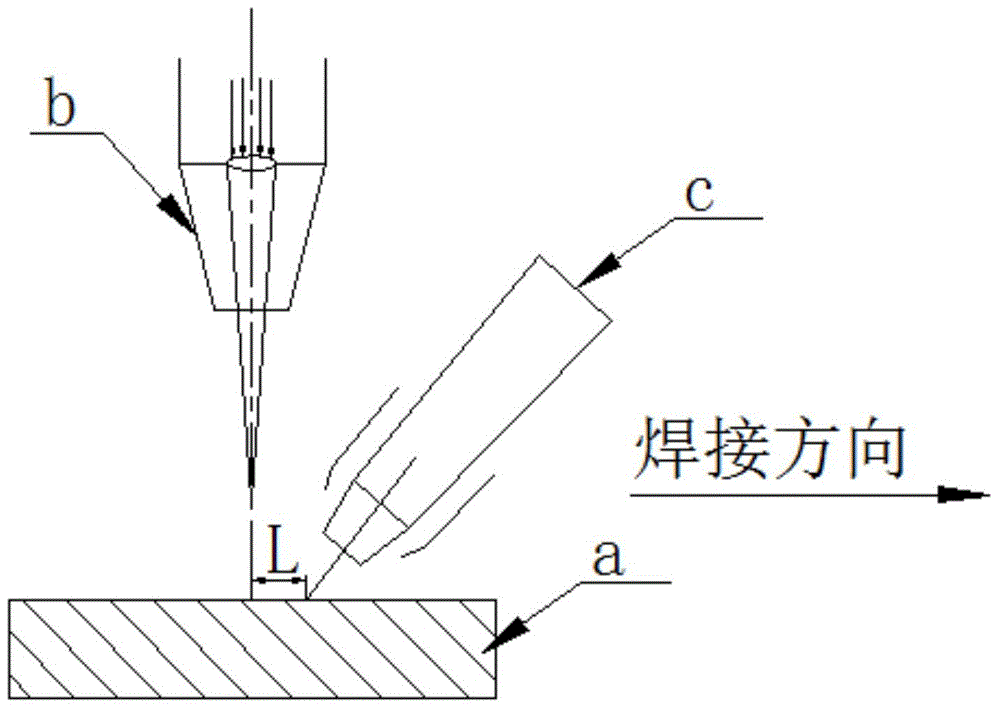

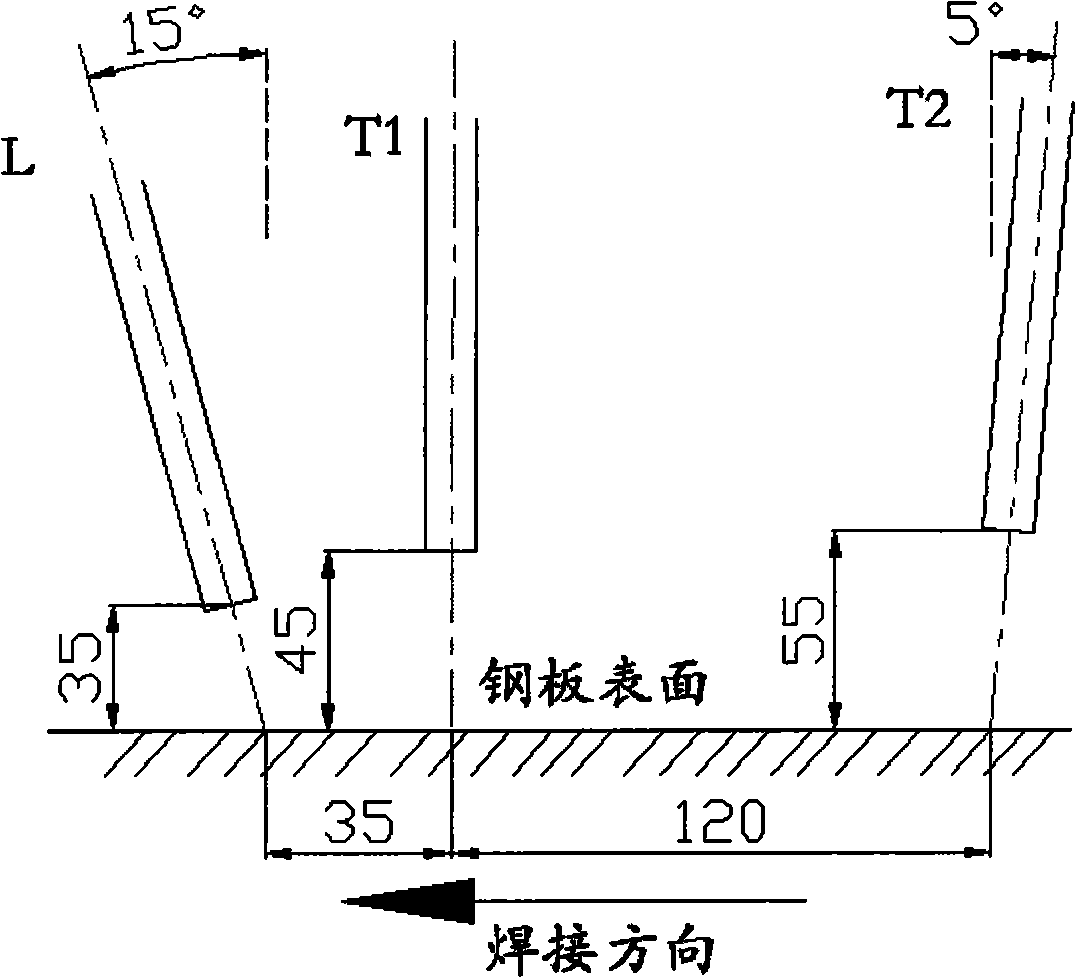

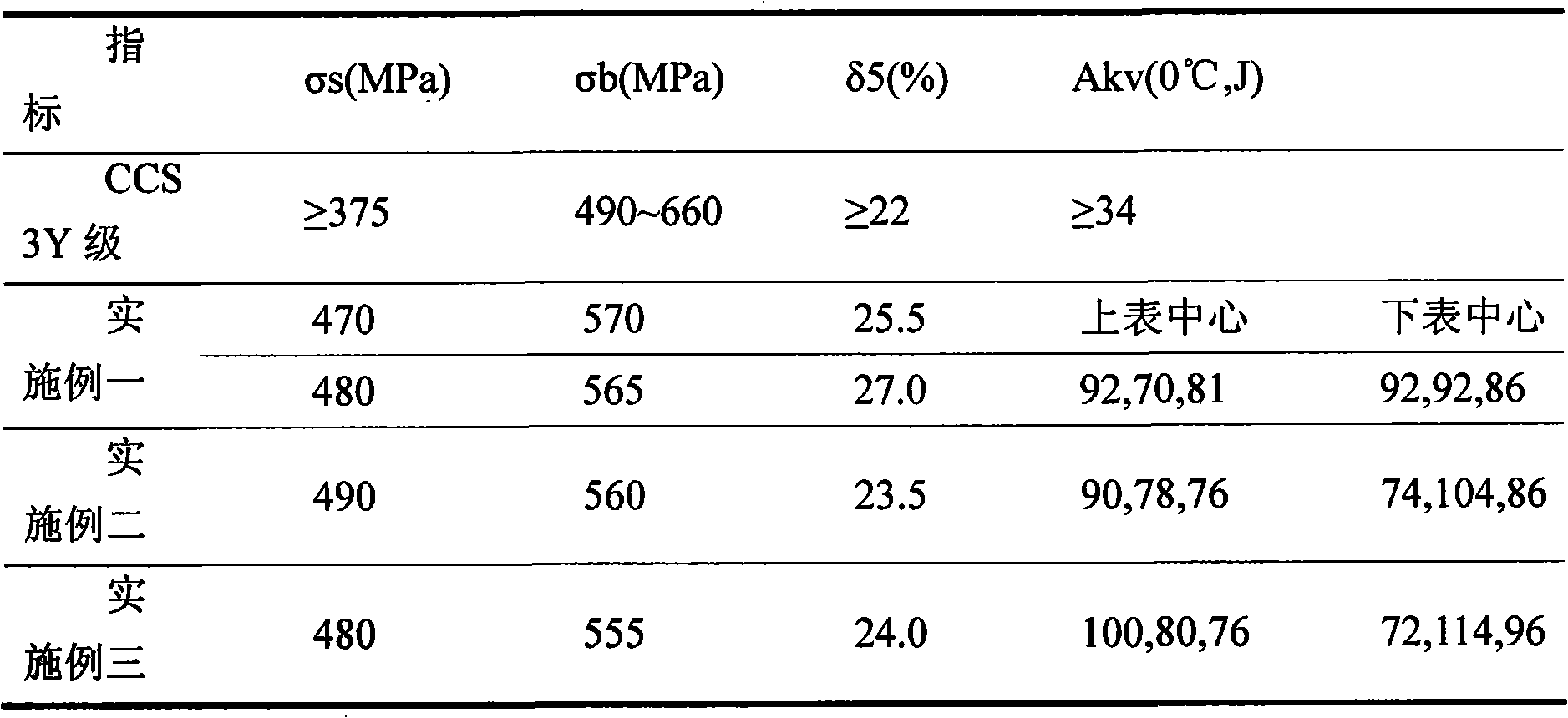

Laser and variable polarity plasma hybrid welding method for magnesium alloy with medium thickness

ActiveCN105033460AAchieve weldingStrong penetrating powerLaser beam welding apparatusShielding gasElectrical polarity

The invention relates to a laser and variable polarity plasma hybrid welding method for a magnesium alloy with a medium thickness. A laser and variable polarity plasma hybrid welding technology is adopted, variable polarity plasma welding is located on the front side of laser welding in the welding direction, the variable polarity plasma welding and the laser welding are conducted simultaneously, and a proper distance is kept between action points of the variable polarity plasma welding and the laser welding, so that welding of magnesium alloy sheets with the medium thickness is achieved; when the thickness of the magnesium alloy sheets is smaller than 25 mm, welding from one side without beveling is adopted, and the magnesium alloy sheets are completely welded in one time, the time is greatly saved, and the welding efficiency is improved; when the thickness of the magnesium alloy sheets is larger than 26 mm, welding from both sides without the beveling is adopted, and a gas mixture of argon gas and helium gas is used as protective gas to increase the depth of fusion, so that welding can be completed efficiently, and a weld joint with well formed surface and without undercuts is obtained. By means of the laser and variable polarity plasma hybrid welding method for the magnesium alloy with the medium thickness, the quality of the interior and the exterior of the weld joint can reach grade II or above grade II, and the joint strength can reach more than 0.80 of base materials.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Submerged arc sintered flux and production method thereof

InactiveCN101537550AEnsuring grain refinementStable welding arcWelding/cutting media/materialsSoldering mediaFerrosiliconRare earth

The invention relates to a hull building high efficiency welding process, and a welding technique for flux copper liner multi-filament single side automatic submerged arc welding, in particular to an automatic submerged arc welding sintered flux comprising a top surface flux and a liner flux and a production method thereof. The submerged arc sintered flux consists of the top surface flux and the liner flux. The top surface flux comprises the following components: 5 to 10 percent of CaO, 15 to 20 percent of MgO, 7 to 14 percent of Al2O3, 3 to 6 percent of MnO, 10 to 15 percent of SiO2, 5 to 10 percent of TiO2, 34 to 38 percent of Fe2O3, 2 percent of rare earth ferrosilicon, 1 percent of ferrotitanium, 0.5 percent of borax, and 0.5 percent of ferromanganese; and the liner flux comprises the following components: 15 to 20 percent of CaO, 30 to 35 percent of MgO, 5 to 10 percent of Fe2O3, 10 to 15 percent of MnO, 15 to 20 percent of SiO2, 5 to 10 percent of TiO2, and 4 to 5 percent of Na2O.

Owner:上海纪好旺造船科技发展有限公司

Welding flux for carbon steel submerged arc strip surfacing and preparation method for welding flux

InactiveCN103753046AFusion wellBeautiful shapeArc welding apparatusWelding/cutting media/materialsMetallurgyThick wall

The invention provides welding flux for carbon steel submerged arc strip surfacing and a preparation method for the welding flux, and belongs to the field of welding materials. The welding flux for carbon steel submerged arc strip surfacing comprises the following components in percentage by weight: 30-45% of SiO2, 25-35% of MgO, 8-20% of Al2O3, 8-20% of CaF2, 2-8% of CaO, 5-12% of MnO, 1-2% of Na2O and 1-2% of K2O. By using the welding flux for the carbon steel submerged arc strip surfacing and the preparation method for the welding flux, surfacing on a transition layer of the surface of carbon steel is performed by the welding flux and a welding strip, a welding process is stable, an effect of fusion between welding ways is high, residues are removed easily, surfaces of the welding ways are formed attractively, edges of welding joints are neat, and requirements of thin-walled pressure vessels such as a boiler and a nuclear power station on surfacing of the transition layer of the carbon steel can be met.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

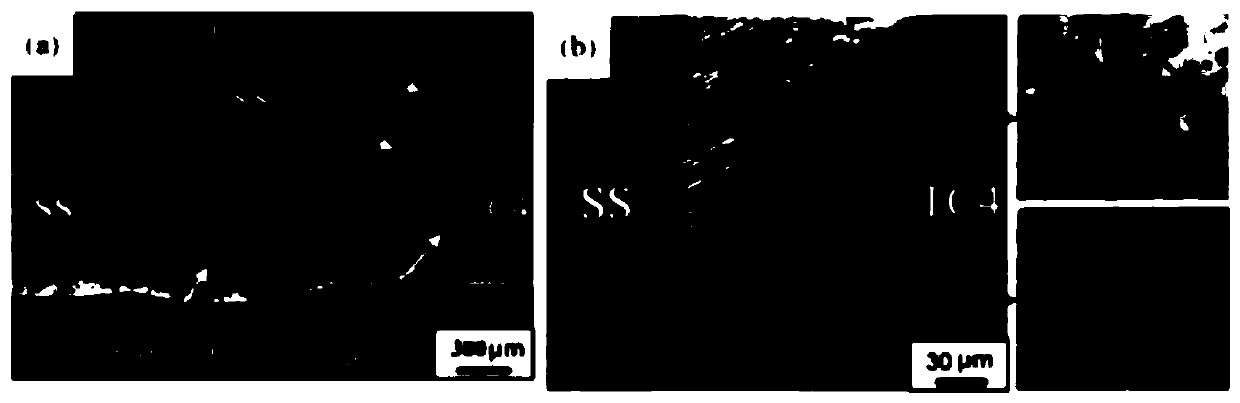

Vanadium intermediate layer-added titanium alloy-stainless steel dissimilar metal laser welding method

ActiveCN107335921AStable laser welding processBeautiful weld shapeWelding/soldering/cutting articlesLaser beam welding apparatusOmegaTitanium alloy

