Environment-friendly coating material defoamer preparation method

A defoamer, an environmentally friendly technology, applied in the field of preparation of environmentally friendly coating defoamers, can solve the problems of poor foam suppression ability, low water solubility, low surface tension, etc., achieve good defoaming effect, aging resistance and service life , Excellent surface activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

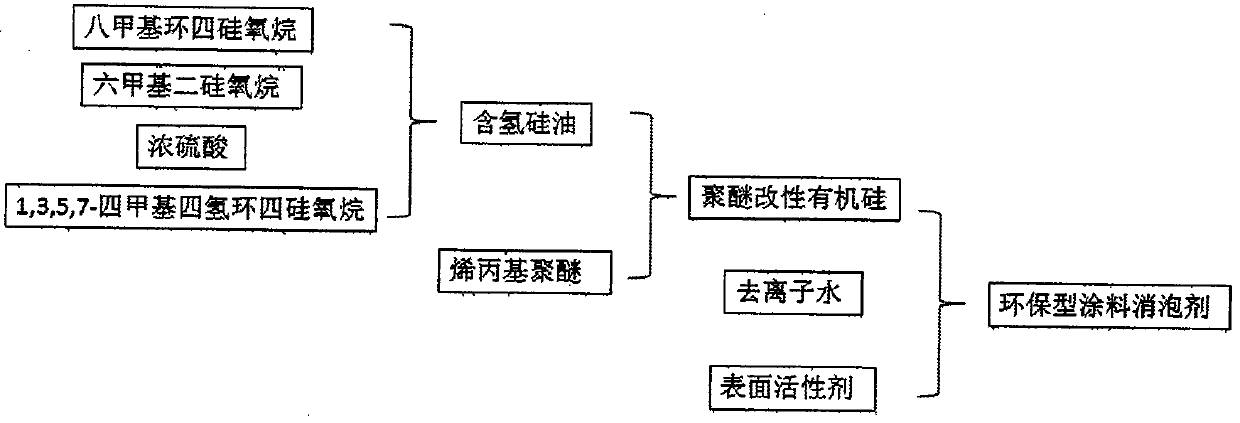

[0022] Such as figure 1 , shown, a kind of preparation method of environment-friendly coating defoamer, comprises the following steps:

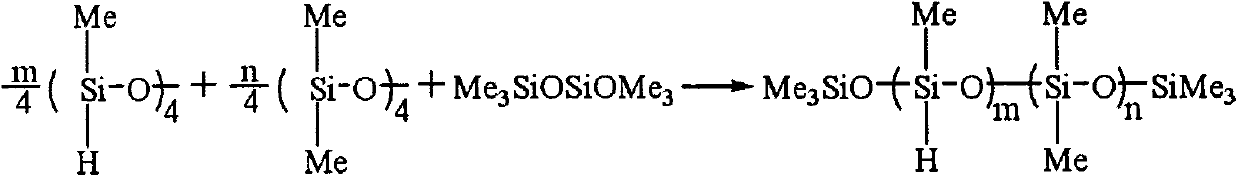

[0023] Step 1. Add octamethylcyclotetrasiloxane, 1,3,5,7-tetramethyltetrahydrocyclotetrasiloxane, hexamethyldisiloxane and catalyst concentrated sulfuric acid into the condenser with stirring and reflux In a multi-port reaction kettle, heat it to 60-100°C with a constant temperature oil bath, and react for 8-12 hours;

[0024] Step 2. Slowly add calcium hydroxide and anhydrous magnesium sulfate to the solution described in step 1, react for 4-8 hours at a temperature of 20-60°C, adjust the pH of the solution to 6-8, and filter to obtain a colorless and clear clear solution;

