Welding process of bellows

A welding process and corrugated pipe technology, applied in the field of corrugated pipe welding process, can solve problems such as hidden dangers in stability and safety, limited application, unsatisfactory high-temperature mechanical properties of welding seams, etc., and achieve excellent synergistic function and good surface shape appearance, excellent abnormal temperature and high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A welding process for bellows, comprising the following steps:

[0030] Step 1: welding characteristic research;

[0031] Step 2: Formulate welding material and welding process;

[0032] Step three: welding;

[0033] Step 4: quality control, described quality control comprises technical work, process control and quality inspection and acceptance.

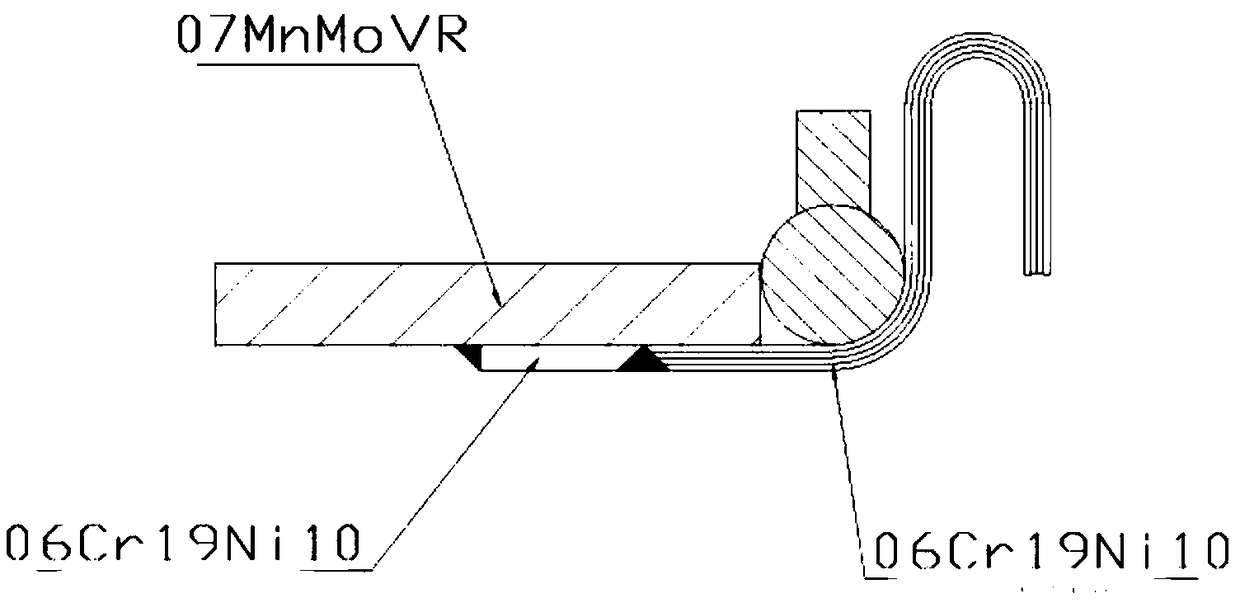

[0034] Further, the research on welding characteristics is a research on the chemical composition and mechanical properties of 07MnMoVR high-strength steel.

[0035] Further, the Mn content of the 07MnMoVR high-strength steel is 1.2%-1.6%, and the tensile strength reaches 630-730 MPa.

[0036] Further, the welding process is electrode arc welding and / or argon tungsten arc welding and / or submerged arc welding.