Owner:JILIN UNIV

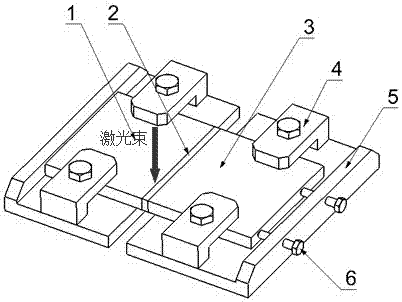

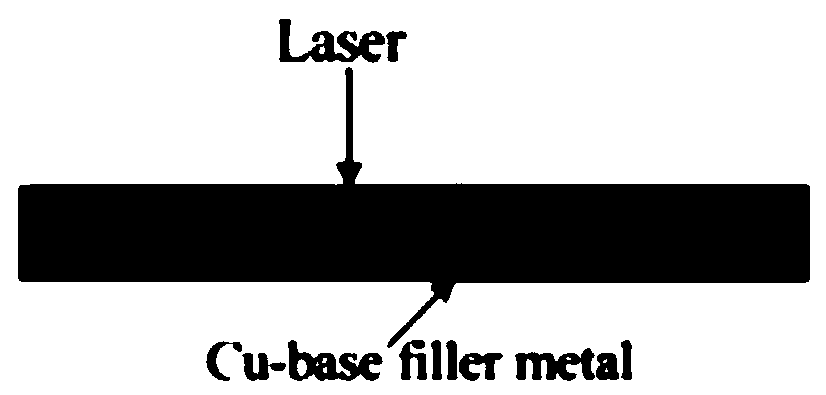

Titanium alloy-stainless steel dissimilar metal laser braze-welding method adopting copper base brazing filler metal

ActiveCN110421223AEasy to shapeAvoid unfusedSoldering apparatusWelding/soldering/cutting articlesLaser lightCopper

The invention relates to a titanium alloy-stainless steel dissimilar metal laser braze-welding method adopting copper base brazing filler metal, and belongs to the technical field of laser gun welding. Aiming at the problem that a brittle Ti-Fe intermetallic compound is produced in the titanium alloy-stainless steel dissimilar metal welding process, a laser light is adopted as a welding heat source, the copper base brazing filler metal is adopted as an interlayer material, and the formation of the Ti-Fe intermetallic compound in the titanium alloy-stainless steel welding process is avoided through laser braze-welding, so that the brittleness of a connector is reduced, and the performance of the connector is improved. By adopting laser single-pass welding, the high-quality and high-efficiency welding connector of dissimilar metal materials containing stainless steel fusion welding seams and unfused stainless steel and braze-welding seams is obtained. The titanium alloy-stainless steel dissimilar metal laser braze-welding method adopting the copper base brazing filler metal comprises the process steps of assembling and clamping a panel, adjusting a pre-tightening force of a stainlesssteel- copper base brazing filler metal-titanium alloy contact surface, focusing a laser beam on a 1.5mm part of a stainless steel plate for welding, and realizing the connection of titanium alloy-stainless steel dissimilar metal.

Owner:XINJIANG UNIVERSITY

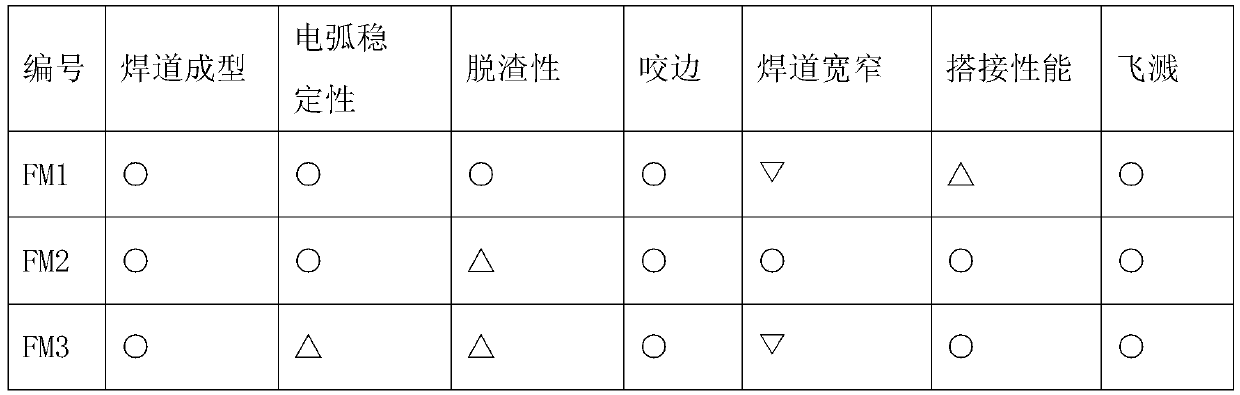

One-face welding and two-face forming welding wire with back face argon-filling-free protection

ActiveCN104191110AGood slag removalNo sticky residueWelding/cutting media/materialsSoldering mediaFerrosiliconArc welding

The invention relates to a one-face welding and two-face forming welding wire with back face argon-filling-free protection. The welding wire is formed by mixing and evenly stirring powder raw materials and sodium water glass with the weight accounting for 20% to 30% of the total weight of the powder raw materials, coating a welding core with the mixture in a pressed mode, and then drying the welding core coated with the mixture. The powder raw materials comprise, by weight, 20 parts to 40 parts of marble, 5 parts to 19 parts of fluorite, 1 part to 5 parts of titanium dioxide, 1 part to 5 parts of quartz, 2 parts to 6 parts of silicon iron, 1 part to 6 parts of ferrotitanium, 1 part to 4 parts of electrolytic manganese, 2 parts to 30 parts of rutile and 3 parts to 10 parts of chromium metal. When the welding wire carries out one-face welding and two-face forming, the coating on the surface of the welding wire will be molten to form a thin slag layer to permeate to the back face of a workpiece to carry out slag protection on welding seams, the welding technology is good in performance, whole-position welding technology performance is provided, the appearance of the welding seams is attractive, the deslagging performance is excellent, and the welding cost and difficulty can be reduced.

Owner:BEIJING JINWEI WELDING MATERIAL +1

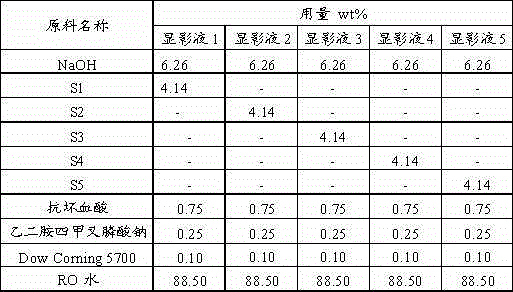

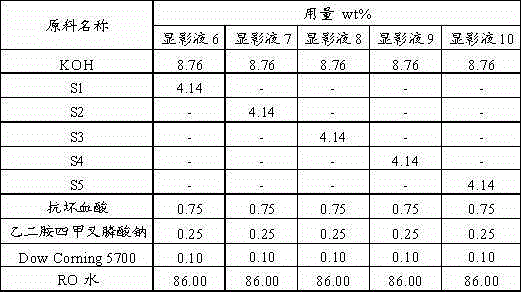

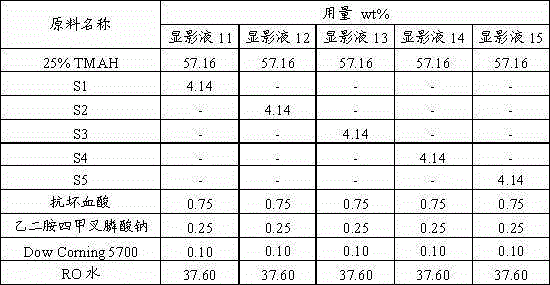

Surface active agent and developing solution used for color filter negative photoresist

InactiveCN105093862AGood developing finenessNo residuePhotosensitive material processingNon ionicPhotoresist

The invention discloses a surface active agent and a developing solution used for color filter negative photoresist. The surface active agent is block type polyether non-ionic surface active agent, and is polyoxyethylene-polyoxypropylene block polymer, wherein EO is polyoxyethylene chain segment and PO is polyoxypropylene chain segment; and the developing solution comprises strong base, the block type polyether non-ionic surface active agent and purified water. Through the above mode, the developing solution is good in developing fineness on non-graphical parts, and the developed graphics have the advantages of completeness and accurate dimension without residue, broken lines, lateral erosion, deformation and the like.

Owner:FUJIFILM ELECTRONICS MATERIALS SUZHOU

Fluid for removing vacuum metallic coated nickel layer for decorating nonmetallic surface

This invention relates to a coating stripping solution for metal surface vacuum-coated with nickel. The coating stripping solution comprises: FeCl3 0.01 mol / L, HNO3 0.02 mol / L, HCl 0.08 mol / L, and NaCl 0.02 mol / L. The coating stripping solution has such advantages as rapid reaction, high stability, and uniform coating stripping, no metal residue, no side corrosion, low cost, high production efficiency, and easy control of the product quality.

Owner:TIANJIN ZHONGHUAN HI TECH

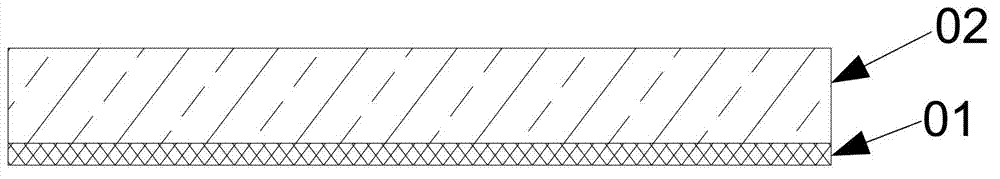

Method for manufacturing passivation layer on pixel electrode, liquid crystal display and manufacturing method thereof

InactiveCN103117249AReduce lossesLoss will notSemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayIndium tin oxide

An embodiment of the invention discloses a method for manufacturing passivation layer on a pixel electrode, a liquid crystal display and a manufacturing method thereof. The method for manufacturing a passivation layer on the pixel electrode includes: forming a passivation layer in a first thickness on the surface of a pixel electrode via process gas in a first flow volume under first power; forming a passivation layer in a second thickness on the surface of passivation layer in the first thickness via process gas in a second flow volume under second power, wherein the first power is smaller than the second power, the first flow volume is smaller than the second flow volume, the first thickness is smaller than the second thickness, the passivation layer in the first thickness and the passivation layer in the second thickness are compact, so that when through holes are drilled in the passivation layers, undercut is avoided, good electric connection between a top electrode and a pixel electrode is guaranteed, the problem that a TFT (thin film transistor) product displays abnormally or cannot display due to contact breakage between the top layer ITO (indium tin oxide) film and the pixel ITO film is solved, product rate of the TFT products is improved.

Owner:TRULY SEMICON

Welding technology

The invention discloses a technology, and particularly discloses a welding technology. The welding technology is characterized by comprising the following steps of material obtaining, clearing before welding, preheating before welding, positioning welding and postweld treatment. The welding technology has the advantages that the steps are simple, operation is convenient, time and labor are saved, safety and reliability are achieved, the stability is good, gas hole weld beading is avoided, concave and undercut phenomena are avoided, forming is good, non-welding defects, cracks and the like are avoided, the requirements for resisting intergranular corrosion and embrittlement are completely met, welding engineering quality is ensured, and the working efficiency is greatly improved.

