Patents

Literature

56results about How to "No corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

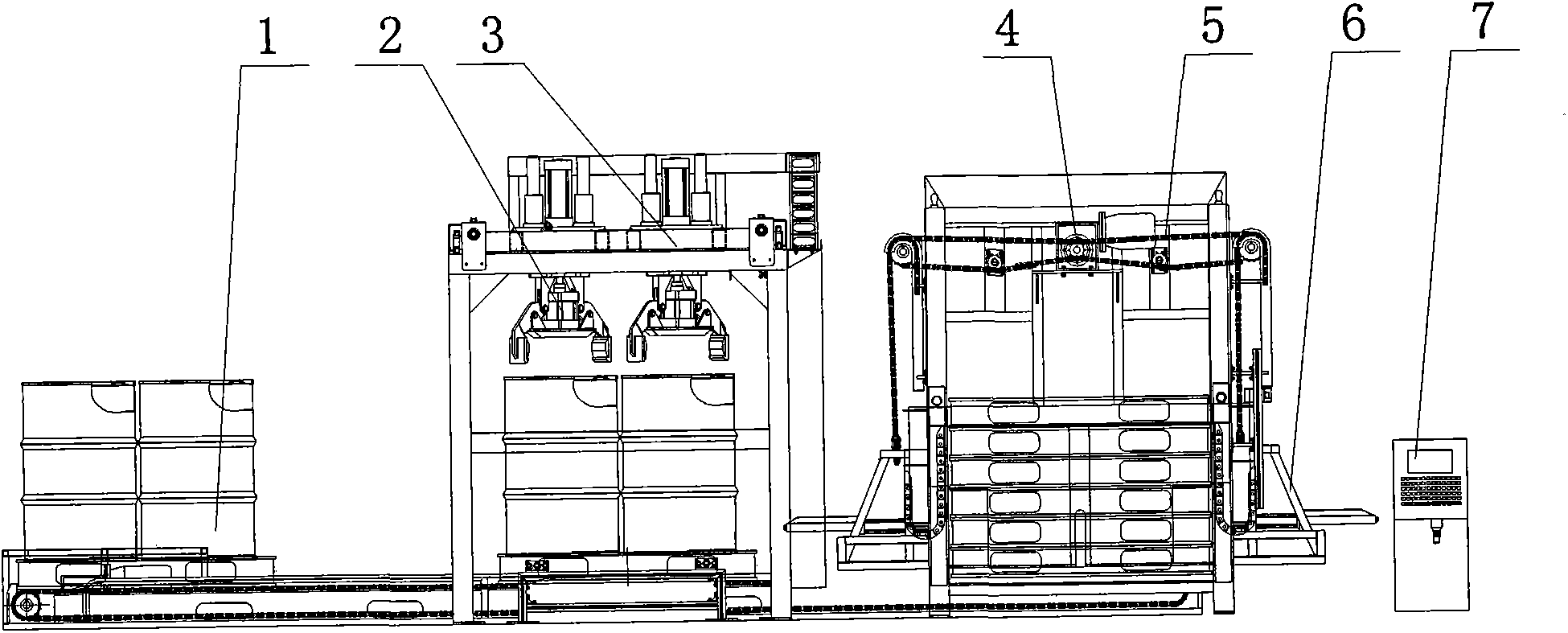

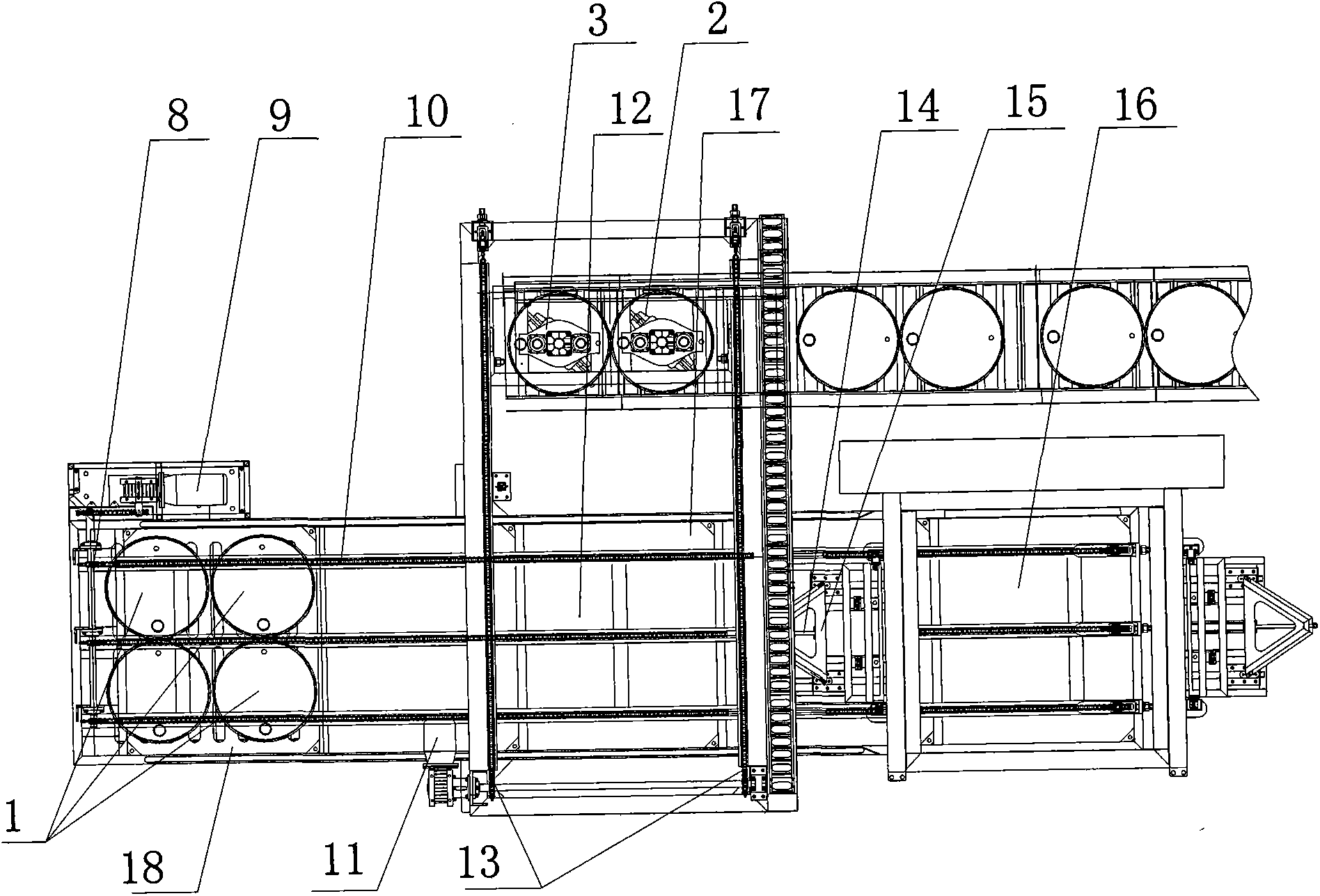

Full-automatic 200L steel drum transfer type stacking system and transfer stacking method thereof

The invention discloses a full-automatic 200L steel drum transfer type stacking system and a transfer stacking method thereof. The system comprises a PLC processing controller used for controlling the full-automatic 200L steel drum transfer type stacking system to automatically operate, and is characterized by further comprising a drum grabbing device used for grabbing a material drum and then placing the material drum into the next procedure, a tray conveying device used for conveying the material drum to the next procedure, and a tray prestoring separation device used for separating the material drum from a tray, wherein the drum grabbing device, the tray conveying device and the tray prestoring separation device are all connected with the PLC processing controller. The full-automatic 200L steel drum transfer type stacking system has the advantages of being free of manual operation, pollution-free, and resistant to corrosion and a high temperature, and achieving unmanned operation of automatic transfer stacking operation on inflammable, highly toxic and highly corrosive operating sites.

Owner:CHANGCHUN BEIFANG INSTR EQUIP

Wear-resisting corrosion-resistant composite coating for ship water-jet propeller impeller and preparation method thereof

ActiveCN103614682ASolving Powder Separation ProblemsImprove performanceMolten spray coatingPump-jetImpeller

The invention discloses a wear-resisting corrosion-resistant composite coating for a ship water-jet propeller impeller and a preparation method thereof, belonging to the technical field of corrosion-resistant wear-resisting coatings of a metal base body. The coating is obtained by a TiC in-situ reinforced NiTi intermetallic compound-based composite coating through solid-solution and aging treatment. The preparation method of the coating comprises the following steps: (1), preparing Ni-Ti-C composite powder by taking sucrose as a precursor of carbon and taking Ti powder and hydroxyl Ni powder as materials; (2), preparing a TiC in-situ reinforced NiTi intermetallic compound-based composite coating on the surface of a stainless steel impeller of a ship water-jet propeller by taking the Ni-Ti-C composite powder as the material through a plasma-beam cladding technology; and (3), carrying out solid-solution treatment and aging treatment on the coating obtained in the step (2) to obtain the coating. The coating disclosed by the invention can greatly improve cavitation erosion resistance, wearing resistance and corrosion resistance of the stainless steel impeller of the ship water-jet impeller.

Owner:中国人民解放军92537部队

Multifunctional colorful waterproof and anticorrosion coating

ActiveCN102146239AIncreased durabilityExtended maintenance timeAnti-corrosive paintsMulticolor effect coatingsWater basedMaterials science

The invention relates to a waterproof building material, in particular to a multifunctional colorful waterproof and anticorrosion coating. A composition of the multifunctional colorful waterproof and anticorrosion coating mainly comprises a water-based fluorocarbon emulsion resin, an ethylene-vinyl acetate copolymer (VAE), a silicate frit, alumina cement, an ester plasticizer, ethylene glycol, inorganic filler and an organic pigment. The multifunctional colorful waterproof and anticorrosion coating disclosed by the invention has the characteristics of good durability, long maintenance time, good corrosion resistance and the like, is mainly applicable to corrosion protections of nontoxic environments, such as waterworks and the like, in particular to protections of concrete structures of industrial and domestic sewage treatment plants and protections of water pipelines, and is also applicable to corrosion protections and water repellencies of concrete structures of landfill sits.

Owner:山东蓝盟防腐科技股份有限公司

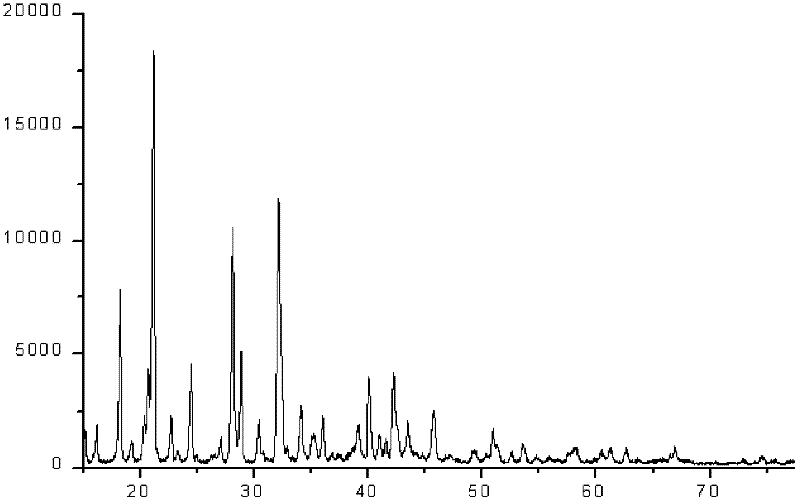

A kind of preparation method of difluorooxalate lithium borate electrolyte salt

InactiveCN102260282ALow toxicityLess corrosiveSecondary cellsGroup 3/13 element organic compoundsSolventLithium compound

The invention provides a preparation process of lithium oxalyldifluoroborate (LiODFB) electrolyte salt. The preparation process comprises the following steps: firstly, adding a fluorine-containing salt compound, a lithium-containing compound and a boron-containing compound in a ball-milling pot on the basis that a molar ratio of fluorine to lithium to boron is (2-6): (2-6): (1-3), ball-milling for 2-24 hours at the temperature of 5 DEG C-80 DEG C, and then placing in a muffle furnace, carrying out thermal treatment for 2 hours-24 hours at the temperature of 80 DGE C-850 DEG C; then mixing theraw materials subjected to high-temperature treatment with oxalate in a solvent, and reacting for 1 hour-12 hours at the temperature of 0 DGE C-160 DEG C, wherein the ratio of oxalate to boron is (1-5): (1-3); and finally, purifying with an organic solvent multiple times so as to obtain the required product. The invention has the advantages that the raw materials have low toxicity, low corrosivity, the preparation process is simple and environmentally-friendly and has no strict requirements for equipment on corrosion resistance, high pressure resistance and the like, and is suitable for industrial production in large scale, and investment is less.