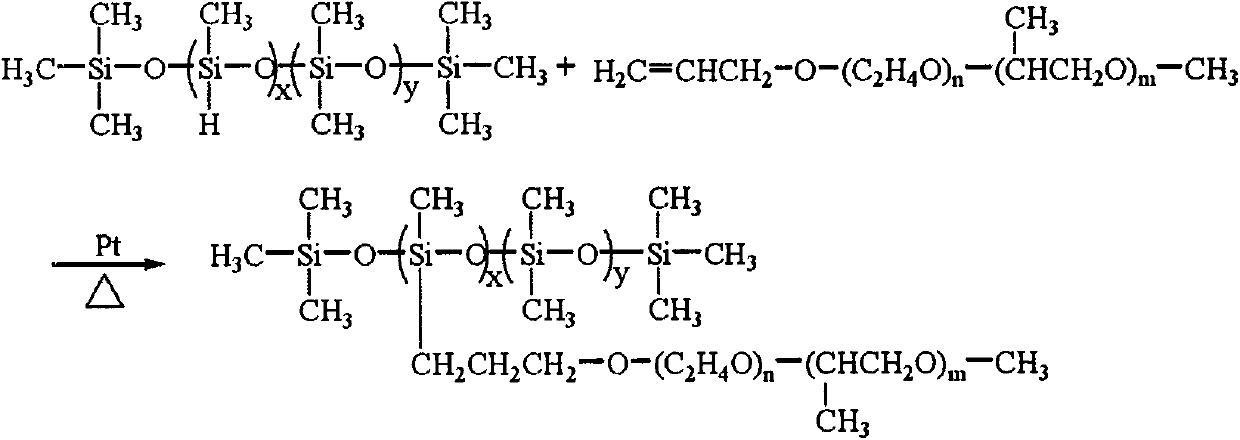

[0025] Step 3, adding allyl polyether and chloroplatinic acid into the solution described in Step 2, heating to 100-150°C with a constant temperature oil bath, and reacting for 6-18 hours to obtain a polyether-modified silicone solution;

[0026] Step 4, add deionized...

Embodiment 1

[0034] Step 1. In a 250ml four-necked glass flask, add 100g of octamethylcyclotetrasiloxane, 7.17g of 1,1,3,3-tetramethyldihydrodisiloxane, 3.2g of concentrated sulfuric acid, and use a constant temperature Heat the oil bath to 60°C and react for 8 hours;

[0035] Step 2: Add 2.42g of calcium hydroxide into the solution, adjust the pH value to 6-7, and filter the product with a vacuum pump after neutralization;

[0036] Step 3: Add 4.08g of anhydrous magnesium sulfate into the solution, heat to 20°C with a constant temperature oil bath, react for 4 hours, and filter with a vacuum pump;

[0037] Step 4: Add 45g of allyl polyether into the solution, react for 6 hours at a temperature of 100°C, and discharge;

[0038] Step 5: Add 100g of deionized water, 3g of Tween 80, 6g of Span 80, and 1.5g of alkylphenol polyoxyethylene ether into a 500ml four-necked glass flask, and react for 2 hours at a temperature of 20°C. Add 20g of the polyether-modified silicone described in step 4, ...

Embodiment 2

[0041] Step 1. In a 250ml four-necked glass flask, add 100g of octamethylcyclotetrasiloxane, 7.17g of 1,1,3,3-tetramethyldihydrodisiloxane, 3.2g of concentrated sulfuric acid, and use a constant temperature Heat the oil bath to 80°C and react for 8 hours;

[0042] Step 2: Add 2.42g of calcium hydroxide into the solution, adjust the pH value to 6-7, and filter the product with a vacuum pump after neutralization;

[0043] Step 3: Add 4.08g of anhydrous magnesium sulfate into the solution, heat to 60°C with a constant temperature oil bath, react for 4 hours, and filter with a vacuum pump;

[0044] Step 4: Add 45g of allyl polyether into the solution, react for 6 hours at a temperature of 130°C, and discharge;

[0045] Step 5: Add 100g of deionized water, 3g of Tween 80, 6g of Span 80, and 1.5g of alkylphenol polyoxyethylene ether into a 500ml four-neck glass flask, and react for 2 hours at a temperature of 60°C. Add 20g of the polyether-modified silicone described in step 4, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com