Copper-nickel-chrome-molybdenum-based alloy powder and fusion covering method thereof

A molybdenum-based alloy, chrome-molybdenum alloy technology, applied in metal material coating process, coating and other directions, can solve the problems of corrosion, copper-based alloy impeller anti-corrosion needs to be improved, cavitation and other problems, to achieve good bonding and improve comprehensive performance And the effect of excellent service life and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In terms of mass percentage, the composition of the copper-nickel-chromium-molybdenum alloy powder is: Ni: 20%, Cr: 20%, Mo: 13%, W: 2%, and the balance is Cu. In terms of mass percentage, the composition of the matrix is: Mn: 11.5%, Al: 7.0%, Fe: 2.5%, Ni: 1.8%, zinc Zn: 0.3%, and the balance is Cu.

Embodiment 2

[0052] In terms of mass percentage, the composition of the copper-nickel-chromium-molybdenum alloy powder is: Ni: 23%, Cr: 23%, Mo: 15%, W: 3%, and the balance is Cu. In terms of mass percentage, the composition of the matrix is: Mn: 13.0%, Al: 8.0%, Fe: 3.0%, Ni: 2.0%, zinc Zn: 0.3%, and the balance is Cu.

Embodiment 3

[0054] In terms of mass percentage, the composition of the copper-nickel-chromium-molybdenum alloy powder is: Ni: 25%, Cr: 25%, Mo: 20%, W: 5%, and the balance is Cu. In terms of mass percentage, the composition of the matrix is: Mn: 14.0%, Al: 8.5%, Fe: 4.0%, Ni: 2.5%, zinc Zn: 0.3%, and the balance is Cu.

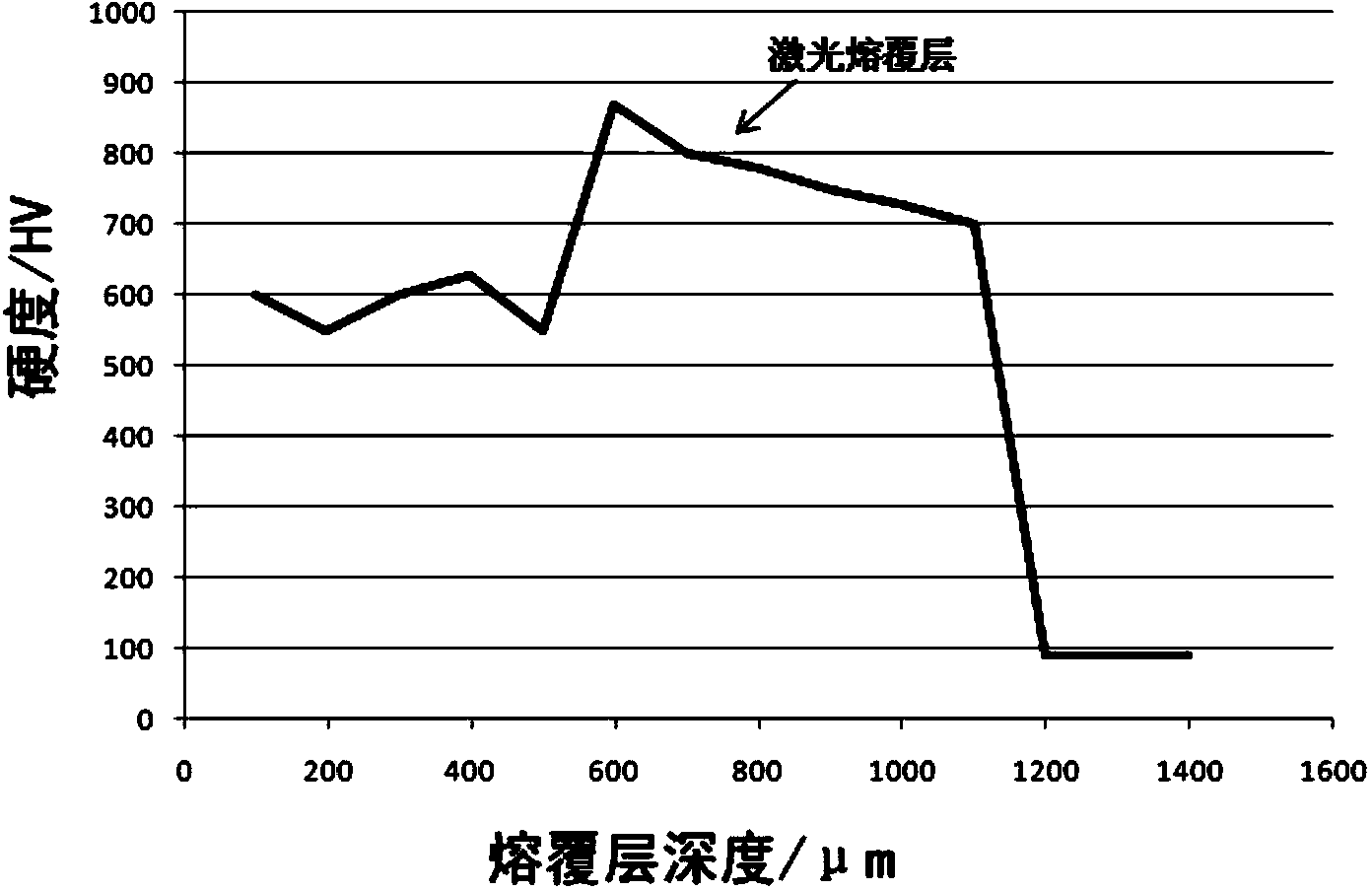

[0055] Select the substrates with the components described in the above three embodiments, and use the above-mentioned laser cladding method to clad the cladding layer of the corresponding material with a thickness of 500 μm on each substrate, and finally form a sample.

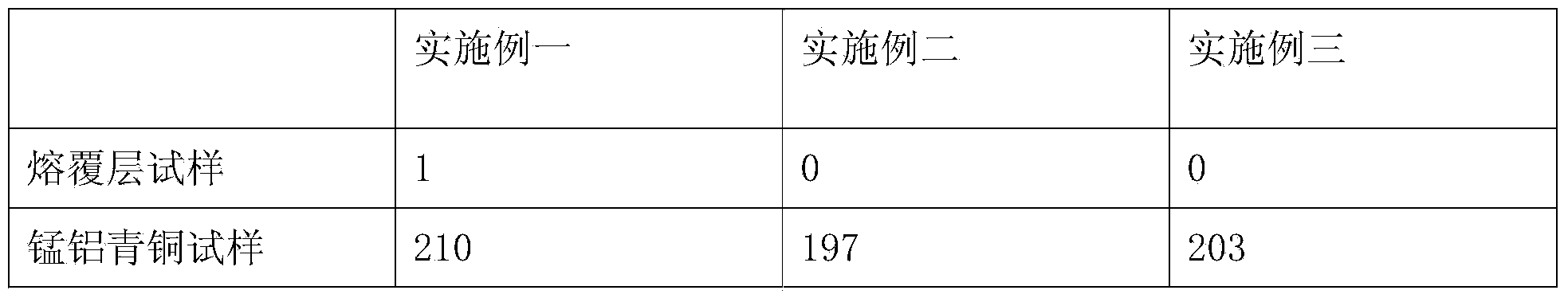

[0056] Next, test the corrosion resistance of the three test samples prepared above, and select three samples of manganese-aluminum bronze (0ZQAI12-8-3-2) with a weight of 15Kg and a thickness of 10mm to test the corrosion resistance. , and then compare and evaluate the corrosion resistance of the present invention.

[0057] Corrosion resistance test The experimental process and results are as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com