Owner:刘振宇

Horizontal welding method

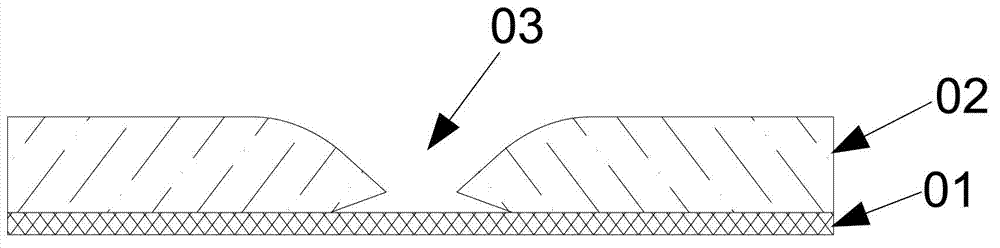

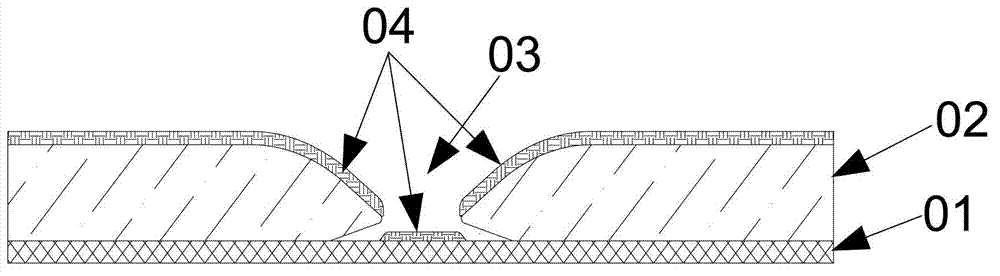

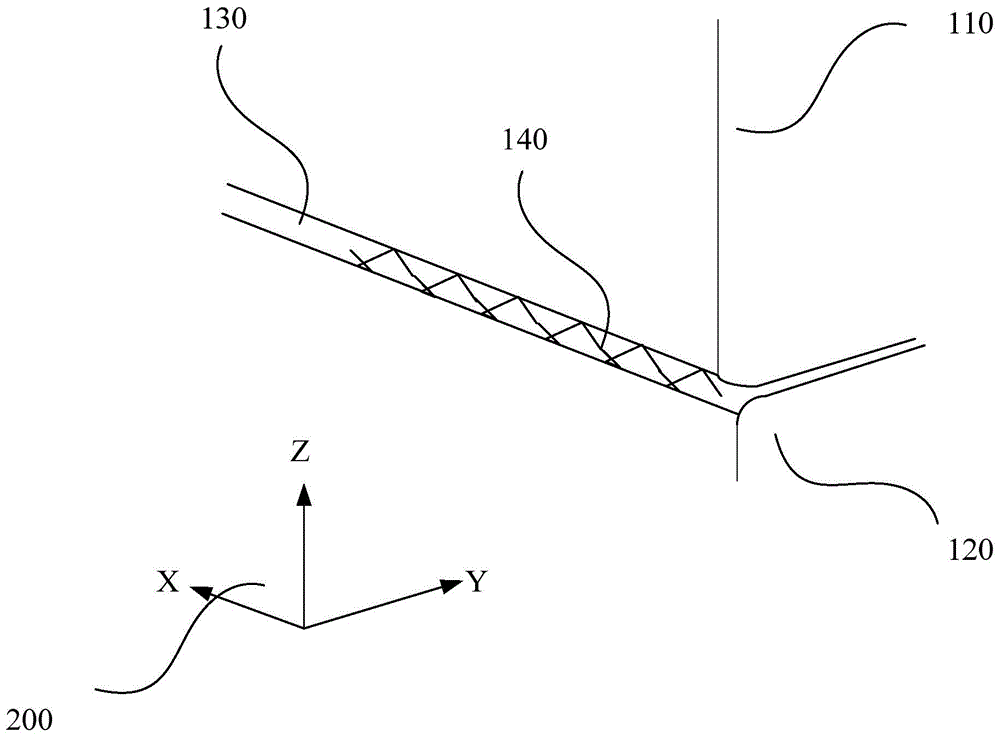

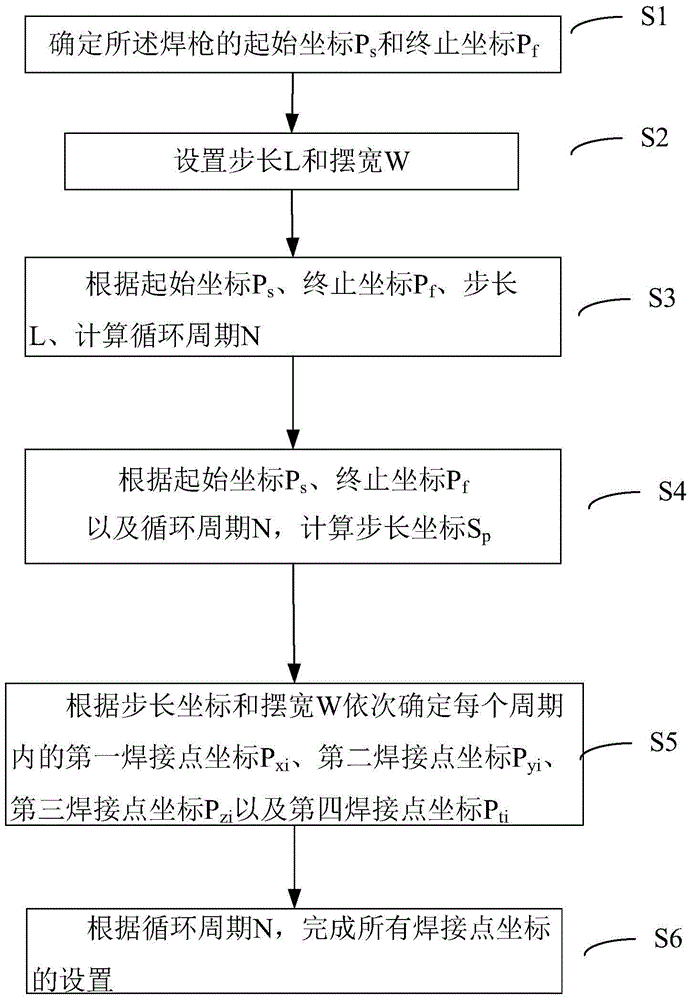

ActiveCN104801876ANo undercutStrong penetrating powerArc welding apparatusWorkpiece edge portionsEngineeringWeld penetration

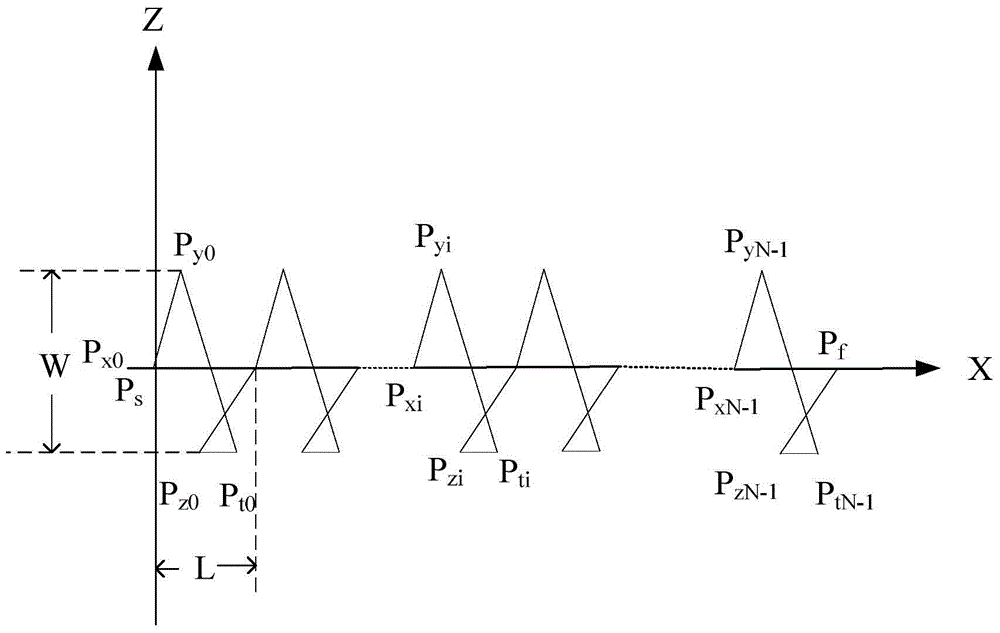

The invention discloses a horizontal welding method, which is used for carrying out horizontal welding on an end bevel formed between upper base metal and lower base metal and comprises the steps that a welding gun swings up and down along a preset track along the direction of surfaces of the upper base metal and the lower base metal, and advances in a reciprocating manner along the extending direction of the end bevel, so as to finish the horizontal welding of the end bevel. According to the horizontal welding method, through the arrangement of a welding preset rail, the retracement reciprocating of welding is realized, the stability of the welding is guaranteed, and a welding part which has no undercut, is excellent in weld penetration and is sound can be obtained.

Owner:上海气焊机厂有限公司

Arc angle laser welding forming method of angle seam joints

InactiveCN108326420AHigh heat input efficiencyLow heat inputLaser beam welding apparatusEngineeringFusion welding

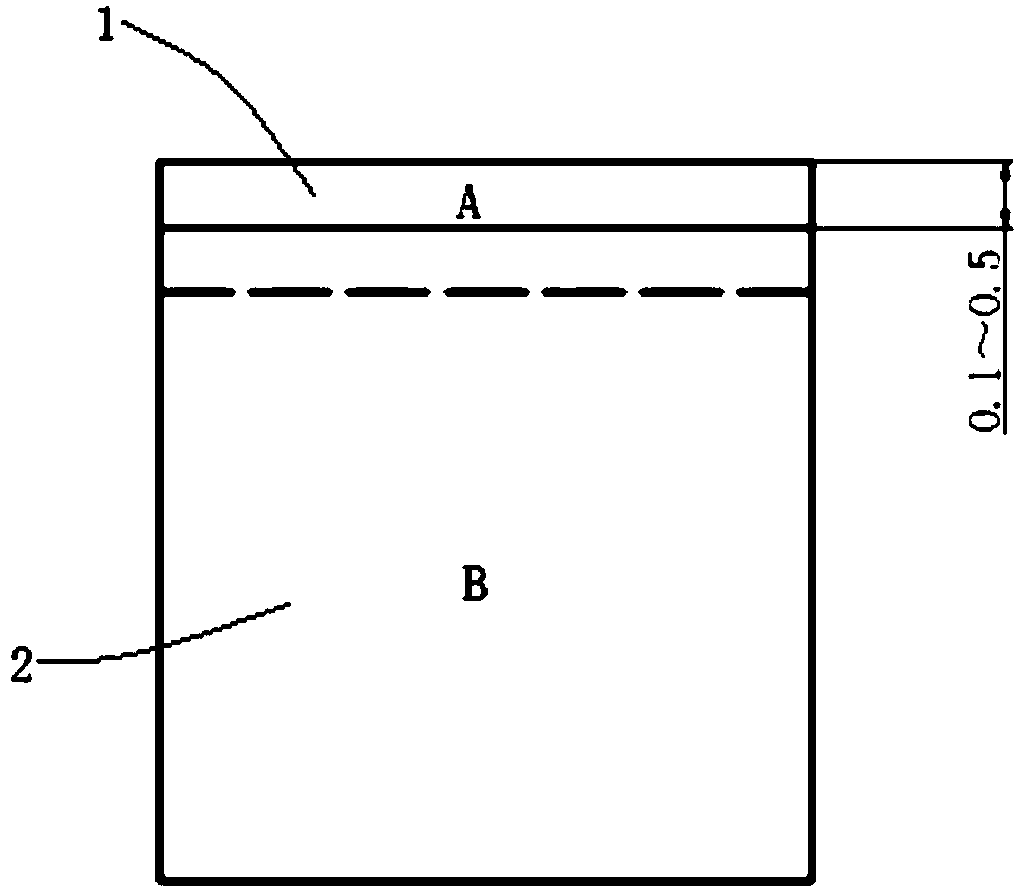

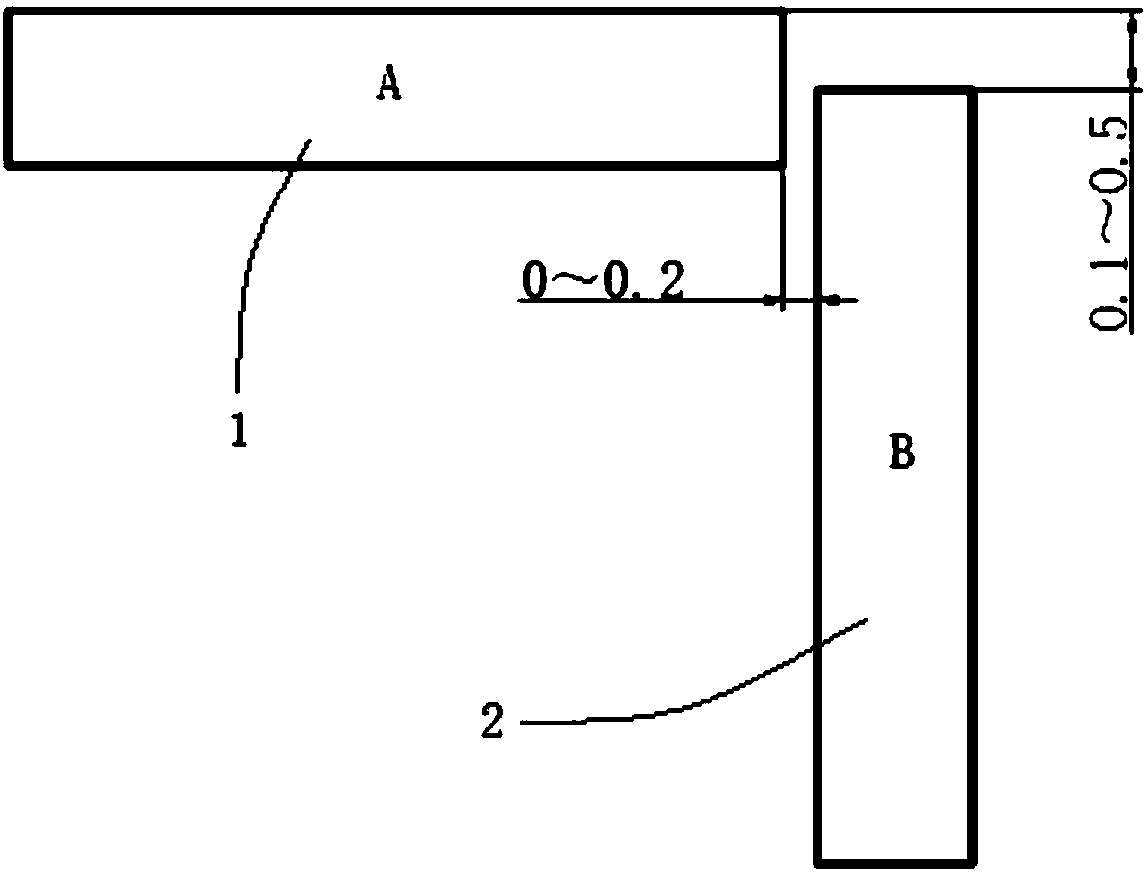

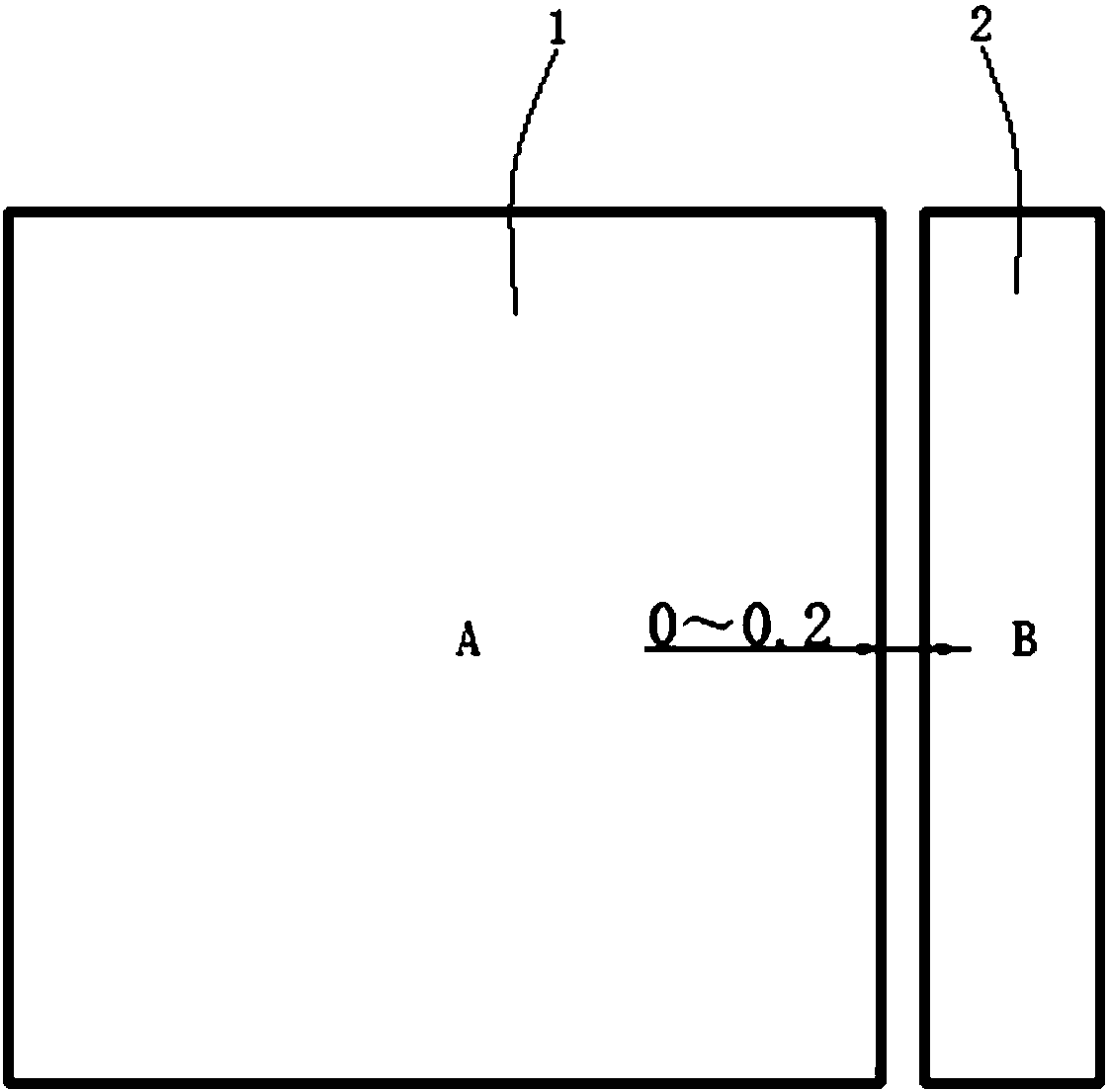

The invention relates to an arc angle laser welding forming method of angle seam joints. The method comprises the steps as follows: two plates are positioned, the plate A and the plate B are perpendicular, the distance between the two plates is controlled within the range of 0-0.2 mm, the to-be-welded end surface of the plate B is located between two plate surfaces of the plate A, and the distancebetween the to-be-welded end surface of the plate B and the outer side plate surface of the plate A is in a range of 0.1-0.5 mm; a laser self-fusion welding manner is adopted for welding forming, andthe focus spot diameter of laser beams is 1.5-2.2 mm. A special welding joint splicing form is adopted, the space occupied by surplus height of appropriate weld seams is reserved, the weld seams haverelatively flat surfaces after welding and form smooth arc angle seams, the weld seam appearance requirement is guaranteed, and the weld seam arc angle forming requirement can be better met; a large-focus spot diameter laser welding technology is adopted, welding seam forming can meet the product requirement, simple polishing treatment is needed only in the later period, and stable production with high quality, efficiency and benefits is realized.