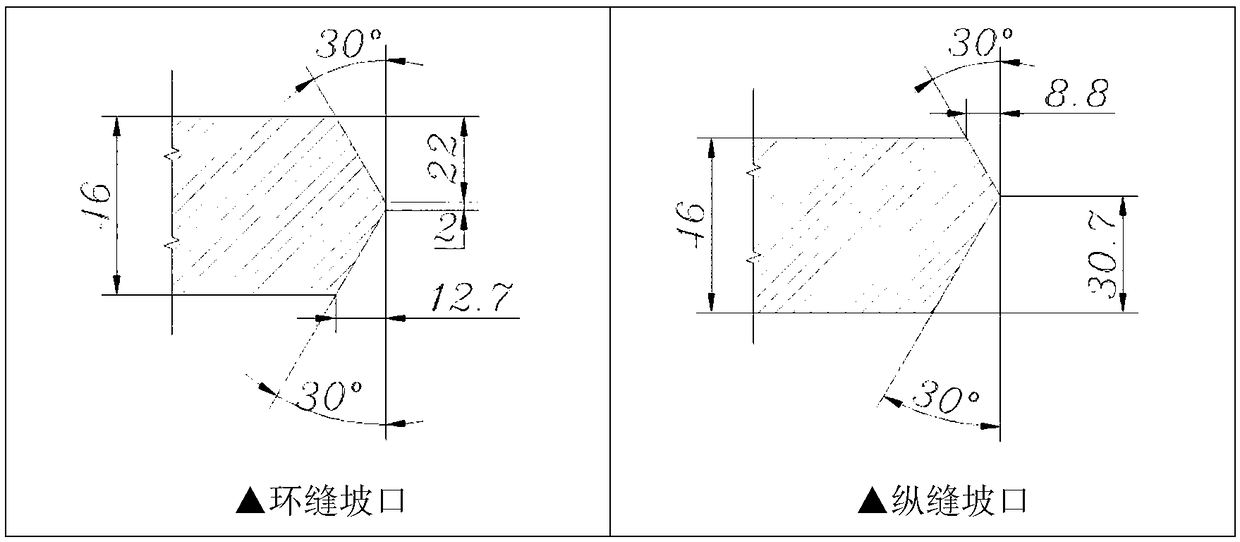

[0037] Further, the longitudinal seam bevel of the welding process is a 1 / 3 asymmetrical X shape without blunt edges, the bevel angle is 60°, processed by 12 planer machines, and the circular seam bevel is a symmet...

Embodiment 2

[0041] For the research on product welding characteristics, according to the analysis of the chemical composition table and mechanical performance table of 07MnMoVR high-strength steel:

[0042] 07MnMoVR high-strength steel chemical composition and mechanical properties table

[0043]

[0044] The Mn content of 07MnMoVR high-strength steel is relatively high, about 1.2% to 1.6%, and the quenched and tempered high-strength plate for pressure vessels with very low C and S content has a tensile strength of 630-730Mpa. Reducing the C content improves the weldability of 07MnMoVR high-strength steel.

[0045] Therefore, there are usually two problems in the weldability of 07MnMoVR high-strength steel:

[0046] (1) Various welding defects caused by welding are mainly various crack problems. The cracks generally produced during welding of 07MnMoVR are welding hot cracks and welding delay cracks.

[0047] (2) Changes in material properties during welding: mainly due to changes in...

Embodiment 3

[0109] A welding material, which is composed of the following chemical components in terms of mass percentage: C ≤ 0.5%, Cr 16.0-18.0%, Fe 6.0-10.0%, Mn ≤ 1.0%, Nb 1.5-3.0%, Si 0.6 ~1.0%, S≤0.015%, P≤0.015%, Ni≥70.0%, k≤0.015%.

[0110] Further, the welding material is composed of the following chemical composition by mass percentage: C 0.3%, Cr16.8%, Fe 7.2%, Mn 0.4%, Nb 2.45%, Si 0.85%, S0.002%, P 0.002 %, K 0.002%, Ni balance.

[0111] Further, the welding process adopted when welding with welding material is selected from MIG arc welding, non-MIG arc welding or automatic welding, preferably non-MIG arc welding process.

[0112] The connection mode between the welding machine and the welding sample is direct current connection. The welding process includes the following steps:

[0113] (1) Clean the groove surface of the sample to be welded, keep it clean and dry, then connect the groove according to the above-mentioned V-shaped butt joint method, fix the position by spo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com