Owner:CHANGZHOU GUOYA NEW ENERGY TECH

Anticorrosive paint

InactiveCN102504674ANo change in flame retardancyConductivity unchangedAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention relates to an anticorrosive paint which comprises epoxy resin, carbon substances, metal and oxides thereof, a flame retardant, a heat insulating material, additives, a mixed solvent and a curing agent substance, wherein the epoxy resin is flame-retardant epoxy resin which is an additive flame-retardant epoxy resin formed by combination of common epoxy resin and the flame retardant or a reactive flame-retardant epoxy resin formed by combination of flame-retardant epoxy resin with a flame-retardant element and an inorganic flame retardant.

Owner:XIAN RUIJINYUAN ENERGY TECH

Magnesite material product

InactiveCN1850712AFlexural strength exceedsReduce manufacturing costSolid waste managementBrown iron oxideCorrosion

The invention is a magnesite product, using magnesium oxide 30-40%, magnesium chloride solution 30-40%, iron oxide powder pigment 0.5-1%, yellow sand 17-25%, sawdust or rice hull powder 5-10%, crushed glass fiber 0.2-1%; firstly placing magnesium oxide, yellow sand and iron oxide powder into a blender and blending for 1-10 minutes, then placing magnesium chloride solution into the blender and blending for 1-10 minutes, and finally placing sawdust or rice hull powder, and crushed glass fiber into the blender and blending for 3-15 minutes, so as to make magnesite pulp; placing above two layers of fillings into a mould, pouring the magnesite pulp into the mould, vibrating uniformly, naturally solidifying at 25 deg.C-30 deg.C, so as to make the magnesite product. And it has advantages of: 1. good anti-theft effect; 2. no pollution and low manufacturing cost; 3. stronger shock resistance, strong bearing ability and good antiaging property; 4. good corrosion resistance.

Owner:徐建军

Houttuynia beverage and its production method

The houttyuynia beverage with the functions of clearing heat away, removing toxic material, elimianting summer-heat and allaying thirst is made up by using drinking water, houttuynia, peppermint, sugar, natural stevioside and citric acid according to a certain mixing ratio through the processes of water extraction, filtering, mixing materials, secondary filtering, homogenizing, sterilizing, filling, sealing and quality inspection. Said product is sweet-sour palatable in taste and has golden yellow colour, and is suitable for large-scale production.

Owner:湖南省岳阳市君山区麒英食品厂

Method for preparation of graphite surface silicon carbide coating

The invention discloses a method for preparation of a graphite surface silicon carbide coating. The method includes: mixing 99.99% of a graphite material with silane in a weight ratio of 1:1 to prepare a graphite-silane mixed material, then conducting furnace pretreatment, energization warming, secondary warming and heat preservation, third warming and heat preservation, fourth warming and heat preservation, and cooling. Specifically, nitrogen charging is carried out during the furnace pretreatment and the energization warming, and charging of a nitrogen-hydrogen mixed gas is performed during the fourth warming and heat preservation. A graphite carbon material workpiece treated by the method can endure a high temperature up to 1600DEG C, is not oxidized below 2000DEG C under an aerobic state, and can resist corrosion of various acid and alkali salts.

Owner:QINGDAO TIANDI CARBON

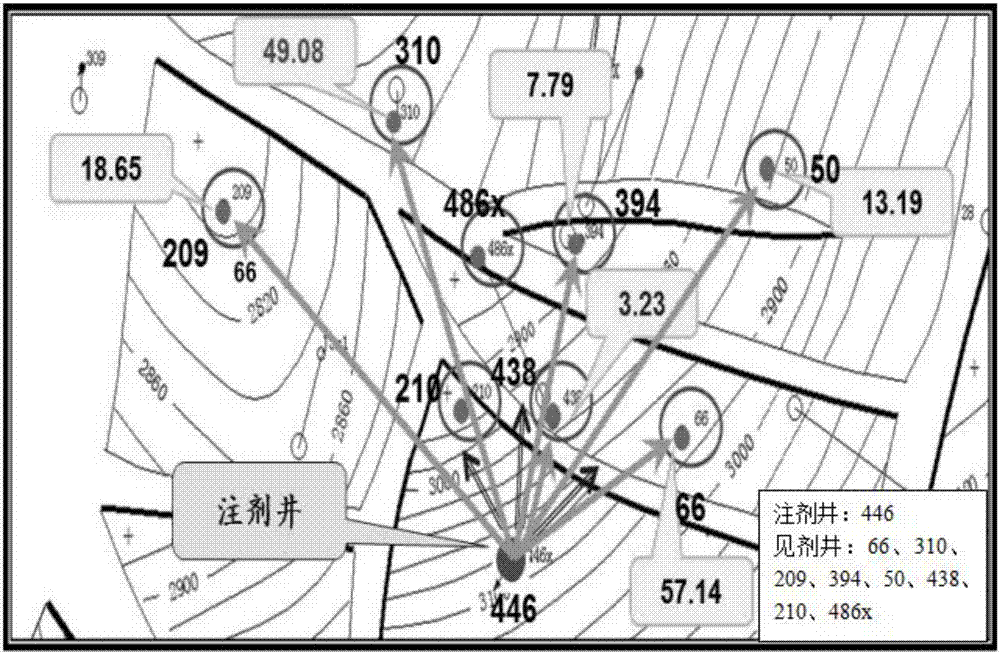

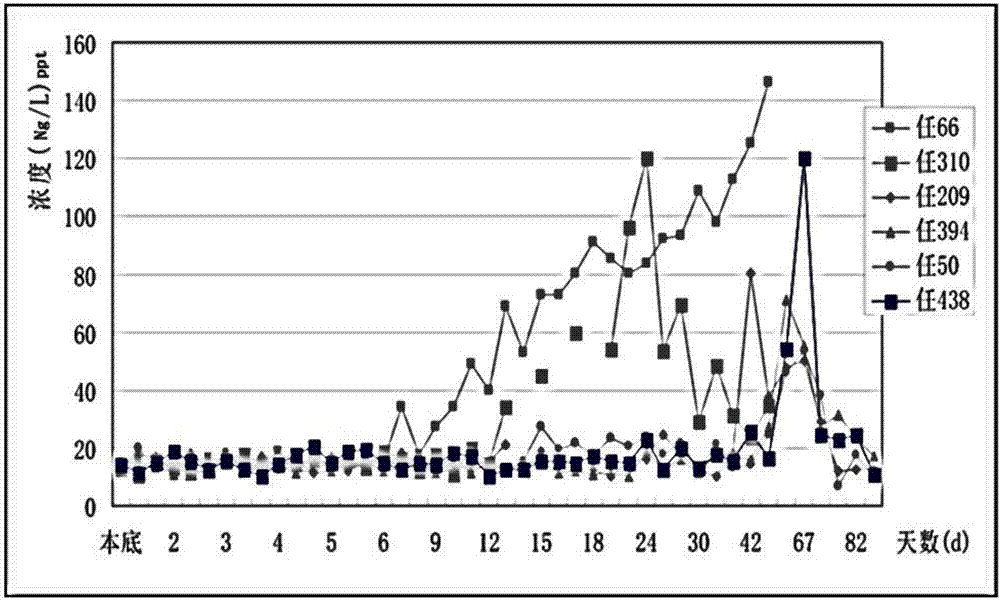

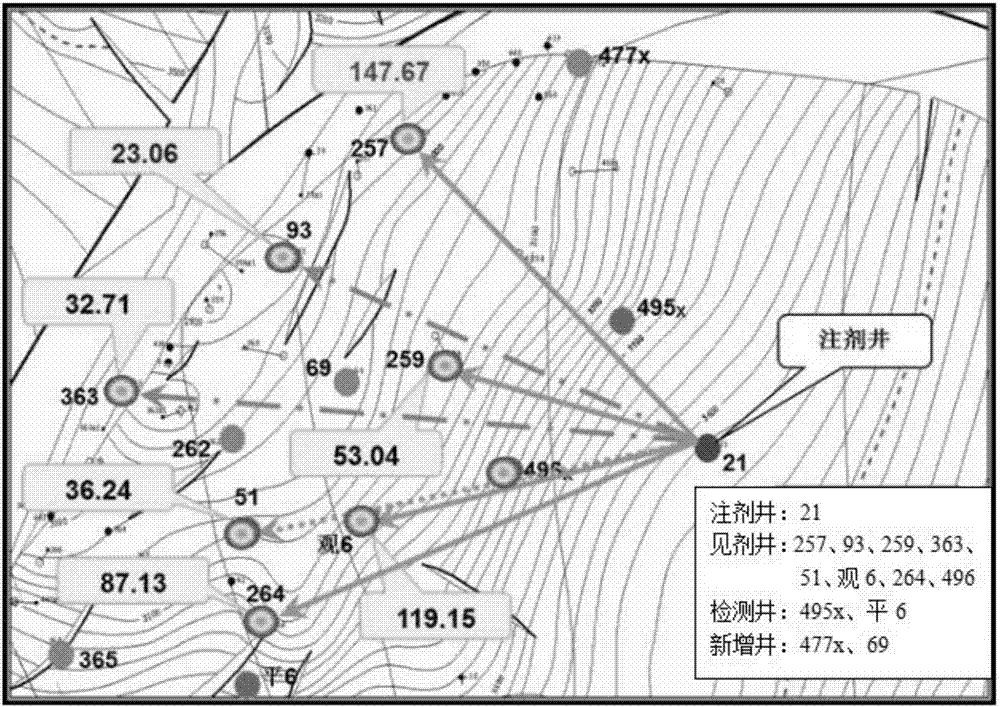

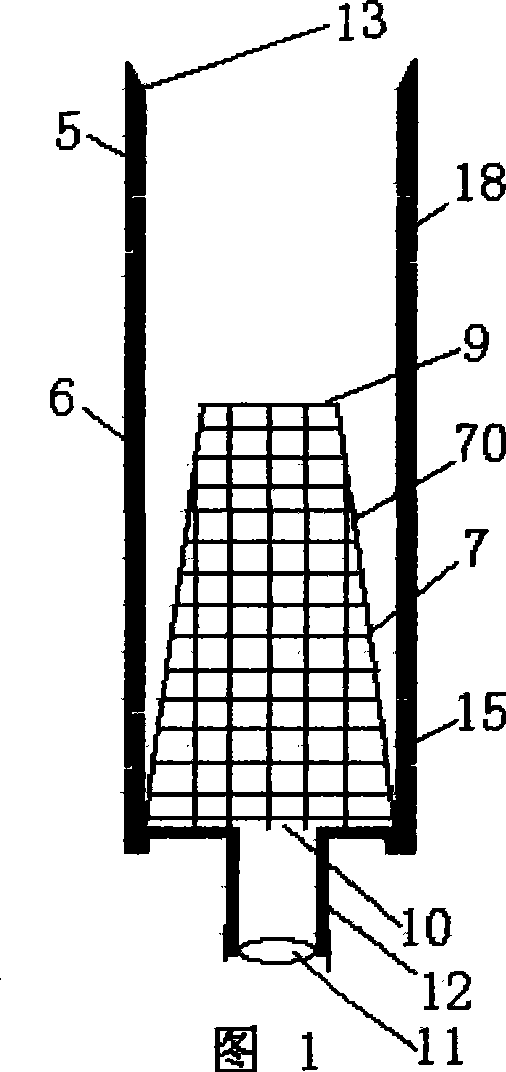

Water-based trace chemical tracer and method for measuring connectivity between water injection wells

ActiveCN107989600ANo pollution in the processNo corrosion resistanceConstructionsPorosityWater based

The invention discloses a water-based trace chemical tracer. The water-based trace chemical tracer comprises the components of perfluoroalkyl sulfonates or perfluoroalkyl carboxylates. A method for measuring connectivity between water injection wells by using the water-based trace chemical tracer comprises the steps that the tracer is prepared into aqueous solution with a certain concentration tobe added into injected water and then is injected into the wells; after the tracer is injected for a period of time, sampling is conducted in a production well, and the concentration of the tracer ismeasured. Through tracer monitoring, the connecting condition of oil-water wells and the water injection wells, the permeability within a water injection wave and the oil reservoir range, change of the permeability and the porosity within a water injection wave and oil reservoir range and the trend of natural cracks and artificial cracks can be understood, the reasonable injection-production ratiois determined, and the injection-production balance is optimized. The water-based trace chemical tracer has no radiation and no toxicity, and is safe, environmentally friendly, and less in using amount, high temperature and high pressure resistance is achieved, and the water-based trace chemical tracer is only soluble in water, has good biological stability and chemical stability, and can be effective in a stratum for a long time.