Owner:WUHAN HGLASER ENG CO LTD

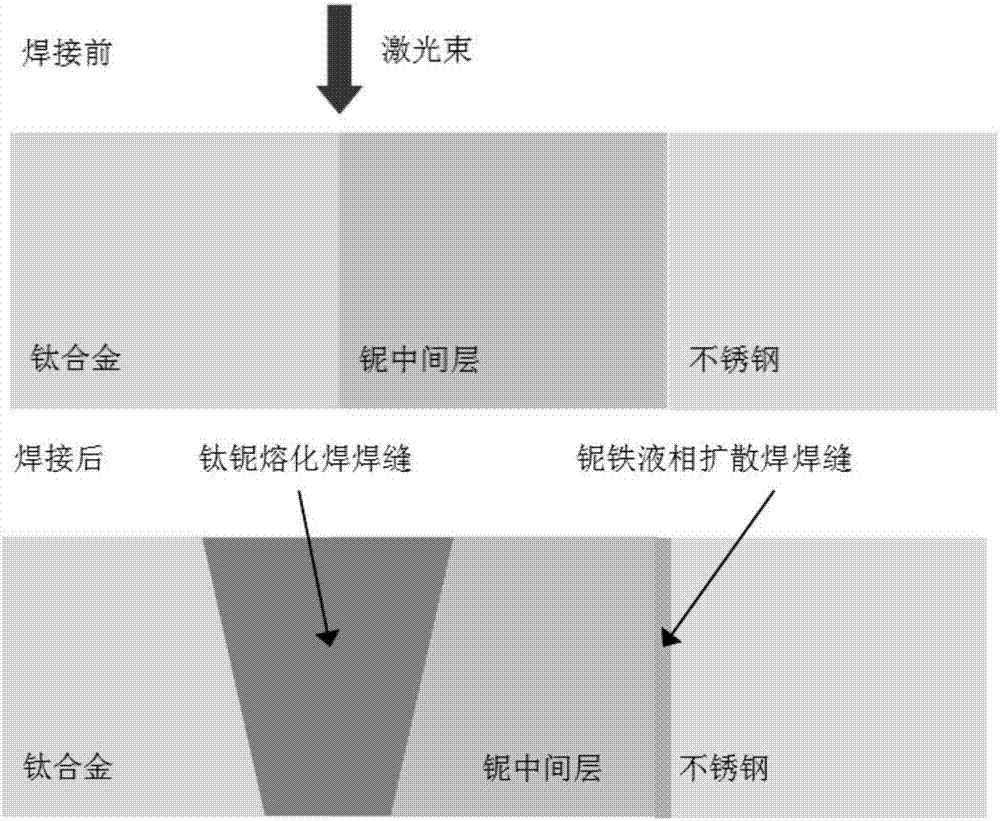

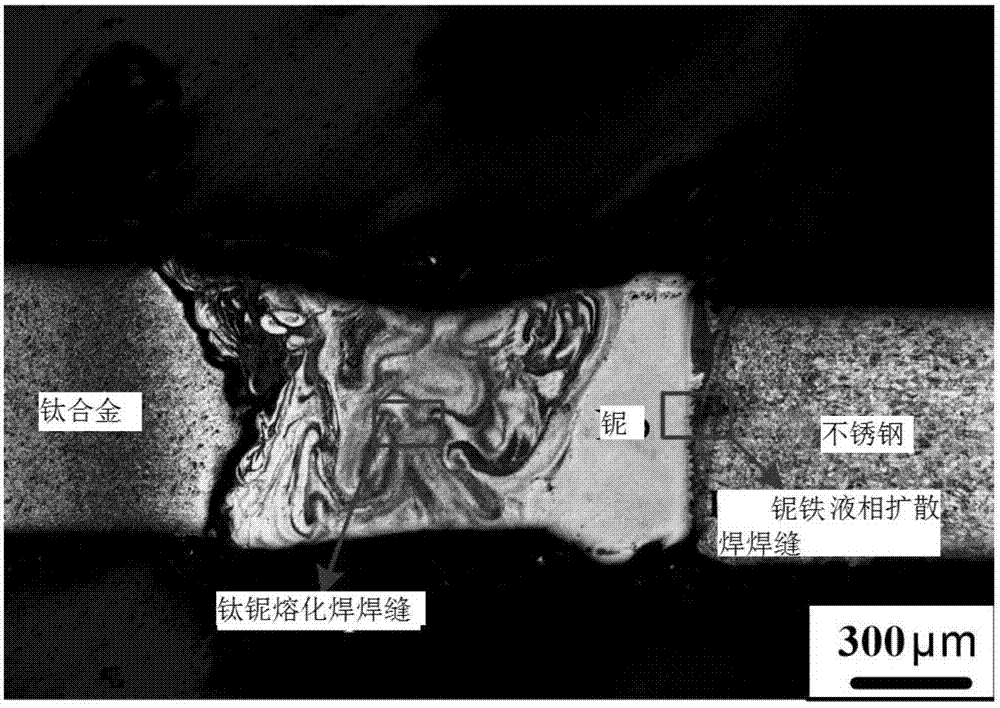

A kind of laser welding method of stainless steel-titanium alloy dissimilar metals

InactiveCN105855705BMeet performance targetsStable laser welding processWelding/soldering/cutting articlesLaser beam welding apparatusNiobiumMetallic materials

The invention discloses a stainless steel-titanium alloy different metal laser welding method. The method takes laser as a welding heat source and niobium is added between stainless steel and a titanium alloy as an intermediate layer. By accurately controlling welding process parameters, a compound connector (titanium-niobium melting connection and niobium-iron liquid-phase dispersion connection) with two connection states is formed under a one-step heating condition, so that high-quality and high-efficiency welding of a stainless steel-titanium alloy different metal material is realized. By controlling the thickness of the intermediate layer and a welding speed of laser welding, metal niobium, which is not melted and has a certain thickness, exists between a titanium-niobium melting-welding welding seam and a niobium-iron liquid-phase dispersion-welding welding seam, and titanium and iron elements are prevented from mutual dispersion to form a crispy iron-titanium intermetallic compound. Finally, a formed welding seam has a beautiful shape, welding technological properties are good and the tensile strength is relatively strong.

Owner:JILIN UNIV

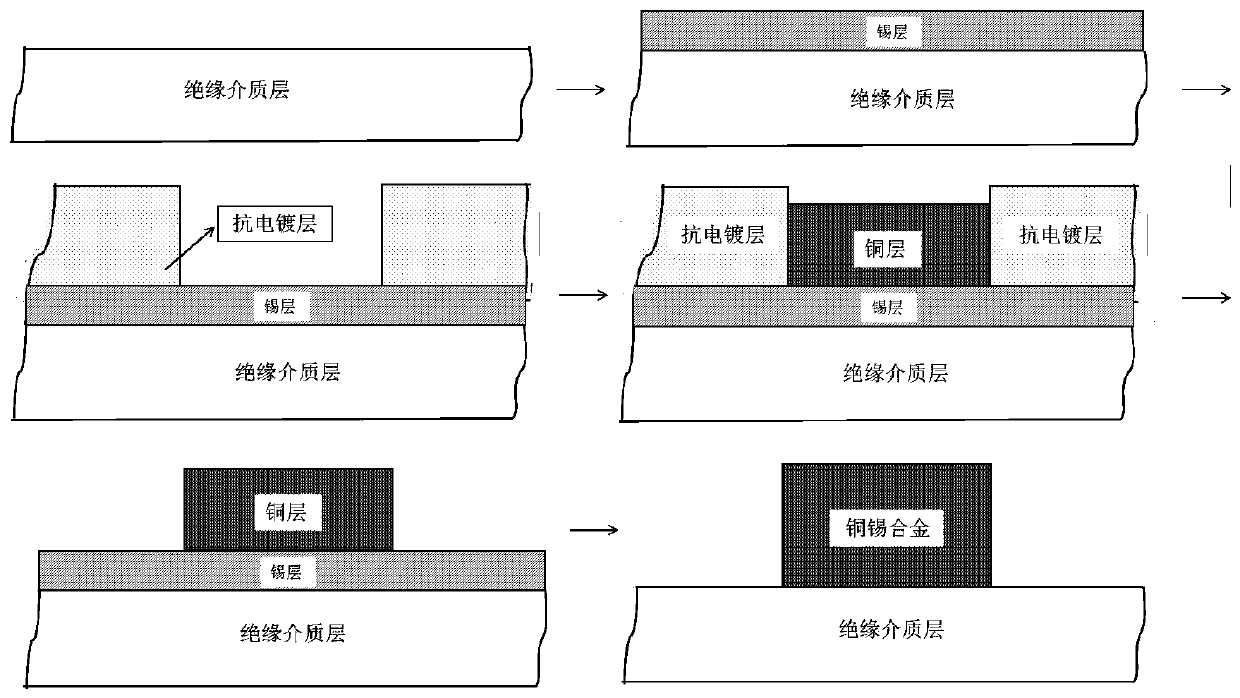

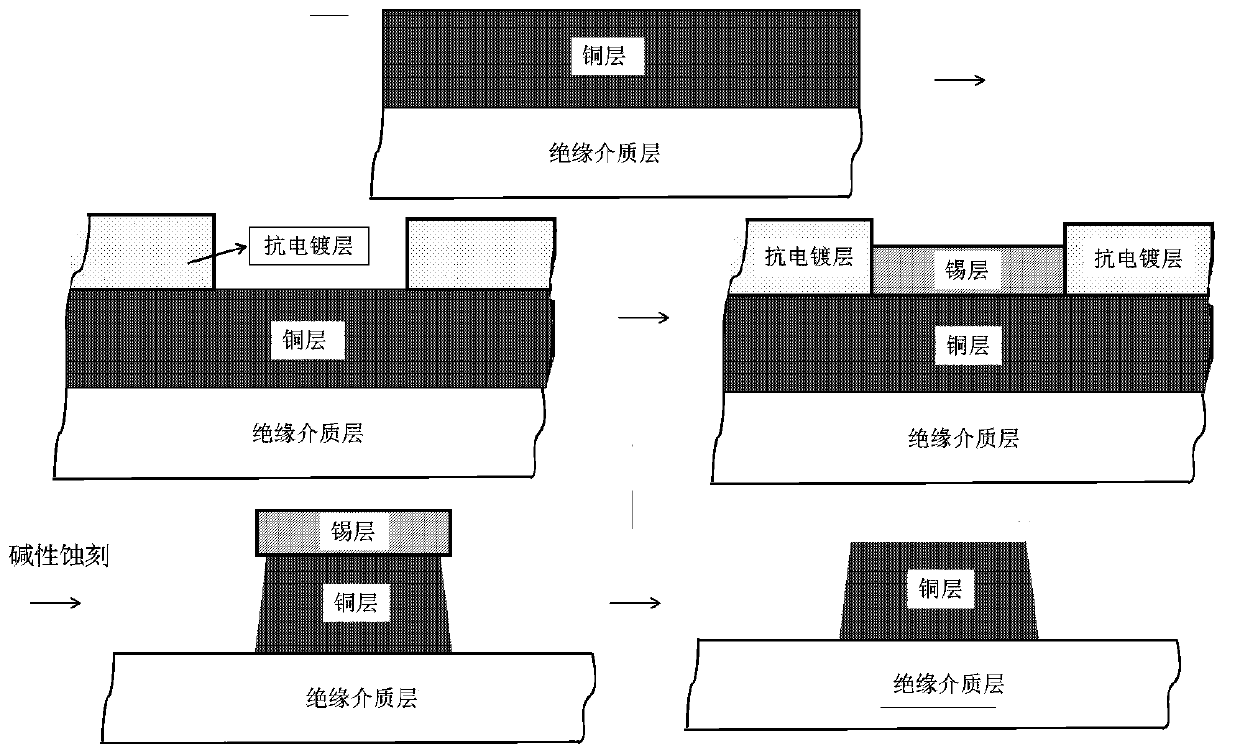

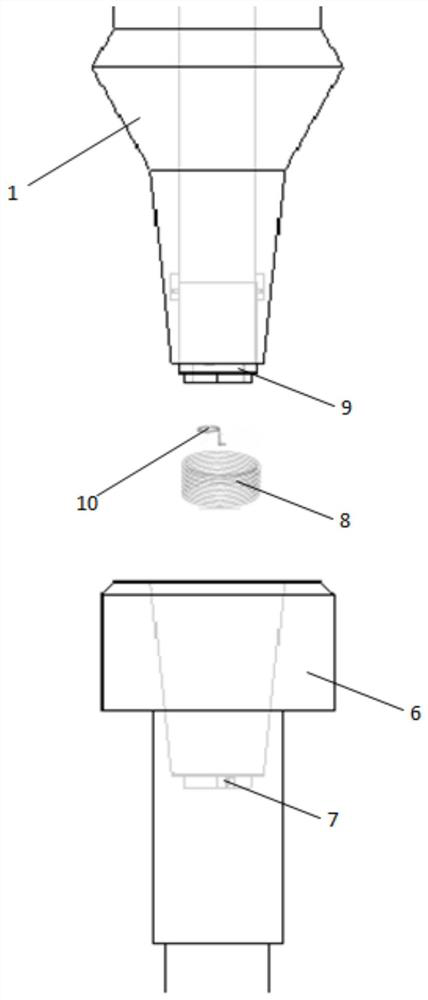

Manufacturing method of printed circuit conductive circuit

PendingCN111405771AAvoid over etchingAvoid poor thermal stabilityConductive material chemical/electrolytical removalElectrically conductiveEtching

