NV-series environment-friendly type rubber floor glue stock and preparation method thereof

An environment-friendly technology for rubber flooring, which is applied in the field of preparation of NV series environment-friendly rubber flooring compounds, which can solve the problems of poor anti-skid, high price, non-wear resistance, etc., and achieve the effect of simple process and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

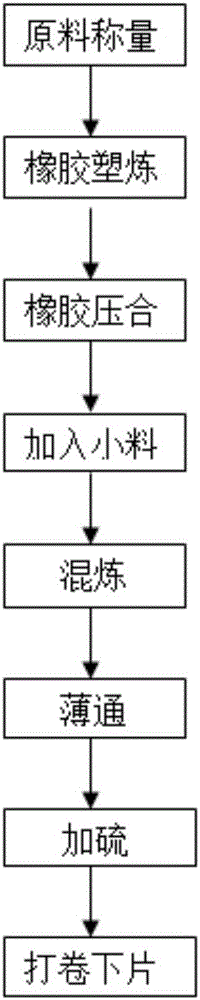

[0030] The preparation method of NV series environment-friendly rubber floor rubber material adopts an open rubber mixing machine, such as figure 1 As shown, the specific steps are as follows:

[0031] Step 1. Weigh the raw materials, and weigh 30% to 36% of NV rubber, 1.5% to 1.8% of zinc oxide, 1.3% to 1.5% of activated magnesium oxide, 0.3% to 0.4% of stearic acid, and environment-friendly anti-aging agent according to the weight percentage 2246 0.5%~0.6%, titanium dioxide 1.7%~3.4%, clay 9.1%~15.5%, flame retardant HP800 0~7%, aluminum hydroxide 0~10.5%, zinc borate 0~5.5%, flame retardant BN -18C 4%~5.5%, white carbon black 6%~13.5%, nano kaolin 6%~21.5%, superfine calcium carbonate 0~10%, antistatic agent 0.6%~0.75%, dispersant FC-303 0.6% ~0.75%, flow aid PEG4000 0.6%~0.75%, anti-ultraviolet agent UV531 0.5%~0.55%, antibacterial agent CZ-KZ10 0.5%~0.55%, deodorant JH-100A 0.6%~0.75%, vulcanizing agent S-80 0.2%~0.25%, environment-friendly accelerator TBZTD 0.5%~0.55%,...

Embodiment 1

[0043] The preparation method of NV series environment-friendly rubber floor compound adopts an open rubber mixing machine, and is implemented according to the following steps:

[0044] Step 1. Weigh the raw materials, and weigh 33.21% of NV rubber, 1.66% of zinc oxide, 1.33% of activated magnesium oxide, 0.33% of stearic acid, 0.5% of environmentally friendly anti-aging agent 2246, 3.32% of titanium dioxide, and 9.96% of clay according to weight percentage , flame retardant HP800 6.64%, zinc borate 3.32%, flame retardant BN-18C 4.98%, white carbon black 13.28%, nano kaolin 6.64%, superfine calcium carbonate 9.96%, antistatic agent 0.66%, dispersant FC- 303 0.66%, flow aid PEG4000 0.66%, anti-ultraviolet agent UV531 0.5%, antibacterial agent CZ-KZ10 0.5%, deodorant JH-100A 0.66%, vulcanizing agent S-80 0.2%, environment-friendly accelerator TBZTD 0.5 %, vulcanizing agent CLD-80 0.33%, pigment 0.17%, the sum of the content percentages of the above components is 100%;

[0045] ...

Embodiment 2

[0053] The preparation method of NV series environment-friendly rubber floor compound adopts an open rubber mixing machine, and is implemented according to the following steps:

[0054] Step 1. Weigh the raw materials, and weigh 34.35% of NV rubber, 1.72% of zinc oxide, 1.37% of activated magnesium oxide, 0.34% of stearic acid, 0.52% of environmentally friendly anti-aging agent 2246, 1.72% of titanium dioxide, and 10.31% of clay according to weight percentage , aluminum hydroxide 10.31%, zinc borate 5.15%, flame retardant BN-18C 5.15%, white carbon black 6.87%, nano kaolin 17.18%, antistatic agent 0.69%, dispersant FC-303 0.69%, flow aid PEG4000 0.69%, anti-ultraviolet agent UV5310.52%, antibacterial agent CZ-KZ10 0.52%, deodorant JH-100A0.69%, vulcanizing agent S-80 0.21%, environment-friendly accelerator TBZTD 0.52%, vulcanizing agent CLD-80 0.34%, pigment 0.17%, the sum of the content percentages of the above components is 100%;

[0055] Step 2, plasticizing the NV rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com