Owner:BEIJING GEPETTO OIL TECH

Composite artificial shone material

InactiveCN1453238AWide variety of sourcesLow costSolid waste managementCeramic shaping apparatusMagnesiumCorrosion

The composite artificial stone material consists of light burnt magnesia 10-35 wt%, mine refuse 40-80 wt%, magnesium chloride 5-20 wt%, water 5-30 wt% and chelating agent 0.01-0.1 wt%. The present invention is favorable to environment protection, and the composite artificial stone material has wide material resource, low cost, no radioactivity, no pollution, high corrosion resistance and rather good machinability.

Owner:孙丽英

Method for manufacturing polyethylene microporous filter tube for secondary filtering of compressed air

InactiveCN102068866ATo achieve innovation and creationAchieve transformationDispersed particle filtrationRoom temperatureFilter media

The invention a method for manufacturing a polyethylene microporous filter tube for secondary filtering of compressed air, which comprises the steps of: A, sieving polyethylene powder with a sieving machine; B, coating silicone oil on the inner wall of an external iron tube mould and the outer wall of an internal iron tube mould for reverse mould sintering and assembling a mould body; C, pouring siftage sieved by the sieving machine between the inner wall of the external iron tube mould and the outer wall of the internal iron tube mould; D, placing the mould body in a constant temperature furnace, sintering for 5-6 hours at 250-300 DEG C; and E, cooling the mould body to room temperature and de-moulding. As a novel filtering medium, the polyethylene microporous filter tube manufactured by novel materials, with novel technology and processes, has high and stable filtering precision, long service life and easy cleaning and is non-toxic, corrosion resisting, temperature resisting at 90 DEG C and can be recycled repeatedly and is an ideal material for various industries to implement high precision gas-solid separation and oil-gas separation. In the manufacturing process, the filter core is only sintered to form at one time, thereby reducing the cumbersome multi-step manufacturing means and saving the labor.

Owner:张柏筠

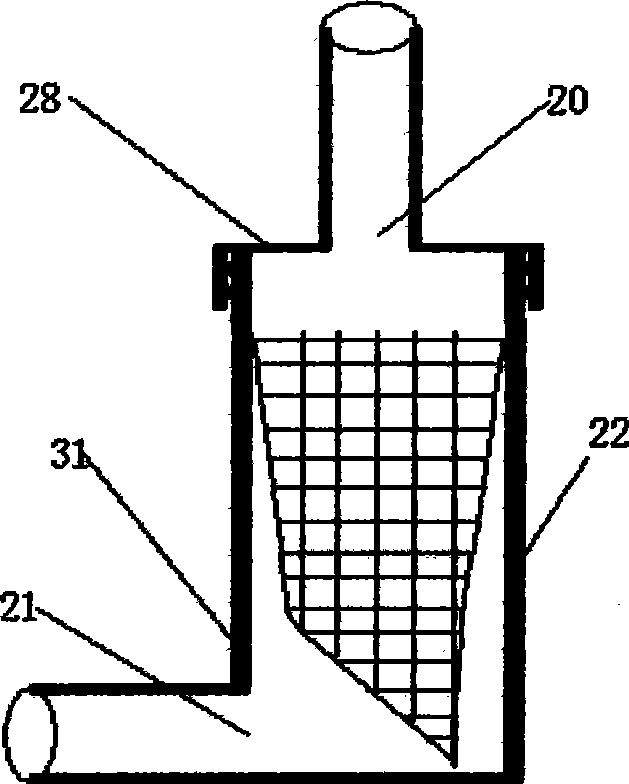

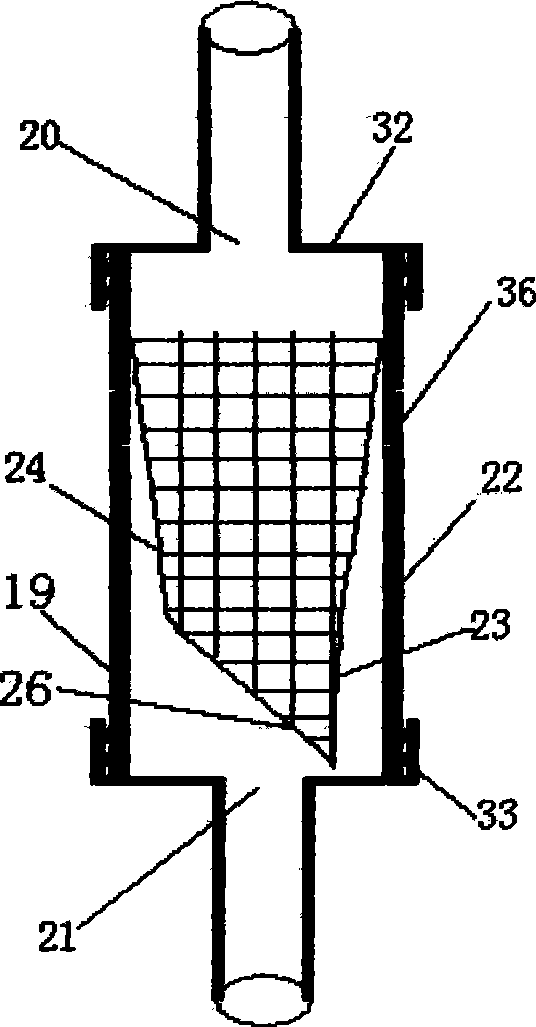

Sucker head of suction device, filter and negative-pressure source

ActiveCN101391118ASolve the blockageEffective filteringWound drainsSuction devicesCause blockageDiaphragm pump

The invention provides a suction apparatus which can uninterruptedly and completely suck liquid gas generated in an operation, can filter impurities and can not cause blockage; the sucked gas liquid containing virus and bacteria is directly discharged outside or into a disinfecting apparatus, so air and environment in a consulting room or a sick room can not be polluted. A filter screen barrel is arranged in the handle tube of a filter or a sucker head; the bottom of the filter screen barrel can be an inclined bottom or a flat bottom; the bottom of the filter screen barrel or the barrel mouth can face towards a liquid outlet; the filer screen barrel can have a conicity or no conicity; the filter screen barrel can be integraly fixed or movably sleeved in the handle tube; and the tail end of the sucker head is communicated with a pipette. A negative pressure source is a membrane pump provided with a sucking nozzle and a discharging nozzle, wherein the sucking nozzle is communicated with the pipette; the discharging nozzle is communicated with a bleeder tube; and the membrane pump is connected with a power supply through a power cord and a power joint.

Owner:左圣林

Synthesis method of radiation-curing polyurethane acrylate paint

InactiveCN104342015ASimple methodLow costAnti-corrosive paintsPolyurea/polyurethane coatingsChemistryToluene diisocyanate

The invention relates to a synthesis method of a radiation-curing polyurethane acrylate paint, which comprises the following steps: adding 2,4-toluene diisocyanate into a 250mL four-neck flask; adding a catalyst dibutyltin dilaurate, and dropwisely adding dehydrated polyoxypropylene diol into a reactor; after finishing charging, heating, and keeping the temperature to react until the -NCO content reaches the theoretical value; adding pentaerythritol triacrylate, keeping the temperature to react for termination, and meanwhile, detecting the -NCO content in the system until the -NCO content reaches the theoretical value; and cooling to room temperature, adding a given amount of trimethylolpropane trimethylacrylate, and regulating the reaction functionality and viscosity of the polyurethane acrylate radiation-curing paint to obtain the radiation-curing polyurethane acrylate paint. The method is simple, is low in cost, and does not need to add any initiator; and the synthetic radiation-curing polyurethane acrylate paint has the advantages of no pollution, high corrosion resistance and high chemical resistance.