The invention discloses a manufacturing method of a printed circuit conductive circuit, and relates to the technical field of printed circuit board manufacturing. The method comprises the following steps: (1) growing a tin seed layer on the surface of a printed circuit insulating substrate; (2) covering the tin seed layer with a patterned dry film; (3) electroplating copper to form a copper conductive circuit; (4) removing the dry film; (5) carrying out heat treatment on the substrate obtained after the treatment in the previous step, so that the copper conductive circuit and the tin seed layer are co-melted into a whole; and 6) etching the tin seed layer to obtain a printed circuit conductive circuit. According to the method, the tin layer etching speed is high, the precision is high, thecircuit is complete and free of side etching, and manufacturing of a high-precision circuit board is facilitated; meanwhile, the copper and the tin are eutectic to form a uniform alloy layer, so thatthe stress between the metals is released, the local defect caused by inconsistent etching speeds of the tin seed layer and the copper conductive wire is prevented, the binding force of the conductive circuit and a bottom layer insulating medium is ensured, and the circuit pattern is good in heat resistance, high in stability and high in reliability.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

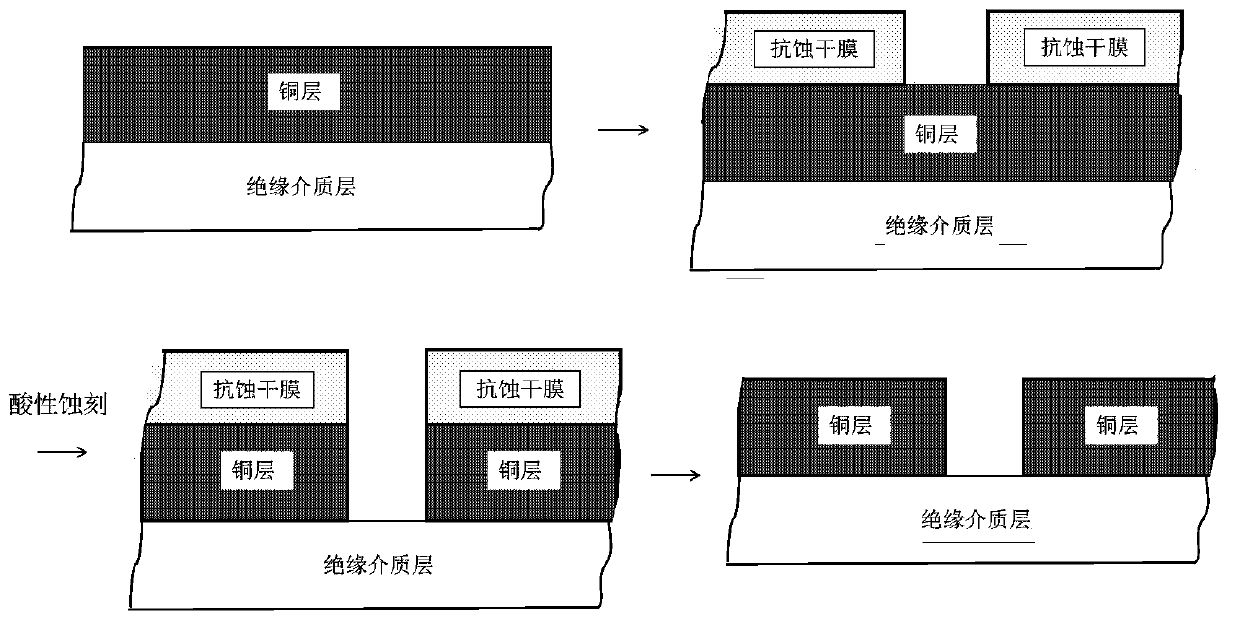

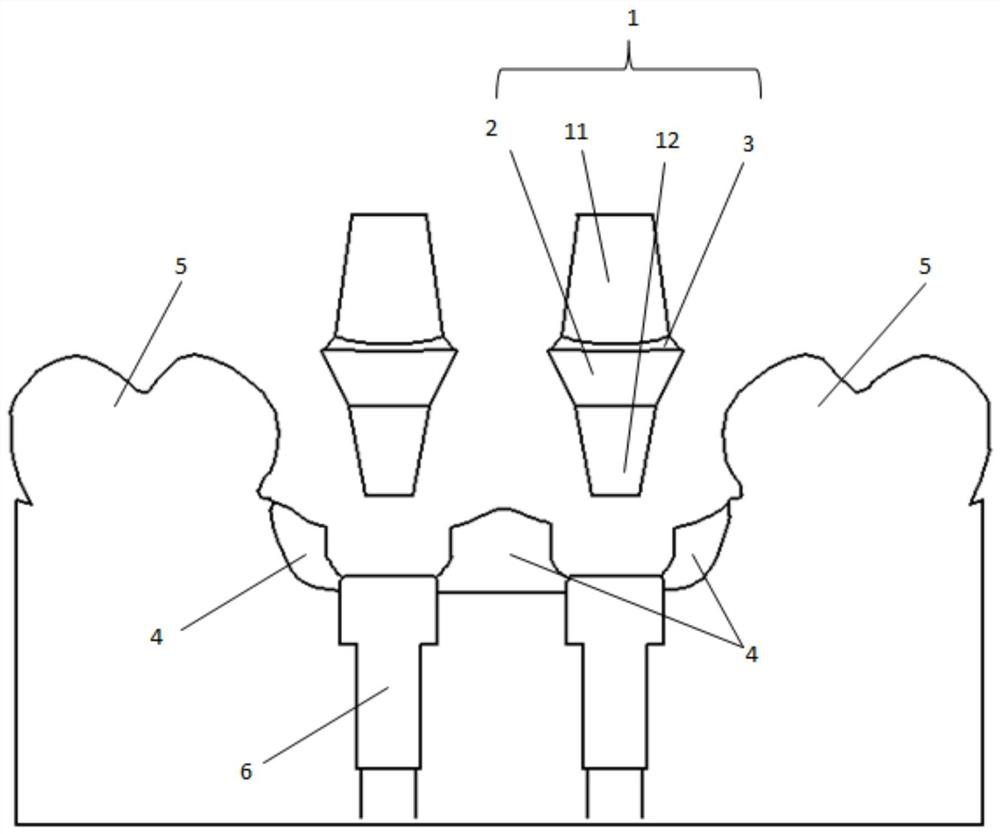

Treatment method of pure titanium personalized abutment

The invention discloses a treatment method of a pure titanium personalized abutment. The treatment method comprises the following steps of designing an abutment by using design software according to the obtained jaw bone model condition of a patient, and inputting data of the abutment into CAD\CAM equipment for processing to obtain a personalized pure titanium abutment; mounting the processed puretitanium abutment on a jaw bone model, and recording an upper jaw frame according to a jaw; adjusting the size and the insertion path of the pure titanium abutment; performing fine trimming on the pure titanium abutment, and then performing polishing and cleaning treatment; and performing anodic oxidation treatment on the surface of a gum penetrating part of the pure titanium abutment. A parallelgrinding instrument is used for ensuring that a single pure titanium abutment does not have undercuts, and two or more pure titanium abutments obtain a consistent common insertion path. An anode electroplating process is used for the gum penetrating part of the pure titanium abutment, so that the corrosion resistance and the wear resistance of the pure titanium abutment are enhanced, the color ofthe gum penetrating part is close to the color of the gum, and the attractive effect is achieved; The treatment method is suitable for all metal restorations of titanium and titanium alloys in dentalrestoration.