Owner:CHONGQING JINYU PIPELINE EQUIP

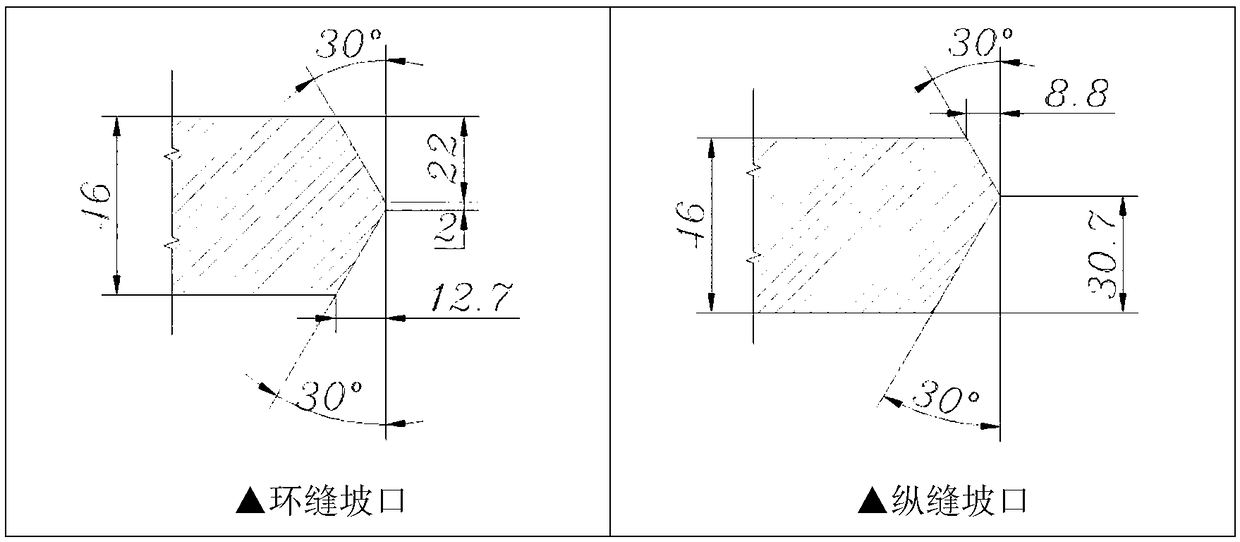

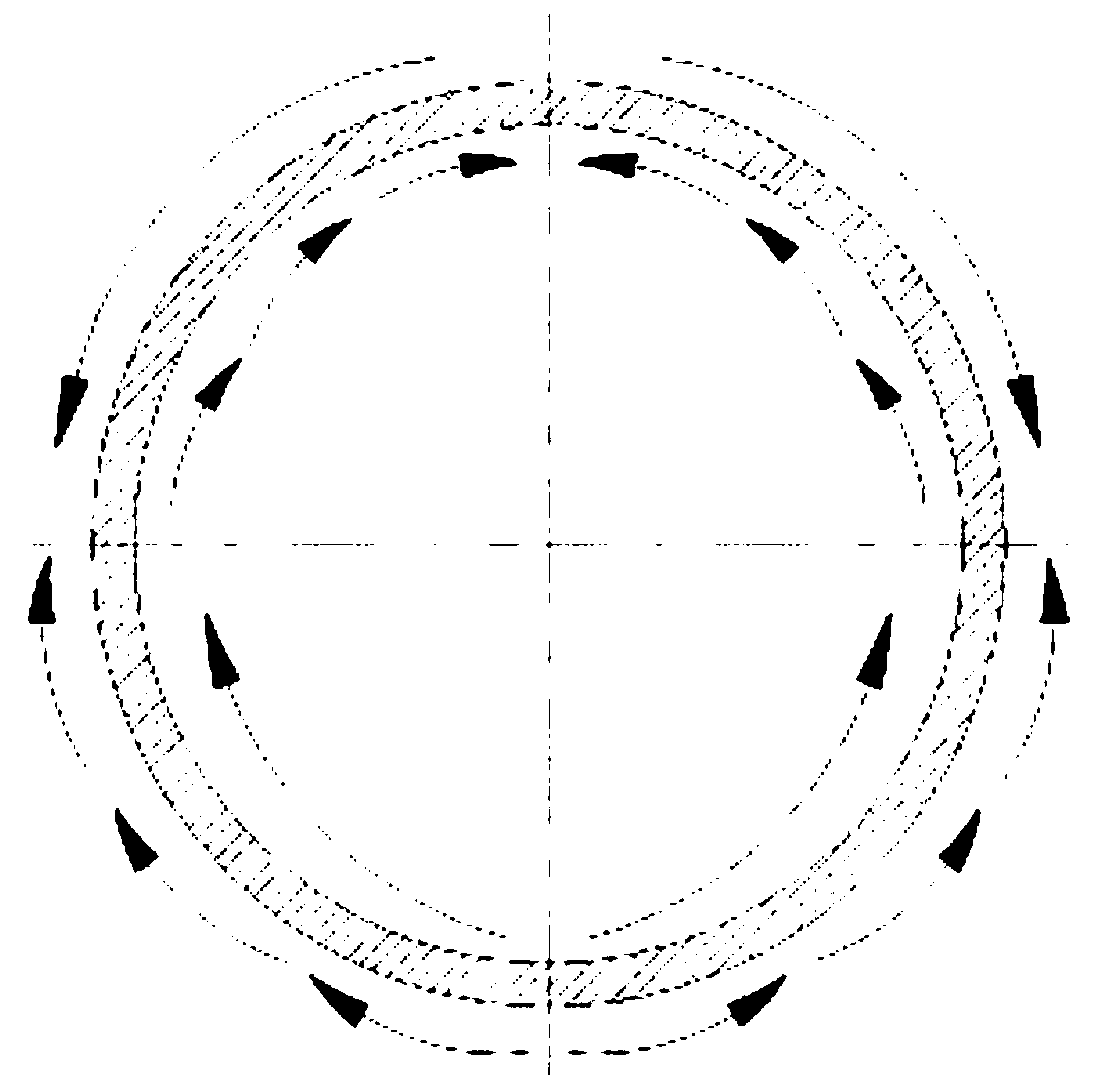

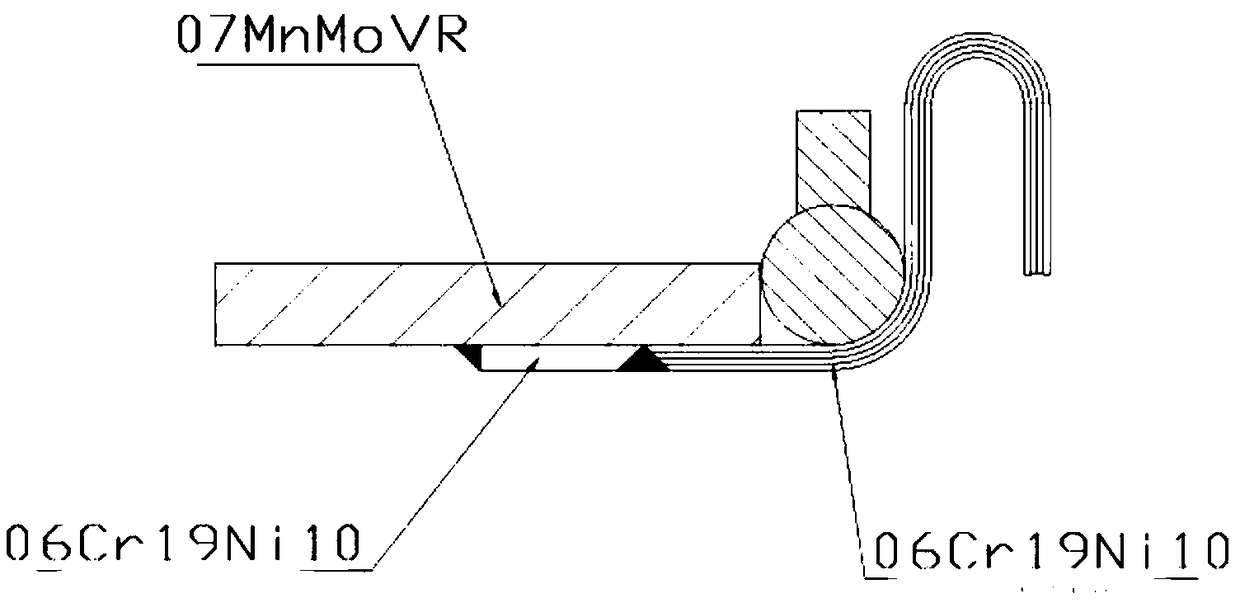

Welding process of bellows

InactiveCN109396610AGood surface morphologyNo crackArc welding apparatusWelding/cutting media/materialsQuality controlEngineering

The invention provides a welding process of a bellows. The welding process of the bellows is characterized by comprising the following steps that step 1, welding characteristic research is carried out; step 2, a welding material and a welding process are formulated; step 3, welding is carried out; and step 4, quality control is carried out, wherein the quality control includes technology work, process control and quality inspection and acceptance.

Owner:JIANGSU FENGHE MACHINERY MFG

High-molecular polymer composite suitable for bioreactor and method for manufacturing high-molecular polymer composite

ActiveCN103421262AGood anti-friction performanceMeets and complies with all performance requirements for contactPoly ether ether ketonePolyamide

The invention relates to a high-molecular polymer composite suitable for a bioreactor and a method for manufacturing the high-molecular polymer composite, and belongs to the technical field of biological pharmacy. The composite comprises, by weight, 55-70 parts of polytetrafluoroethylene, 10-15 parts of polyether-ether-ketone, 8-12 parts of polyphenyl ester, 3-5 parts of polyphenyl ether, 3-5 parts of polyethylene, 3-5 parts of polyamide and 3-5 parts of zirconia or silicon nitride. The high-molecular polymer composite and the method have the advantages that problems that parts of existing composites in the prior art are toxic, the existing composites are volatile, are easy to decompose, are poor in temperature resistance and corrosion resistance and are not suitable for bioreactors, or the existing compositions are only suitable for membrane bioreactors and are poor in abrasion resistance are solved; all requirements on the performance of the high-molecular polymer composite which is in contact with biological products in the bioreactor are met, the high-molecular polymer composite has self-lubricating performance, and the abrasion resistance of the high-molecular polymer composite is greatly improved.

Owner:成都英德生物医药设备有限公司

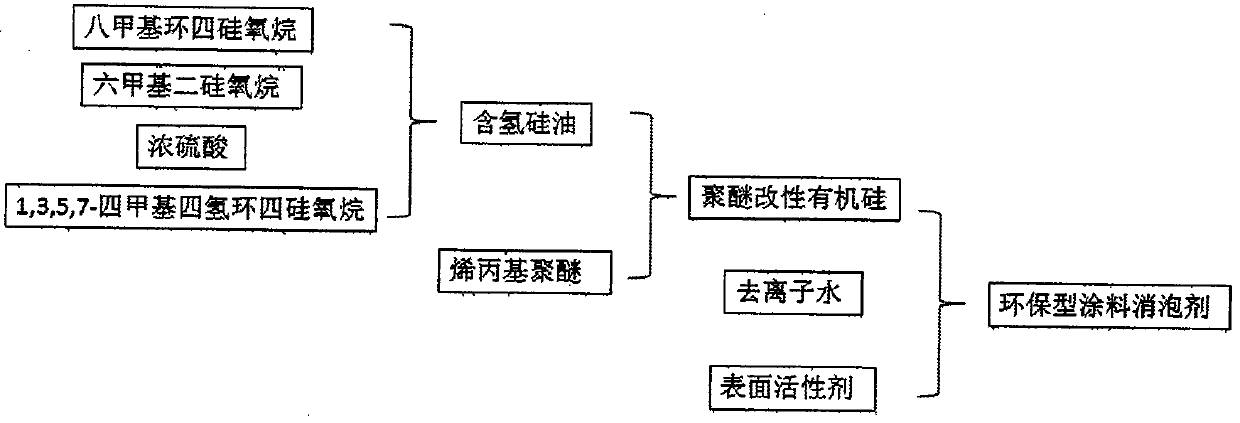

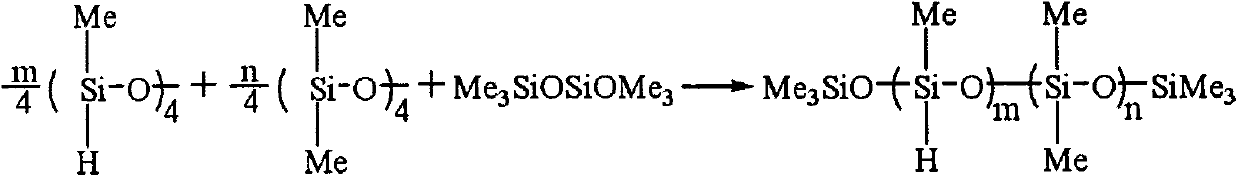

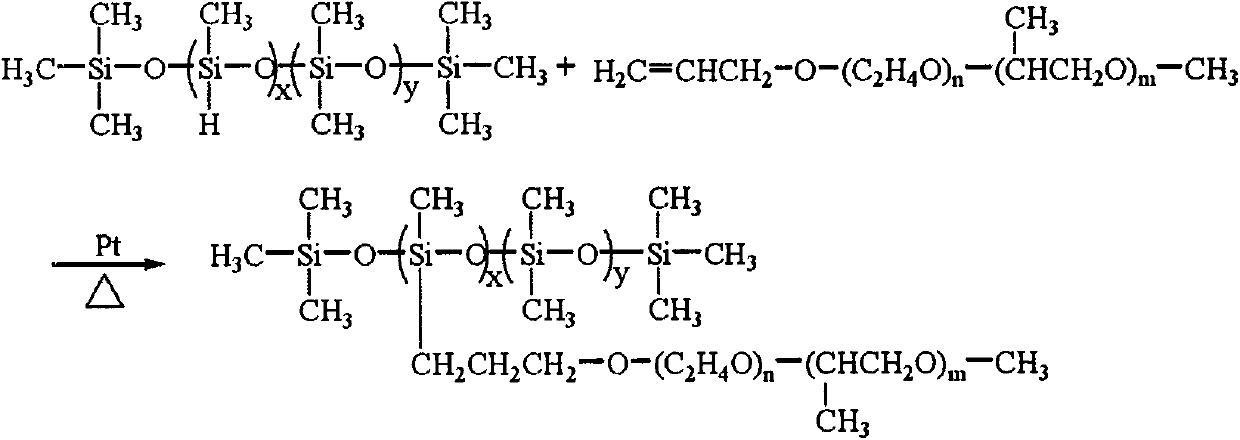

Environment-friendly coating material defoamer preparation method

InactiveCN110845903AGood defoaming effectImprove surface activityCoatingsFoam dispersion/preventionMeth-Active agent

The invention relates to an environment-friendly coating material defoamer preparation method, which comprises: 1, mixing octamethylcyclotetrasiloxane and concentrated sulfuric acid, and reacting under a heating condition to prepare hydrogen-containing silicone oil; 2, mixing the hydrogen-containing silicone oil and allyl polyether, and reacting under a heating condition to prepare polyether modified organic silicon; and 3, mixing the polyether modified organic silicon, deionized water and a surfactant, and reacting under a heating condition to prepare an aqueous coating material defoamer. According to the invention, the prepared environment-friendly coating material defoamer overcomes the use limitation of the traditional organic silicon defoaming agent, has excellent characteristics of self-emulsifying, self-dispersing, stable emulsifying property, good defoaming and foam inhibition property, high-temperature resistance, acid resistance and alkali resistance, has advantages of high defoaming speed, high foam inhibition capacity and long action time compared with foreign products, has good development prospects, can replace foreign products, and enhances the competitiveness of domestic products.

Owner:郑州中岳高新材料有限公司

Copper-nickel-chrome-molybdenum-based alloy powder and fusion covering method thereof

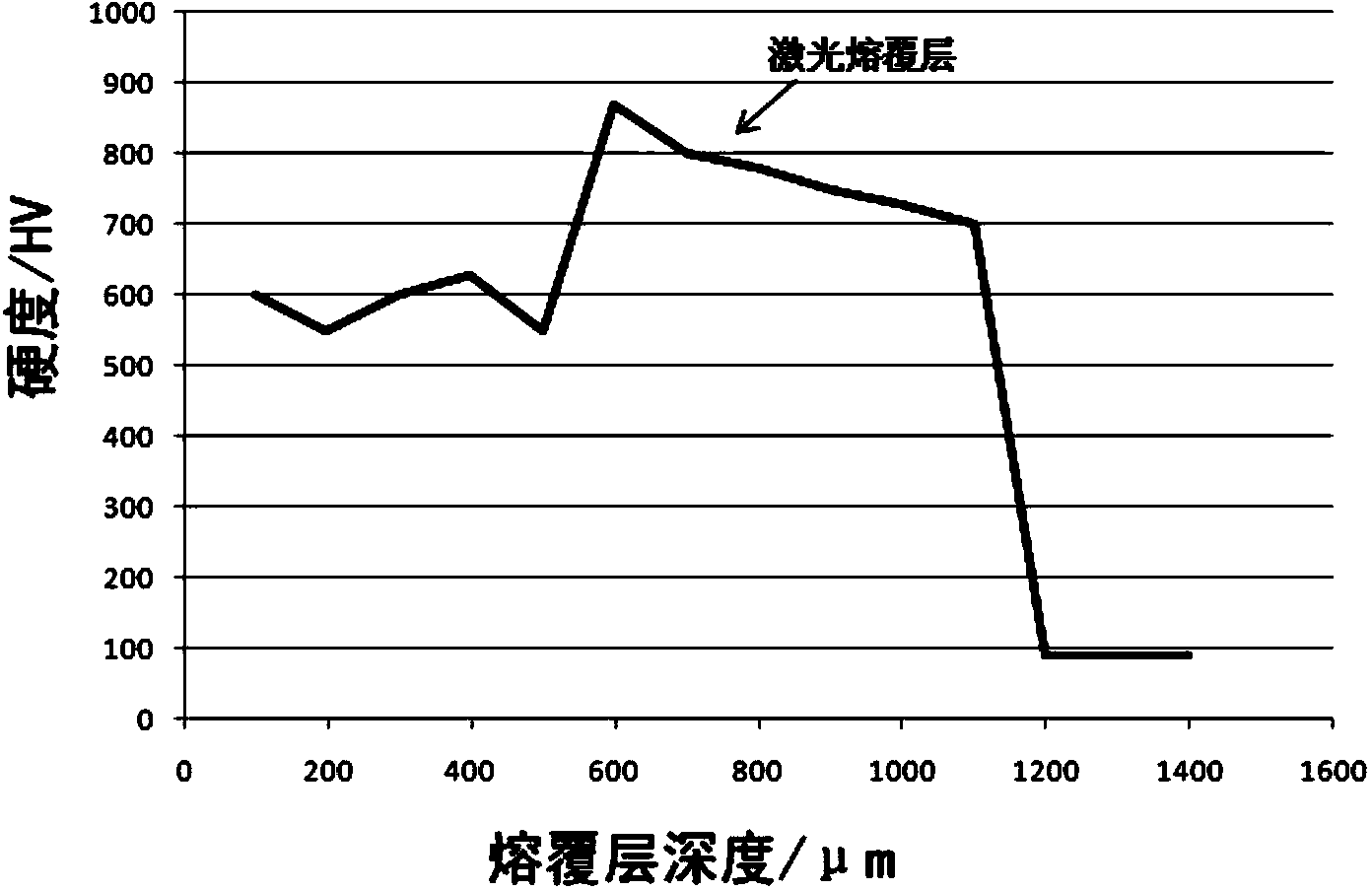

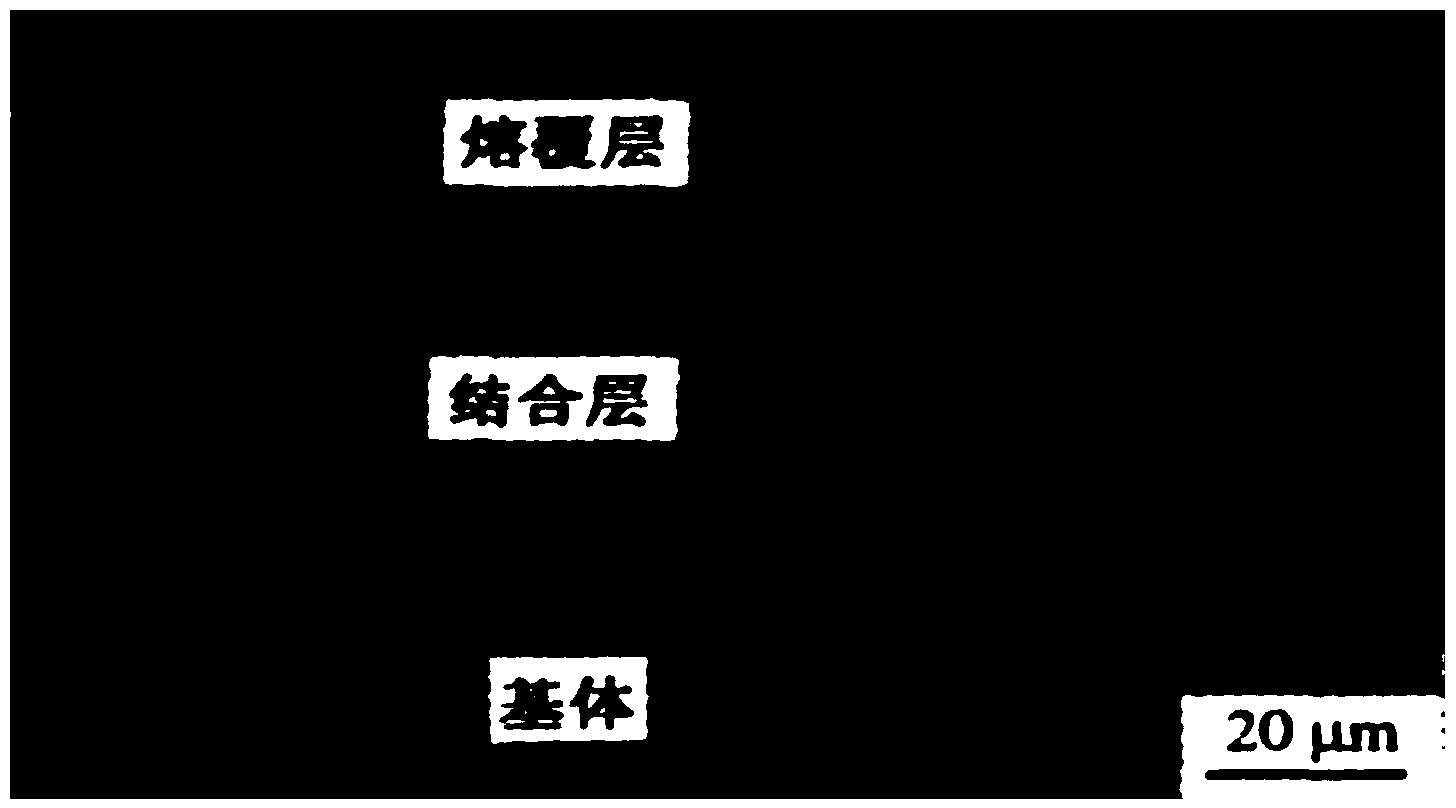

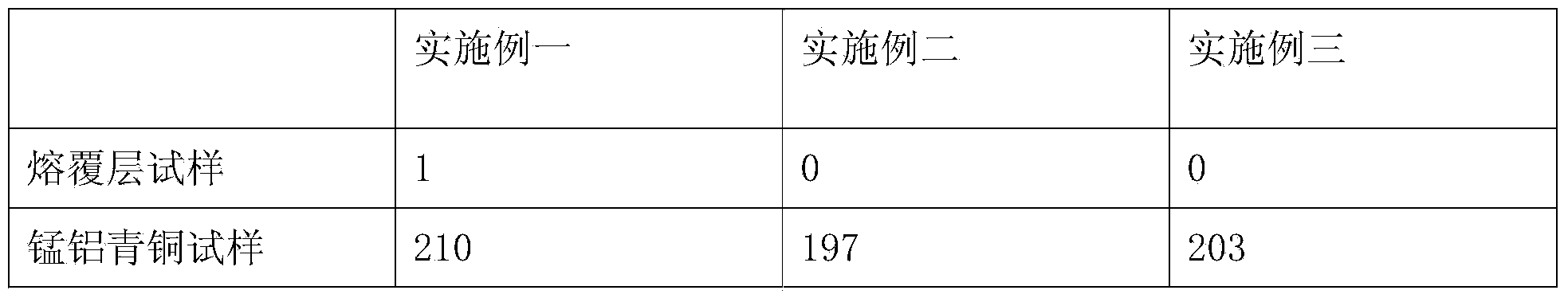

ActiveCN103962546AStrong Adhesive PerformanceStrong anti-penetration performanceMetallic material coating processesChromiumNickel

The invention discloses copper-nickel-chrome-molybdenum-based alloy powder and a laser fusion covering method thereof and relates to substrate fusion covering materials and a laser fusion covering technology thereof. According to the copper-nickel-chrome-molybdenum-based alloy powder and the laser fusion covering method thereof, substrate corrosion resistance and cavitation resistance can be improved. The copper-nickel-chrome-molybdenum-based alloy powder comprises, by weight, the components of 5%-8% of NbC powder and 92%-95% of copper-nickel-chrome-molybdenum alloy powder, wherein the copper-nickel-chrome-molybdenum alloy powder comprises 20%-25% of Ni, 20%-25% of Cr, 13%-20% of Mo, 2%-5% of W, and the balance Cu. The laser fusion covering method comprises two steps of copper-nickel-chrome-molybdenum-based alloy powder preparing and cladding layer preparing.

Owner:河北瑞驰伟业科技有限公司

Flame-retardant leather brick and embroidery method thereof

The invention discloses a flame-retardant leather brick and an embroidery method thereof. The flame-retardant leather brick comprises a leather layer and a flame-retardant PU layer, wherein the flame-retardant PU layer is prepared from polyether polyol, bentonite, dimethyl silicone oil, 1,4-butanediol, an amine catalyst, an antioxidant, water, magnesium carbonate, glycerol triacetate, potassium isooctanoate, a flame retardant additive, vinyl trimethoxy silane and isocyanate. According to the flame-retardant leather brick, the raw materials in use do not contain harmful substances, no harm is caused to the human body, and the flame-retardant leather brick is environmentally friendly, has the advantages of being high in strength, resistant to earthquakes, retardant to flame, low in smoke content, free of toxicity and formaldehyde, resistant to water, moisture, corrosion and high temperature, insulating, light, quick to install, resistant to aging and abrasion and the like, and is free ofpollution, safe, environmentally friendly, long in service life, easy and convenient to construct, reasonable in price and aesthetical.