Owner:北京联袂义齿技术有限公司

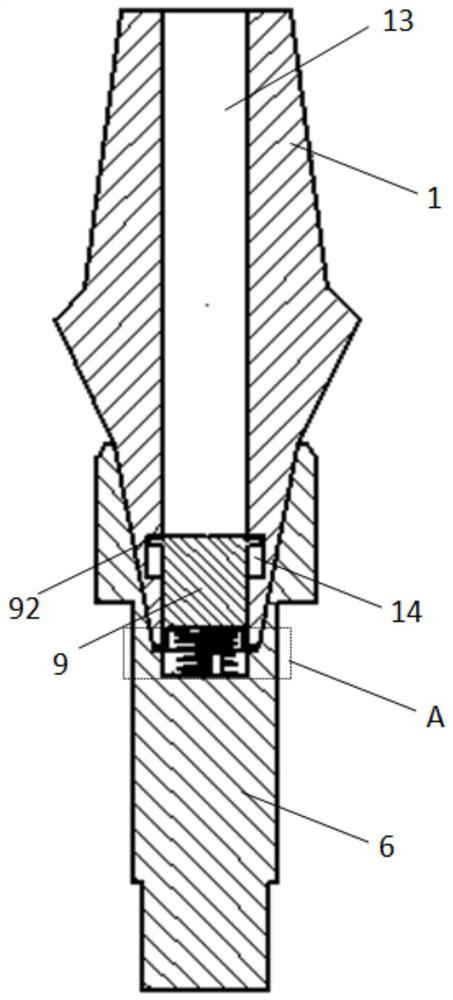

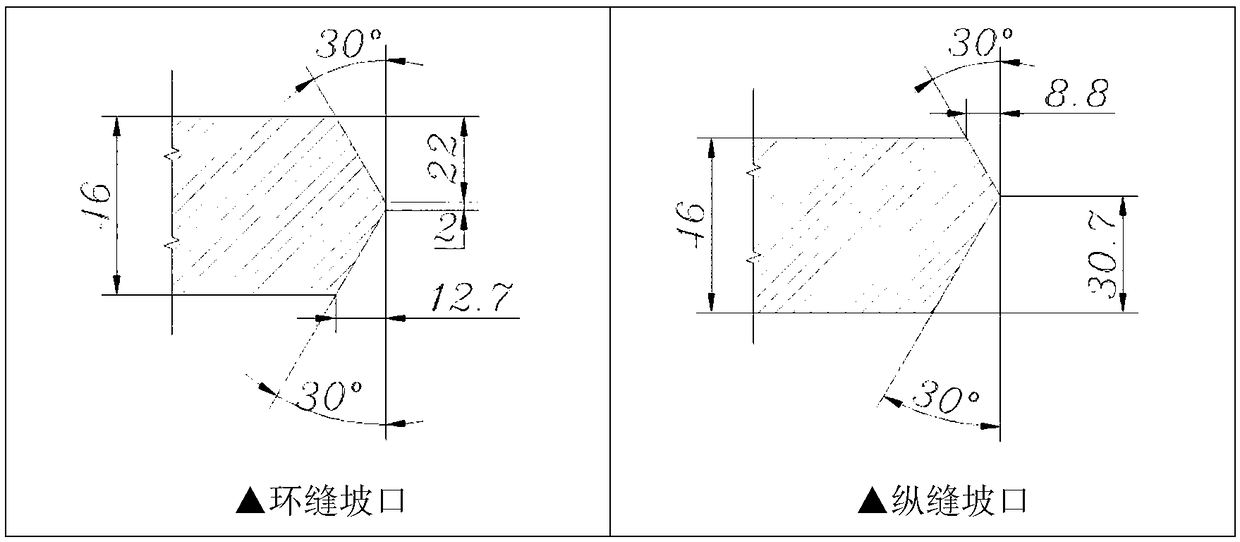

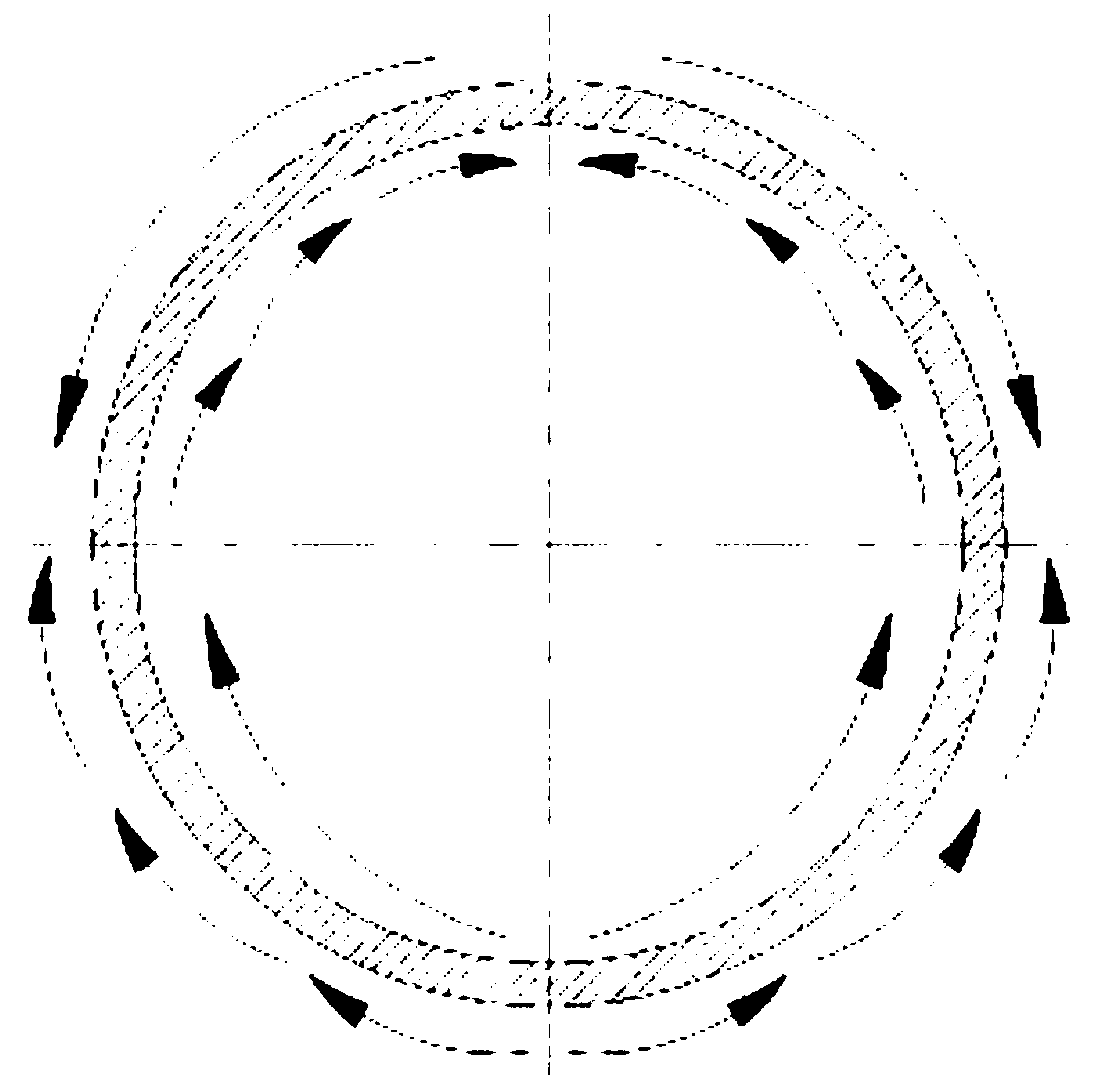

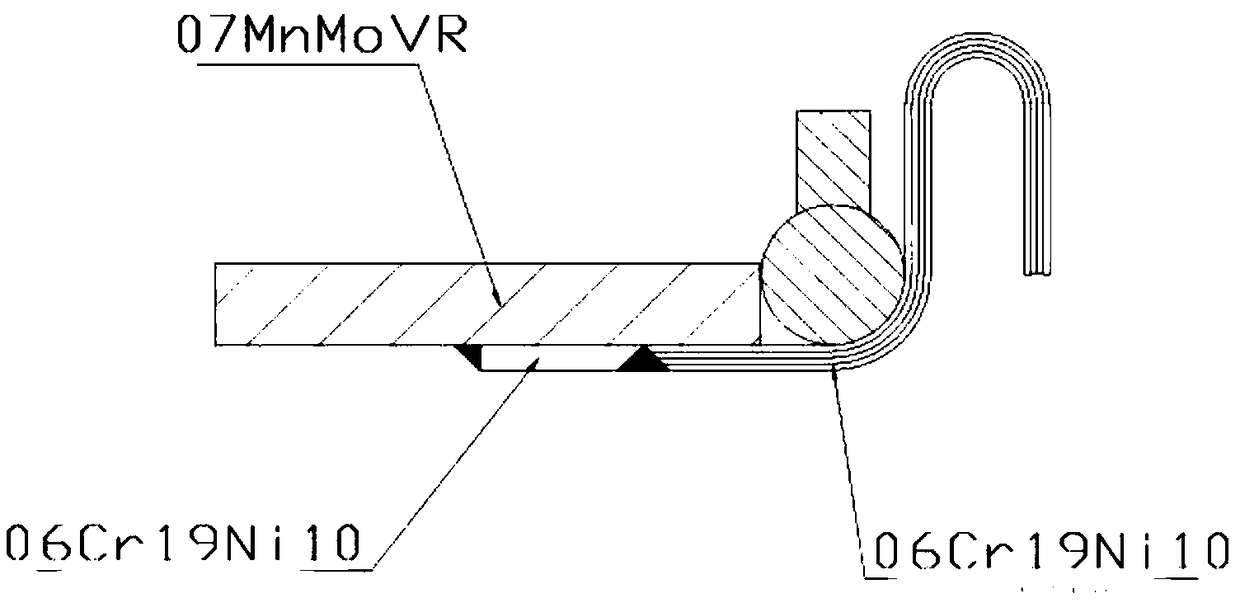

Welding process of bellows

InactiveCN109396610AGood surface morphologyNo crackArc welding apparatusWelding/cutting media/materialsQuality controlEngineering

The invention provides a welding process of a bellows. The welding process of the bellows is characterized by comprising the following steps that step 1, welding characteristic research is carried out; step 2, a welding material and a welding process are formulated; step 3, welding is carried out; and step 4, quality control is carried out, wherein the quality control includes technology work, process control and quality inspection and acceptance.

Owner:JIANGSU FENGHE MACHINERY MFG

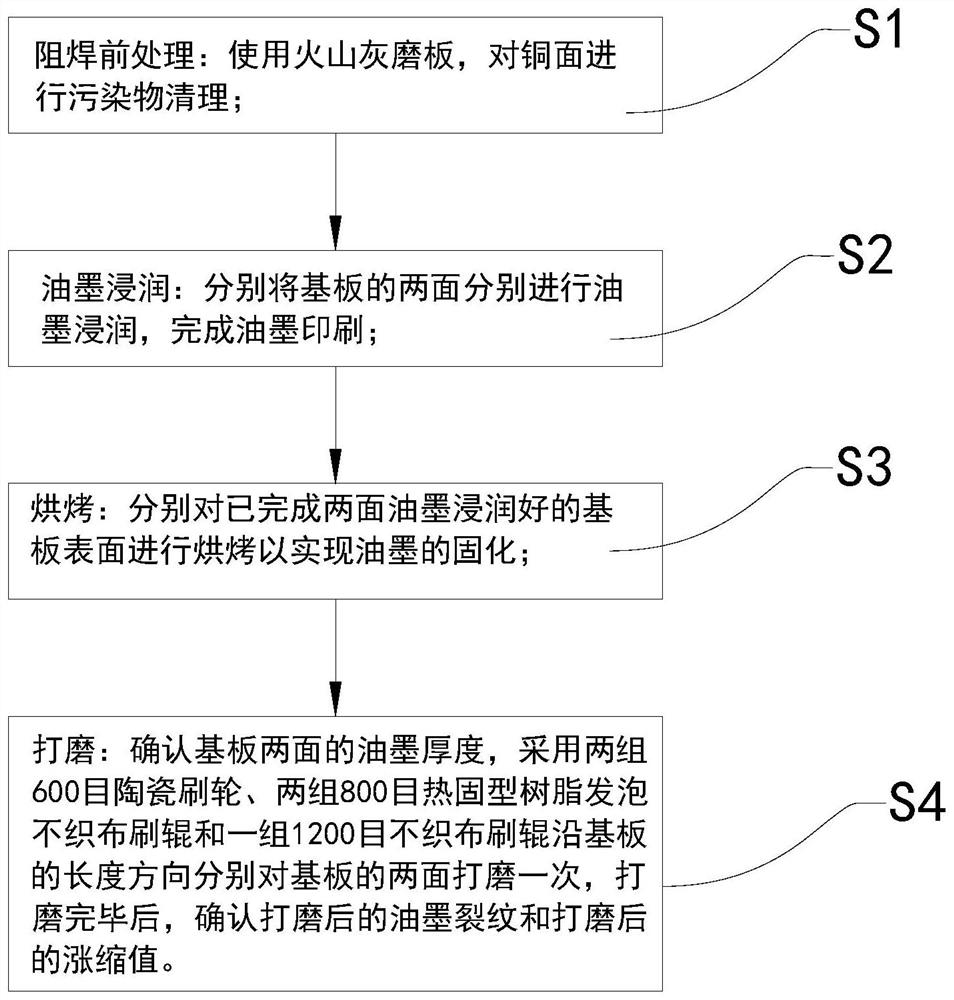

Novel circuit board ink windowing method

PendingCN112689396ANo undercutNo cracks and voidsNon-metallic protective coating applicationSolder maskMechanical engineering

The invention discloses a novel circuit board ink windowing method, and relates to the technical field of printed circuit boards. The method comprises the following steps: performing solder mask pretreatment: cleaning pollutants on a copper surface by using a volcanic ash grinding plate; performing ink infiltration: performing ink infiltration on the two faces of the substrate to complete ink printing; baking: respectively baking the surface of the substrate with the ink infiltrated on the two sides to realize the curing of the ink; and polishing: determining the thickness of the ink on the two sides of the substrate, and respectively polishing the two sides of the substrate once along the length direction of the substrate by adopting two groups of 600-mesh ceramic brush wheels, two groups of 800-mesh thermosetting resin foaming non-woven fabric brush rollers and a group of 1200-mesh non-woven fabric brush rollers. The traditional solder resist ink manufacturing process is abandoned, the solder resist exposure and development processes are replaced by removing the surface bonding pad ink in a ceramic polishing manner, and the windowing effect is achieved. The IC solder-resisting bridge technology which cannot meet the requirement that the distance between circuit bonding pads is smaller than or equal to 0.075 mm in a traditional mode can be achieved, and it is guaranteed that ink between bridges is free of lateral erosion and cracks and cavities.

Owner:信丰迅捷兴电路科技有限公司 +1

Welding material composition for flux adhesive fiberglass backing (FAB)

ActiveCN108145339AEnsuring grain refinementStable welding arcArc welding apparatusWelding/cutting media/materialsMetallurgyImpurity

The invention discloses a welding material composition for flux adhesive fiberglass backing (FAB). The welding material composition comprises a welding wire, a surface welding flux and filler powder.The welding wire comprises 0.08%-0.17% of C, 0.01%-0.04% of Si, 1.0%-2.5% of Mn, 0.1%-0.5% of Cr+Ni, 0.010%-0.025% of S, 0.010%-0.025% of P, and the balance Fe powder. The surface welding flux comprises 10%-20% of SiO2, 15%-35% of MgO, 5%-15% of TiO2, 7%-20% of Al2O3, 5%-20% of CaO, 0.01%-0.04% of S, 0.01%-0.04% of P, 0.01%-0.1% of H2O, 0.1%-0.2% of impurities and the balance Fe powder. The fillerpowder comprises 0.004%-0.01% of C, 0.01%-0.4% of Si, 1.0%-2.5% of Mn, 2.0%-5.0% of Ni, 0.2%-1.0% of Mo, 0.02%-0.04% of S, 0.02%-0.04% of P and the balance Fe powder. By adoption of the welding material composition, production efficiency can be improved by 3-5 times, and the cost is reduced by 50%-60% compared with that of imported welding materials of the same kind.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

A double tungsten electrode tig narrow gap welding method with high deposition efficiency and high welding speed

The invention relates to a high-deposition efficiency and high-welding speed dual-tungsten electrode TIG (Tungsten Inert Gas) welding method for a narrow gap, and belongs to the technical field of TIGwelding. Two different welding guns: an axisymmetrical static tungsten electrode welding gun and a non-axisymmetrical rotating tungsten electrode welding gun, are employed; the welding method comprises the following steps of firstly forming a U-shaped groove in a workpiece, and performing pretreatment on the groove; arranging the two welding guns front and back in a welding direction, and adjusting a posture of each of the two welding guns; enabling distance from one of the two welding gun to the workpiece and distance from the other welding gun to the workpiece to be equal; setting each of welding machines to be in an advanced gas feed mode, centering the welding guns, setting each of wire feeding mechanisms to be in a delayed wire feed mode and an advanced wire drawing mode, and firstlyperforming advanced heating premelting on a weldment; and turning a tungsten electrode of a second welding gun by a motor control box switch of the second welding gun before arc striking, wherein direct current welding is employed. During welding, arc striking is performed on the two welding guns simultaneously for welding, and thus, the front face of a weld joint can be formed well and has no defects: undercuts and the like; welding deposition efficiency and welding speed are obviously increased, and dual-tungsten electrode TIG high-speed welding of the narrow gap with good sidewall fusion degree can be performed.