Owner:王世茸

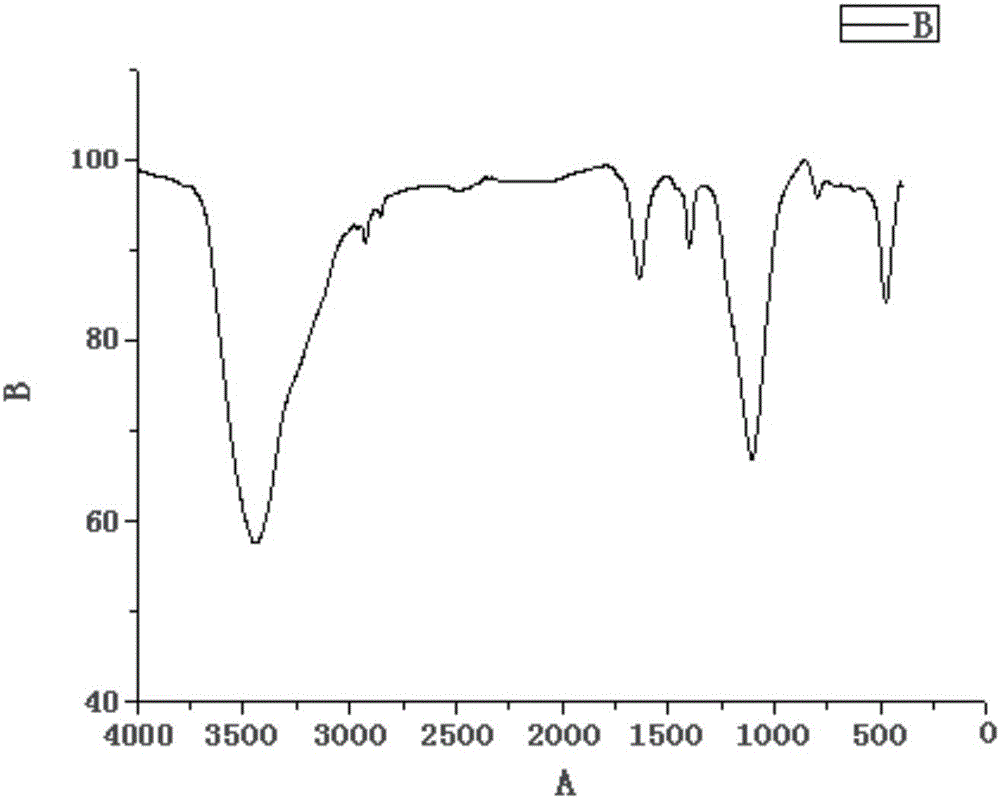

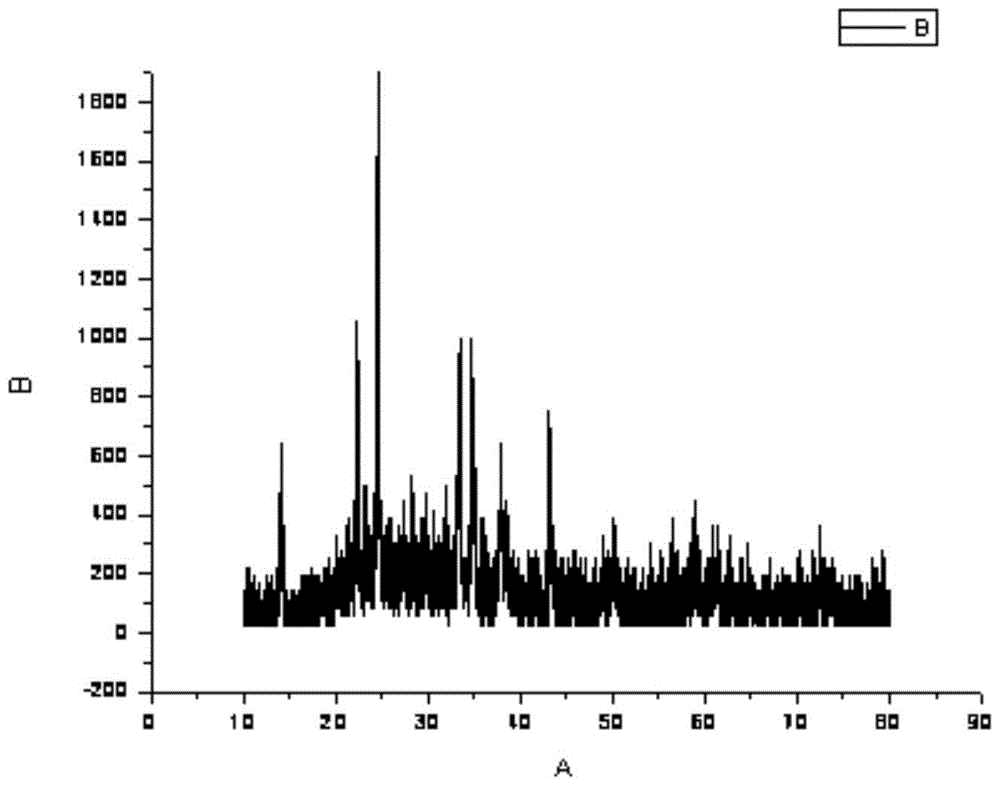

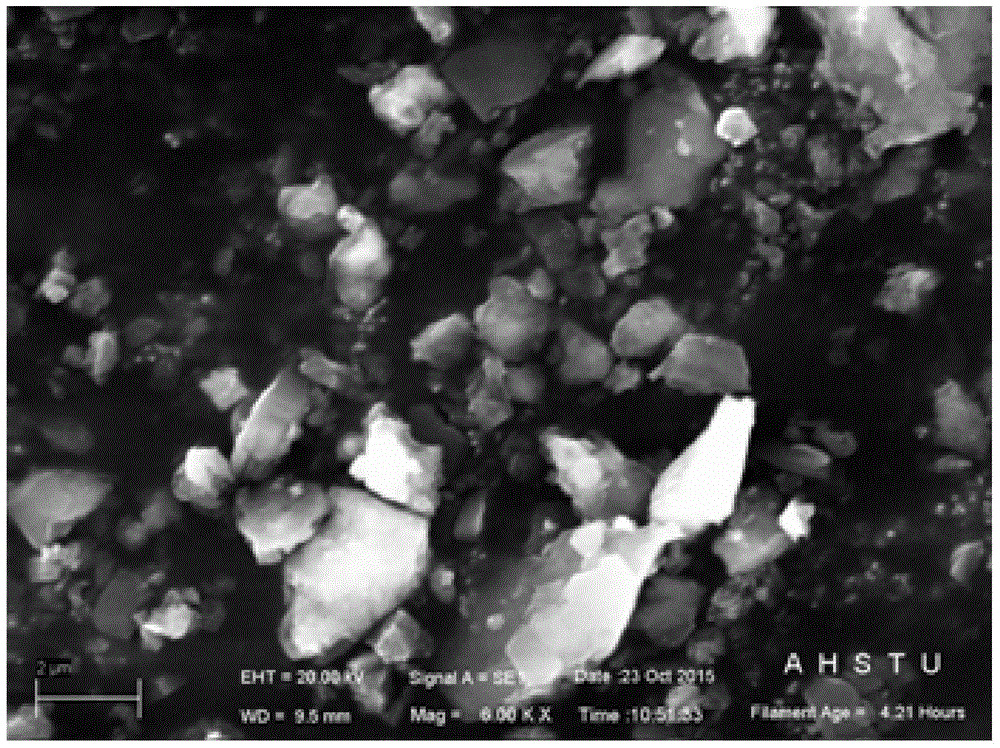

Method for preparing high-purity silicon by energy-saving and environmental protection technology

ActiveCN105668572AReduce energy consumptionThe preparation process is simpleChemical industrySilicon compoundsThermal insulationCarbon black

A method for preparing high-purity silicon by an energy-saving and environmental protection technology comprises the following steps: uniformly mixing quartz sand or white carbon black and a reducing agent according to the weight ratio of (0.8-1.2): (1.2-1.6) to obtain a mixture, putting the mixture into a heating furnace with furnace chamber volume being 10-30 liters; spraying carbon powder of 100-325 meshes onto the surface of the mixture with the mass ratio of the carbon power to the mixture being (0.1-0.5): (2.0-2.8); heating the furnace chamber of the heating furnace to 200-260 DEG C for 0.5-1 h, and carrying out thermal insulation for 1-2h; heating the furnace chamber of the heating furnace to 300-400 DEG C for 0.5-1 h, and carrying out thermal reaction for 3-6 h to obtain a reaction product; cooling the reaction product to room temperature, washing the reaction product with normal-temperature distilled water for several times to obtain a washed product; and drying the washed product at the temperature of 90-110 DEG C to obtain elemental silicon. The method is green and environmentally friendly, has advantages of low energy consumption, simple process, low cost and few and simple equipment, and is easy to use at large scale in the industry. In addition, purity of the prepared elemental silicon is high.

Owner:ANHUI SCI & TECH UNIV

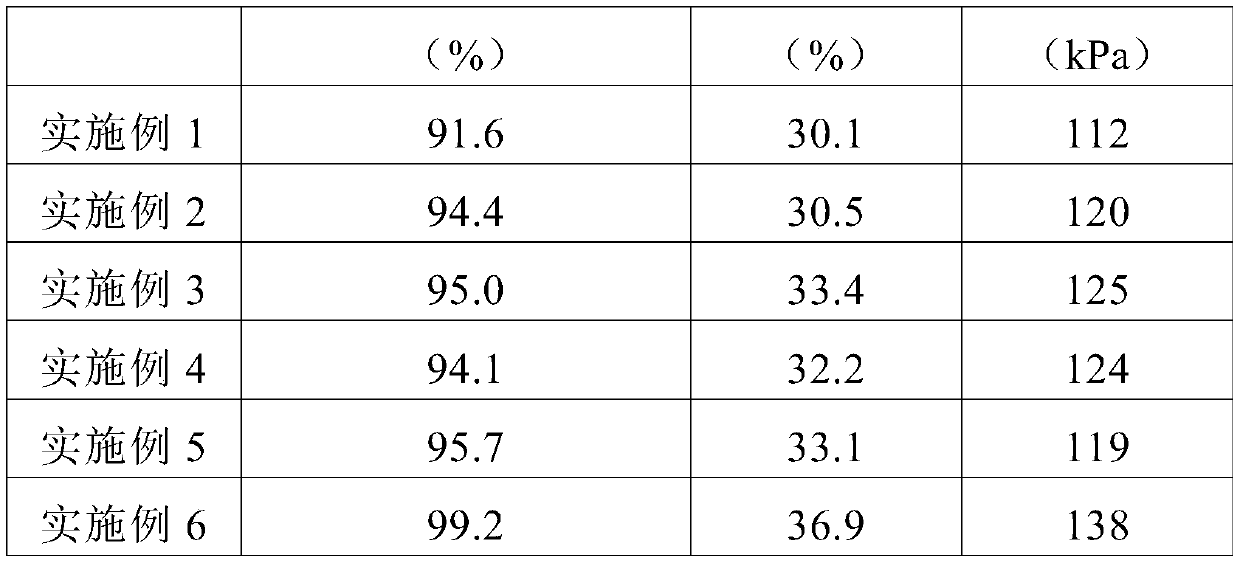

Manufacturing method for ultrafine powder enhanced composite board

The invention provides a manufacturing method for ultrafine powder enhanced composite board. The manufacturing method is characterized in that a board having the characteristics similar to natural stone materials and elegant texture is prepared by mixing tree waste raw materials such as construction wastes, slag ultrafine powder and fly ash, a proper amount of magnesia, and a trace amount of boric oxide, water and cement. Since the slag ultrafine powder is obtained by grinding blast-furnace slag and has high specific surface area and high fineness, the slag ultrafine powder can be modified to be a potential self-gelating material. In an alkaline condition, activity can be fully played, so that a plurality of performances of concrete and cement are greatly improved and increased. The manufacturing method is an environment-friendly technology, and has wide sources of materials and low cost. The composite board has good use performance, low toxicity, moisture resistance, corrosion resistance and no pollution, integrates the advantages of ceramic and glass ceramics, has the advantages of no radiation, pollution resistance and corrosion resistance, and has relatively good processability.

Owner:SHENZHEN KENAILE NEW MATERIAL

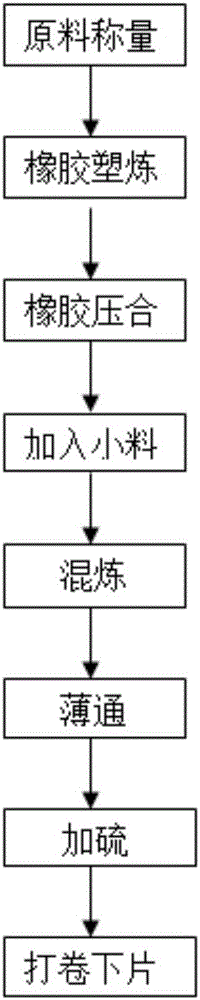

NV-series environment-friendly type rubber floor glue stock and preparation method thereof

The invention discloses NV-series environment-friendly type rubber floor glue stock, which is composed of the following raw materials (by weight): NV rubber, zinc oxide, active magnesium oxide, stearic acid, an anti-ageing agent, titanium dioxide, argil, a fire retardant HP800, aluminium hydroxide, zinc borate, a fire retardant BN-18C, white carbon black, nano-kaolin, ultrafine calcium carbonate, an antistatic agent, a dispersant, a flow promoter, an anti-ultraviolet agent, an antibacterial agent, a deodorant, a vulcanizing agent S-80, a promoter, a vulcanizing agent CLD-80 and a pigment. The invention also discloses a preparation method of the NV-series environment-friendly type rubber floor glue stock. The problem that existing flooring is not water-resistant, wear-resistant, waterproof or anti-microbial, is expensive in price and releases harmful gas or radioactive element is solved in the invention.