Owner:SHANDONG UNIV

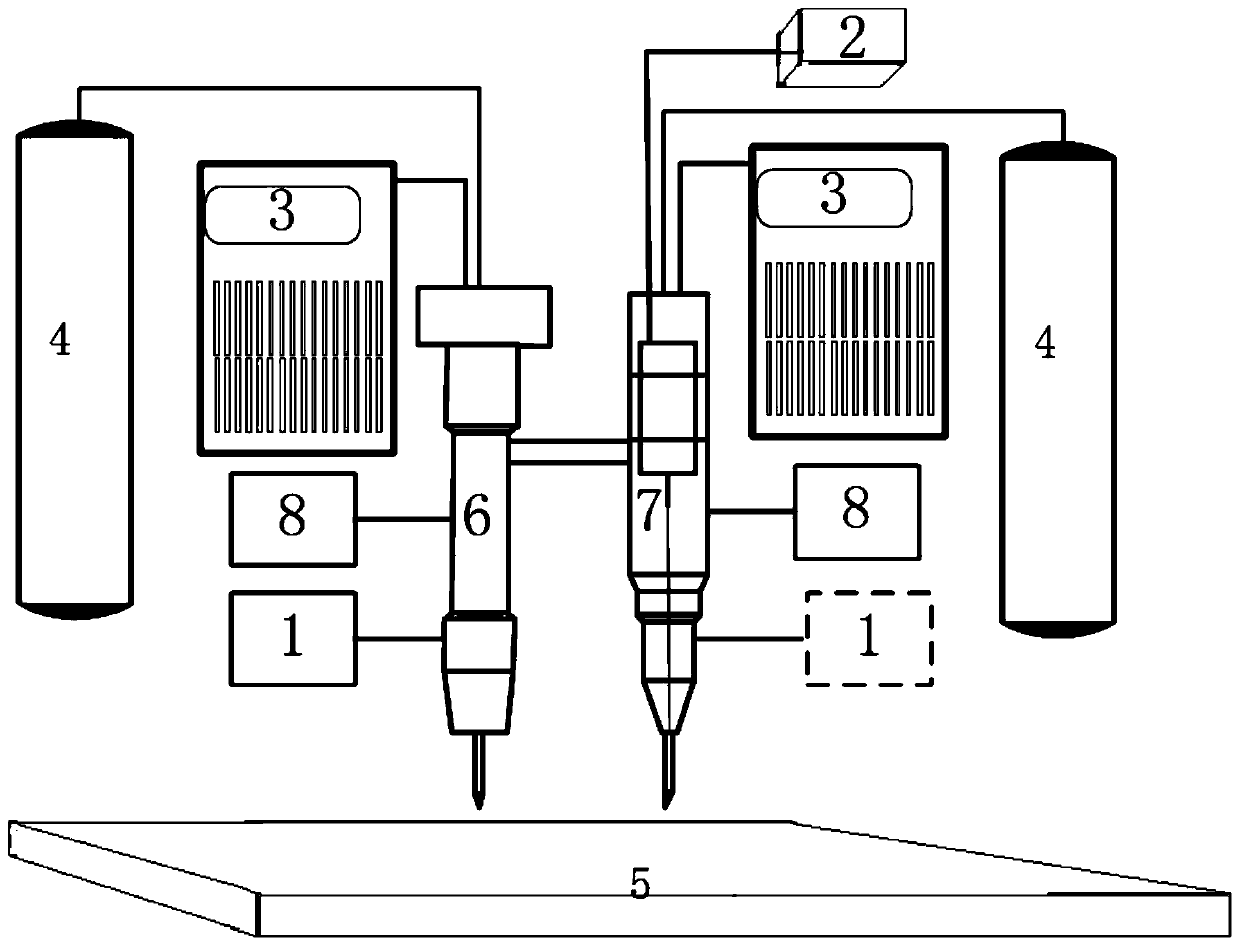

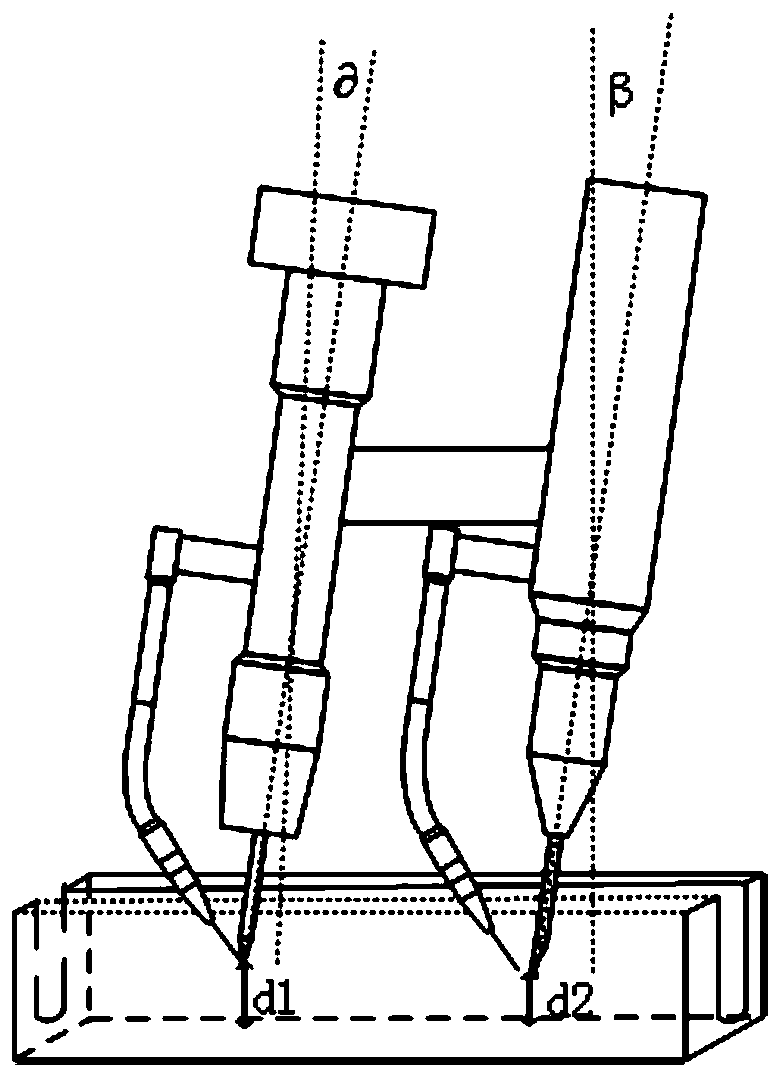

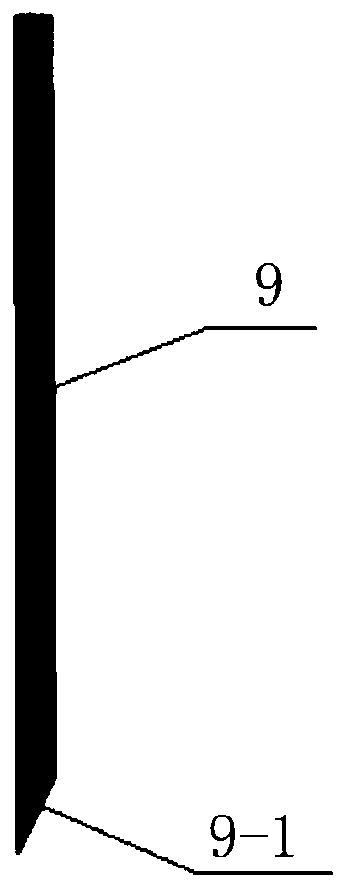

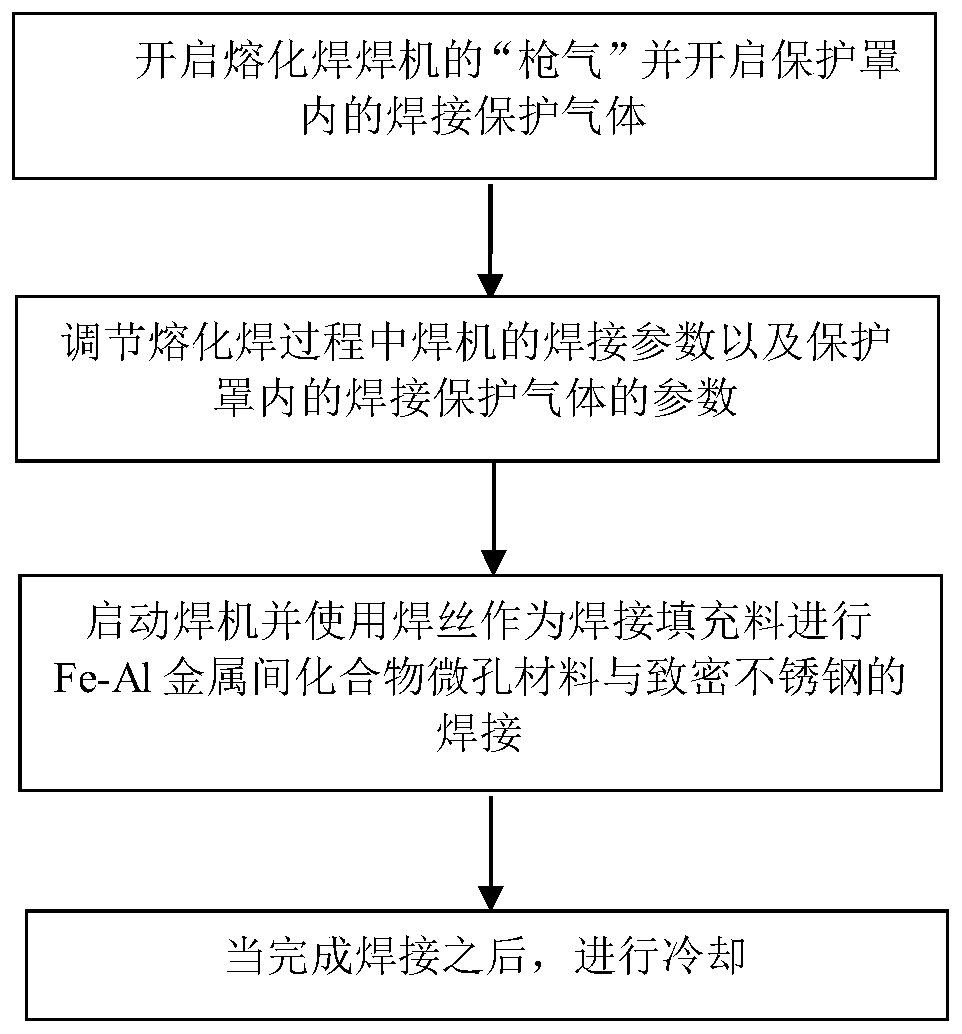

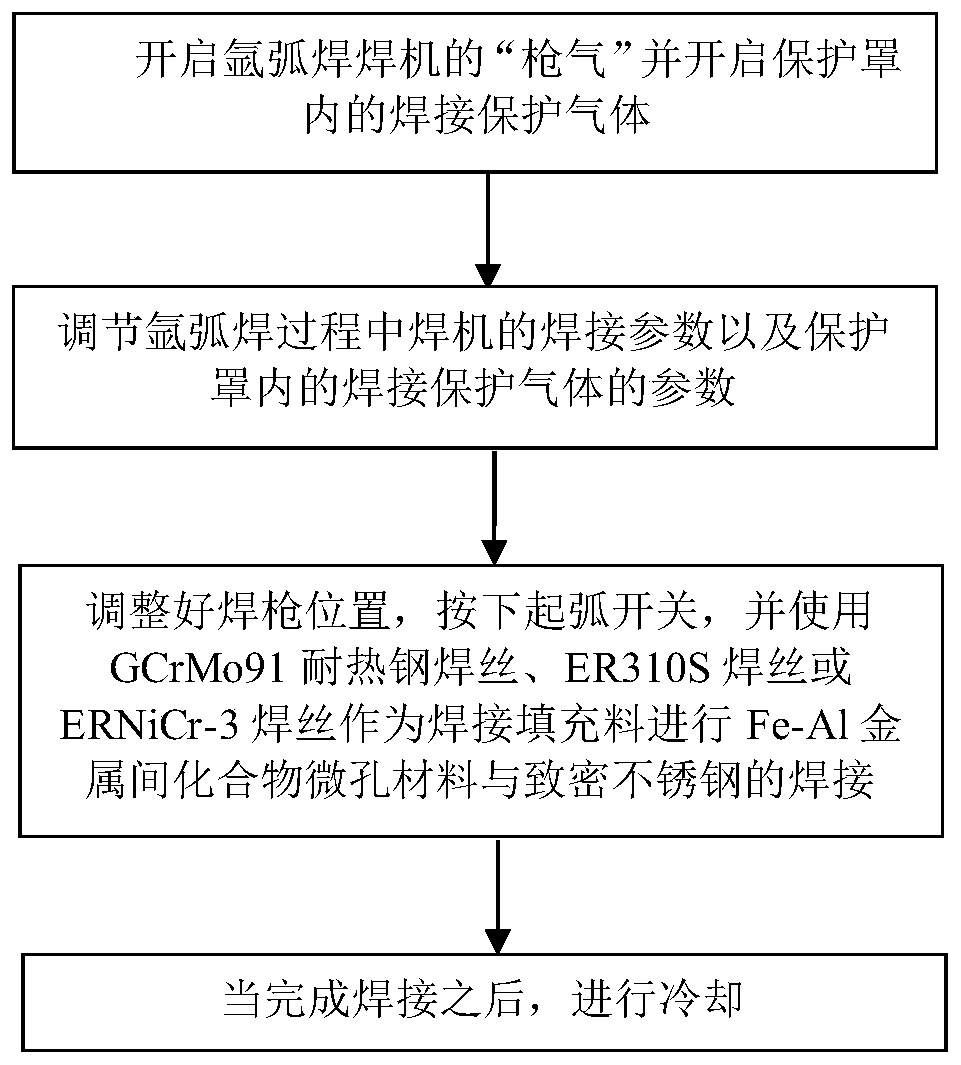

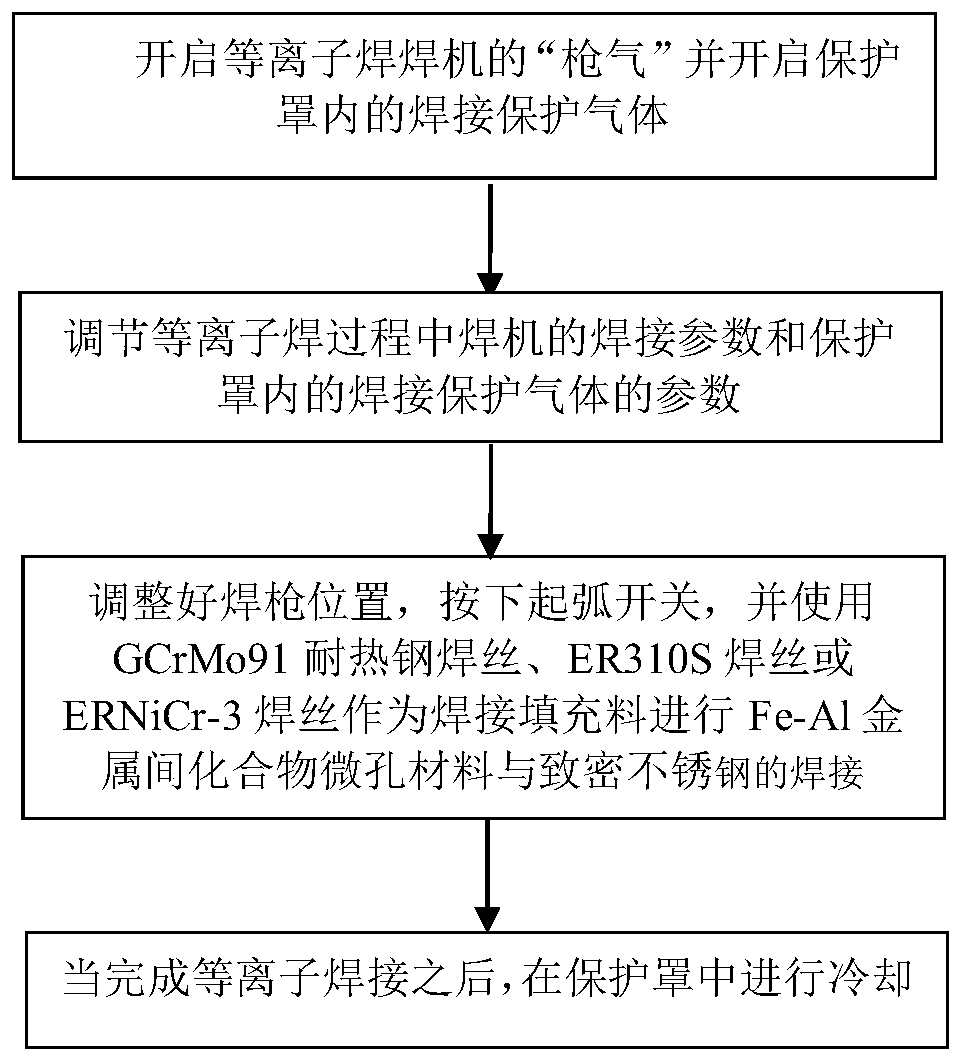

Method for welding Fe-Al intermetallic compound microporous material and welding part thereof

ActiveCN111151842AImprove stabilityUniform weldingElectrode holder supportersPlasma welding apparatusWeld seamFusion welding

The invention discloses a method for welding an Fe-Al intermetallic compound microporous material and a welding part thereof, relates to the technical field of welding, and aims to solve the problem that the welding between an Fe-Al microporous material and compact stainless steel is very difficult. The method for welding the Fe-Al intermetallic compound microporous material comprises the steps ofstarting the gun gas of a fusion welding machine and starting the welding protective gas in a protective cover; adjusting welding parameters of the welding machine and parameters of the welding protective gas in the protective cover in the fusion welding process; starting the welding machine and using a welding wire as welding filler to weld the Fe-Al intermetallic compound microporous material with the compact stainless steel; and cooling after the welding is completed. By implementing the method for welding the Fe-Al intermetallic compound microporous material, the welded Fe-Al intermetallic compound microporous material is firmly combined with the compact stainless steel, the stability is high, the welding seam is complete and uniform, and the defects such as undercut, surface cracks and misrun are eliminated.