Owner:XIAN AEROSPACE HUAYANG PRINTING & PACKAGING MACHINERY

High performance antifreeze special for concrete

The invention discloses a high performance antifreeze special for concrete, and the high performance antifreeze comprises the following raw materials by weight: 0.3-0.6 part of sodium dodecylbenzenesulfonate, 0.1-0. 4 parts of polyacrylamide, 7 to 12 parts of PET hydrolyzate, 0.4 to 0.8 part of sodium lignosulfonate, 0.7 to 1.2 parts of sodium alkyl sulfonate, 0. 3-0.8 part of diisopropanolamine,0.4-1 part of sodium methylene dinaphthalene sulfonate, 0.4-0.8 part of a polycarboxylic acid sputum retaining agent, 0.4-0.9 part of alkyl glycoside and 0.3-0.9 part of sodium hexametaphosphate. Thehigh performance antifreeze special for the concrete has the advantages such as good effect, no cracking, corrosion resistance, wide application range, good waterproof and impermeability.

Owner:临泉县凯晟建筑工程有限公司

Luminescent ceramic material as well as preparation method and application thereof

The invention discloses a preparation method of a luminescent ceramic material. The luminescent ceramic product is red, blue, purple or green fluorescent ceramic; red luminous powder is contained in the red fluorescent ceramic; blue luminous powder is contained in the blue fluorescent ceramic; purple luminous powder is contained in the purple fluorescent ceramic; green luminous powder is contained in the green fluorescent ceramic. Compared with the prior art, the luminescent ceramic material, the preparation method and application have the advantages that the luminescent ceramic material is applicable to various ceramic tiles or glass; the obtained fluorescent product can be continuously luminescent in dark places after the material with the functions of light absorption, light storage and luminescence absorbs various kinds of visible light and reaches the saturation; the cycle use without the number of times is realized; the afterglow time is long; the brightness is high; a series of characteristics of corrosion resistance, abrasion resistance, aging resistance, flame retardance, no toxic and side effects, no radioactivity and the like are realized.

Owner:赣州艺佳兴陶瓷有限公司

Paint applied to interior of yellow mealworm breeding wooden case

The invention provides a paint applied to the interior of a yellow mealworm breeding wooden case. The paint is prepared from the following raw materials by weight: 15 parts of epoxy resin, 12 parts of phenolic resin, 6 parts of amino resin, 4 parts of paraffin, 0.2 part of bentonite, 3 parts of maize starch, 1.2 parts of microcrystal powder, 1.5 parts of glass fiber powder, 6 parts of Brazilian palm wax, 2.5 parts of a forming agent, 1.5 parts of tributyl citrate, 0.2 part of fumed silica and 65 parts of a solvent. The paint has strong anticorrosion performance, does not volatilize poisonous and harmful gas, and can form a smooth coating with high compactness, and the formed coating is nontoxic, pose no adverse influence to yellow mealworms and can prevent yellow mealworms from climbing up since the coating has high surface smoothness.

Owner:张悦

Special coating for food cans and preparation method thereof

ActiveCN103409035BStrong anti-corrosion abilityStrong rust resistanceAnti-corrosive paintsEpoxy resin coatingsHigh resistanceBenzene

The invention belongs to and relates to the technical field of can processing, and particularly relates to in-can paint for a can pack and preparation thereof. The special paint for a food can comprises the following components in percentage by mass: 30-70% of resin, 2-3% of amino, 0.5-2% of curing agent, 0.5-2% of surface accelerator and 56-67% of solvent. The special paint for a food can only contains an extremely small amount of benzene, and has no toxic action on human bodies. The paint provided by the invention has very high corrosion resistance and rust resistance, favorable acid resistance and sulfidation resistance, and high resistance to elevated temperatures. The paint provided by the invention is simple and quick in storage method and high in production efficiency.

Owner:蚌埠飞浦科技包装材料有限公司

Normal-temperature curable waterborne damping paint

The invention relates to a normal-temperature curable waterborne damping paint, which is composed of the following raw materials by weight: 30-50 parts of a water-based acrylic emulsion; 35-55 parts of filler; 0.2-1 part of a dispersing agent; 3-10 parts of a film-forming agent; 0.3-1 part of a defoaming agent and 0.3-1 part of an adhesion promoter; 0.1-0.4 part of an antirust agent; 1-4 parts ofpurified water; 0.5-3 parts of a thickening agent; and 0.05-0.3 part of a multifunctional assistant. The damping paint has the advantages of high damping properties, strong bonding force, high self-strength, flash rust resistance, corrosion resistance, environmental friendliness and the like.

Owner:三友(天津)高分子技术有限公司

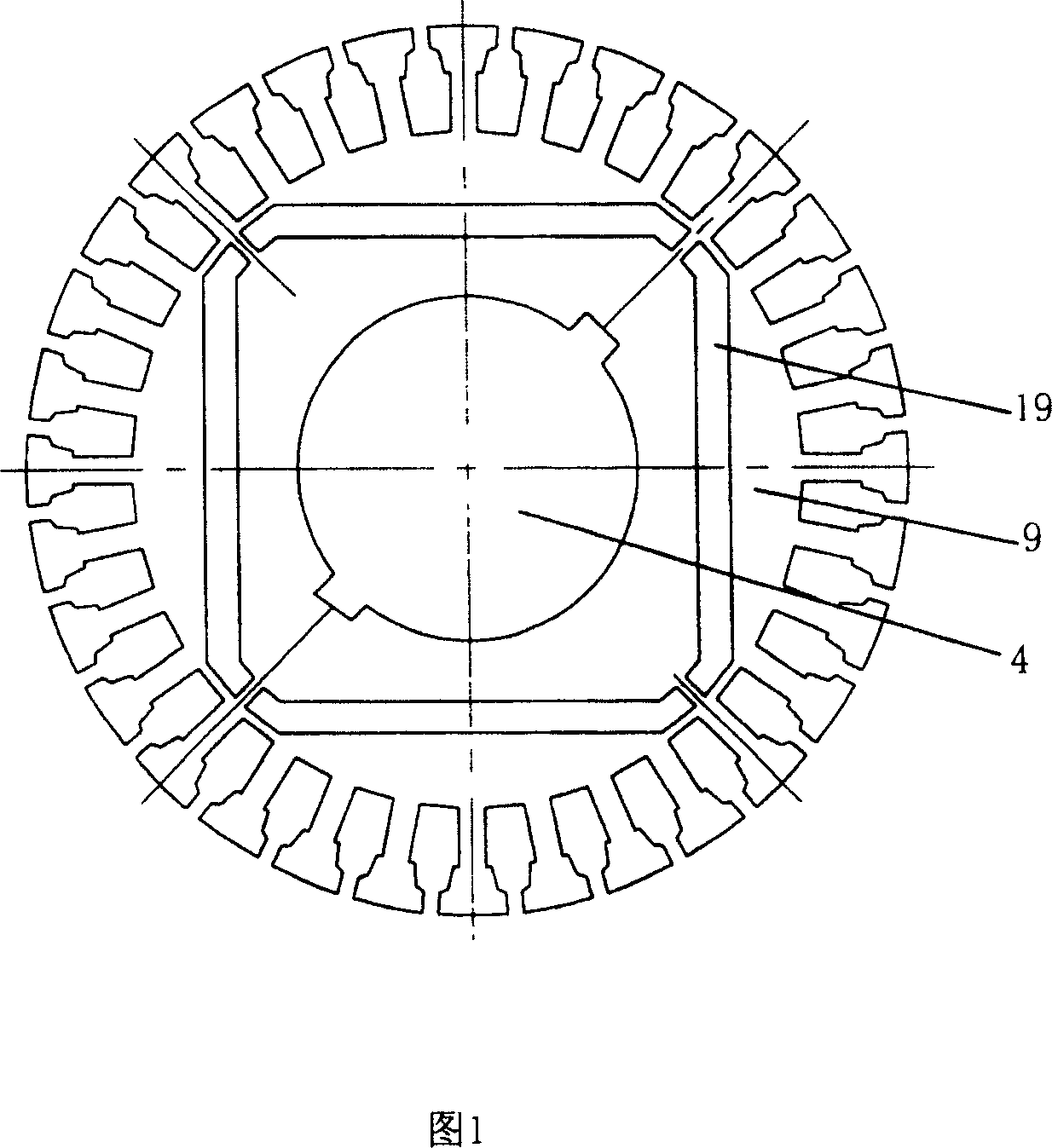

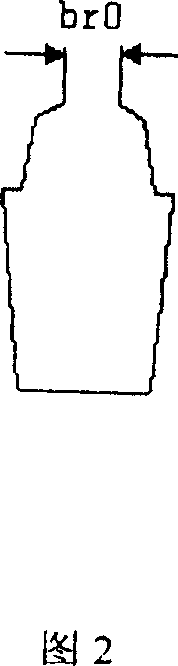

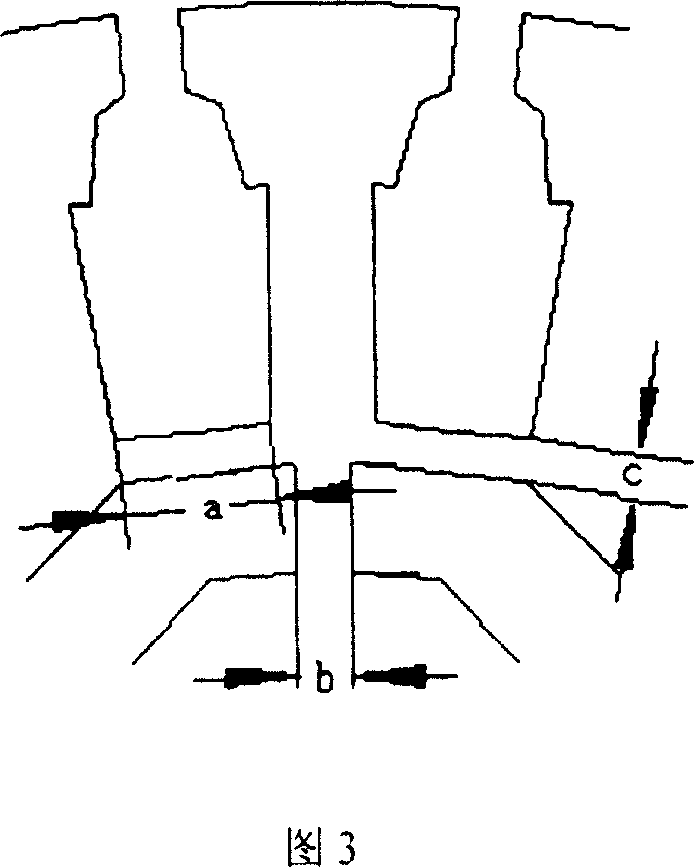

Permanent magnet synchronous motor for shielded pump

InactiveCN100345358CSmall sizeImprove efficiencyMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsPower factorPermanent magnet synchronous motor

Owner:SHENYANG POLYTECHNIC UNIV

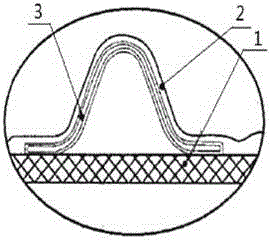

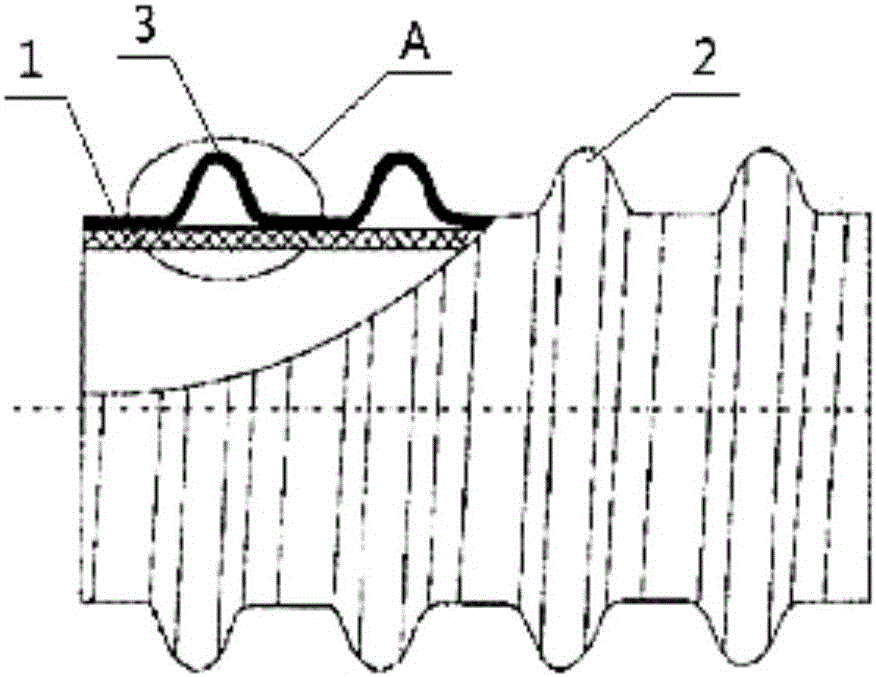

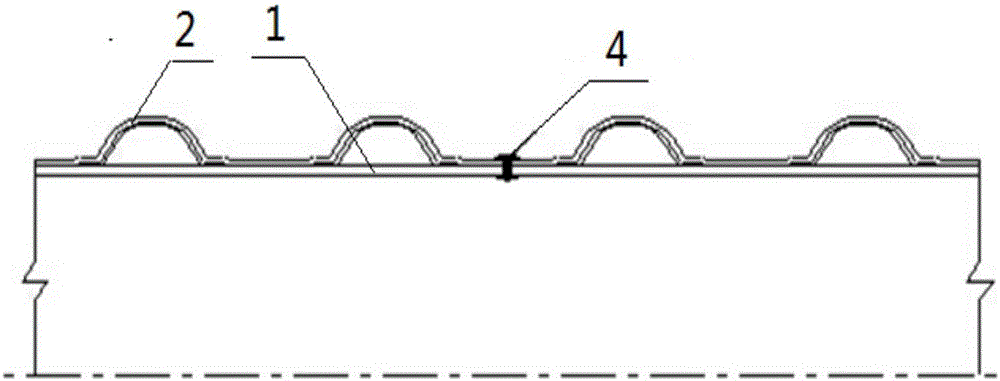

High-density polyethylene (HDPE)-reinforced winding corrugated pipe

InactiveCN105805435AReduce weightHigh strengthCorrosion preventionPipe protection against corrosion/incrustationLow-density polyethylenePolyvinyl chloride

The invention discloses a high-density polyethylene (HDPE)-reinforced winding corrugated pipe. The high-density polyethylene-reinforced winding corrugated pipe comprises an inner-layer pipe body, adhesive resin layers, a steel belt corrugated framework and an outer-layer corrugated pipe body. The steel belt corrugated framework is arranged between the inner-layer pipe body and the outer-layer corrugated pipe body. The steel belt corrugated framework is bonded with the inner-layer pipe body and the outer-layer corrugated pipe body through the adhesive resin layers correspondingly. The inner-layer pipe body and the outer-layer corrugated pipe body are both made of HDPE materials. The steel belt corrugated framework is made of inverted-U-shaped spiral steel belts which are formed by high-quality cold-rolled steel sheets through one-time rolling. The HDPE-reinforced winding corrugated pipe is made of HDPE, and compared with cement pipes and other polyvinyl chloride (PVC) pipes, the HDPE-reinforced winding corrugated pipe is lighter, higher in strength, nontoxic, resistant to corrosion, free of scaling and capable of being recycled. The HDPE-reinforced winding corrugated pipe can be used in the environment with the temperature of minus 60 DEG C without breakage, the anti-cracking capacity during medium delivery is high, the scratch sensitivity is low, the tenacity is high, the adaptability to the differential settlement of a pipe base is high, and no base is needed under the good soil condition.

Owner:HUBEI FEIGE TECH

Method for fabricating zirconium oxide high-pressure cylinder piston rod

The invention provides a method for fabricating a zirconium oxide high-pressure cylinder piston rod. The method is simple, zirconium oxide powder is taken as a raw material, a zirconium oxide high-pressure cylinder piston rod blank is sintered under the two-way hot-pressing temperature oscillation condition, and the product performance is improved, so that the prepared piston rod is free of metal, free of pollution, and applicable to a high-pressure abrasive environment, and has the characteristics of being high-pressure resistant, wear-resistant, corrosion-resistant, high in hardness, less in deformation possibility and the like.

Owner:邓湘凌

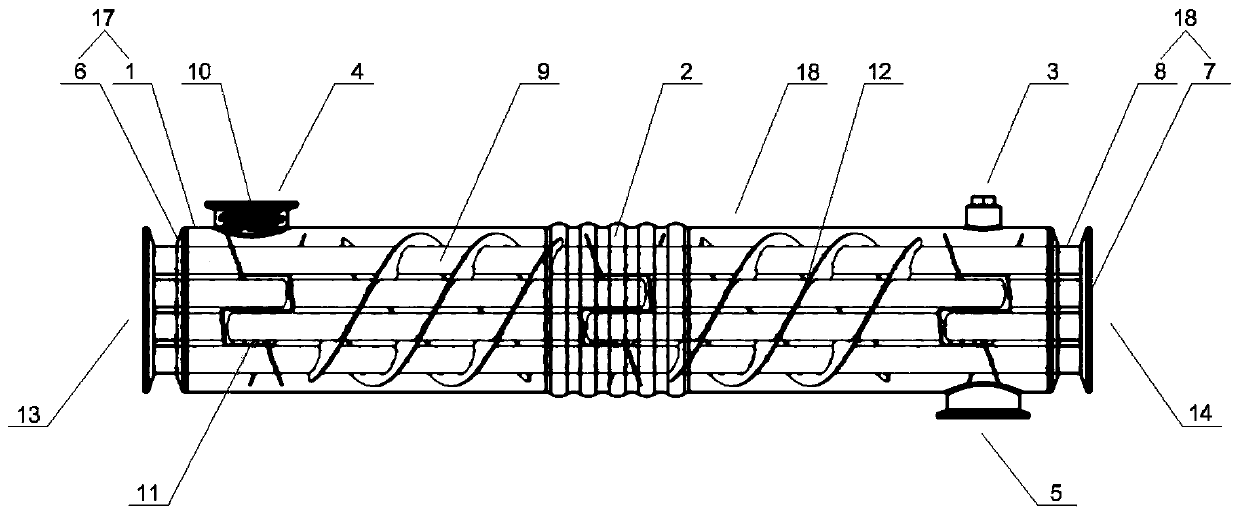

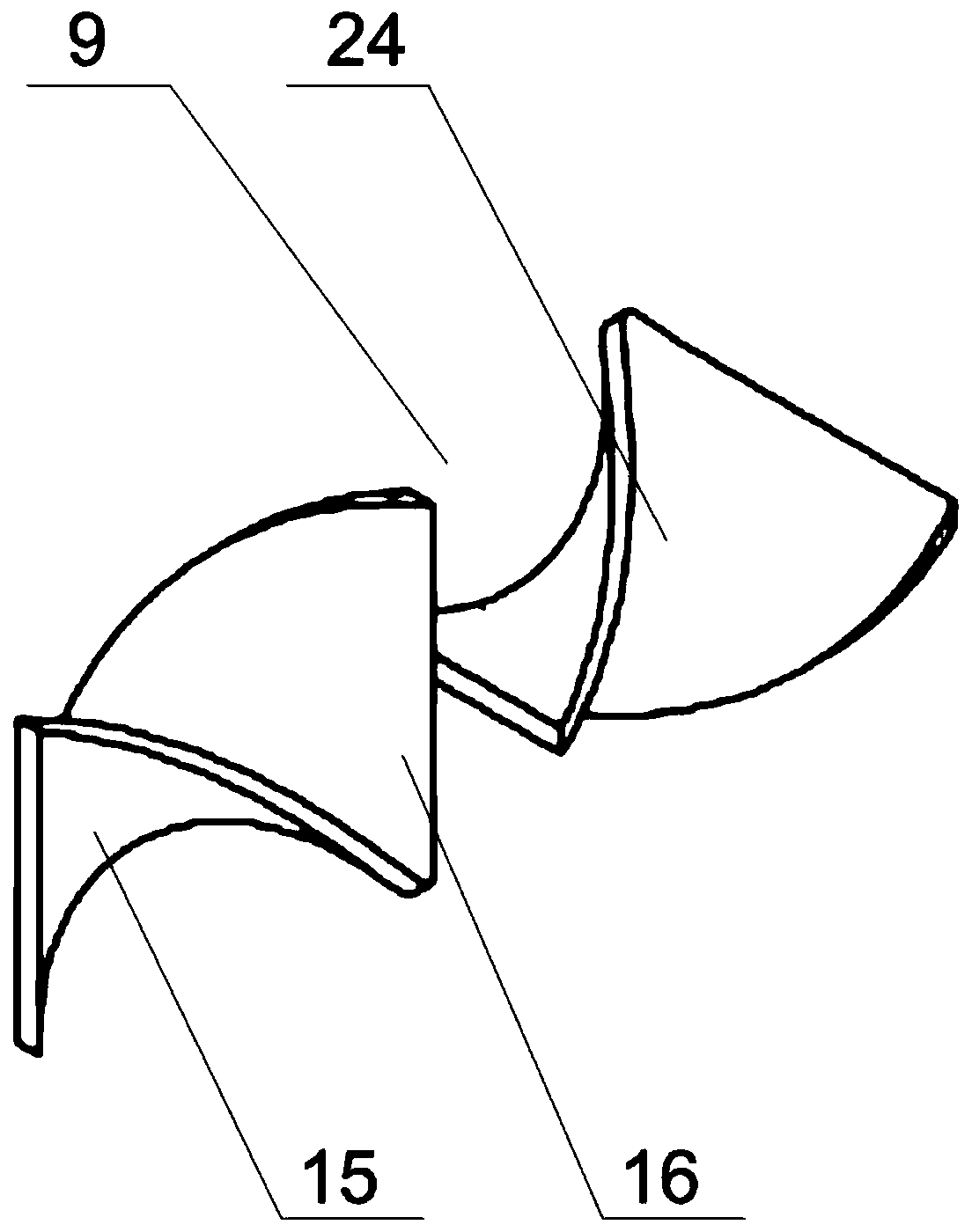

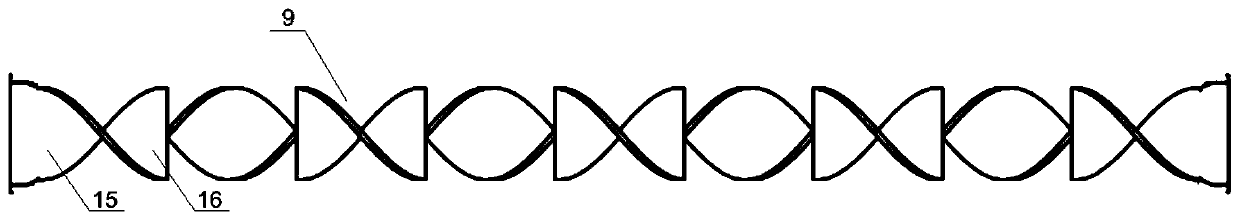

Cutting type spiral distribution sanitary heat exchanger

InactiveCN111271990ASpeed up heat exchangeChange directionHeat exchanger casingsStationary tubular conduit assembliesThermodynamicsEngineering

The invention discloses a cutting type spiral distribution sanitary heat exchanger. The cutting type spiral distribution sanitary heat exchanger comprises an outer tube side (17) and an inner tube side (18) arranged in the outer tube side (17); the outer tube side (17) is internally provided with a first turbulator (10), a second turbulator (11) and a baffle plate (12); the inner tube side (18) comprises a plurality of medium tubes (8) for allowing mediums to circulate; and the medium tubes (8) are internally provided with spiral distributors (9). According to the cutting type spiral distribution sanitary heat exchanger, impact of cold / hot mediums to the medium tubes can be reduced, damage of medium pressure to the medium tubes is reduced, meanwhile, the medium flowing direction is changed, and retention zones are decreased; and the mediums circulate spirally in the medium tubes, residual mediums on the walls of the tubes are decreased, the mediums can conduct heat exchange more easily, and the heat exchange efficiency is improved.

Owner:NA SHENG CLEAN TECH SUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com