Owner:AT&M ENVIRONMENTAL ENG TECH CO LTD

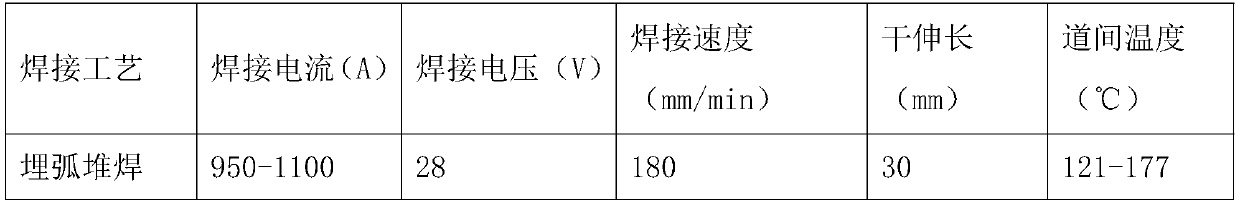

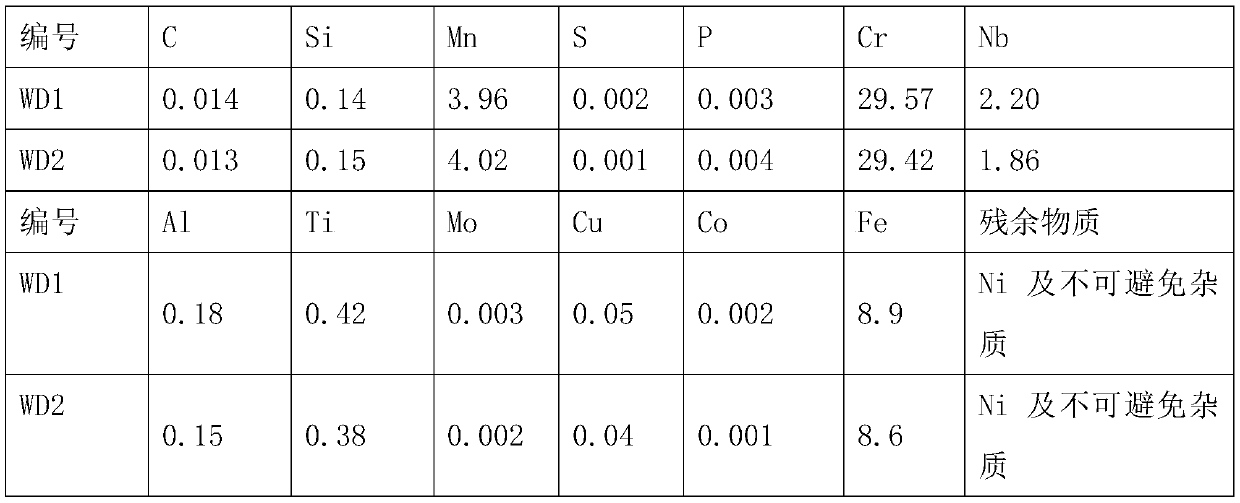

Welding flux matched with nickel-base welding strip with high Mn and high Nb crack-resistant defects, and welding method

InactiveCN110640355AReasonable design of ingredientsGuaranteed Crack SensitivityArc welding apparatusWelding/cutting media/materialsIron alloysAlloy composition

The invention relates to a welding flux matched with a nickel-base welding strip with high Mn and high Nb crack-resistant defects, and a welding method. The invention aims to provide the welding fluxmatched with the nickel-base welding strip with the high Mn and high Nb crack-resistant defects, and the welding method. The welding flux provided by the invention is prepared from CaF2, SiO2, Al2O3,CaO, MgO, Cr2O3, an iron alloy or NaF, S and P. The welding method is characterized in that the welding current is 950 to 1100 A, the welding voltage is 28V, the welding speed is 180mm / min, and the surfacing layer thickness is 30mm. According to the welding flux matched with the nickel-base welding strip with the high Mn and high Nb crack-resistant defects, and the welding method provided by the invention, the problem of high crack sensitivity of similar products is solved, novel high-Mn high-Nb alloy components are provided, and the problem of engineering application of large-thickness heat cracks is solved. The welding flux matched with the nickel-base welding strip with the high Mn and high Nb crack-resistant defects, and the welding method provided by the invention are applied to the field of nuclear power welding.

Owner:HARBIN WELL WELDING CO LTD +1

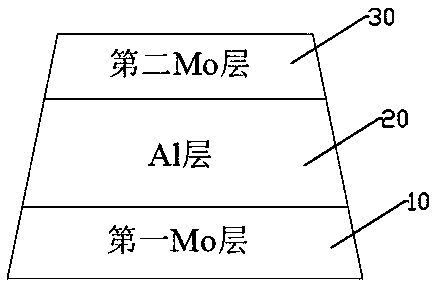

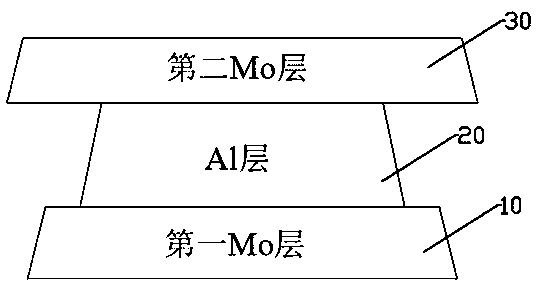

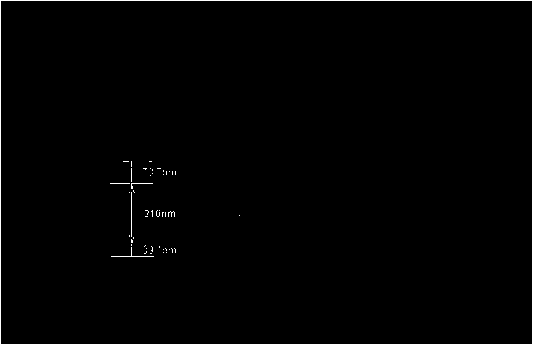

Manufacturing method of touch screen metal wire

ActiveCN110647255AImprove adhesionEtching speed is fastInput/output processes for data processingSi substrateO-Phosphoric Acid

The invention discloses a manufacturing method of a touch screen metal wire, which comprises the following steps of: a, sputtering a first Mo layer, a middle Al layer and a second Mo layer on a glasssubstrate in sequence by taking argon as working gas; b, etching the sputtered Mo-Al-Mo layer by adopting a nitric acid-phosphoric acid-acetic acid system etching solution, wherein the mass percent ofthe nitric acid is 8-11%, and when the first Mo layer and the second Mo layer are sputtered, oxygen is respectively introduced into the sputtering system, the oxygen introduction amount during sputtering of the second Mo layer is equal to the oxygen introduction amount during sputtering of the second Mo layer. When the first Mo layer and the second Mo layer are sputtered respectively, oxygen is introduced into the sputtering system, the oxygen introduction amount in the sputtering system when the first Mo layer and the second Mo layer are sputtered is controlled, and the mass percent of nitric acid-phosphoric acid-acetic acid system etching liquid is controlled, so that the structure of the obtained metal wire has no undercut phenomenon, and the climbing effect is very good.

Owner:TRULY OPTO ELECTRONICS

Welding process

InactiveCN106808119AQuality assuranceSimple stepsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringIndustrial engineering

The invention discloses a process, in particular to a welding process. The welding process is characterized by comprising the following steps: material taking, pre-welding cleaning work, pre-welding preheating, positioning welding and post-welding treatment. The welding process has the beneficial effects that the steps are simple, the operation is convenient, the time and labor are saved, the safety and reliability are good, the stability is good, air holes and overlaps are avoided, the phenomena of denting and undercutting are avoided, formation is good, defects such as incomplete welding and cracks are avoided, the requirements of intergranular corrosion resistance and embrittlement resistance are completely met, the quality of a welding project is guaranteed, and the working efficiency is greatly improved.

Owner:侯霞

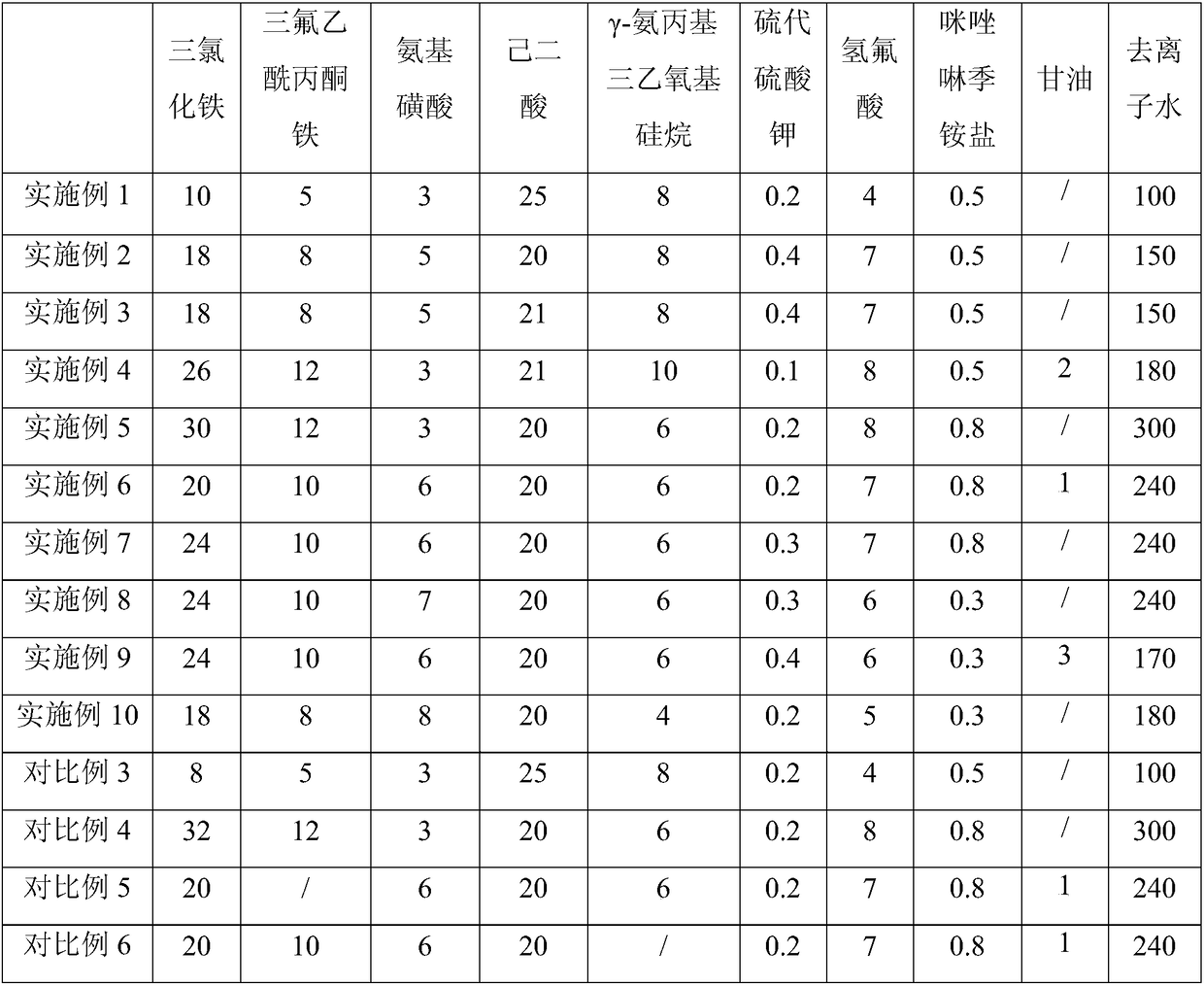

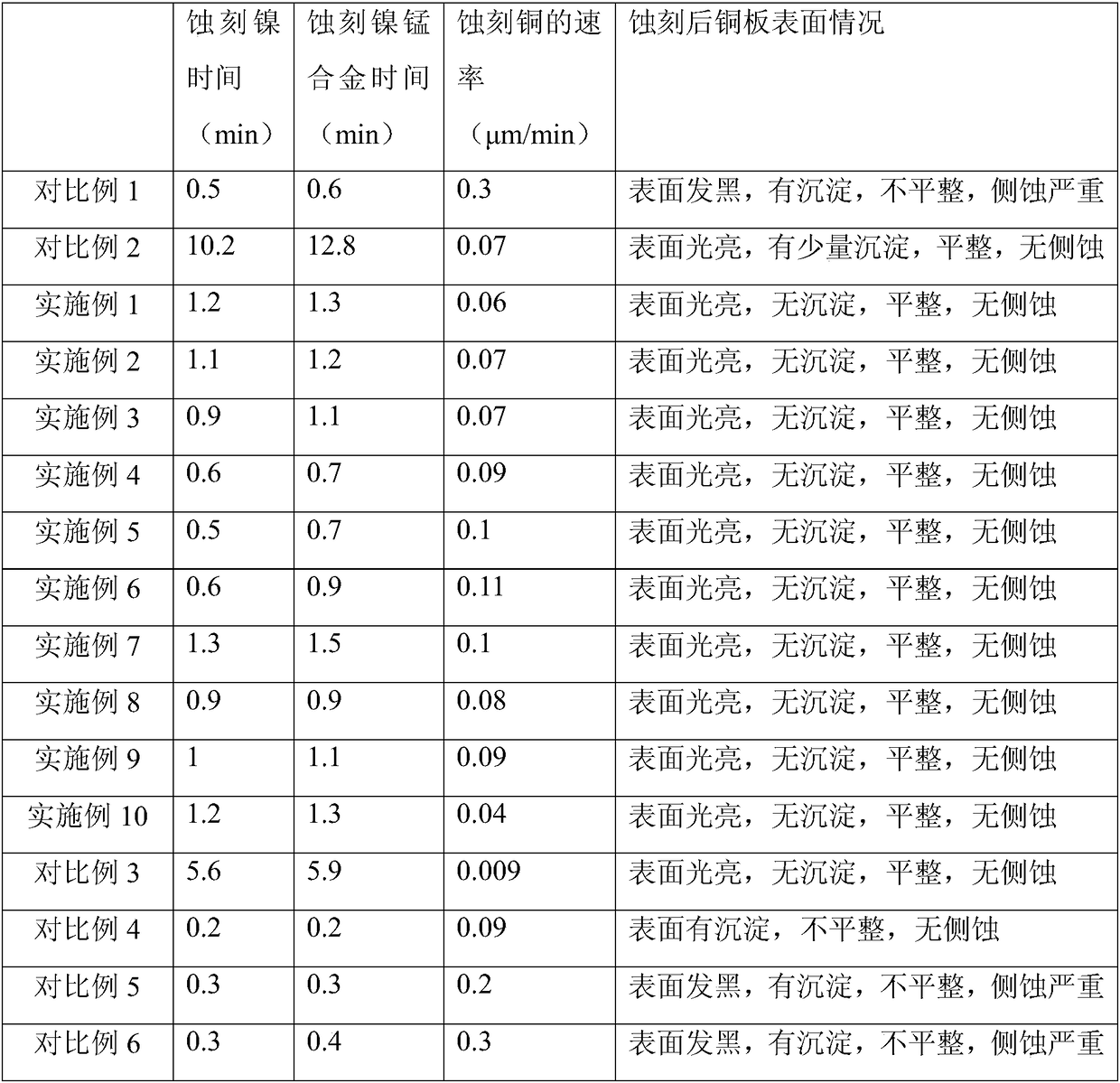

A kind of selective etching liquid of nickel or nickel alloy and its preparation method and application

The invention discloses elective etching solution of nickel or nickel alloy, and a preparation method and application thereof. The etching solution is prepared from the following ingredients in parts by weight: ferric trichloride, ferric trifluoroacetylacetonate, sulfamic acid, hexanedioic acid, gamma-3-aminopropyltriethoxysilane, potassium thiosulfate, hydrofluoric acid, imidazoline ammonium salt and deionized water. The etching solution provided by the invention has a proper etching speed for the nickel or nickel alloy, hardly corrodes copper, and is high in selectivity. In addition, an etched copper plate has a light surface, is free from sediments, is smooth and is free from lateral erosion.

Owner:江苏和达电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com